Mitsubishi Lancer Evolution IX. Manual — part 482

ON-VEHICLE SERVICE

MULTIPORT FUEL INJECTION (MPI)

13A-403

FUEL PUMP RESISTOR CHECK

M1131052700049

1. Disconnect the fuel pump resistor connector.

2. Measure the resistance between terminals.

Standard value: 0.45

− 0.65 Ω

3. If the resistance is out of specification, replace the

fuel pump resistor.

INTAKE AIR TEMPERATURE SENSOR

CHECK

M1131002801118

1. Disconnect the air flow sensor connector.

2. Measure resistance between terminals No. 5 and

No. 6.

Standard value:

13

− 17 kΩ (at −20°C)

5.3

− 6.7 kΩ (at 0°C)

2.3

− 3.0 kΩ (at 20°C)

1.0

− 1.5 kΩ (at 40°C)

0.56

− 0.76 kΩ (at 60°C)

0.30

− 0.42 kΩ (at 80°C)

3. Measure resistance while heating the sensor

using a hair drier.

Normal condition:

4. If the value deviates from the standard value or

the resistance remains unchanged, replace the air

flow sensor assembly.

ENGINE COOLANT TEMPERATURE

SENSOR CHECK

M1131003101060

CAUTION

Be careful not to touch the connector (resin sec-

tion) with the tool when removing and installing.

1. Remove the engine coolant temperature sensor.

AK304577

1 2

AB

Fuel pump resistor

Equipment side connector

<L. H. drive vehicles>

<R. H. drive vehicles>

Fuel pump resistor

connector

Fuel pump resistor

Fuel pump

resistor

connector

AK304578

6 7

1 2 3 4 5

AB

Air flow sensor

Equipment side

connector

Temperature (

°C)

Resistance (k

Ω)

Higher

Smaller

AKX01621

Intake air temperature

sensor

AD

AK304579

1 2

AB

Equipment side

connector

Engine coolant

sensor

AKX01622

ON-VEHICLE SERVICE

MULTIPORT FUEL INJECTION (MPI)

13A-404

2. With temperature sensing portion of engine

coolant temperature sensor immersed in hot

water, check resistance.

Standard value:

14

− 17 kΩ (at −20°C)

5.1

− 6.5 kΩ (at 0°C)

2.1

− 2.7 kΩ (at 20°C)

0.9

− 1.3 kΩ (at 40°C)

0.48

− 0.68 kΩ (at 60°C)

0.26

− 0.36 kΩ (at 80°C)

3. If the resistance deviates from the standard value

greatly, replace the sensor.

4. Apply sealant to threaded portion.

Specified sealant:

3M NUT Locking Part No. 4171 or equivalent

5. Install the engine coolant temperature sensor and

tighten it to the specified torque.

Tightening torque: 29

± 10 N⋅m

THROTTLE POSITION SENSOR CHECK

M1131003200796

1. Disconnect the throttle position sensor connector.

2. Measure the resistance between the throttle

position sensor side connector terminal No. 1 and

terminal No. 4.

Standard value: 3.5

− 6.5 kΩ

3. Measure the resistance between the throttle

position sensor side connector terminal No. 2 and

terminal No. 4.

Normal condition:

4. If the resistance is outside the standard value, or if

it doesn’t change smoothly, replace the throttle

position sensor.

NOTE: For the throttle position sensor adjustment

procedure, refer to

.

OXYGEN SENSOR CHECK

M1131005001434

Oxygen sensor (front)

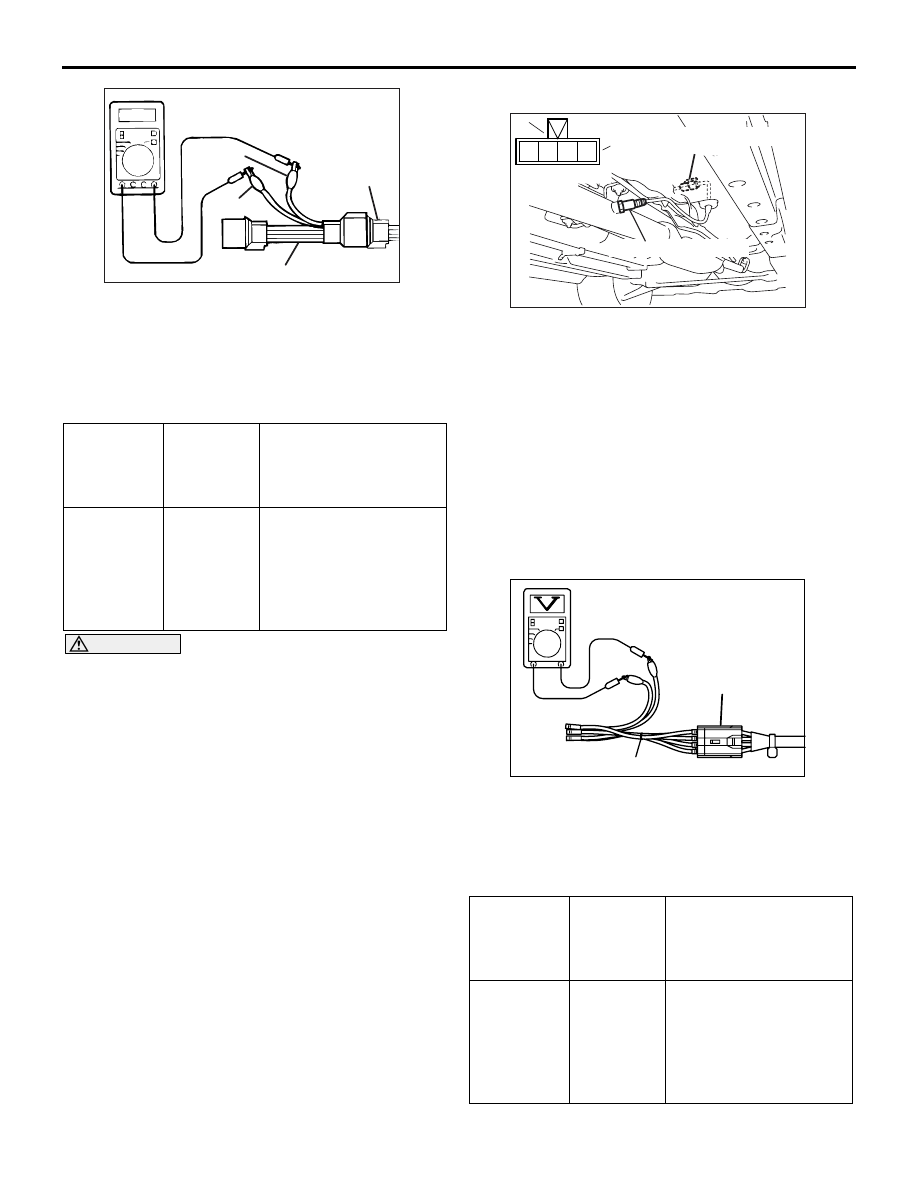

1. Disconnect the oxygen sensor connector and

connect the special tool test harness (MD998464)

to the connector on the oxygen sensor side.

2. Make sure that there is continuity (4.5

− 8.0 Ω at

20

°C) between terminal No. 1 (red clip of special

tool) and No. 3 (blue clip of special tool) on the

oxygen sensor connector.

3. If there is no continuity, replace the oxygen

sensor.

4. Warm up the engine until engine coolant is 80

°C

or higher.

5. Perform a tracing for 5 minutes or more with the

engine speed of 4,500 r/min.

AKX01623AD

AK304568

1

2 3

4

AB

Equipment

side connector

Throttle

position sensor

Throttle valve slowly

open until fully open from

the idle position

Changes smoothly in

proportion to the opening

angle of the throttle valve

AK304581

1

2

3

4

AB

Equipment side

connector

Oxygen sensor (front)

Oxygen sensor (front)

connector

ON-VEHICLE SERVICE

MULTIPORT FUEL INJECTION (MPI)

13A-405

6. Connect a digital voltage meter between terminal

No. 2 (black clip of special tool) and No. 4 (white

clip of special tool).

7. While repeatedly racing the engine, measure the

oxygen sensor output voltage.

Standard value:

CAUTION

• Be very careful when connecting the jumper

wire; incorrect connection can damage the

oxygen sensor.

• Be careful the heater is broken when voltage

of beyond 8 V is applied to the oxygen sensor

heater.

NOTE: If the sufficiently high temperature (of

approximate 400

°

C or more) is not reached

although the oxygen sensor is normal, the output

voltage would be possibly low although the rich

air-fuel ratio. Therefore, if the output voltage is

low, use a jumper wire to connect the terminal No.

1 (red clip of special tool) and the terminal No. 3

(blue clip of special tool) of the oxygen sensor

with a (+) terminal and (

−

) terminal of 8 V power

supply respectively, then check again.

8. If the sensor is defective, replace the oxygen

sensor.

NOTE: For removal and installation of the oxygen

sensor, refer to GROUP 15

−

Exhaust Manifold

Oxygen sensor (rear)

1. Disconnect the oxygen sensor connector and

connect the special tool test harness (MB991658)

to the connector on the oxygen sensor side.

2. Make sure that there is continuity (11

− 18 Ω at

20

°C) between terminal No. 3 and No. 4 on the

oxygen sensor connector.

3. If there is no continuity, replace the oxygen

sensor.

4. Warm up the engine until engine coolant is 80

°C

or higher.

5. Perform a tracing for 5 minutes or more with the

engine speed of 4,500 r/min.

6. Connect a digital voltage meter between terminal

No. 1 and No. 2.

7. While repeatedly racing the engine, measure the

oxygen sensor output voltage.

Standard value:

Engine

Oxygen

sensor

output

voltage

Remarks

When

racing the

engine

0.6

− 1.0 V If you make the air-fuel

ratio rich by racing the

engine repeatedly, a

normal oxygen sensor

will output a voltage of

0.6

− 1.0 V.

AK305450

Black

White

MD998464

Oxygen

sensor

equipment

side connector

AB

Engine

Oxygen

sensor

output

voltage

Remarks

When

racing the

engine

0.6

− 1.0 V If you make the air-fuel

ratio rich by racing the

engine repeatedly, a

normal oxygen sensor

will output a voltage of

0.6

− 1.0 V.

AK304582

1

2 3

4

AB

Equipment side

connector

Oxygen sensor (rear)

Oxygen sensor (rear)

connector

AK301808

MB991658

AB

Oxygen sensor

ON-VEHICLE SERVICE

MULTIPORT FUEL INJECTION (MPI)

13A-406

CAUTION

• Be very careful when connecting the jumper

wire; incorrect connection can damage the

oxygen sensor.

• Be careful the heater is broken when voltage

of beyond 12 V is applied to the oxygen sen-

sor heater.

NOTE: If the sufficiently high temperature (of

approximately 400

°

C or more) is not reached

although the oxygen sensor is normal, the output

voltage would be possibly low although the rich

air-fuel ratio. Therefore, if the output voltage is

low, use a jumper wire to connect the terminal No.

3 and the terminal No. 4 of the oxygen sensor with

a (+) terminal and (

−

) terminal of 12 V power sup-

ply respectively, then check again.

8. If the sensor is defective, replace the oxygen

sensor.

NOTE: For removal and installation of the oxygen

sensor, refer to GROUP 15

−

Exhaust Pipe and

INJECTOR CHECK

M1131005201267

Check the Operation Sound

1. Use a stethoscope to listen to the operation sound

(clicking) of the injectors while the engine is idling

or cranking.

CAUTION

Beware that the operation sounds of other injec-

tors can be heard even if the injector that is being

inspected might not be operating.

2. Verify that the operation sound increases with the

engine speed.

NOTE: If the operating sound cannot be heard,

inspect the injector actuation circuit.

Measurement of Resistance between Ter-

minals

1. Disconnect the injector connector.

2. Measure the resistance between terminals.

Standard value: 2

− 3 Ω (at 20°C)

3. Connect the injector connector.

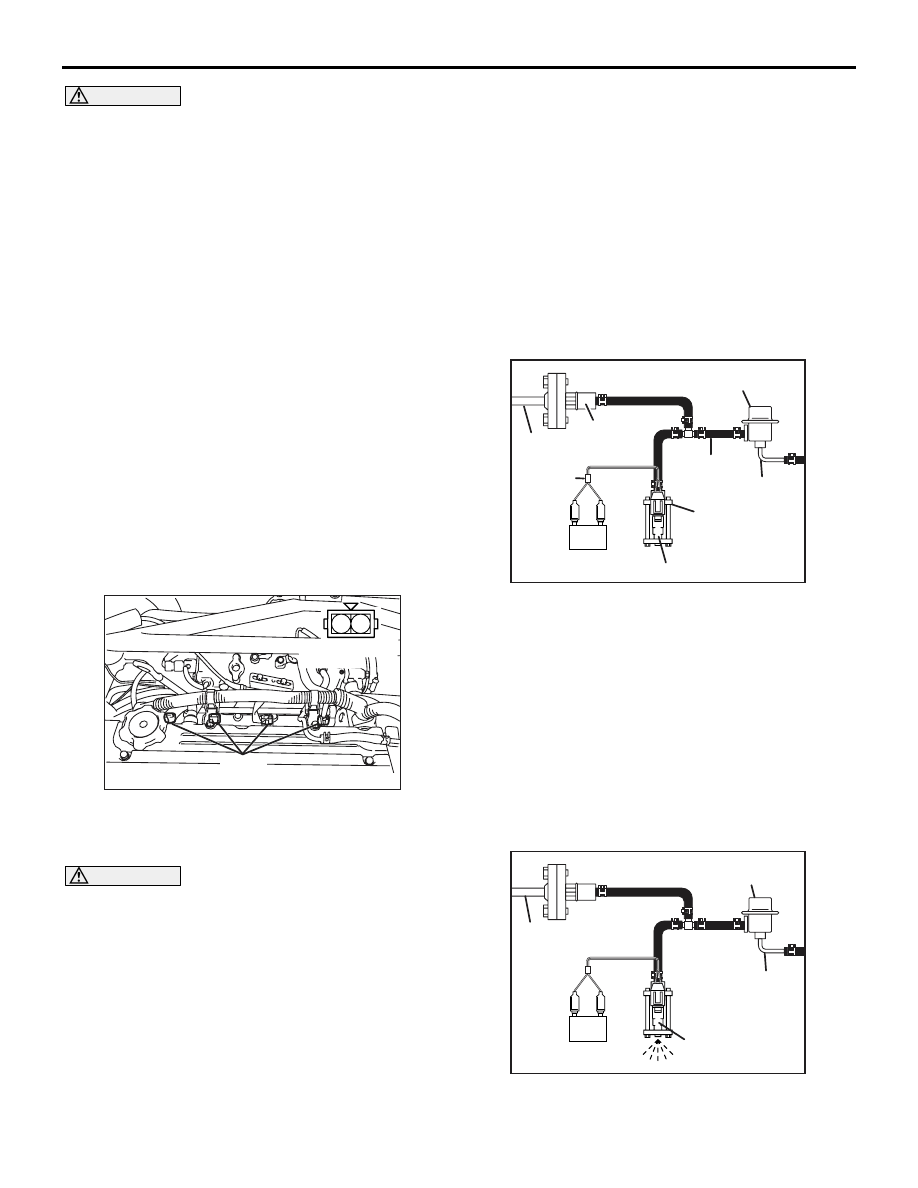

Check the Injection Condition

1. Following the steps below, bleed out the residual

pressure within the fuel pipe line to prevent flow of

the fuel (Refer to

).

2. Remove the injector.

3. Assemble the following special tools as shown in

Fig.

• Injector test set (MD998706)

• Injector test harness (MB991607)

• Injector test adaptor (MD998741)

• Injector test holder assembly (MB991976)

4. Connect the M.U.T.-II/III to the diagnosis

connector.

5. Turn the ignition switch to "ON" position (But do

not start the engine).

6. Select "Item No. 07" from the M.U.T.-II/III actuator

test to drive the fuel pump.

7. Activate the injector and check the atomized

spray condition of the fuel.

AK304583

1

2

AB

Equipment side

connector

Injector

AK301464

MD998741

MD998706

MB991976

MB991607

AC

High-pressure

fuel hose

Fuel pressure

regulator

Return hose

Battery

Injector

AK301465AC

High-pressure

fuel hose

Fuel pressure

regulator

Return hose

Battery

Injector

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст