Mitsubishi Lancer Evolution IX. Manual — part 574

TRAILING ARM

REAR SUSPENSION

34-11

REMOVAL SERVICE POINT

<<A>> TRAILING ARM ASSEMBLY AND

KNUCKLE DISCONNECTION

CAUTION

• Do not remove the nut from ball joint. Loosen

it and use special tool ball joint remover

(MB991897 or MB992011) to avoid possible

damage to ball joint threads.

• Hang special tool ball joint remover

(MB991897 or MB992011) with a cord to pre-

vent it from falling.

AC106820 AE

Cord

Bolt

MB991897

or

MB992011

Nut

Ball joint

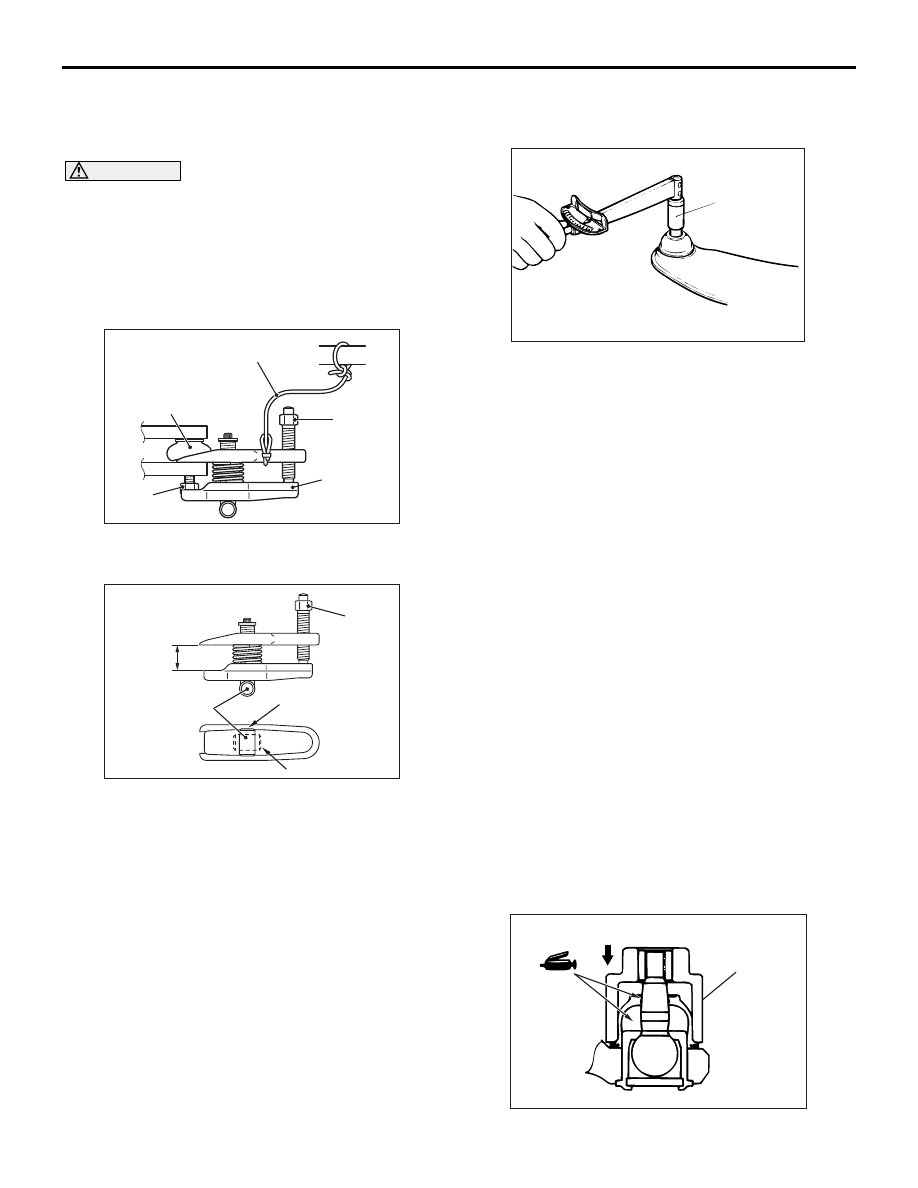

1. Install the special tool ball joint remover

(MB991897 or MB992011) as shown in the figure.

AC106821

Knob

Parallel

Bolt

Good

Bad

AB

2. Turn the bolt and knob as necessary to make the

jaws of the special tool ball joint remover

(MB991897 or MB992011) parallel, tighten the

bolt by hand and confirm that the jaws are still

parallel.

NOTE: When adjusting the jaws in parallel, make

sure the knob is in the position shown in the fig-

ure.

3. Tighten the bolt with a wrench to disconnect the

trailing arm assembly and the knuckle.

INSPECTION

M1341002300289

BALL JOINT STARTING TORQUE CHECK

ACX00716

MB990326

AB

1. After shaking the ball joint stud several times, use

special tool preload socket (MB990326) to

measure the starting torque of the ball joint.

Standard value: 0.5

− 2.5 N⋅m

2. When the measured value exceeds the standard

value, replace the trailing arm assembly.

3. When the measured value is lower than the

standard value, check that the ball joint turns

smoothly without excessive play. If there is no

excessive play, the ball joint can be reused.

DUST COVER CHECK

1. Check the dust cover for cracks or damage by

pushing it with your finger.

2. If the dust cover is cracked or damaged, replace

the trailing arm assembly.

NOTE: Cracks or damage to the dust cover may

cause damage to the ball joint. When it is dam-

aged during service work, replace the dust cover.

TRAILING ARM BALL JOINT DUST

COVER REPLACEMENT

M1341010900424

Only when the dust cover is damaged accidentally

during service work, replace the dust cover as fol-

lows:

1. Remove the dust cover.

AC212031AB

MB990800

LOWER ARM ASSEMBLY AND ASSIST LINK

REAR SUSPENSION

34-12

2. Fill the multipurpose grease in the dust cover and

lubricate the lip (Amount of filling grease in the

dust cover: approximately 7 g).

3. Using special tool ball joint remover and installer

(MB990800), punch the dust cover until it contacts

the snap ring.

4. Press the dust cover with your finger to check that

there are no cracks or damage in the dust cover.

LOWER ARM ASSEMBLY AND ASSIST LINK

REMOVAL AND INSTALLATION

M1341017100065

CAUTION

• During maintenance, take care not to contact the parts or tools to the caliper, because the paint of

caliper will be scratched. And if there is brake fluid on the caliper, wipe out quickly.

•

Post-installation Operation

• Press the dust cover with your finger to check that there

are no cracks or damage in the dust cover.

• Wheel Alignment Check and Adjustment (Refer to

).

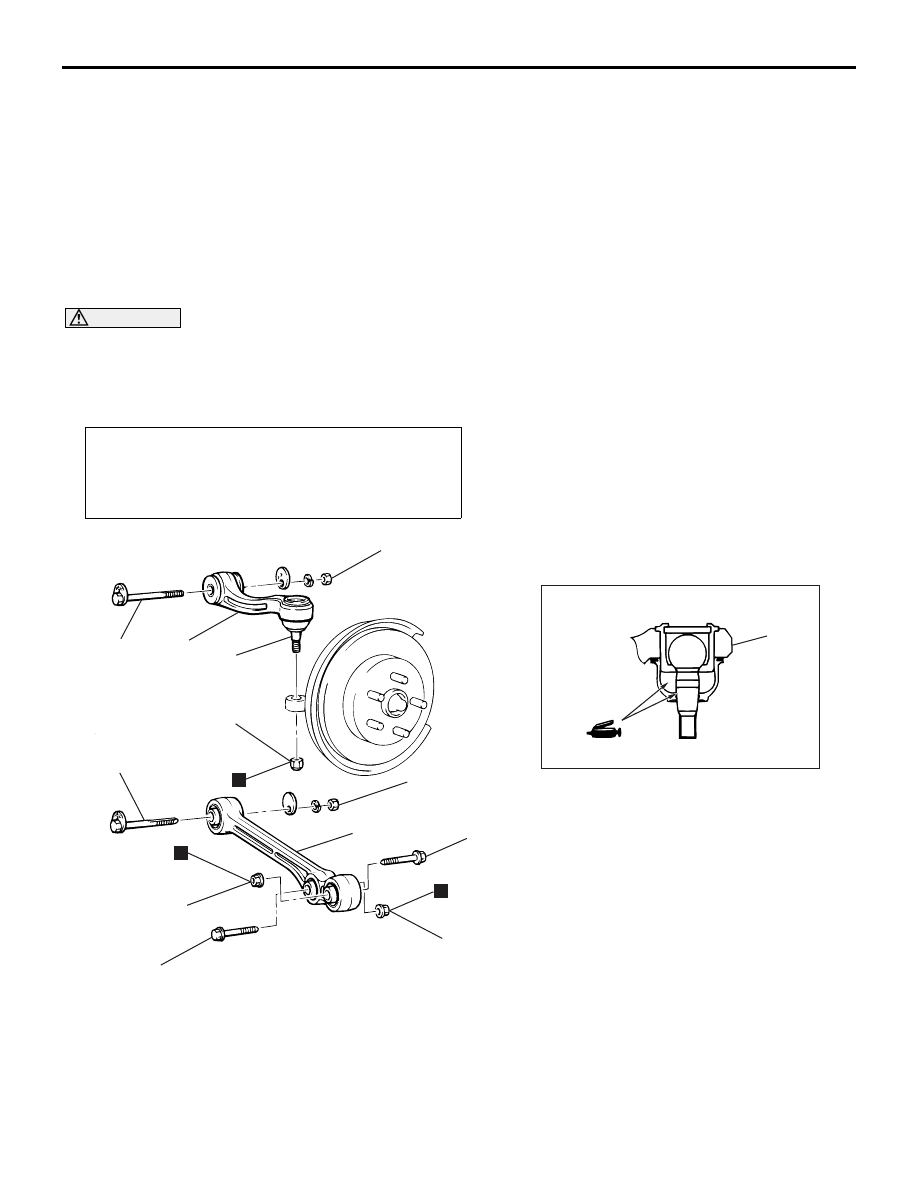

AC310785

1

AB

88 ± 10 N·m*

4

N

88 ± 10 N·m*

3

2

N

93 ± 15 N·m*

2

81 ± 6 N·m

N

6

5

93 ± 15 N·m*

6

Lower arm assembly removal

steps

1.

Lower arm assembly to shock

absorber connecting bolt

<<

A

>>

2.

Lower arm assembly mounting bolt

>>

A

<< 3.

Lower arm assembly

Assist link removal steps

<<

B

>>

4.

Assist link and knuckle connection

<<

C

>>

5.

Assist link mounting bolt

6.

Assist link assembly

*

: To prevent bushings from breakage, the parts indicated by * should be temporarily tightened,

and then fully tightened with the vehicle on the ground in the unladen condition.

LOWER ARM ASSEMBLY AND ASSIST LINK

REAR SUSPENSION

34-13

REMOVAL SERVICE POINTS

<<A>> LOWER ARM ASSEMBLY MOUNT-

ING BOLT REMOVAL

AC310794

Mating marks

AB

Make mating marks on the lower arm and the

decentering cam bolt, then remove the lower arm

and the decentering cam bolt.

<<B>> ASSIST LINK AND KNUCKLE

DISCONNECTION

CAUTION

• Do not remove the nut from ball joint. Loosen

it and use special tool ball joint remover

(MB991897 or MB992011) to avoid possible

damage to ball joint threads.

• Hang special tool ball joint remover

(MB991897 or MB992011) with a cord to pre-

vent it from falling.

AC106820 AE

Cord

Bolt

MB991897

or

MB992011

Nut

Ball joint

1. Install special tool ball joint remover (MB991897

or MB992011) as shown in the figure.

AC106821

Knob

Parallel

Bolt

Good

Bad

AB

2. Turn the bolt and knob as necessary to make the

jaws of special tool ball joint remover (MB991897

or MB992011) parallel, tighten the bolt by hand

and confirm that the jaws are still parallel.

NOTE: When adjusting the jaws in parallel, make

sure the knob is in the position shown in the fig-

ure.

3. Tighten the bolt with a wrench to disconnect the

assist link assembly and the knuckle.

<<C>> ASSIST LINK MOUNTING BOLT

REMOVAL

AC310795

Mating marks

Eccentric

cam bolt

AB

Make mating marks on the assist link and the

decentering cam bolt, then remove the toe control

arm and the decentering cam bolt.

INSTALLATION SERVICE POINT

>>A<< LOWER ARM ASSEMBLY INSTAL-

LATION

AC310797AB

With countersunk Ø10mm:

LH side lower arm assembly

With red marking: RH side

lower arm assembly

Check the identification mark, install the lower arm

assembly.

LOWER ARM ASSEMBLY AND ASSIST LINK

REAR SUSPENSION

34-14

INSPECTION

M1341017200051

ASSIST LINK BALL JOINT STARTING

TORQUE CHECK

ACX00716

MB990326

AB

1. After shaking the assist link ball joint stud several

times, measure the starting torque of the assist

link ball joint by using special tool preload socket

(MB990326).

Standard value: 0.5

− 2.5 N⋅m

2. When the measured value exceeds the standard

value, replace the assist link.

3. When the measured value is lower than the

standard value, check that the assist link ball joint

turns smoothly without excessive play. If there is

no excessive play, the ball joint can be reused.

ASSIST LINK SLIDE BUSHING STARTING

TORQUE CHECK

AC212117

MB990326

AB

1. After inserting the bolt to the assist link slide bush

and attaching the washer in the opposite

direction, install the nut. After rotating the inner

sleeve (include the washer) several times,

measure the starting torque of the assist link slide

bushing by using special tool preload socket

(MB990326).

Standard value: 0.5

− 2.0 N⋅m

2. When the measured value exceeds the standard

value, replace the assist link.

3. When the measured value is lower than the

standard value, check that the assist link slide

bushing turns smoothly without excessive play. If

there is no excessive play, the slide bushing can

be reused.

ASSIST LINK BALL JOINT DUST COVER

CHECK

1. Check the dust cover for cracks or damage by

pushing it with your finger.

2. If the dust cover is cracked or damaged, replace

the trailing arm assembly.

NOTE: Cracks or damage of the dust cover may

cause damage to the ball joint. When it is dam-

aged during service work, replace the dust cover.

LOWER ARM PILLOW BALL BUSHING

STARTING TORQUE CHECK

AC310798

MB990326

AB

Pillow ball bushing

1. Insert the bolt to the lower arm pillow ball bushing,

in the opposite direction, insert the washer then

install the nut. After rotating the inner sleeve

(contained washer) several times, measure the

starting torque of the lower arm below ball

bushing using special tool preload socket

(MB990326).

Standard value: 0.5

− 3.0 N⋅m

2. When the measured value exceeds the standard

value, replace the lower arm assembly.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст