Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 567

SPECIAL TOOLS

TSB Revision

BASIC BRAKE SYSTEM

35A-17

STEP 4. Check the wheel bearings for wear, damage or

dryness.

Q: Is there fault?

YES : Apply grease or replace the part. Then go to Step 5.

NO : Go to Step 5.

STEP 5. Recheck symptom.

Q: Is the symptom eliminated?

YES : Diagnosis is complete.

NO : Start over at step 1. If a new symptom surfaces, refer

to the symptom chart.

SPECIA L TO O LS

M1351000600081

AC000862

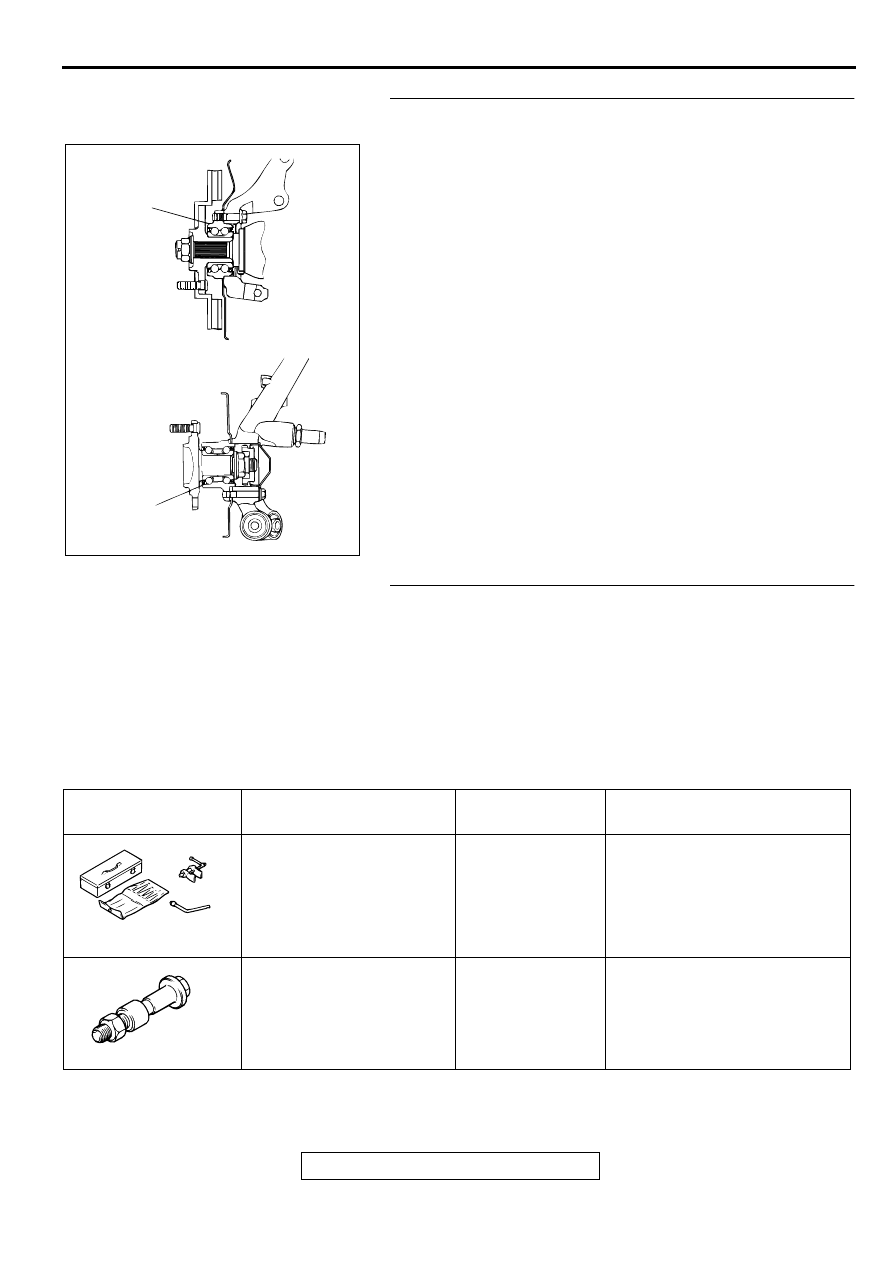

WHEEL

BEARING

WHEEL

BEARING

<FRONT>

<REAR>

AB

TOOL

TOOL NUMBER AND

NAME

SUPERSESSION

APPLICATION

MB990964

Brake tool set

A: MB990520

Disc brake piston expander

B: MB990619

Installer

General service

tool

•

Pushing-in of the disc brake

piston

•

Installation of the drum brake

wheel cylinder piston cup

MB990998

Front hub remover and

installer

MB990998-01

Provisional holding of the wheel

bearing

MB990964

A

B

MB990998

ON-VEHICLE SERVICE

TSB Revision

BASIC BRAKE SYSTEM

35A-18

O N -VEH IC LE SERVIC E

BRAKE PEDAL CHECK AND ADJUSTMENT

M1351000900082

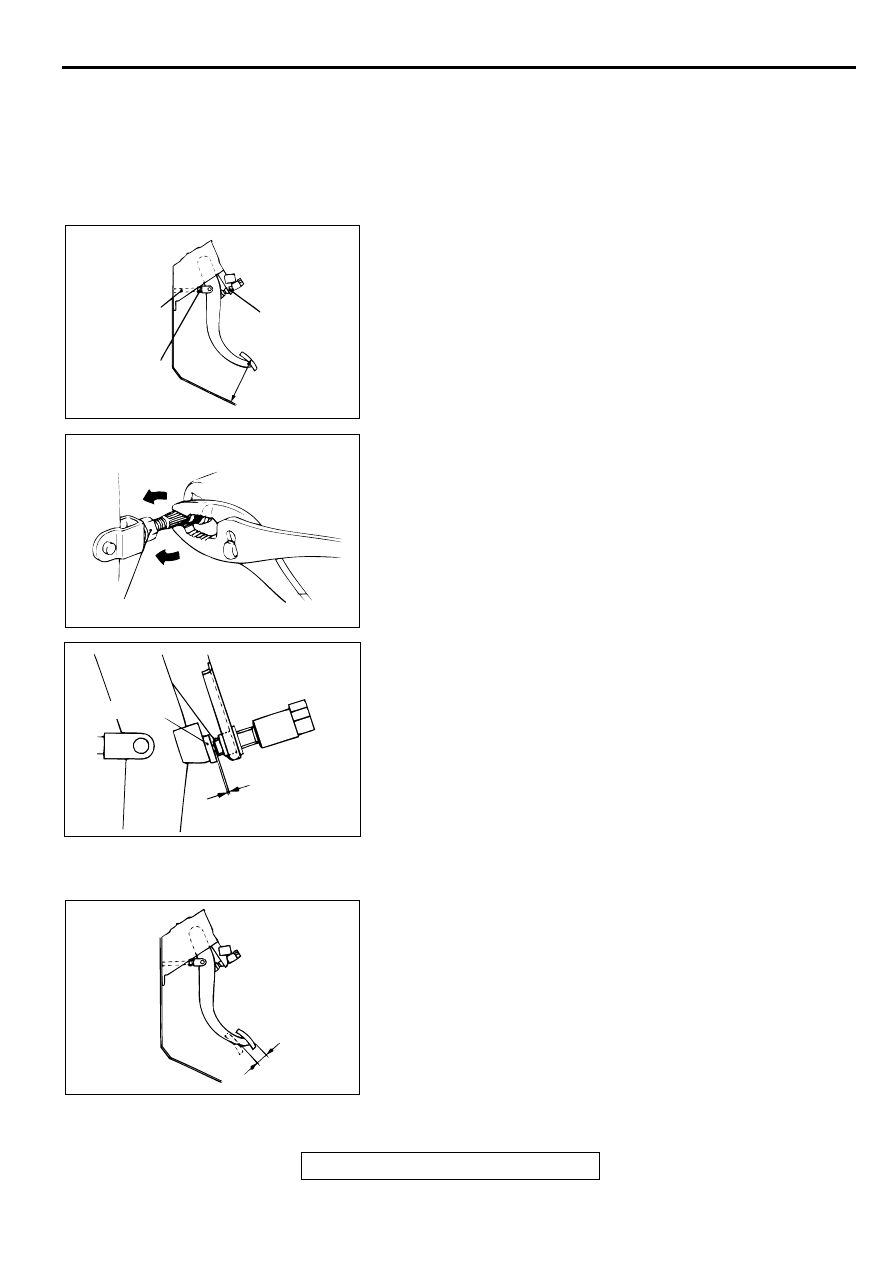

BRAKE PEDAL HEIGHT

1. Turn up the carpet etc. under the brake pedal.

2. Measure the brake pedal height as illustrated. If it is not

within the standard value, adjust as follows.

Standard value: 175

−

178 mm (6.9

−

7.0 inches) [From

the surface of melting sheet (floorboard) to the face of

pedal pad]

(1) Disconnect the stoplight switch connector.

(2) Rotate the stoplight switch 1/4 turn counter clockwise to

loosen.

(3) Loosen the operating rod jam nut. Turn the serrations of

the operating rod with pliers to adjust the brake pedal

height to the standard value.

(4) Turn the stoplight switch until it contacts the stopper.

During this step, secure the pedal by moving it forward by

hand.

(5) Adjust the stoplight switch so that it has the specified

clearance as shown. Turn the stoplight switch 1/4 turn

clockwise to secure.

(6) Connect the connector of the stoplight switch.

(7) Check to be sure that the stoplight does not illuminated

with the brake pedal released

3. Return the carpet, etc. to its original position.

BRAKE PEDAL FREE PLAY

1. Turn the ignition switch to the "LOCK" (OFF) position,

depress the brake pedal two or three times. After eliminating

the vacuum in the brake booster, press the pedal down by

hand, and confirm that the amount of movement before

resistance is met (free play) is within the standard value

range.

Standard value: 3

−

8 mm (0.12

−

0.31 inch)

AC000864 AB

STOPLIGHT

SWITCH

OPERATING

ROD

OPERATING

ROD JAM NUT

AC000865

PEDAL DOWN

PEDAL UP

JAM NUT

AB

AC000866AB

STOPPER

0.5

–

1.5 mm

(0.02

–

0.06 in)

AC000867

ON-VEHICLE SERVICE

TSB Revision

BASIC BRAKE SYSTEM

35A-19

2. If the brake pedal play is not within the standard value,

check the following, and adjust or replace if necessary:

•

Excessive play between the brake pedal and the clevis pin,

or between the clevis pin and the brake booster operating

rod

•

Brake pedal height

•

Installation position of the stoplight switch, etc.

CLEARANCE BETWEEN BRAKE PEDAL AND

FLOORBOARD

1. Turn up the carpet etc. under the brake pedal.

2. Start the engine, depress the brake pedal with

approximately 490 N (110 pound) of force, and measure the

clearance between the brake pedal and the floorboard.

Standard value: 90 mm (3.5 inches) or more [From the

surface of melting sheet (floorboard) to the face of

pedal pad]

3. If the clearance is outside the standard value, check for air

trapped in the brake line, thickness of the disc brake pad,

clearance between the lining and the drum and dragging in

the parking brake. And then adjust and replace defective

parts as required.

4. Return the carpet etc. to its original position.

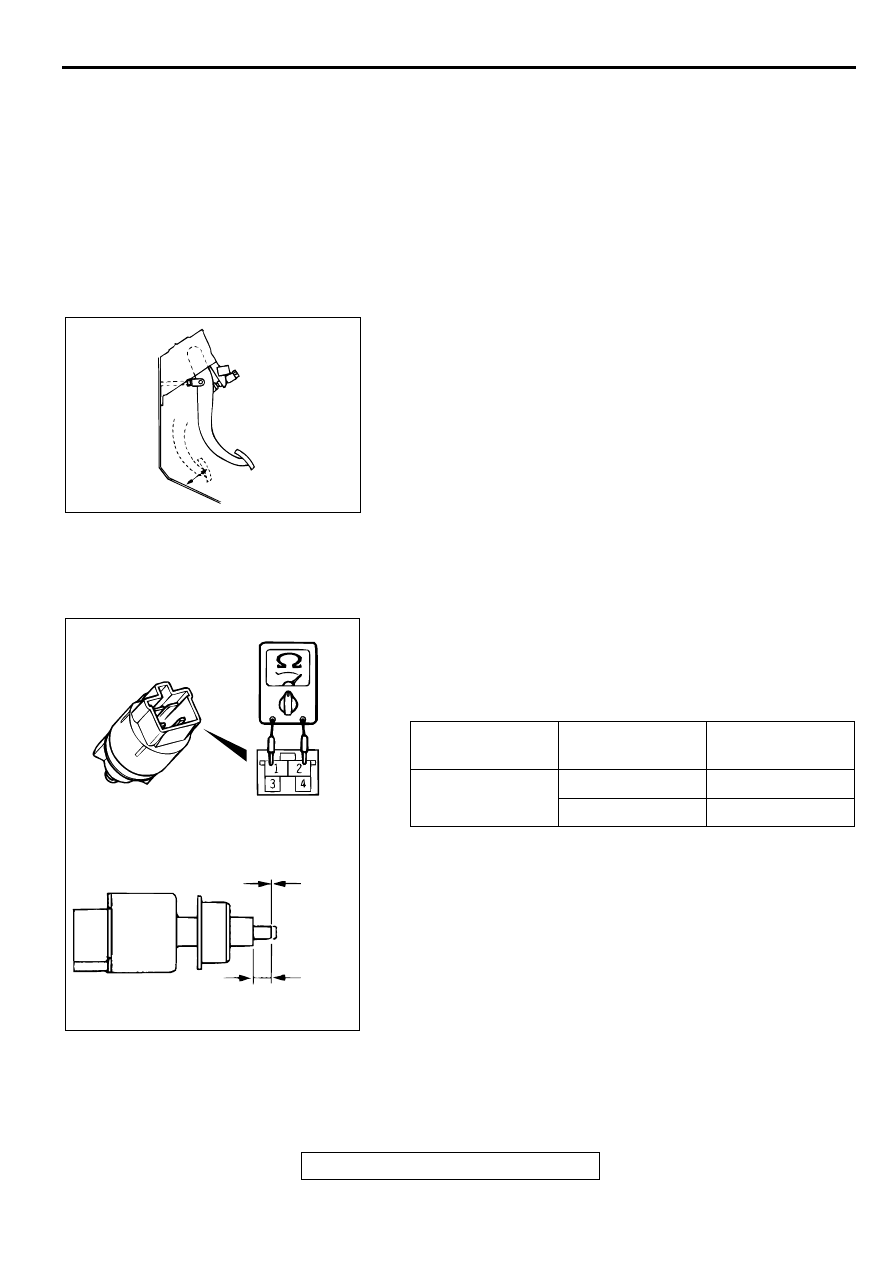

STOPLIGHT SWITCH CHECK

M1351008900105

1. Connect an ohmmeter between the stoplight switch

connector terminals.

2. There should be no continuity between the terminals when

the plunger is pushed in as shown. There should be

continuity when it is released.

AC000868

TESTER

CONNECTION

PLUNGER

SPECIFIED

CONDITION

1

−

2

IN

Open circuit

OUT

Less than 2

Ω

ACX00671AB

NO CONTINUITY CONTINUITY

4 mm

(0.16 in)

ON-VEHICLE SERVICE

TSB Revision

BASIC BRAKE SYSTEM

35A-20

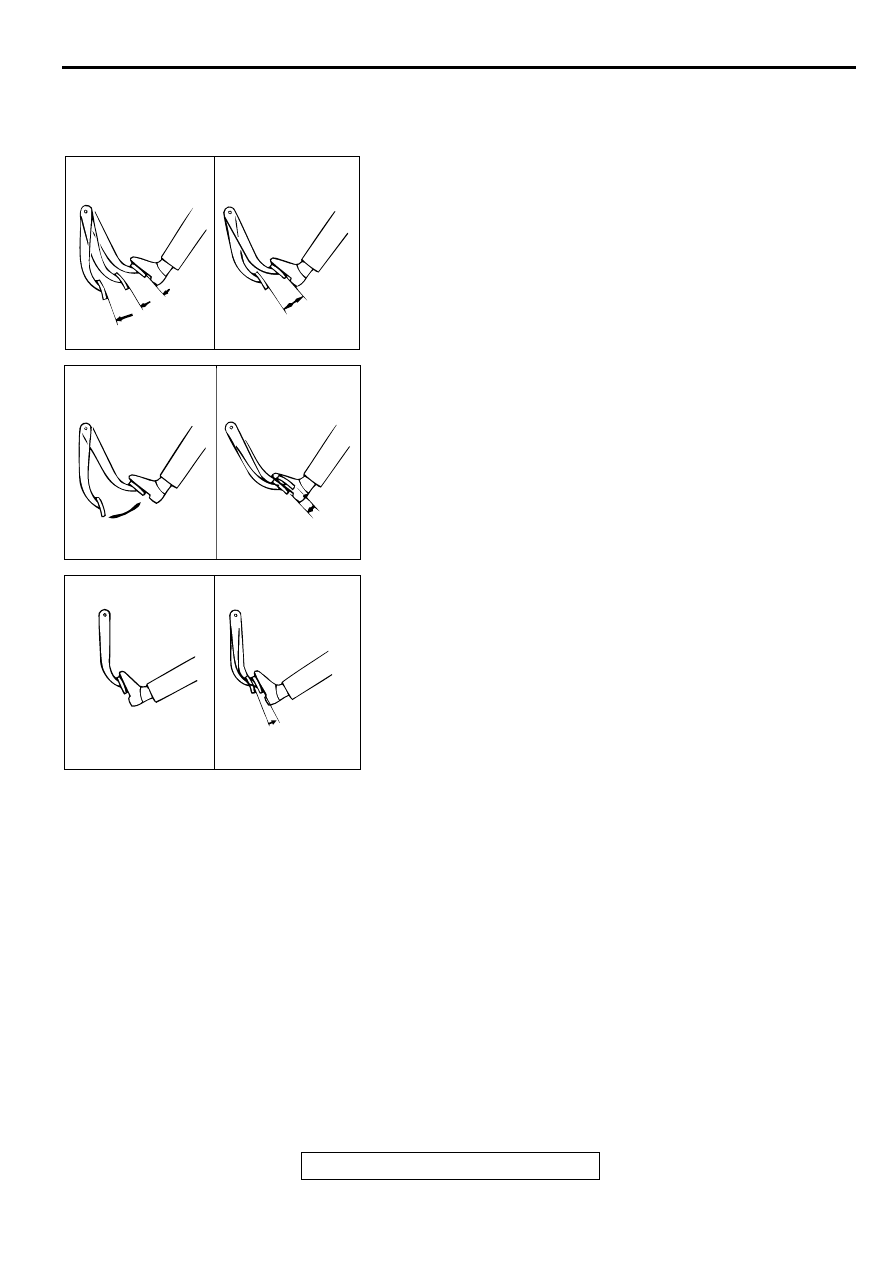

BRAKE BOOSTER OPERATING TEST

M1351001000071

1. For simple checking of the brake booster operation, carry

out the following tests:

(1) Run the engine for one or two minutes, and then stop it. If

the pedal depresses fully the first time but gradually

becomes higher when depressed succeeding times, the

booster is operating properly. If the pedal height remains

unchanged, the booster is defective. Go to step 2.

(2) With the engine stopped, step on the brake pedal several

times. Then step on the brake pedal and start the engine.

If the pedal moves downward slightly, the booster is in

good condition. If there is no change, the booster is

defective. Go to step 3.

(3) With the engine running, step on the brake pedal and

then stop the engine. Hold the pedal depressed for 30

seconds. If the pedal height does not change, the booster

is in good condition, if the pedal rises, the booster is

defective.

2. If the above three tests are okay, the booster is OK. If one of

the above three tests is not okay, the check valve, vacuum

hose, or booster is defective. Check the check valve (Refer

to

.), vacuum hose for leaks, high volume engine

vacuum applied to booster. Repair or replace as necessary.

If these are OK, replace booster and repeat this test starting

at Step 1.

AC000870

GOOD

NO GOOD

AB

AC000871 AB

WHEN ENGINE

IS STOPPED

WHEN ENGINE

IS STARTED

AC000872

GOOD

NO GOOD

AB

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст