Mitsubishi Montero (1991+). Manual — part 174

intake hoses and EGR pipe. Disconnect oxygen sensor electrical

connector.

2) Remove oil pipe and EGR valve. Disconnect exhaust fitting

and remove rear heat protector. Remove oil return pipe. Remove

turbocharger assembly. See Fig. 11.

Fig. 11: Removing Rear Turbocharger (Stealth & 3000GT)

Courtesy of Mitsubishi Motor Sales of America.

Inspection

Check turbine and compressor wheels for cracking and other

damage. Make sure turbine and compressor wheels turn smoothly. Check

for oil leakage from turbocharger assembly. Check for proper wastegate

valve operation. See SYSTEM & COMPONENT TESTING article.

Installation

1) To install, reverse removal procedure. Before oil pipe

flare nut (above turbocharger) is installed, pour clean engine oil

into turbocharger. Ensure oil and air hoses are properly installed and

securely clamped.

2) Use new gaskets. Adjust accelerator cable (if necessary).

Refill engine oil and coolant. Check for oil and coolant leaks.

Tighten all bolts to specification. See TORQUE SPECIFICATIONS table.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS TABLE

Applications Ft. Lbs. (N.m)

Fuel Tank Nuts . . . . . . . . 15-22 (20-30)

Fuel Tank Drain Plug . . . . . ... 11-18 (15-24)

Exhaust Manifold-To-Engine Nuts . . . 18-22 (24-30)

Exhaust Manifold-To-Turbocharger Bolts . . 40-47 (54-64)

Exhaust Pipe Bolts . . . . . . . 22-29 (30-39)

Oil Pipe-To-Engine . . . . . . . 10-14 (14-19)

Oxygen (O2) Sensor . . . . . . . 29-36 (39-49)

Plenum-To-Intake Manifold Bolts . . . 11-15 (15-20)

Water Pipe-To-Turbocharger

Except Stealth & 3000GT . . . . .. 25-36 (34-49)

Stealth & 3000GT . . . . . . . ... 22 (30)

INCH Lbs. (N.m)

Fuel Rail Bolts . . . . . . .. 84-108 (10-12)

Heat Protector Bolts . . . . . . 108-132 (12-15)

ISC Switch Screws . . . . . . 20-54 (2.5-4.5)

TPS Switch Screws . . . . . . 13-20 (1.5-2.5)

Wastegate Actuator Bolts . . . . ... 84-108 (9-12)

RIDING HEIGHT ADJUSTMENT

1991 Mitsubishi Montero

1991-92 WHEEL ALIGNMENT

Riding Height Adjustment

Chrysler Motors: Ram-50

Mitsubishi: Montero, Pickup

RIDING HEIGHT ADJUSTMENT

Before adjusting alignment, check riding height. Ensure

vehicle is on level floor and tires are properly inflated. Bounce

vehicle several times and allow suspension to settle.

Visually inspect vehicle, from front to rear or side to

side, for signs of abnormal height. Remove extra heavy items from

passenger and luggage compartments. If riding height is not within

specification, check and repair suspension before adjusting alignment.

See RIDING HEIGHT SPECIFICATIONS (FRONT) table.

RIDING HEIGHT SPECIFICATIONS (FRONT) (1)

Application (2) In. (mm)

Montero . . . . . . . 2.80 (71.1)

Pickup 4WD & Ram-50 4WD . . . 3.07 (78.0)

(1) - Ensure tire inflation is correct and vehicle

is level.

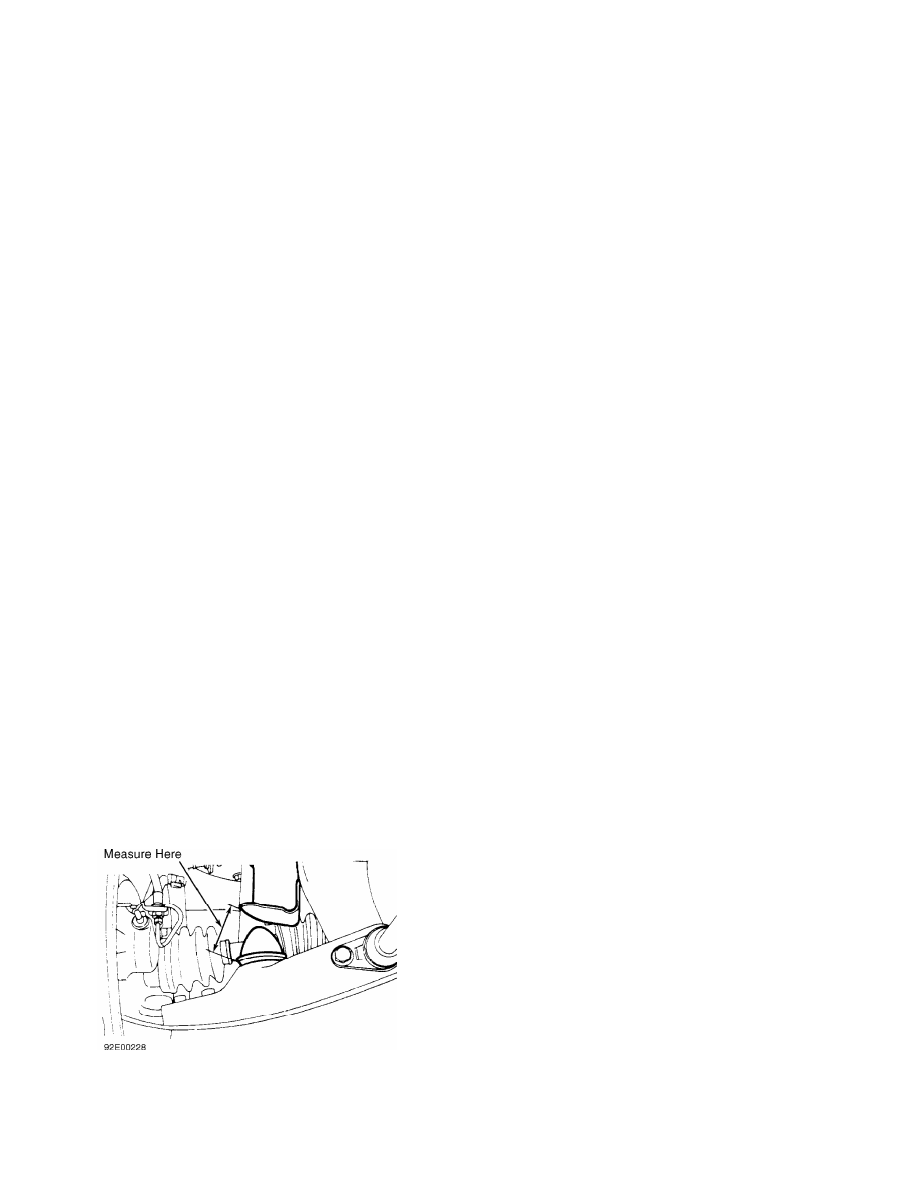

(2) - Distance between lower control bump stopper

and bracket. See Fig. 1.

RIDING HEIGHT SPECIFICATIONS 1992 (FRONT) ( 1)

Application In. (mm)

Montero . . . . .. 0.83-0.91 (21.0-23.0)

Pickup 4WD & Ram-50 4WD . . . 3.11 (79.0)

(1) - Distance between lower control bumper and

bracket.

Fig. 1: Measuring Front Riding Height (Typical 4WD)

Courtesy of Mitsubishi Motor Sales of America.

SCHEDULED SERVICES

1991 Mitsubishi Montero

1987-95 MAINTENANCE

Mitsubishi Maintenance & Service Intervals

Montero

* PLEASE READ THIS FIRST *

NOTE: All SERVICE SCHEDULES are listed for normal service

vehicles. If vehicle is operated under severe service

conditions, see

SEVERE SERVICE REQUIREMENTS (PERFORM W/SERVICE SCHEDULES)

for items requiring additional maintenance.

NOTE: This article contains scheduled maintenance service

information. Fluid types and capacities listed with each

service in this article are only those necessary to perform

that scheduled service. For specifications pertaining to

fluid capacities for the entire vehicle, fuse and circuit

breaker identification, wheel and tire size, battery type,

warranty information, or model identification refer to the

MAINTENANCE INFORMATION article in this section.

CAUTIONS & WARNINGS

SUPPLEMENTAL RESTRAINT SYSTEM (AIR BAG)

NOTE: See the AIR BAG RESTRAINT SYSTEM article in the

ACCESSORIES/SAFETY EQUIPMENT Section.

Modifications or improper maintenance, including incorrect

removal and installation of the Supplemental Restraint System (SRS),

can adversely affect system performance. DO NOT cover, obstruct or

change the steering wheel horn pad in any way, as such action could

cause improper function of the system. Use only plain water when

cleaning the horn pad. Solvents or cleaners could adversely affect the

air bag cover and cause improper deployment of the system.

WARNING: To avoid injury from accidental air bag deployment, read and

carefully follow all warnings and service precautions. See

appropriate AIR BAG RESTRAINT SYSTEM article in the

ACCESSORIES/SAFETY EQUIPMENT section.

CAUTION: Disconnect negative battery cable before servicing any air

bag system, steering column or passenger side dash

component. After any repair, turn ignition key to the ON

position from passenger’s side of vehicle in case of

accidental air bag inflation

AIR CONDITIONING SERVICING

WARNING: R-134a service equipment or vehicle A/C systems SHOULD NOT

be pressure tested or leak tested with compressed air. Some

mixtures of air/R134a have shown to be combustible at

elevated pressures. These mixtures are dangerous and may

cause fire and/or explosions. See the appropriate

A/C SYSTEM GENERAL SERVICING article in the AIR CONDITIONING

& HEAT section.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст