Mitsubishi Lancer Evolution IX. Manual — part 293

TRANSMISSION

MANUAL TRANSMISSION OVERHAUL

22B-17

>>H<< REVERSE BRACKET FORK ROD /

REVERSE BRACKET INSTALLATION

AK204453AC

Reverse shift check parts

Reverse bracket

fork rod

CAUTION

Install the reverse bracket fork rod with its two

grooves facing the reverse shift check parts.

Install the reverse bracket fork rod and reverse

bracket.

>>I<< REVERSE LEVER ASSEMBLY

INSTALLATION

AK203322AD

Reverse lever assembly

Reverse bracket

1. Install the shifter cap on the cam of the reverse

lever assembly, and then install the reverse shift

fork.

2. Raise the reverse shift fork and fit its cam in the

reverse bracket.

>>J<< SHIFT CHECK SLEEVE / CHECK

BALL / CHECK SPRING / CHECK BALL

PLUG INSTALLATION

AK204381

AK204381AC

B

A

CAUTION

• The check balls are not reusable.

• Confirm the lengths of the shift check sleeves

and check springs before installing them. (A:

short, B: long)

• Be careful not to let the check balls drop into

the air breathing grooves in the clutch hous-

ing.

Install the two shift check sleeves, two check balls,

two check springs and two check ball plugs into posi-

tion.

>>K<< DIFFERENTIAL SIDE BEARING

ADJUSTMENT SHIM INSTALLATION

CAUTION

Do not use more than two shims.

Install the appropriate adjustment shims that will pro-

vide the differential side bearing with a preload within

the standard value range.

Standard value: 0.15

− 0.21 mm

AK204383AC

L

Transmission

case

Differential side bearing

outer race

Adjustment shim

1. Selecting appropriate shims

(1) Measure the distance between the end

surface and the adjustment shim fitting surface

on the transmission case (L1). Next, measure

the distance between the clutch housing end

surface and the differential side bearing end

surface (L2).

(2) Use the following equation to calculate the

clearance L between the transmission case

and the differential side bearing outer race:

L = L1

− L2

(3) Select an adjustment shim (or a set of

adjustment shims) with a thickness of L plus

0.15 mm to 0.21 mm (standard value range).

AK204355AC

MB991969

L1

MB991969

Straight edge

Straight edge

Measurement “a”

TRANSMISSION

MANUAL TRANSMISSION OVERHAUL

22B-18

2. Measuring distances L1 and L2

(1) Install the special tool Adjustment adapter

(MB991969) into the differential side rear

bearing hole in the transmission case. Use the

following equation to calculate the distance L1

(see the illustration above):

L1 = 25.00 (height of MB991969)

− measure-

ment "a"

(2) Attach the outer race onto the differential side

bearing on the final gear side, and rotate the

final gear set five or more times by hand while

holding the outer race down lightly to keep it

from tilting.

NOTE: Rotating the final gear in this way will

help the bearing rollers to seat completely

against their races.

AK204382AC

Pick tester

Height gauge

CAUTION

Before making the following measurement, make

sure to confirm that the outer race is level by

measuring the height of the outer race surface at

three different points.

(3) Use a height gauge to measure the distance

between the differential side bearing outer

race and the transmission mounting surface of

the clutch housing (L2).

>>L<< DIFFERENTIAL SIDE BEARING

OUTER RACE INSTALLATION

AK203785

1. Heat the transmission case to about 100

°C

(maximum temperature: 120

°C).

AK204354

AK204354AC

MB991966

2. Using the special tool Bearing outer race installer

(MB991966) to install the differential side bearing

outer race.

TRANSMISSION

MANUAL TRANSMISSION OVERHAUL

22B-19

>>M<< ADJUSTMENT SHIM

INSTALLATION (INPUT SHAFT REAR

BEARING / MAIN SHAFT REAR BEARING

/ REVERSE IDLER GEAR)

CAUTION

Use only one shim each for the main shaft rear

bearing, input shaft rear bearing and reverse

idler gear.

Install the selected shims into the relevant locations.

(Refer to adjustment of transmission - shim selection

for adjustment of input shaft rear bearing end play,

main shaft rear bearing end play and reverse idler

gear end play)

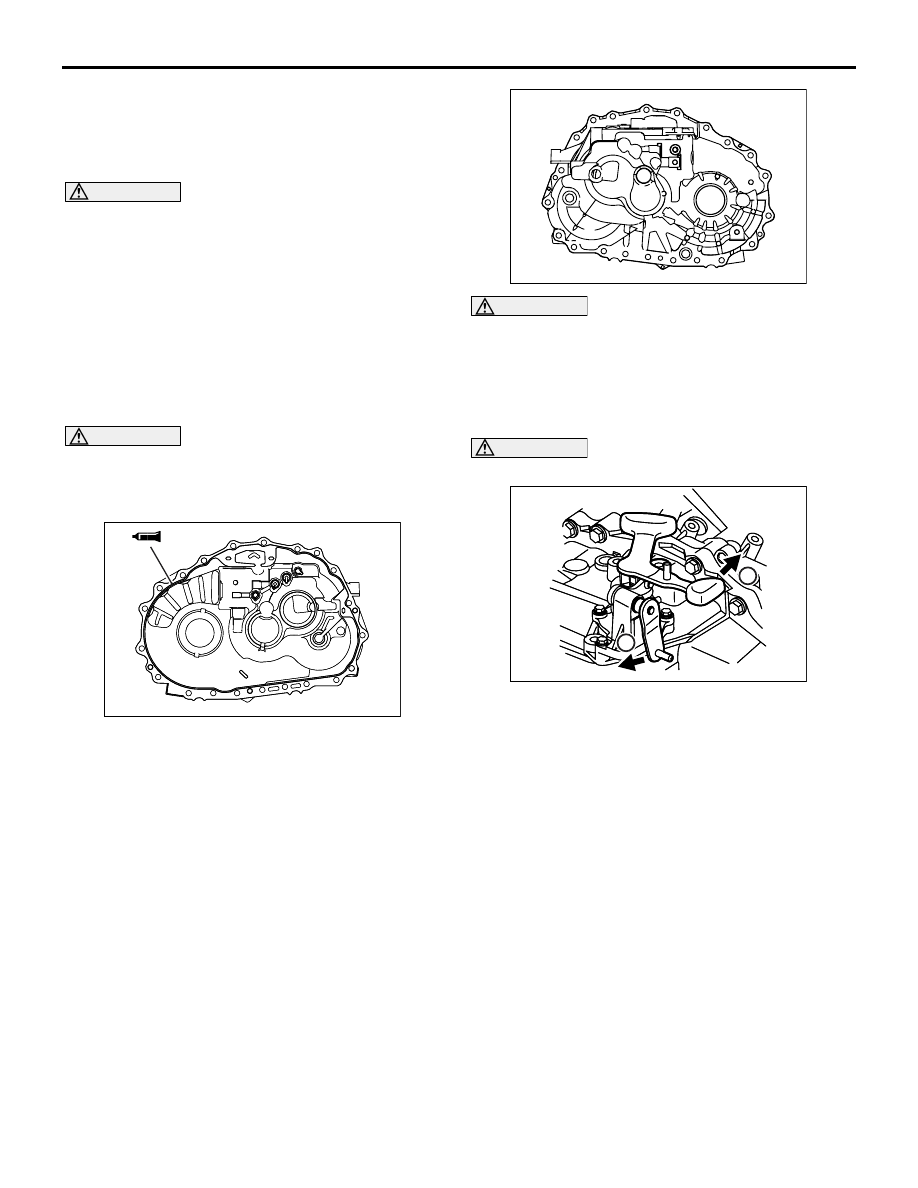

>>N<< TRANSMISSION CASE

INSTALLATION

CAUTION

The snap ring is not reusable.

1. Install the snap ring temporarily in the main shaft

rear bearing location in the transmission case.

AK204379

AK204379AC

2. Apply sealant as indicated in the above

illustration.

Specified sealant: MITSUBISHI GENUINE

PART MD997740 or equivalent

3. Expand the snap ring in the main shaft rear

bearing location through the bore plug mounting

hole and place the transmission case over the

clutch housing.

AK204378AC

A

A

A

A

A

A

A

A

A

A

B

B

B

B

B

B

B

B

B

A

A

Bolt colors

A: Yellow

B: Black

CAUTION

Bolts (B) are not reusable.

4. Tighten all the bolts to the specified torque.

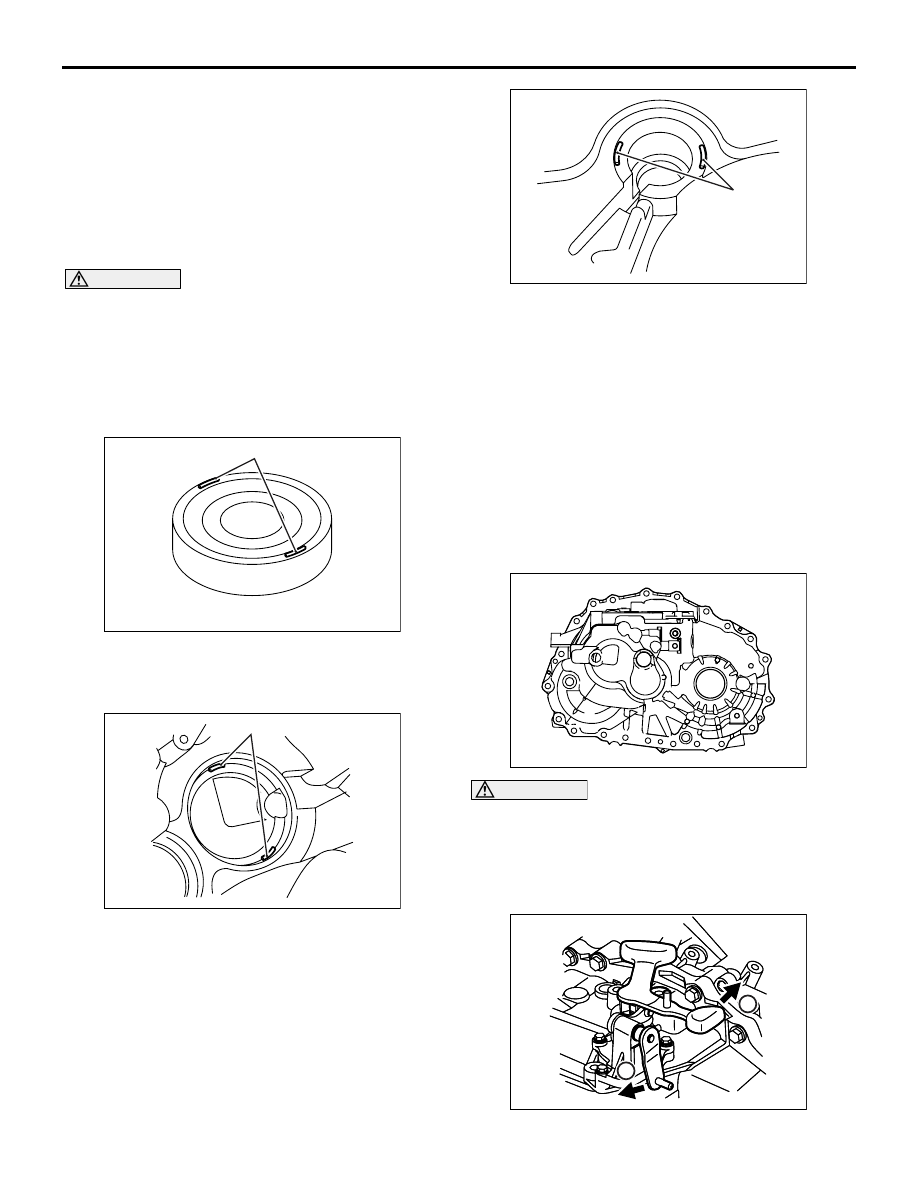

>>O<< CONTROL ASSEMBLY

INSTALLATION

CAUTION

The O-ring is not reusable.

AK204384

AK204384AC

1

2

1. Install the control assembly and tighten the bolts

to the specified torque.

2. With the gear shifted into 2nd, raise the main shaft

and install the snap ring tightly on the main shaft

rear bearing.

NOTE:

To shift the gear into 2nd, move the lever in the

order of the numbers indicated in the illustration.

>>P<< REVERSE SWITCH INSTALLATION

1. Apply sealant to the threads on the reverse

switch.

Specified sealant: MITSUBISHI GENUINE

PART MD997740 or equivalent

2. Install the reverse switch on the transmission

case.

TRANSMISSION

MANUAL TRANSMISSION OVERHAUL

22B-20

ADJUSTMENT OF TRANSMISSION

M1222013800011

SHIM SELECTION FOR ADJUSTMENT OF

INPUT SHAFT REAR BEARING END

PLAY, MAIN SHAFT REAR BEARING END

PLAY AND REVERSE IDLER GEAR END

PLAY

<Measurement using Solder>

CAUTION

• If solder is not available, select the thrust

washer in accordance with Plastigage

method.

• If the thrust washer appropriate for the stand-

ard value cannot be selected using solder,

select the thrust washer in accordance with

Plastigage method.

AK204380AC

Solder

1. Put the solder (1.0 mm diameter, about 10 mm

long) on the input shaft rear bearing as indicated

in the illustration.

AK204385AC

Solder

2. Put the solder (1.0 mm diameter, about 10 mm

long) on the main shaft rear bearing fitting surface

in the transmission case as indicated in the

illustration.

AK204386AC

Solder

3. In the case of the reverse idler gear:

(1) Put the solder (1.0 mm diameter, about 10 mm

long) on the surface of the reverse idler gear

mounting boss in the transmission case as

indicated in the Illustration.

(2) Install the adjusting shim having minimum

thickness.

4. Install the snap ring temporarily in the main shaft

rear bearing location in the transmission case.

5. Expand the snap ring in the main shaft rear

bearing location through the bore plug mounting

hole, and place the transmission case over the

clutch housing.

AK204378AC

A

A

A

A

A

A

A

A

A

A

B

B

B

B

B

B

B

B

B

A

A

Bolt colors

A: Yellow

B: Black

CAUTION

In the following step, use the same transmission

case bolts that were removed during disassem-

bly.

6. Install and tighten the transmission case bolts to

the specified torque.

AK204384

AK204384AC

1

2

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст