Mitsubishi Lancer Evolution IX. Manual — part 329

D998713

SPECIAL TOOLS

ENGINE MECHANICAL

11A-5

MD998713

Camshaft oil seal installer

Camshaft oil seal installation

D998727

MD998727

Oil pan FIPG cutter

Oil pan removal

D998781

MD998781

Flywheel stopper

Supporting the flywheel

MB990938

Installer bar

Crankshaft rear oil seal

installation

D998776

MD998776

Crankshaft rear oil seal

installer

D998285

MD998285

Crankshaft front oil seal

guide

Crankshaft front oil seal

installation

MD998375

Crankshaft front oil seal

installer

B991654

MB991654

Cylinder head bolt wrench

(12)

Removal and installation of

cylinder head bolt

Tool

Number

Name

Use

D998738

SPECIAL TOOLS

ENGINE MECHANICAL

11A-6

MD998738

Adjusting bolt

Supporting the timing belt

tensioner arm and timing belt

tensioner adjuster

B991367

MB991367

Special spanner

Holding the crankshaft camshaft

drive sprocket

B991385

MB991385

Pin

D998767

MD998767

Tensioner wrench

Valve timing belt tension

adjustment

B991454

MB991454

Engine hanger balancer

When the engine hanger is used:

Supporting the engine assembly

during removal and installation of

the transmission assembly

NOTE: Special tool MB991454 is

a part of engine hanger

attachment set MB991453.

Z203830

MB991895

Engine hanger

B991928

A

B

C

D

E

F

Slide bracket (HI)

MB991928

A: MB991929

B: MB991930

C: MB991931

D: MB991932

E: MB991933

F: MB991934

Engine hanger

A: Joint (50)

× 2

B: Joint (90)

× 2

C: Joint (140)

× 2

D: Foot (standard)

× 4

E: Foot (short)

× 2

F: Chain and hook

assembly

Tool

Number

Name

Use

ON-VEHICLE SERVICE

ENGINE MECHANICAL

11A-7

ON-VEHICLE SERVICE

DRIVE BELT TENSION CHECK

M1111003100612

CAUTION

Check the drive belt tension after turning the

crankshaft clockwise one turn or more.

AC211616AB

A

Indicator mark

1. Make sure that the indicator mark is within the

area marked with A in the illustration.

2. If the mark is out of the area, replace the drive

belt. (Refer to

).

NOTE: The drive belt tension check is not neces-

sary as auto-tensioner is adopted.

AUTO-TENSIONER CHECK

M1111003000284

OPERATION CHECK

1. Turn OFF the engine from the idle state then

check to see that the drive belt is not protruding

from the pulley width of the auto-tensioner.

2. Remove the drive belt.(Refer to

).

Y1848AU

AC211619

3. Securely insert the spindle handle or ratchet

handle with a 12.7 mm insertion angle into the jig

hole of the auto tensioner. Turn the auto-tensioner

to the left and right to check and see that there is

no threading.

4. If there are any problems in the procedure 1 or 3,

replace the auto-tensioner.(Refer to

5. Install the drive belt.(Refer to

FUNCTION CHECK

You can verify if the auto-tensioner is defective or not

by checking the drive belt tension.

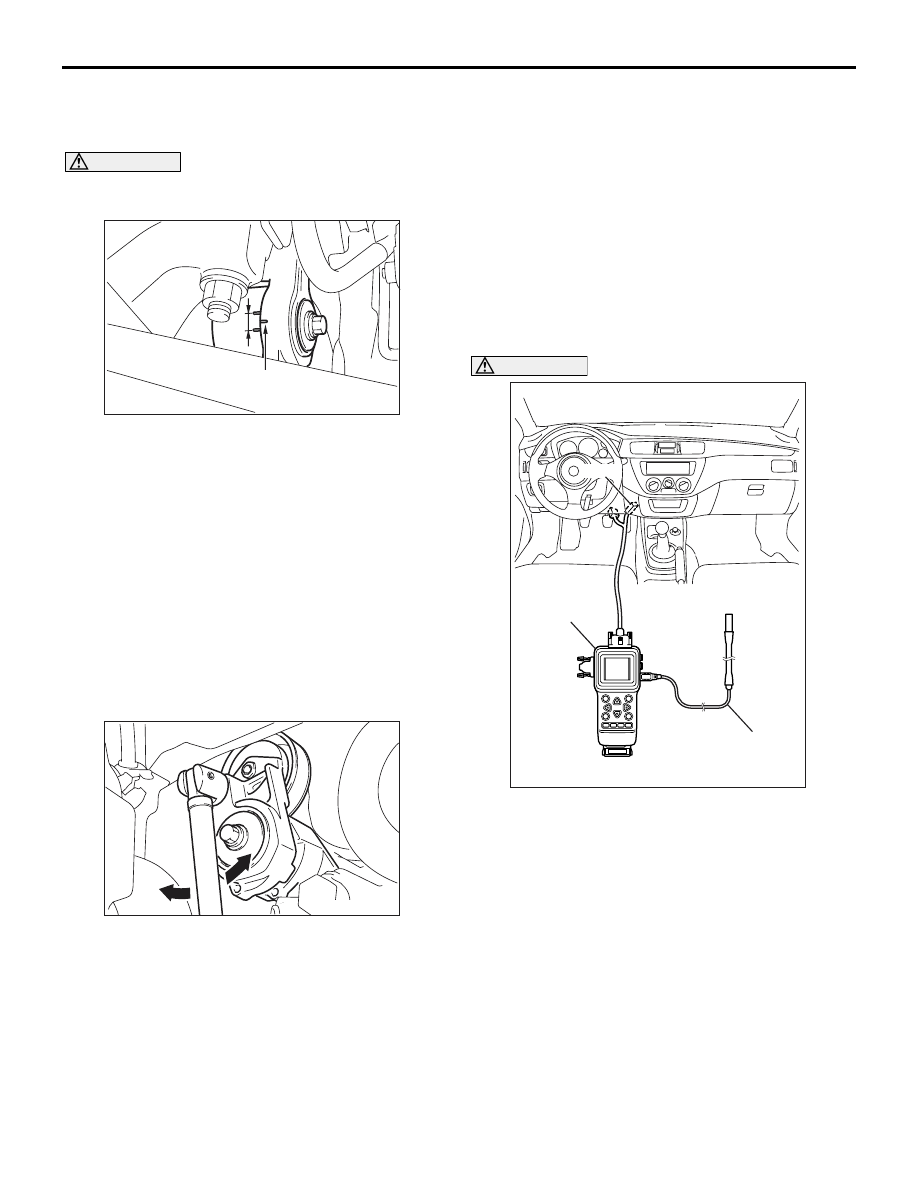

When using the M.U.T.-II

1. Check the drive belt tension. (Refer to

2. Measure the drive belt tension vibration frequency

by the following procedures:

AC211432

16-pin

AB

M.U.T.-II

MB991668

CAUTION

To prevent damage to the M.U.T.-II, always turn

the ignition switch to the "LOCK" (OFF) position

before connecting or disconnecting the M.U.T.-II.

(1) Connect special tool belt tension meter set

(MB991668) to the M.U.T.-II.

(2) Connect the M.U.T.-II to the diagnosis

connector.

(3) Turn the ignition switch to "ON" position, and

select "BELT TENSION" on the menu screen.

ON-VEHICLE SERVICE

ENGINE MECHANICAL

11A-8

CAUTION

• The temperature of the surface of the belt

should be as close to normal temperature as

possible.

• Do not allow any contaminants such as water

or oil to get onto the microphone.

• If strong gusts of wind blow against the

microphone or if there are any loud sources

of noise nearby, the values measured by the

microphone may not correspond to actual

values.

• If the microphone is touching the belt while

the measurement is being made, the values

measured by the microphone may not corre-

spond to actual values.

• Do not take the measurement while the vehi-

cle's engine is running.

AC102806AB

MB991668

15˚

15˚

Gentry tap with

your finger

Water pump

pulley

Power steering

oil pump pulley

10 – 20 mm

(4) Hold special tool belt tension meter set

(MB991668) to the middle of the drive belt

between the pulleys (at the place indicated by

arrow), approximately 10

− 20 mm away from

the rear surface of the belt so that it is

perpendicular to the belt (within an angle of

±

15 degree).

(5) Gently tap the middle of the belt between the

pulleys (the place indicated by the arrow) with

your finger as shown in the illustration, and

measure that the vibration frequency of the

belt is within the standard value.

Standard value: 110

− 144 Hz

3. If not within the standard value, replace the

auto-tensioner. (Refer to

).

When using the V.C.I.

1. Check the drive belt tension. (Refer to

2. Measure the drive belt tension vibration frequency

by the following procedures:

AC211433

16-pin

AB

MB991824

MB991668

MB991911

CAUTION

To prevent damage to special tool V.C.I.

(MB991824), always turn the ignition switch to

the "LOCK" (OFF) position before connecting or

disconnecting special tool V.C.I. (MB991824).

(1) Connect special tool belt tension meter set

(MB991668) to special tool V.C.I. (MB991824).

(2) Connect special tool M.U.T.-III main harness B

(MB991911) to special tool V.C.I. (MB991824).

(3) Connect special tool M.U.T.-III main harness B

(MB991911) to the diagnosis connector.

(4) Turn the ignition switch to "ON" position, and

select "Belt Tension" on the menu screen.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст