Mitsubishi Lancer Evolution IX. Manual — part 83

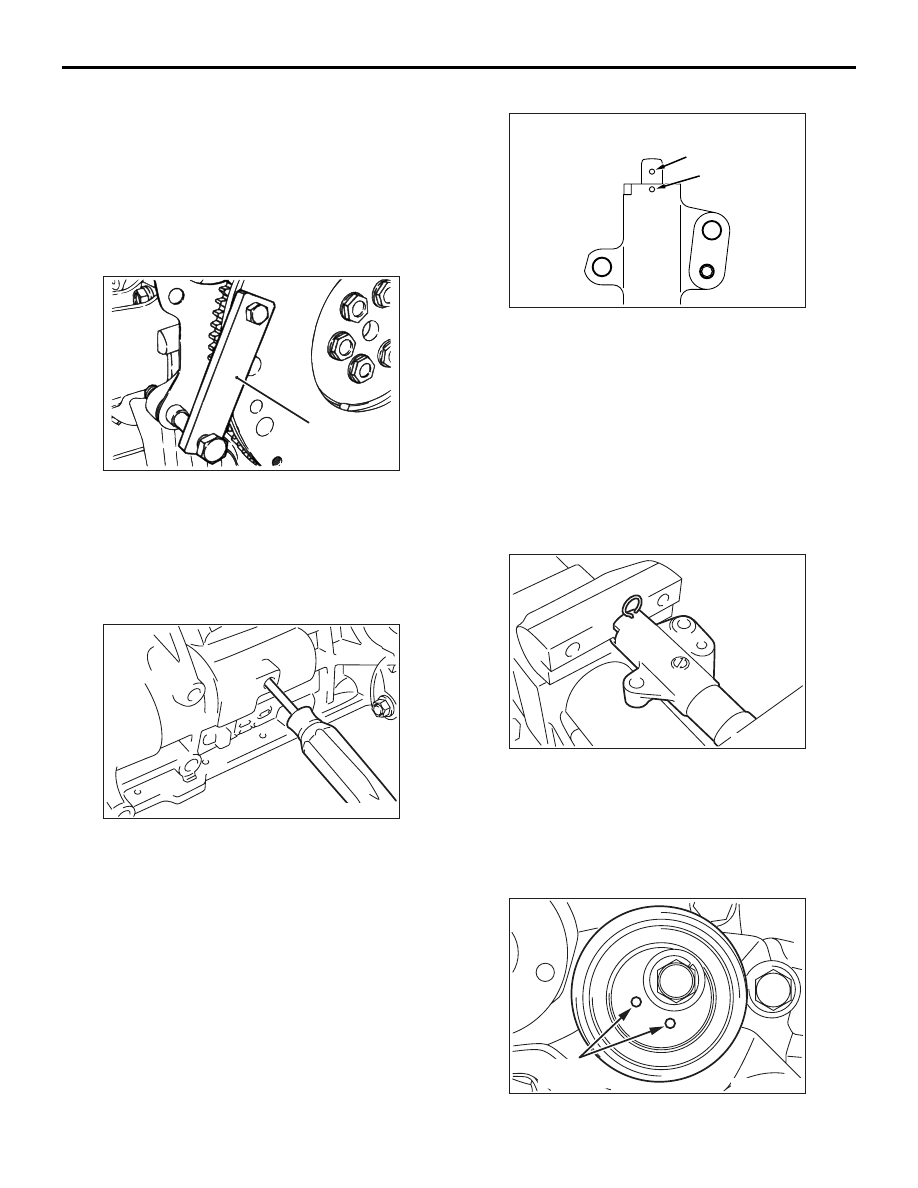

TIMING BELT

ENGINE OVERHAUL

11B-23

1. Clean and then degrease the crankshaft sprocket,

sprocket fitting surface of the crankshaft, and

crankshaft sensing blade. Install the crankshaft

sprocket and crankshaft sensing blade on the

crankshaft.

2. Clean the bolt hole in the crankshaft, and then

washer.

3. Apply a necessary minimum amount of oil to the

threads and seating surface of the crankshaft bolt.

4. Hold the drive plate using the special tool

Flywheel stopper (MD998781).

5. Tighten the crankshaft bolt to a torque of 167 N

⋅m.

>>I<< OIL PUMP SPROCKET

INSTALLATION

1. Prevent the counterbalancer shaft from rotating in

the same method as in the removal procedure.

2. Install the oil pump sprocket.

3. Apply a thin coat of engine oil to the seating

surface of the nut.

4. Tighten the flange nut to 54

± 5 N⋅m.

>>J<< AUTO-TENSIONER INSTALLATION

1. If the auto-tensioner rod remains in its fully

extended position, reset it to the retracted position

as follows:

(1) Clamp the auto-tensioner in a vise at right

angles to the jaws.

(2) Push in the rod little by little with the vise until

the set hole A in the rod is aligned with the set

hole "B" in the cylinder.

(3) Insert a piece of wire (1.4 mm diameter) into

the set holes.

(4) Remove the auto-tensioner from the vise.

2. Install the auto-tensioner in position. Leave the

wire installed until the auto-tensioner is

completely installed.

>>K<< TENSIONER PULLEY

INSTALLATION

Install the tensioner pulley with its holes aligned as

shown in the drawing.

AK202738

MD998781

AC

AK300172

AK301074

A

B

AD

AK300154

AK300147

Tensioner

pulley hole

AE

TIMING BELT

ENGINE OVERHAUL

11B-24

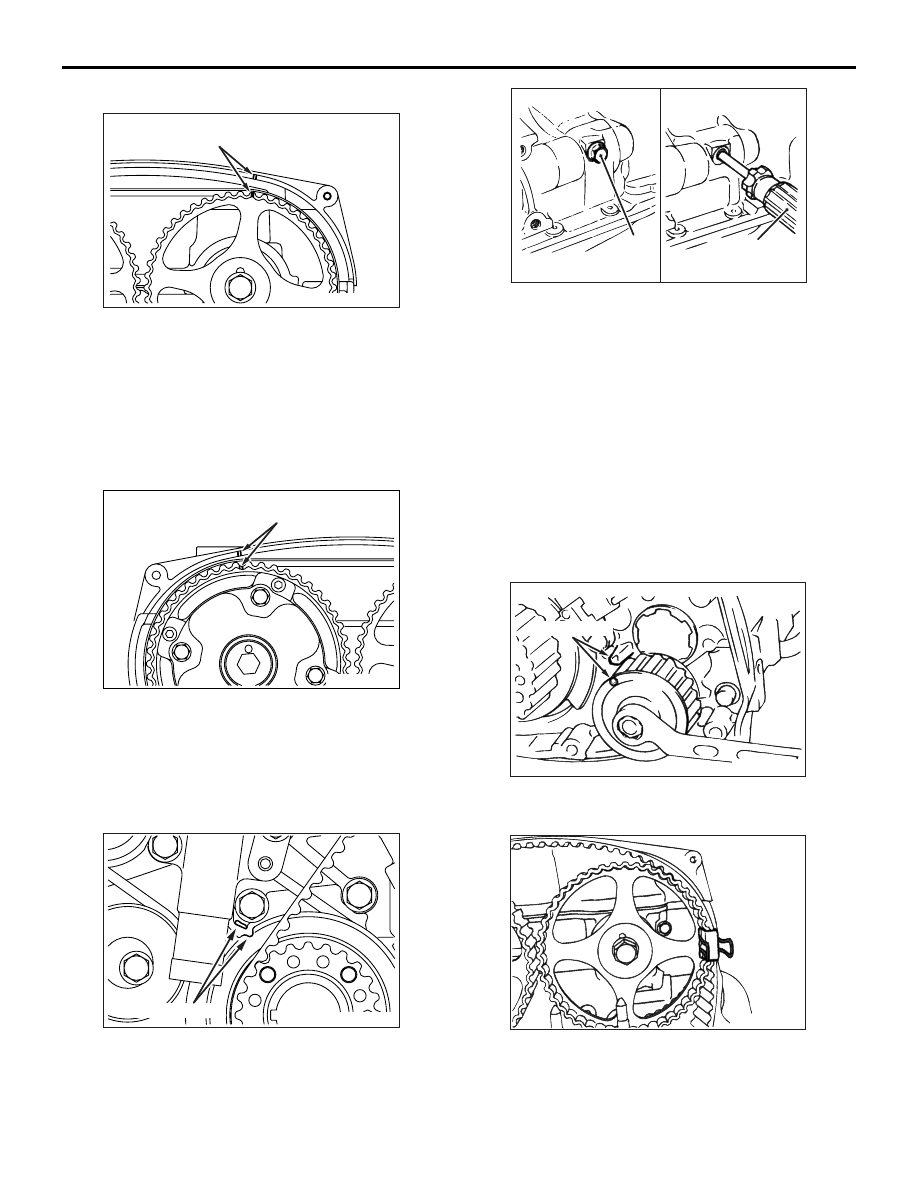

>>L<< TIMING BELT INSTALLATION

1. Bring the timing mark on the exhaust camshaft

sprocket to a point one sprocket tooth away from

the timing mark on the rocker cover in the

anti-clockwise direction.

NOTE: If the timing marks were aligned, the

exhaust camshaft would be turned anti-clockwise

by one sprocket tooth and stay there by the force

of the valve springs.

2. Align the timing mark on the intake camshaft

sprocket with that on the rocker cover.

NOTE: The intake camshaft will be turned slightly

clockwise from where the timing marks are

aligned by the force of the valve springs and stay

there.

3. Bring the timing mark on the crankshaft sprocket

to a point one sprocket tooth away from the

mating timing mark in the anti-clockwise direction

like in the operation with the exhaust camshaft

sprocket.

4. Align the timing mark on the oil pump sprocket

with that on the cylinder block.

(1) Remove the plug from the cylinder block.

(2) Insert a crosspoint screwdriver with a shank

diameter of 8 mm through the plug hole. If it

can be inserted 60 mm or more, the sprocket

is in the correct phase. If the insertion depth is

up to 20

− 25 mm, the screwdriver is blocked

by the counterbalancer shaft. Then turn the oil

pump sprocket one turn and realign the timing

marks. Then check that the screwdriver can

be inserted 60 mm or more. Keep the

screwdriver inserted until installation of timing

belt is finished.

(3) Turn the oil pump sprocket anti-clockwise by

one sprocket tooth.

5. Install the timing belt on the exhaust camshaft

sprocket, and hold it in place with a paper clip at

the point indicated in the drawing.

AK304440AB

Timing marks

AK501745

Timing marks

AB

AK304563AB

Timing marks

AK202752

Crosspoint

screwdriver

AD

Plug

AK202761

Timing marks

AD

AK202771

TIMING BELT

ENGINE OVERHAUL

11B-25

6. Turn the intake camshaft sprocket anti-clockwise

to bring the timing mark on it one sprocket tooth

away from the mating timing mark in the

anti-clockwise direction. Then install the timing

belt on the sprocket and hold it in place with a

paper clip.

NOTE: The timing marks will be aligned when the

belt is installed since the intake camshaft is turned

slightly clockwise by the force of the valve

springs.

7. Turn the exhaust camshaft sprocket clockwise to

align the timing marks, and make sure that the

intake camshaft sprocket timing marks are also

aligned.

8. Install the timing belt on the idler pulley, oil pump

sprocket, and crankshaft sprocket, in this order.

NOTE: There should be no slack in the installed

portion of the belt.

9. Install the timing belt on the tensioner pulley.

NOTE: Turning slightly the intake camshaft

sprocket anti-clockwise will facilitate installation of

the belt on the tensioner pulley.

10.Turn slightly the crankshaft sprocket clockwise to

take up the slack in the idler pulley portion of the

timing belt.

11.Check that each of the timing marks on the

crankshaft, oil pump, and exhaust camshaft

sprockets is one sprocket tooth away from its

mating timing mark in the anti-clockwise direction.

12.Turn the tensioner pulley anti-clockwise using the

special tool Tension pulley socket wrench

(MD998767) to give tension to the belt and hold

the tensioner in position by temporarily tightening

the tensioner lock bolt.

NOTE: Take up the slack in the belt portion

between the intake and exhaust camshaft sprock-

ets.

AK501746

AK501747

Timing marks

AB

AK202762AE

Crankshaft

sprocket

Oil pump

sprocket

AK501748AB

V.V.T.

sprocket

Tensioner

pulley

AK202763AB

Crankshaft

sprocket

AK202764

MD998767

AD

TIMING BELT

ENGINE OVERHAUL

11B-26

13.Turn the crankshaft clockwise to make the timing

mark align with the No.1 cylinder top dead centre

mark.

14.Install the special tool Set screw (MD998738) and

turn down the tool until the wire (inserted in the

auto-tensioner when it was installed) can be

moved freely.

15.Loosen the tensioner pulley lock bolt.

CAUTION

Prevent the timing belt from slipping as it

becomes loose following rotation of the intake

and exhaust camshafts.

16.Turn the torque wrench attached to the special

tool Tension pulley socket wrench (MD998767)

anti-clockwise until the slack in the timing belt is

taken up.

17.Turn the torque wrench clockwise from the

position of step 16 until the torque wrench reading

becomes 3.5 N

⋅m, then tighten the tensioner

pulley lock bolt.

18.Remove the special tool Set screw (MD998738)

that was installed in step 14.

19.Turn the crankshaft clockwise two turns, then let it

alone for approx. 15 minutes.

20.Check that the wire (inserted in the auto-tensioner

when it was installed) can be moved freely. If the

wire can be pulled freely, the belt tensioner is

adjusted properly. Remove the wire. At that time,

check that the auto-tensioner rod extends by the

specified amount.

Standard value: 3.8

− 4.5 mm

CAUTION

Be sure to check the tightening torque of the

crankshaft bolt anytime the crankshaft has been

turned anti-clockwise. If the torque lower than

specification, tighten the bolt to the specified

torque.

21.If the wire cannot be pulled out freely, perform the

steps 14 through 18 again to make the belt

tension proper.

>>M<< PLUG CAP INSTALLATION

CAUTION

Do not reuse the washer.

1. Install the washer to the plug cap.

2. Holding the hexagonal portion of the camshaft

with a wrench, tighten the plug cap to the

specified torque of 32

± 2 N⋅m.

AK202774

MD998738

AD

AK202775

MD998767

AD

AK202829

Extension

amount

AB

AK403836

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст