Mitsubishi Lancer Evolution IX. Manual — part 290

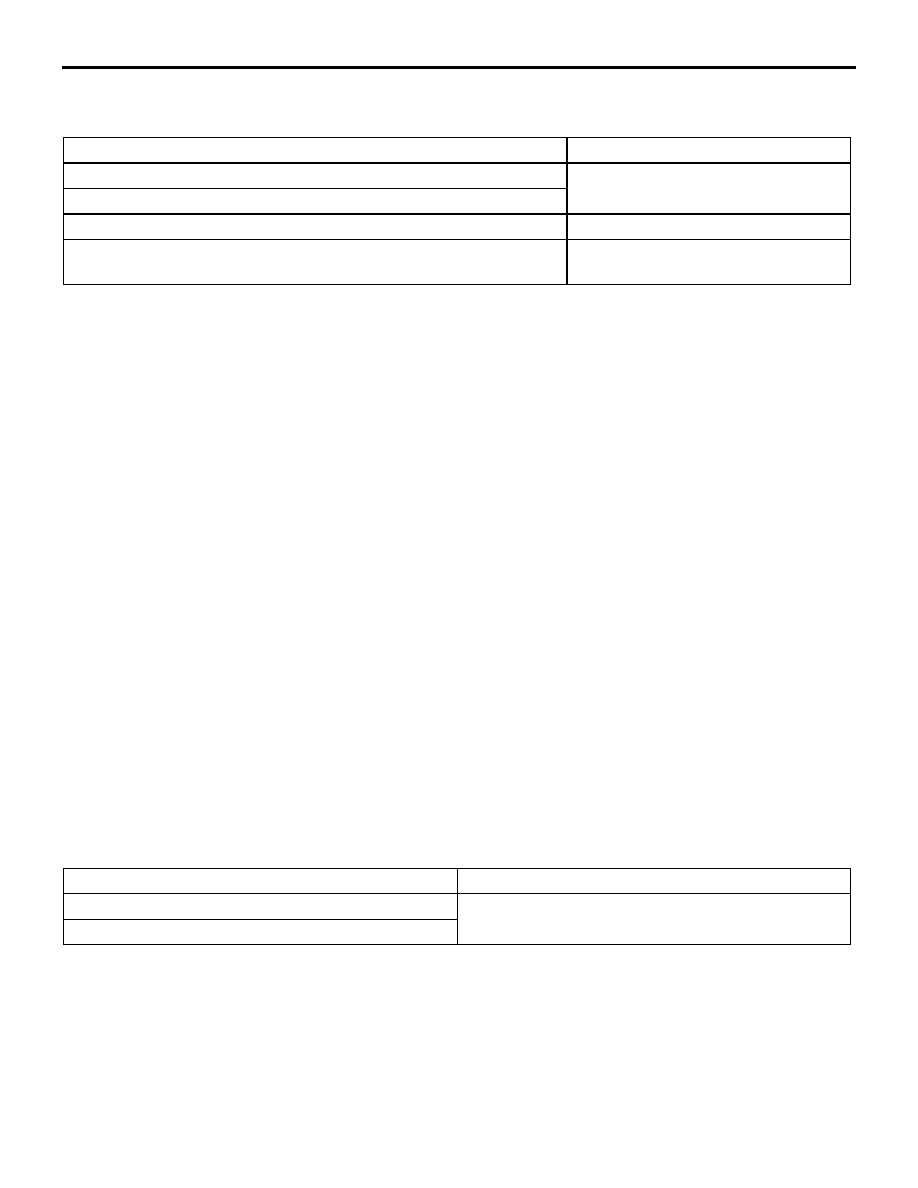

SEALANTS

MANUAL TRANSMISSION OVERHAUL

22B-5

SEALANTS

M1222000500151

Item

Brand

Clutch housing and transaxle case contact surface

MITSUBISHI GENUINE PART

MD997740 or equivalent

Reverse switch

Air breather

3M 8513 or equivalent

Differential drive gear bolt

3M STUD Locking No. 4170 or

equivalent

FORM-IN-PLACE GASKET (FIPG)

This transmission has several areas where the

form-in-place gasket (FIPG) is used for sealing. To

ensure that the FIPG fully serves its purpose, it is

necessary to observe some preCAUTIONs when

applying it. Bead size, continuity and location are of

paramount importance.

Too thin a bead can cause leaks. Too thick a bead,

on the other hand, can be squeezed out of location,

causing blocking or narrowing of fluid passages. To

prevent leaks or blocking of passages, therefore, it is

absolutely necessary to apply the FIPG evenly with-

out a break, while observing the correct bead size.

REMOVAL OF FIPG SEALED PARTS

Parts sealed with an FIPG can be easily removed

without the use of a special method. However, the

FIPG in some joints may have to be broken by tap-

ping parts with a mallet or similar tool.

CLEANING FIPG APPLICATION

SURFACE

Thoroughly remove all substances deposited on the

FIPG application surface, using a gasket scraper.

Make sure that the FIPG application surface is flat

and smooth. Also make sure that the surface is free

of oils, greases, and foreign substances. Do not fail

to remove old FIPG that may remain in the fastener

fitting holes.

APPLICATION OF FIPG

Applied FIPG bead should be of the specified size

and free of any break. FIPG can be wiped away

unless it has completely hardened. Install the mating

parts into position while the FIPG is still wet (in less

than 10 minutes after application). Do not allow FIPG

to spread beyond the sealing areas during installa-

tion. Avoid operating the transmission or letting oils

or water come in contact with the sealed area before

a time sufficient for FIPG to harden (approximately

one hour) has passed.

FIPG application method may vary from location to

location. Follow the instructions for each particular

case described later in this manual.

LUBRICANTS

M1222000400121

Item

Brand

Transfer oil seal lip

Shell Sunlight Grease 2, Retinax A, or equivalent

O-rings

SNAP RING, SPACER AND THRUST PLATE FOR ADJUSTMENT

MANUAL TRANSMISSION OVERHAUL

22B-6

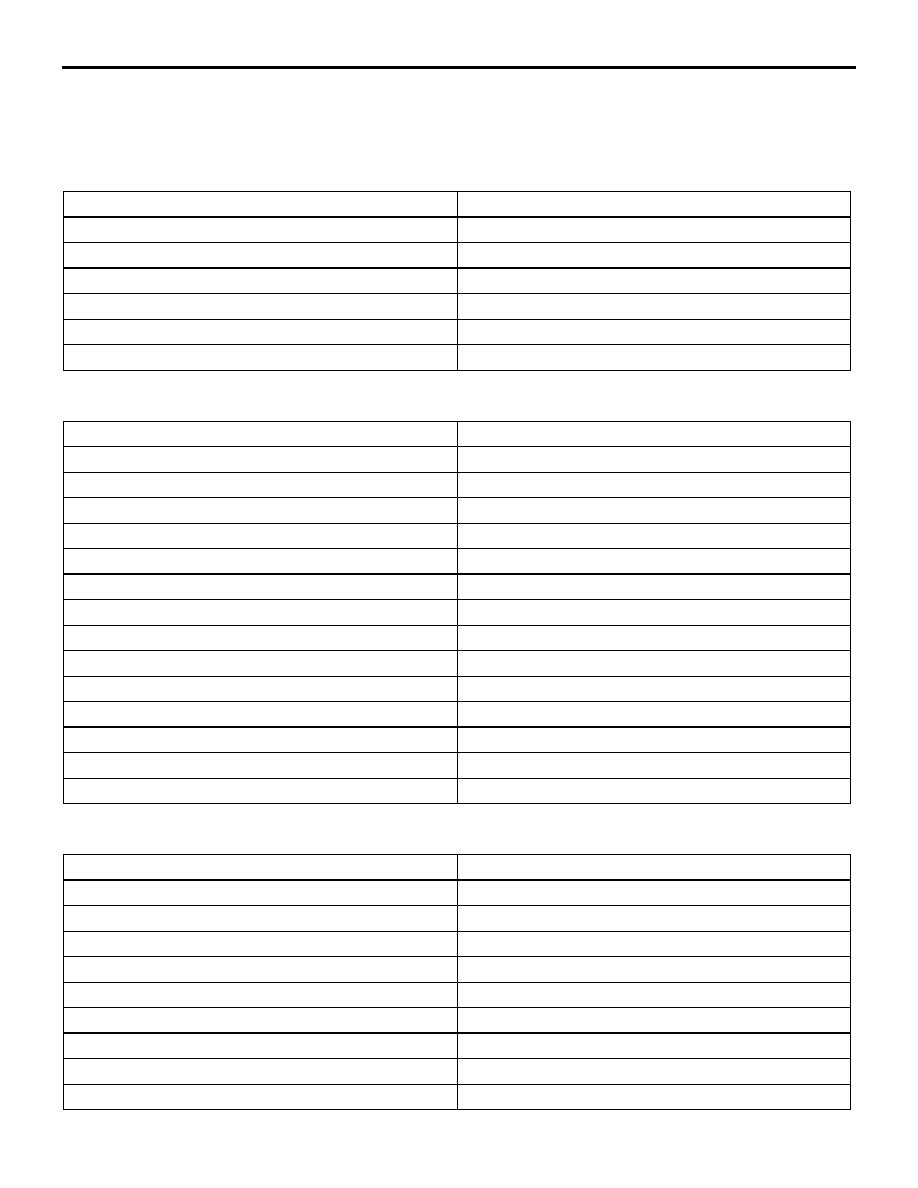

SNAP RING, SPACER AND THRUST PLATE FOR

ADJUSTMENT

M1222012000175

Adjustment shims (for differential side bearing preload adjustment)

Thickness mm

Thickness mm

0.48

0.72

0.52

0.76

0.56

0.80

0.60

0.84

0.64

0.88

0.68

0.92

Adjustment shims (for input shaft end play adjustment)

Thickness mm

Thickness mm

0.44

1.00

0.48

1.04

0.52

1.08

0.56

1.12

0.60

1.16

0.64

1.20

0.68

1.24

0.72

1.28

0.76

1.32

0.80

1.36

0.84

1.40

0.88

1.44

0.92

1.48

0.96

1.52

Adjustment shims (for main shaft end play adjustment)

Thickness mm

Thickness mm

0.44

0.80

0.48

0.84

0.52

0.88

0.56

0.92

0.60

0.96

0.64

1.00

0.68

1.04

0.72

1.08

0.76

SNAP RING, SPACER AND THRUST PLATE FOR ADJUSTMENT

MANUAL TRANSMISSION OVERHAUL

22B-7

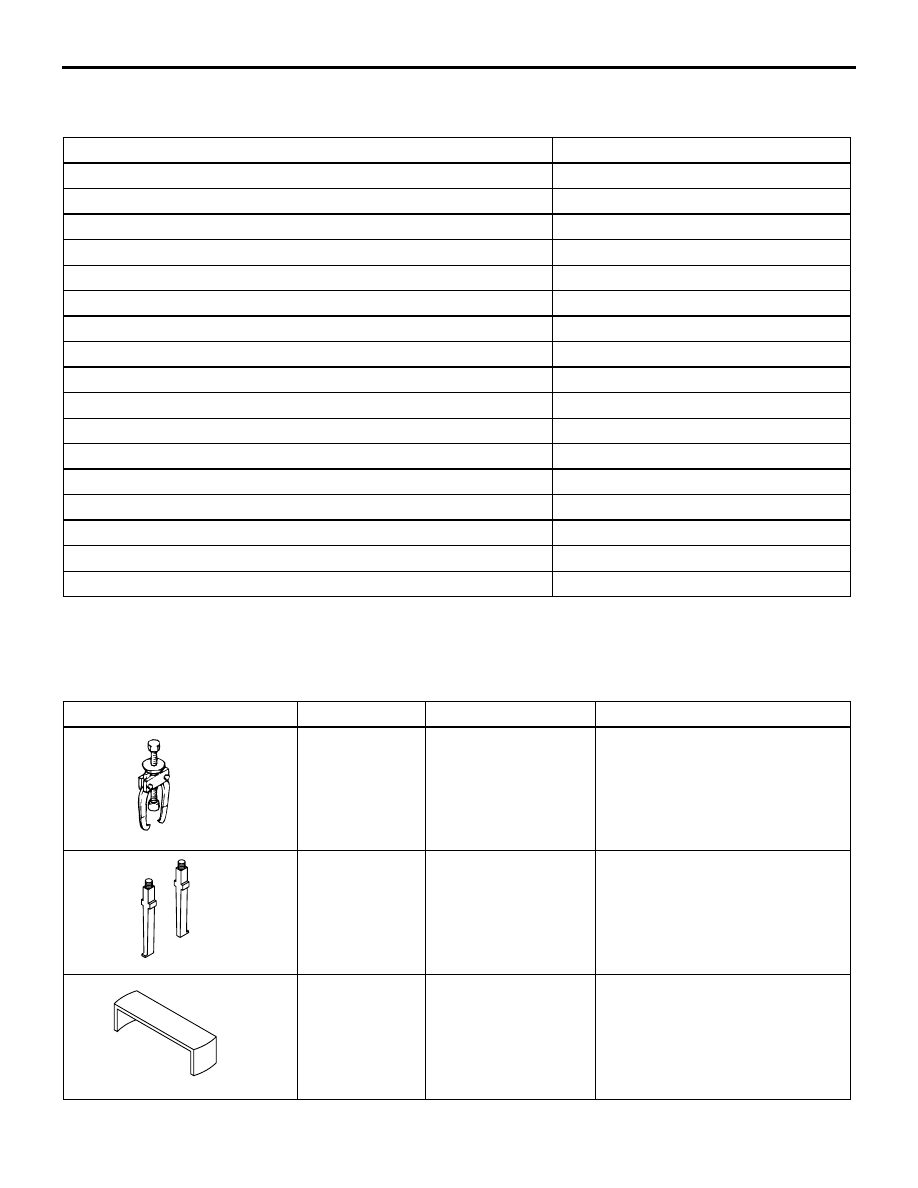

Adjustment shims (for reverse idler gear end play adjustment)

Thickness mm

Thickness mm

1.76

2.24

1.80

2.28

1.84

2.32

1.88

2.36

1.92

2.40

1.96

2.44

2.00

2.48

2.04

2.52

2.08

2.56

2.12

2.60

2.16

2.64

2.20

Thrust washers (for adjustment of distance between input shaft front bearing and thrust washer)

Thickness mm

Thickness mm

3.84

4.02

3.90

4.08

3.96

4.14

Snap rings (for input shaft 6th gear bushinging end play adjustment)

Thickness mm

Thickness mm

1.71

2.01

1.76

2.06

1.81

2.11

1.86

2.16

1.91

2.21

1.96

2.26

TORQUE SPECIFICATIONS

MANUAL TRANSMISSION OVERHAUL

22B-8

TORQUE SPECIFICATIONS

M1222013900074

Item

Torque N

⋅m

Transfer bolts

70

± 10

Roll stopper bracket bolts

69

± 9

Vehicle speed sensor bolts

11

± 1

Reverse switch

28

± 5

Stopper bolts

29

± 1

Shift check plugs

15

± 2

Transaxle case bolts (with sealant)

63

± 1

Transaxle case bolts

52

± 1

Shift check plugs

15

± 2

Reverse lever assembly

14

± 1

Main shaft bearing retainer bolts

7.3

± 1.0

Drain plugs

35

± 4

Filler plugs

35

± 4

Differential drive gear bolts

158

± 7

Transfer cover case bolts

23

± 3

Plugs

30

± 2

Magnet plugs

30

± 2

SPECIAL TOOLS

M1222000600170

Tool

Number

Name

Use

MB990810

MB990810

Side bearing puller

Use with claws

MB991967

Claws

Removal of differential side

bearing outer race

MB991968

Bridge

Removal of differential side

bearing outer race

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст