Mitsubishi Lancer Evolution IX. Manual — part 489

ON-VEHICLE SERVICE

SERVICE BRAKES

35A-11

BRAKE DISC THICKNESS CHECK

M1351002400469

CAUTION

Take care not to contact the parts or tools to the

caliper because the paint of caliper will be

scratched. And if there is brake fluid on the cali-

per, wipe it off quickly.

ACX00668AB

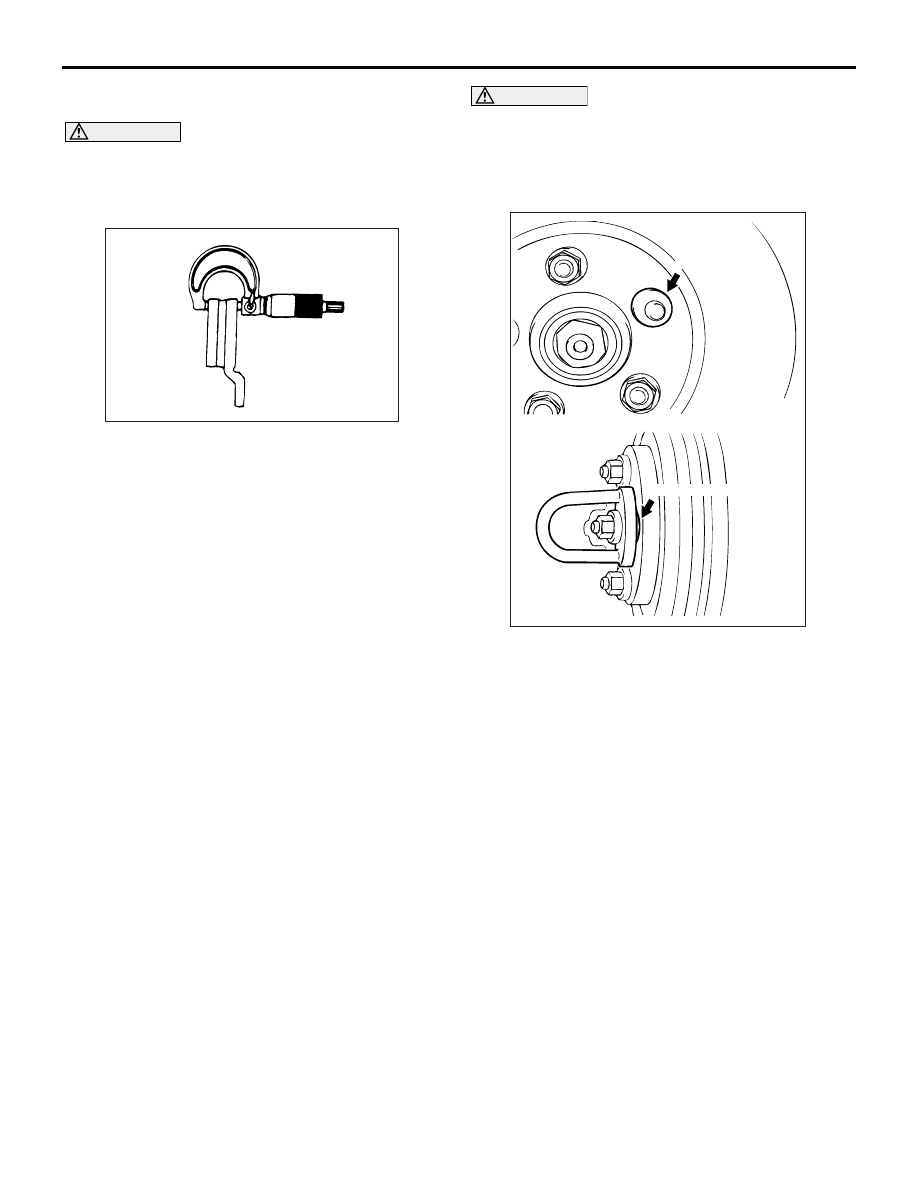

1. Using a micrometer, measure disc thickness at

eight positions, approximately 45 degrees apart

and 10 mm from the outer edge of the disc.

Standard value:

<Front> 32.0 mm

<Rear> 22.0 mm

Minimum limit:

<Front> 29.8 mm

<Rear> 20.4 mm

NOTE: Thickness variation (at least 8 positions)

should not be more than 0.015 mm.

CAUTION

• After a new brake disc is installed, always

grind the brake disc with on-the-car type

brake lathe. If this step is not carried out, the

brake disc run-out exceeds the specified

value, resulting in judder.

•

AC006226 AB

M12 flat washer

M12 flat washer

When the on-the-car type lathe is used, first

install a M12 flat washer on the stud bolt in

the brake disc side according to the figure,

and then install the adapter. If the adapter is

installed with M12 flat washer not seated, the

brake disc rotor may be deformed, resulting

in inaccurate grinding.

• Grind the brake disc with all wheel nuts diag-

onally and equally tightened to the specified

torque 100 N

⋅m. When all numbers of wheel

nuts are not used, or the tightening torque is

excessive or not equal, the brake disc rotor or

drum may be deformed, resulting in judder.

2. If the disc thickness is less than the limits, replace

it with a new one. If thickness variation exceeds

the specification, turn rotor with an on-the-car type

brake lathe ("Accuturn-8750" or equivalent).

If the calculated final thickness after turning the

rotor is less than the standard value, replace the

disc.

ON-VEHICLE SERVICE

SERVICE BRAKES

35A-12

BRAKE DISC RUN-OUT CHECK AND

CORRECTION

M1351009400534

CAUTION

Take care not to contact the parts or tools to the

caliper because the paint of caliper will be

scratched. And if there is brake fluid on the cali-

per, wipe it off quickly.

1. Remove the brake assembly, and then hold it with

wire.

2. Temporarily install the disc with the hub nut.

ACX00669AB

3. Place a dial gauge approximately 5 mm from the

outer circumference of the brake disc, and

measure the run-out of the disc.

Limit: 0.03 mm

AC210711AB

Chalk marks

4. If the brake disc run-out exceeds the limit, correct

it as follows:

(1) Chalk phase marks on the wheel stud and the

brake disc, which run-out is excessive as

shown.

AC102438 AC

<Front>

AC205869AC

<Rear>

(2) Remove the brake disc. Then place a dial

gauge as shown, and measure the axial play

by pushing and pulling the wheel hub.

Limit: 0.05 mm

(3) If the axial play exceeds the limit, disassemble

the hub and knuckle assembly to check each

part.

(4) If the axial play does not exceed the limit,

dephase the brake disc and secure it. Then

recheck the brake disc run-out.

ON-VEHICLE SERVICE

SERVICE BRAKES

35A-13

CAUTION

• After a new brake disc is installed, always

grind the brake disc with on-the-car type

brake lathe. If this step is not carried out, the

brake disc run-out exceeds the specified

value, resulting in judder.

•

AC006226 AB

M12 flat washer

M12 flat washer

When the on-the-car type lathe is used, first

install a M12 flat washer on the stud bolt in

the brake disc side according to the figure,

and then install the adapter. If the adapter is

installed with M12 flat washer not seated, the

brake disc rotor may be deformed, resulting

in inaccurate grinding.

• Grind the brake disc with all wheel nuts diag-

onally and equally tightened to the specified

torque 100 N

⋅m. When all numbers of wheel

nuts are not used, or the tightening torque is

excessive or not equal, the brake disc rotor or

drum may be deformed, resulting in judder.

5. If the run-out cannot be corrected by changing the

phase of the brake disc, replace the brake disc or

grind it with the on-the-car type brake lathe

("Accuturn-8750" or equivalent).

BRAKE PEDAL

SERVICE BRAKES

35A-14

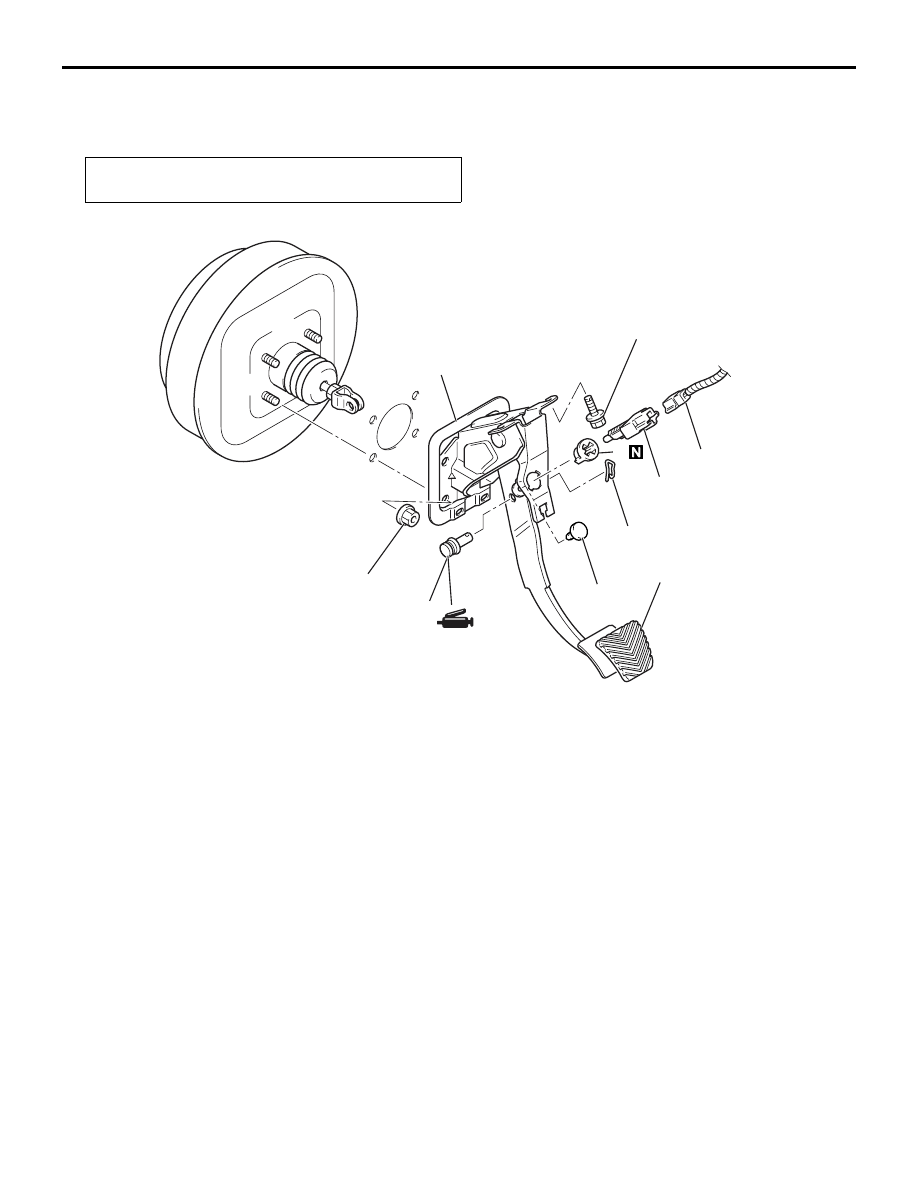

BRAKE PEDAL

REMOVAL AND INSTALLATION

M1351003400473

Post-installation Operation

• Brake Pedal Adjustment (Refer to

AC211554 AB

12 ± 2 N·m

14 ± 3 N·m

6

1

2

3

4

7

8

5

Removal steps

1. Harness connector

2. Stoplamp switch

3. Brake pedal clip

4. Brake pedal stopper

5. Brake booster pin

6. Brake pin assembly

7. Brake pedal pad

>>

A

<< 8. Brake pedal assembly

Removal steps (Continued)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст