Mitsubishi Lancer Evolution IX. Manual — part 88

CYLINDER HEAD AND VALVES

ENGINE OVERHAUL

11B-43

REMOVAL SERVICE POINTS

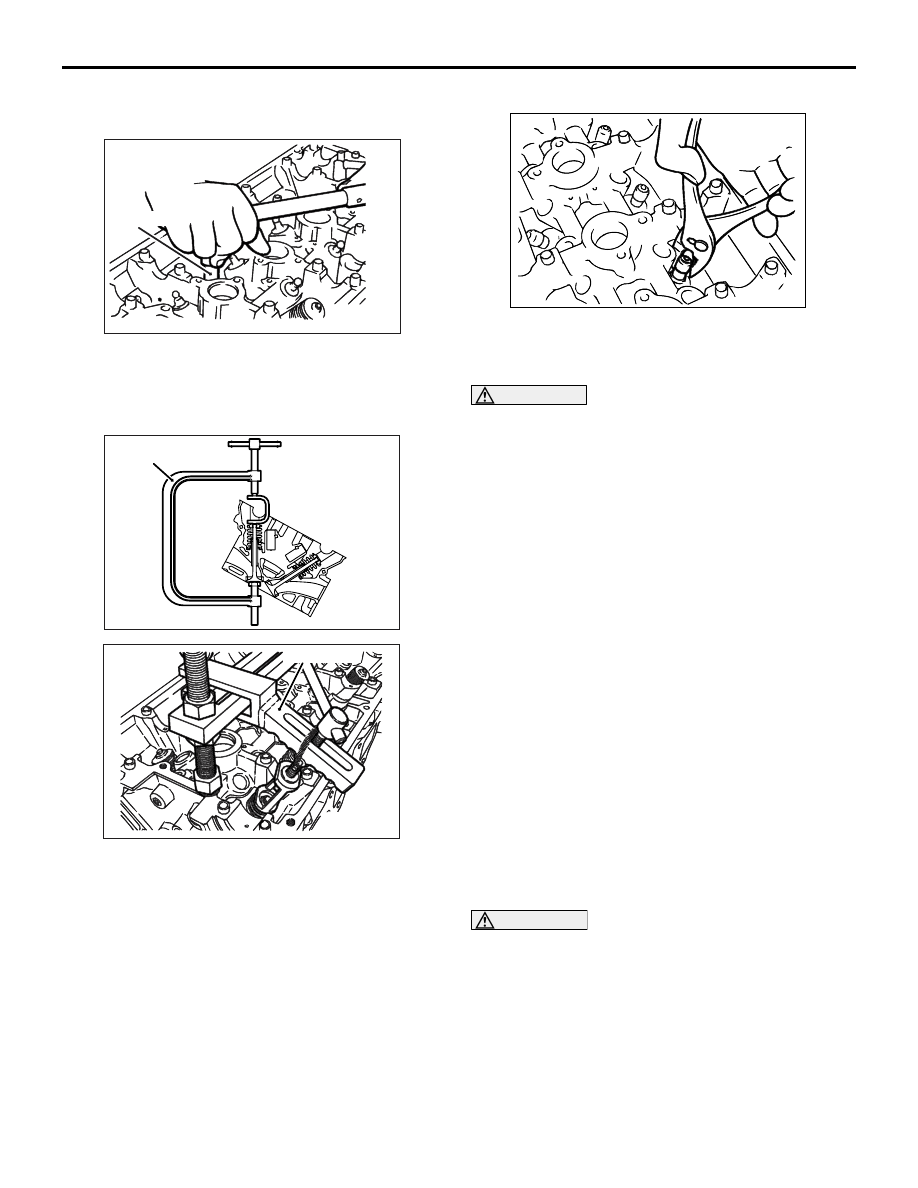

<<A>> CYLINDER HEAD BOLT REMOVAL

Use the special tool Cylinder head bolt wrench

(MB991654) to loosen the cylinder head bolts.

<<B>> RETAINER LOCK REMOVAL

Compress the valve spring using the special tool

Valve spring compressor (MD998735 or MD998772),

then remove the retainer lock.

NOTE: Store removed valves, springs and other

parts, after putting to each of them a tag that identi-

fies its cylinder No. or installation location.

<<C>> VALVE STEM SEAL REMOVAL

Do not reuse removed valve stem seal.

<<D>> VALVE HANDLING PRECAUTIONS

WARNING

Sodium reacts violently with water or mois-

ture generation heat and liberating hydro-

gen. It must be handled with utmost care

because otherwise the following dangerous

conditions may result:

•

Loss of eyesight if sodium gets in eyes.

•

Burns if sodium contacts skin.

•

Fire hazard.

1. Handling of Sodium-filled Exhaust Valves

(1) Sodium-filled exhaust valves are not

dangerous and may be handled in the same

way as ordinary valves unless they are

broken.

(2) Never try to break the valves and expose

sodium to the air.

(3) When worn exhaust valves are to be

discarded, have them disposed of by a

salvage company equipped with special

disposal system, notifying them that the valves

contain sodium.

(4) Should the exhaust valves be broken,

neutralize sodium using the method described

below, and discard the valves in the same way

as ordinary valves.

CAUTION

• Do not let the solution contact the eyes or the

skin.

• Should it get in the eyes, immediately flush

them with clean water thoroughly, and receive

medical attention. When it contacts he skin,

wash with ample amounts of clean water.

AK202723

MB991654

AE

AK202873

MD998735

AD

AK202742

MD998772

AD

AK304633

CYLINDER HEAD AND VALVES

ENGINE OVERHAUL

11B-44

2. How to Neutralize Sodium

(1) Place a container filled with more than 10 litres

of water in a well ventilated large space.

(2) Wear rubber gloves and goggles, and carefully

take out broken valves from the cylinder head.

CAUTION

• Valves must be neutralized one at a time.

• Put a valve in the container only after sodium

in the preceding one has completely reacted

with water.

(3) Put a broken valves in the water-filled

container and quickly get away from the

container at least 2 or 3 m.

(4) Keep fire away from the container during the

neutralization. The resulting hydrogen gas is

highly explosive.

NOTE: The reaction occurs when water enters

the cavity in he valve. Hydrogen gas may be

trapped inside the valve, temporarily blocking

the water passage. In such a case, wait until

hydrogen gas in released and remaining

sodium reacts with water.

(5) After the neutralization of sodium, water in the

container contains sodium hydroxide and is

highly alkaline. The water solution should be

disposed of according to local regulations.

INSTALLATION SERVICE POINTS

>>A<< VALVE STEM SEAL INSTALLA-

TION

CAUTION

The special tool must always be used when

installing the valve stem seal. Improper installa-

tion could result in oil leaks past the valve guide.

1. Install the valve spring seat.

2. Install the valve.

3. Apply a thin coat of engine oil to a new valve stem

seal.

4. Use the special tool Valve stem seal installer

(MD998737) to install the stem seal on the valve

guide. Use the stem of the valve to guide the stem

seal.

NOTE: Do not confuse the stem seals for intake

valves with those for exhaust valves.

>>B<< VALVE SPRING INSTALLATION

Install the valve spring whose small diameter is

shown from the rocker arm side.

AK304485

MD998737

AC

AK304538AB

Intake valve stem seal

Colour: Gray

Exhaust valve stem seal

Colour: Grayish green

AK305040AB

Small diameter

CYLINDER HEAD AND VALVES

ENGINE OVERHAUL

11B-45

>>C<< RETAINER LOCK INSTALLATION

Compress the valve spring using the special tool

Valve spring compressor (MD998735 or MD998772),

then install the retainer lock.

>>D<< CYLINDER HEAD BOLT

INSTALLATION

1. When reusing a cylinder head bolt, check that its

nominal length (shank length) is not greater than

the limit. If the limit is exceeded, replace the bolt.

Limit: 99.4 mm

2. Apply engine oil to the threads and washer of the

bolt.

3. Tighten the bolts to 78

± 2 N⋅m in the indicated

sequence.

NOTE: Use the special tool Cylinder head bolt

wrench (MB991654) to tighten the bolts.

4. Loosen all the bolts completely.

5. Tighten the bolts again to a torque of 20

± 2 N⋅m

in the indicated sequence.

CAUTION

• If the tightening angle is smaller than 90°,

proper fastening performance could not be

assured. Be sure to respect that angle.

• If the bolt is tightened to an angle greater than

the specified angle, loosen the bolt com-

pletely and then retighten it beginning with

the first step.

6. Make paint marks on each bolt’s head and on the

cylinder head.

7. Turn the bolts 90

° in the tightening direction and in

the indicated sequence.

AK202873

MD998735

AD

AK202742

MD998772

AD

AK300591AB

Shank length

AK202723

MB991654

AE

1

3

9

6

8

2

5

7

4

10

AK202806

Timing belt side

AB

AK202720

Paint marks

90˚

90˚

AB

CYLINDER HEAD AND VALVES

ENGINE OVERHAUL

11B-46

8. Give another 90

° turn in the tightening direction to

each bolt, making sure that the paint mark on the

bolt head and that on the cylinder head are on the

same line.

INSPECTION

M1113007000981

CYLINDER HEAD

1. Before cleaning the cylinder head, check it for

traces of water and gas leakage and for cracks

and any other damage.

2. Thoroughly remove oils, scale, sealants, carbon

and other contamination. Clean the oil passages,

then check using compressed air that they are not

blocked.

CAUTION

The thickness of the metal that can be removed

by grinding from both the cylinder head and the

mating cylinder block is limited to 0.2 mm in

total.

3. Check the cylinder head gasket surface for warp

using a straightedge and thickness gauge.

If the surface is warped beyond the limit, grind the

surface for rectification.

Gasket surface warp

Standard value: Less than 0.05 mm

Limit: 0.2 mm

Grinding limit: 0.2 mm

Cylinder head height (standard value for new

part): 131.9

− 132.1 mm

VALVES

1. Check the valve face for correct contact with the

seat. Reface the valve if the contact is partial or

one sided.

2. Measure the margin.

Replace the valve if its margin is smaller than the

limit.

Standard values:

Intake 1.0 mm

Exhaust 1.5 mm

Limits:

Intake 0.5 mm

Exhaust 1.0 mm

3. Measure the total length of the valve.

Replace the valve if the length is less than the

limit.

Standard values:

Intake 109.5 mm

Exhaust 109.7 mm

Limits:

Intake 109.0 mm

Exhaust 109.2 mm

AK202724

AK300593AB

Margin

Contact

(Should be at

centre of face)

AK202876

Total length

AB

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст