Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 691

55-1

GROUP 55

CONTENTS

GENERAL INFORMATION . . . . . . . .

MANUAL A/C DIAGNOSIS . . . . . . . .

INTRODUCTION TO MANUAL A/C

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . .

MANUAL A/C DIAGNOSTIC

TROUBLESHOOTING STRATEGY . . . . . .

SYMPTOM CHART. . . . . . . . . . . . . . . . . . .

SYMPTOM PROCEDURES . . . . . . . . . . . .

CHECK AT ECU TERMINAL . . . . . . . . . . .

TROUBLESHOOTING HINT. . . . . . . . . . . .

SPECIAL TOOLS. . . . . . . . . . . . . . . .

ON-VEHICLE SERVICE. . . . . . . . . . .

REFRIGERANT LEVEL TEST . . . . . . . . . .

MAGNETIC CLUTCH TEST . . . . . . . . . . . .

RECEIVER DRIER TEST . . . . . . . . . . . . . .

PRESSURE SWITCH CHECK . . . . . . . . . .

COMPRESSOR DRIVE BELT

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . .

CHARGING . . . . . . . . . . . . . . . . . . . . . . . .

PERFORMANCE TEST . . . . . . . . . . . . . . .

REFRIGERANT LEAK REPAIR

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR NOISE CHECK . . . . . . . .

POWER RELAY CHECK . . . . . . . . . . . . . .

IDLE-UP OPERATION CHECK . . . . . . . . .

HEATER CONTROL ASSEMBLY AND

A/C SWITCH . . . . . . . . . . . . . . . . . . . .

REMOVAL AND INSTALLATION . . . . . . . .

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . .

HEATER UNIT, HEATER CORE, BLOWER

ASSEMBLY, EVAPORATOR UNIT . .

REMOVAL AND INSTALLATION . . . . . . . .

BLOWER ASSEMBLY AND

RESISTOR . . . . . . . . . . . . . . . . . . . . .

REMOVAL AND INSTALLATION . . . . . . . .

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR ASSEMBLY AND TENSION

PULLEY . . . . . . . . . . . . . . . . . . . . . . .

REMOVAL AND INSTALLATION . . . . . . . .

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSOR MAGNETIC CLUTCH

OPERATION INSPECTION . . . . . . . . . . . .

REVOLUTION PICK-UP SENSOR CHECK

MAGNETIC CLUTCH . . . . . . . . . . . . . . . . .

CONDENSER AND CONDENSER FAN

MOTOR . . . . . . . . . . . . . . . . . . . . . . . .

REMOVAL AND INSTALLATION . . . . . . . .

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . .

REFRIGERANT LINE . . . . . . . . . . . . .

REMOVAL AND INSTALLATION . . . . . . . .

VENTILATORS . . . . . . . . . . . . . . . . . .

REMOVAL AND INSTALLATION . . . . . . . .

55-2

SPECIFICATIONS . . . . . . . . . . . . . . .

FASTENER TIGHTENING

SPECIFICATIONS . . . . . . . . . . . . . . . . . . .

GENERAL SPECIFICATIONS . . . . . . . . . .

SERVICE SPECIFICATIONS . . . . . . . . . . .

GENERAL INFORMATION

TSB Revision

HEATING AND AIR CONDITIONING

55-3

.

G EN ER A L IN FO R M ATIO N

M1552000100050

The heater system uses a two-way-flow full-air-mix

system that features high performance and low

operating noise. It includes an independent face air

blowing function. In addition, an air purifier has been

included.

SAFETY PRECAUTIONS

WARNING

Wear safety goggles and gloves when

servicing the refrigeration system to prevent

severe damage to eyes and hands.

Because R-134a refrigerant is a hydro fluorocarbon

(HFC) which contains hydrogen atoms in place of

chlorine atoms, it will not cause damage to the ozone

layer.

Ozone filters out harmful radiation from the sun. To

assist in protecting the ozone layer, Mitsubishi

Motors Corporation recommends an R-134a

refrigerant recycling device.

Refrigerant R-134a is transparent and colorless in

both the liquid and vapor state. Since it has a boiling

point of

−

29.8

°

C (

−

21.64

°

F) at atmospheric pressure,

it will be a vapor at all normal temperatures and

pressures. The vapor is heavier than air, non-

flammable, and non-explosive. The following

precautions must be observed when handling R-

134a.

WARNING

Do not heat R-134a above 40

°

C (104.0

°

F) or it

may catch fire and explode.

R-134a evaporates so rapidly at normal atmospheric

pressures and temperatures that it tends to freeze

anything it contacts. For this reason, extreme care

must be taken to prevent any liquid refrigerant from

contacting the skin and especially the eyes. Always

wear safety goggles when servicing the refrigeration

part of the A/C system. Keep a bottle of sterile

mineral oil handy when working on the refrigeration

system.

1. Should any liquid refrigerant get into the eyes, use

a few drops of mineral oil to wash them out. R-

134a is rapidly absorbed by the oil.

2. Next splash the eyes with plenty of cold water.

3. Call your doctor immediately even though

irritation has ceased after treatment.

CAUTION

Keep R-134a containers upright when charging

the system.

In most instances, moderate heat is required to bring

the pressure of the refrigerant in its container above

the pressure of the system when charging or adding

refrigerant.

A bucket or large pan of hot water not over 40

°

C

(104.0

°

F) is all the heat required for this purpose. Do

not heat the refrigerant container with a blow torch or

any other means that would raise temperature and

pressure above this temperature. Do not weld or

steam clean on or near the system components or

refrigerant lines.

WARNING

The leak detector for R-134a should be used

to check for refrigerant gas leaks.

CAUTION

Do not allow liquid refrigerant to touch bright

metal or it will be stained.

When metering R-134a into the refrigeration system

keep the supply tank or cans in an upright position. If

the refrigerant container is on its side or upside

down, liquid refrigerant will enter the system and

damage the compressor.

Refrigerant will tarnish bright metal and chrome

surfaces, and in combination with moisture can

severely corrode all metal surfaces.

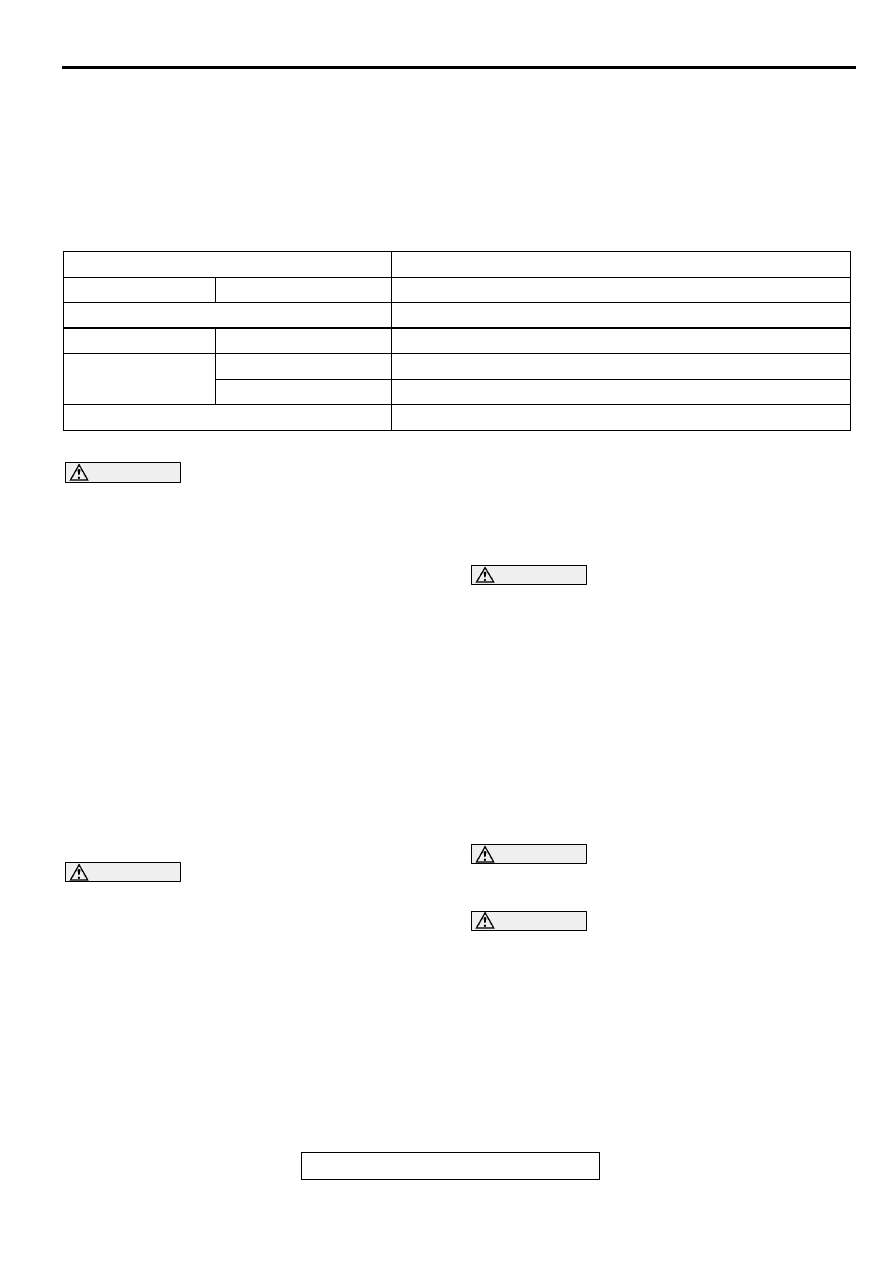

Items

Specifications

Heater unit

Type

Two-way-flow full-air-mix system

Heater control assembly

Dial type

Compressor

Model

Scroll type <MSC90C>

Dual pressure

switch kPa (psi)

High-pressure switch

ON

→

OFF: 2,942 (426.7), OFF

→

ON: 2,354 (341.4)

Low-pressure switch

ON

→

OFF: 196 (28.4), OFF

→

ON: 221 (32.1)

Refrigerant and quantity g (oz)

R-134a (HFC-134a), Approximately 415

−

435 (14.6

−

15.3)

MANUAL A/C DIAGNOSIS

TSB Revision

HEATING AND AIR CONDITIONING

55-4

OPERATION

Condenser fan and radiator fan control

•

For the operation of each fan, refer to GROUP

14, Diagnosis - Symptom Chart

.

Compressor control

When operating the air conditioning switch

•

The air thermo sensor, which senses the

temperature of the air flowing out of the

evaporator, deactivates the compressor at 5

°

C

(41.0

°

F) or below.

•

The dual pressure switch turns OFF when the

refrigerant pressure becomes excessively high or

low, thus protecting the compressor circuit. (See

Table below.)

•

When the air thermo sensor is activated, the dual

pressure switch is ON, and the ignition switch,

blower switch, and air conditioning switch are

ON, the A/C compressor relay is energized.

When operating the air outlet changeover control

knob

•

When the air outlet changeover control knob is

moved to DEFROSTER or DEFROSTER/FOOT

position, the defroster switch, which is connected

in series to the air conditioning switch, is turned

on. The other compressor control than the above

is the same as that when operating the air

conditioning switch.

When compressor locks <vehicles with 3.0 L

engine>

•

Since the compressor and alternator are driven

by the same belt, the electric generating function

of the alternator also stops when the belt is

broken. In order to assure the electric generating

function of the alternator, there is an A/C-ECU to

prevent breaking of the belt due to slipping when

the compressor locks. The A/C-ECU makes a

comparative calculation of the compressor

revolutions and the engine revolutions which are

detected by the revolution pick-up sensor. When

70% or more slip ratio continues for 3 seconds or

more, the A/C compressor relay goes from on to

off; at the same time, the operation display in the

air conditioner switch blinks to announce an

abnormality.

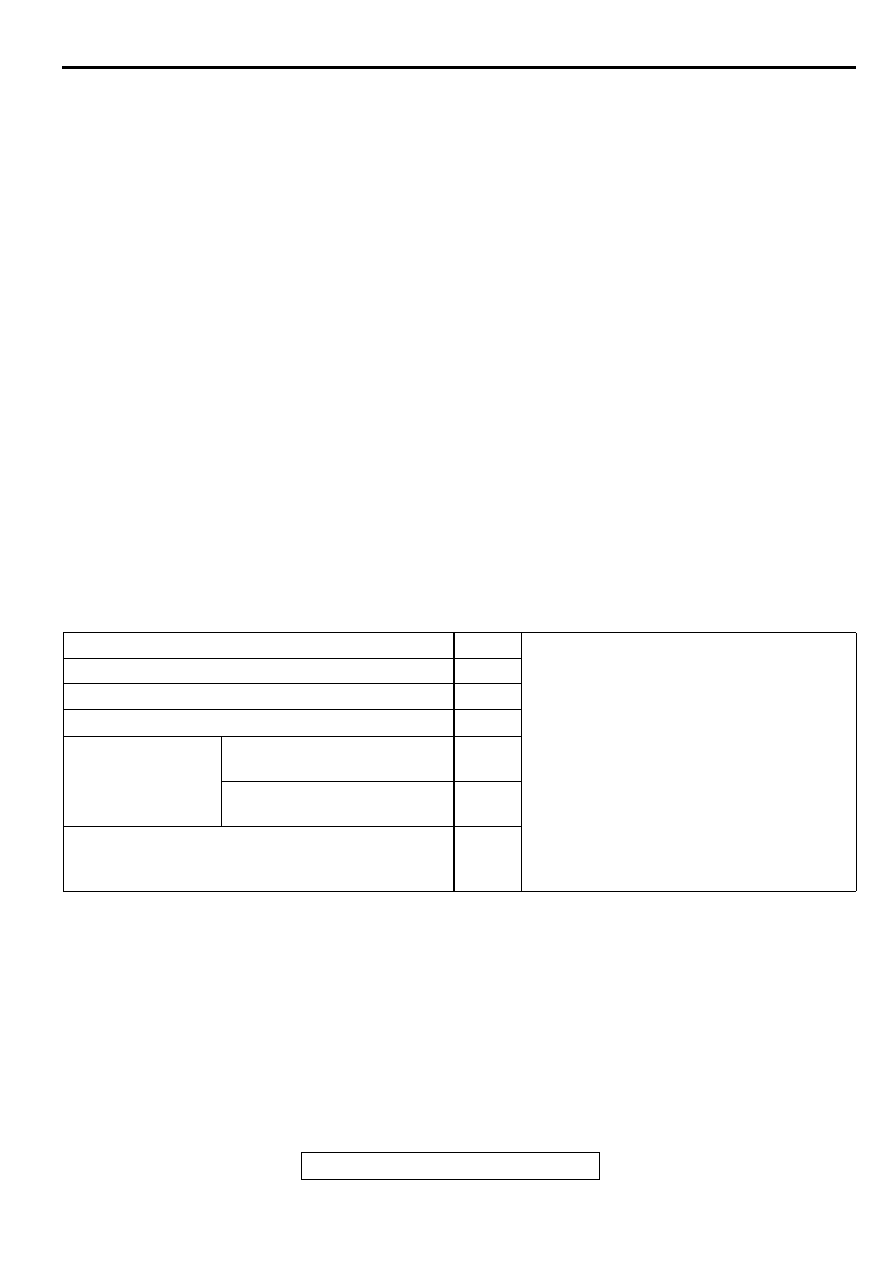

A/C Compressor Relay ON Conditions

M A N U A L A /C D IA G N O S IS

INTRODUCTION TO MANUAL A/C DIAGNOSIS

M1552012200087

With this system, after the outside air or inside air is

taken in through the damper, it is fed to the

evaporator by the blower fan and motor and cooled.

The air cooled by the air mix damper is mixed

appropriately with the warmed air to achieve a

comfortable temperature. If the A/C does not operate

or the cooled air is not discharged, the machine

components or relay may be faulty.

Ignition switch (IG2)

ON

NOTE: . A/C compressor relay is de-

energized when any one switch, sensor or

control unit shown on the left turns off.

NOTE: . The

*

marked device measures the

temperature of the outlet air, and according

to the control characteristics of the magnetic

clutch for the compressor, the automatic

compressor controller outputs the "HI" signal

(12V). When air of 5

°

C (41.0

°

F) or less

blows out of the evaporator, the compressor

magnetic clutch will be turned off.

Blower switch

ON

Air conditioning switch or defroster switch

ON

Air thermo sensor

*

Dual pressure

switch

Low-pressure side 221 kPa

(32.1 psi) or higher

ON

High-pressure side 2,942 kPa

(426.7 psi) or below

ON

A/C compressor relay driving transistor (within

automatic compressor controller and engine control

module <M/T>, powertrain control module <A/T>)

ON

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст