Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 353

INTAKE MANIFOLD <3.0L>

TSB Revision

INTAKE AND EXHAUST

15-13

REMOVAL SERVICE POINT

<<A>> FUEL RAIL, INJECTOR AND FUEL PRESSURE

REGULATOR REMOVAL

CAUTION

Care must be taken when removing the fuel rail not to drop

the injector.

Remove the fuel rail with the injectors and pressure regulator

attached to it.

INSTALLATION SERVICE POINTS

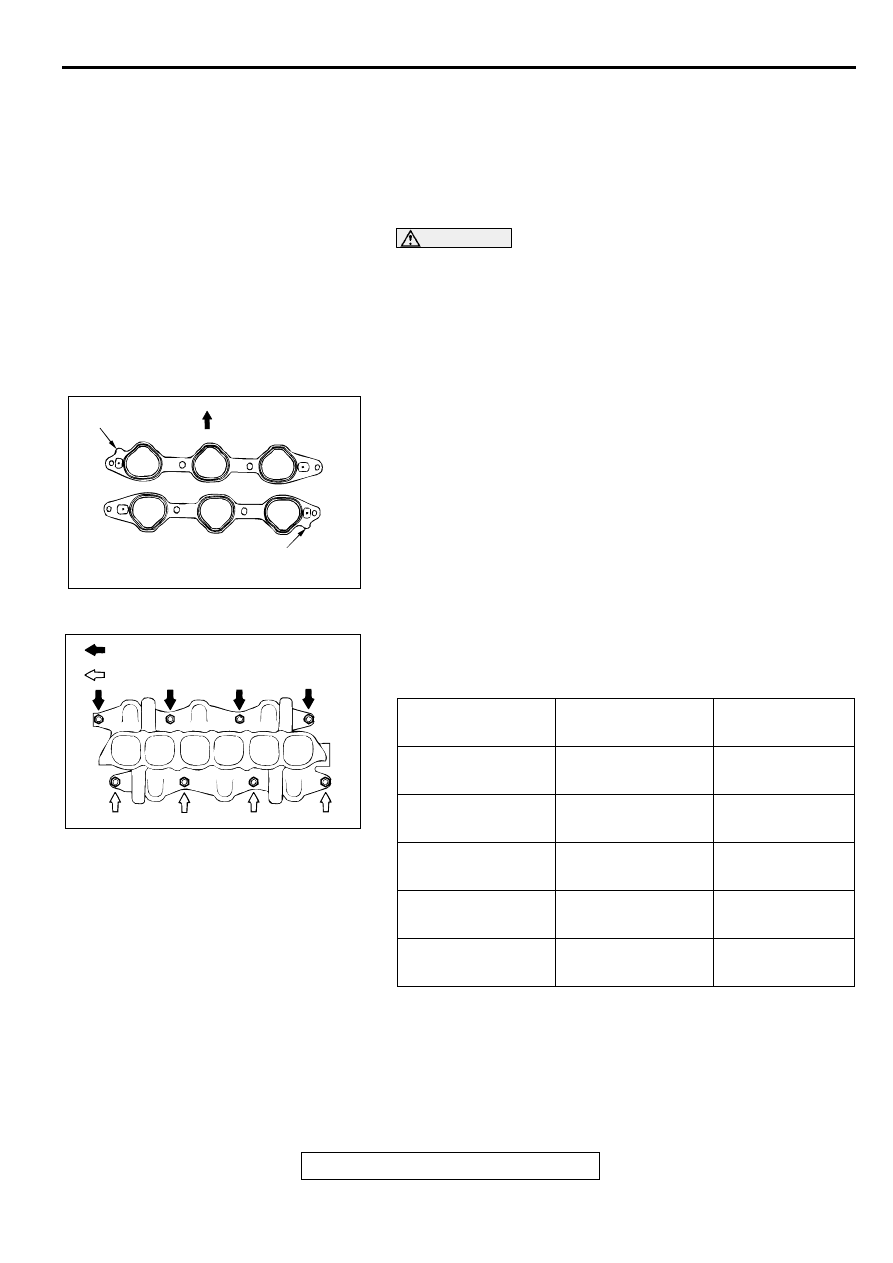

>>A<< INTAKE MANIFOLD GASKET INSTALLATION

Install the gasket with the protrusions in the position illustrated.

>>B<< INTAKE MANIFOLD INSTALLATION

1. Coat the intake manifold mounting studs with engine oil.

2. Tighten the intake manifold mounting nuts by the following

procedure.

>>B<<

12. INTAKE MANIFOLD

>>A<<

13. INTAKE MANIFOLD GASKET

REMOVAL STEPS (Continued)

ACX02434 AC

PROTRUSION

PROTRUSION

FRONT OF VEHICLE

ORDER

MOUNTING NUTS

TIGHTENING

TORQUE

1st

Right-bank nuts

6.4

±

1.4 N

⋅

m

(56

±

13 in-lb)

2nd

Left-bank nuts

22

±

1 N

⋅

m

(16

±

1 ft-lb)

3rd

Right-bank nuts

22

±

1 N

⋅

m

(16

±

1 ft-lb)

4th

Left-bank nuts

22

±

1 N

⋅

m

(16

±

1 ft-lb)

5th

Right-bank nuts

22

±

1 N

⋅

m

(16

±

1 ft-lb)

AC001433

RIGHT BANK

LEFT BANK

AB

INTAKE MANIFOLD <3.0L>

TSB Revision

INTAKE AND EXHAUST

15-14

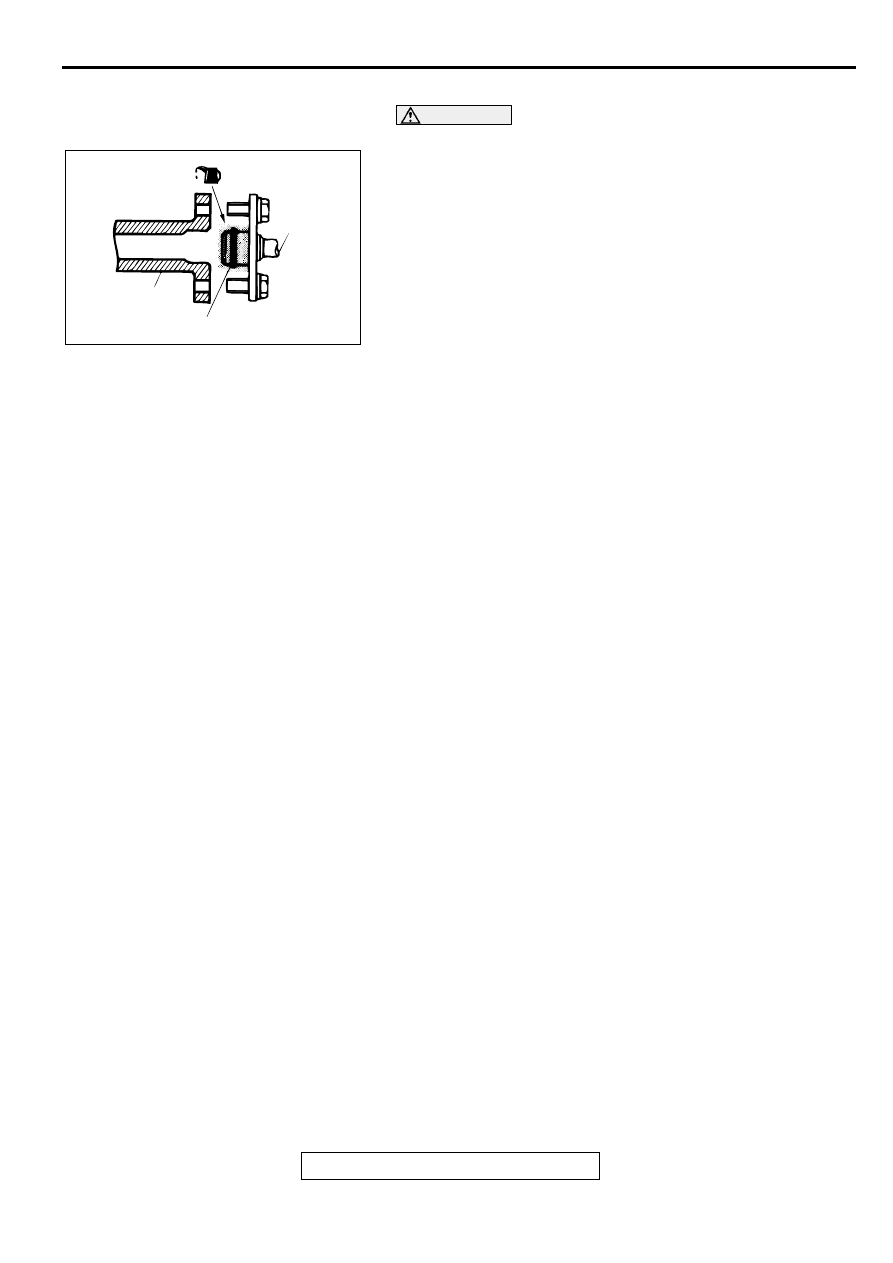

>>C<< HIGH-PRESSURE FUEL HOSE INSTALLATION

CAUTION

Be careful not to allow any engine oil to enter the fuel rail.

1. When connecting the high-pressure fuel hose to the fuel rail,

apply a small amount of new engine oil to the O-ring and

then insert the high-pressure fuel hose, being careful not to

damage the O-ring.

2. While turning the high-pressure fuel hose to the left and

right, install it to the fuel rail.

3. Check that the injector turns smoothly. If it does not turn

smoothly, the O-ring may be trapped. Remove the high-

pressure fuel hose and then re-insert it into the fuel rail and

check again.

INSPECTION

M1151003100122

Check the following points; replace the part if a problem is

found.

INTAKE MANIFOLD CHECK

1. Check for damage or cracking of any part.

2. Check for obstruction of the negative pressure (vacuum)

outlet port, and for obstruction of the water passage or gas

passage.

3. Using a straight edge and feeler gauge, check for distortion

of the cylinder head installation surface.

Standard value: 0.15 mm (0.006 inch) or less

Limit: 0.20 mm (0.008 inch)

AC001436

HIGH-

PRESSURE

FUEL HOSE

FUEL RAIL

O-RING

AB

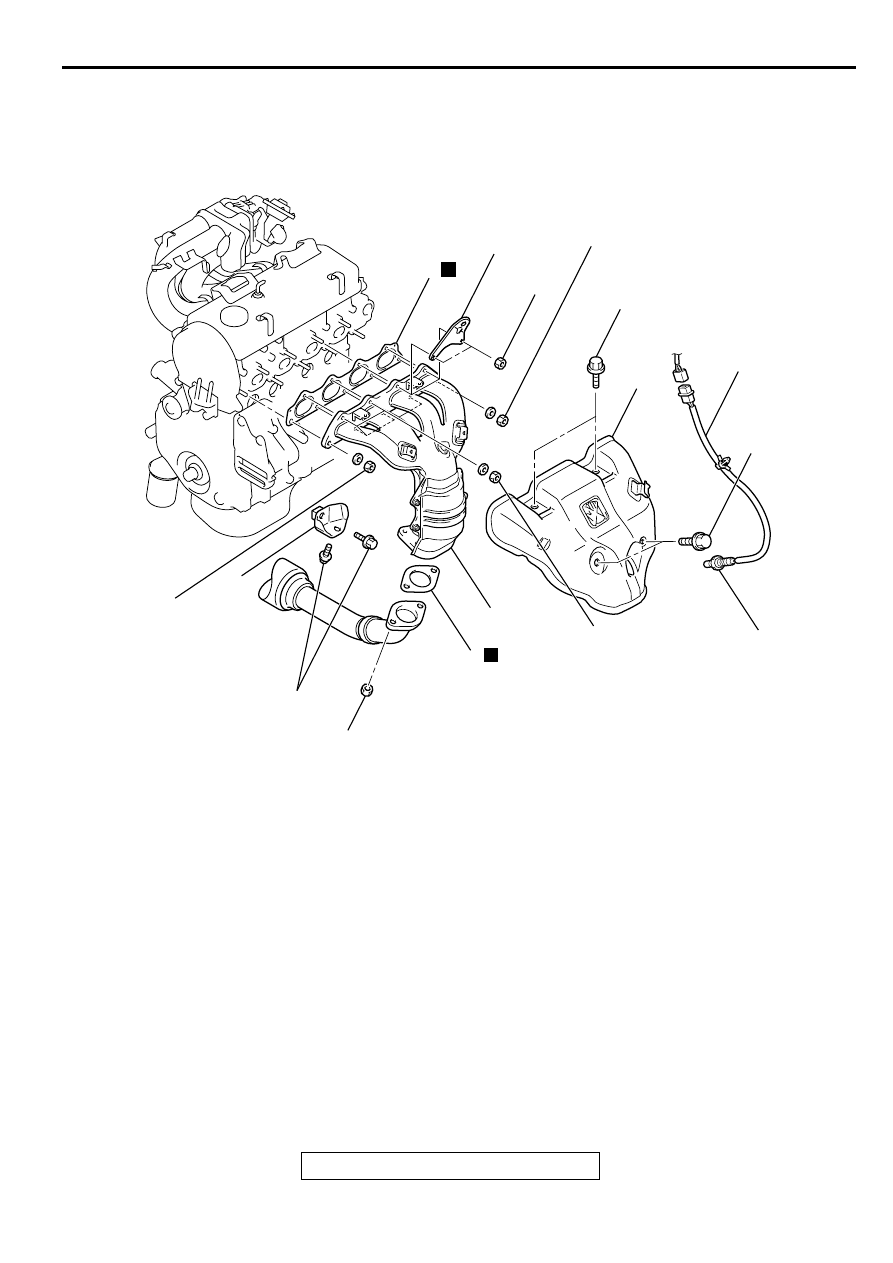

EXHAUST MANIFOLD <2.4L>

TSB Revision

INTAKE AND EXHAUST

15-15

EXH AU ST M AN IFO LD <2.4L>

REMOVAL AND INSTALLATION

M1151003300115

AC001808

44 ± 5 N·m

33 ± 3 ft-lb

29 ± 3 N·m

22 ± 2 ft-lb

49 ± 5 N·m

36 ± 4 ft-lb

49 ± 5 N·m

36 ± 4 ft-lb

29 ± 3 N·m

22 ± 2 ft-lb

14 ± 1 N·m

120 ± 13 in-lb

14 ± 1 N·m

120 ± 13 in-lb

35 ± 6 N·m

26 ± 4 ft-lb

1

49 ± 10 N·m

37 ± 7 ft-lb

2

3

4

5

6

N

N

AD

7

REMOVAL STEPS

<<A>> >>A<<

1. HEATED OXYGEN SENSOR

(FRONT)

2. HEAT PROTECTOR

3. ENGINE HANGER

4. EXHAUST MANIFOLD

5. EXHAUST MANIFOLD GASKET

6. GASKET

7. EXHAUST MANIFOLD BRACKET

REMOVAL STEPS (Continued)

EXHAUST MANIFOLD <2.4L>

TSB Revision

INTAKE AND EXHAUST

15-16

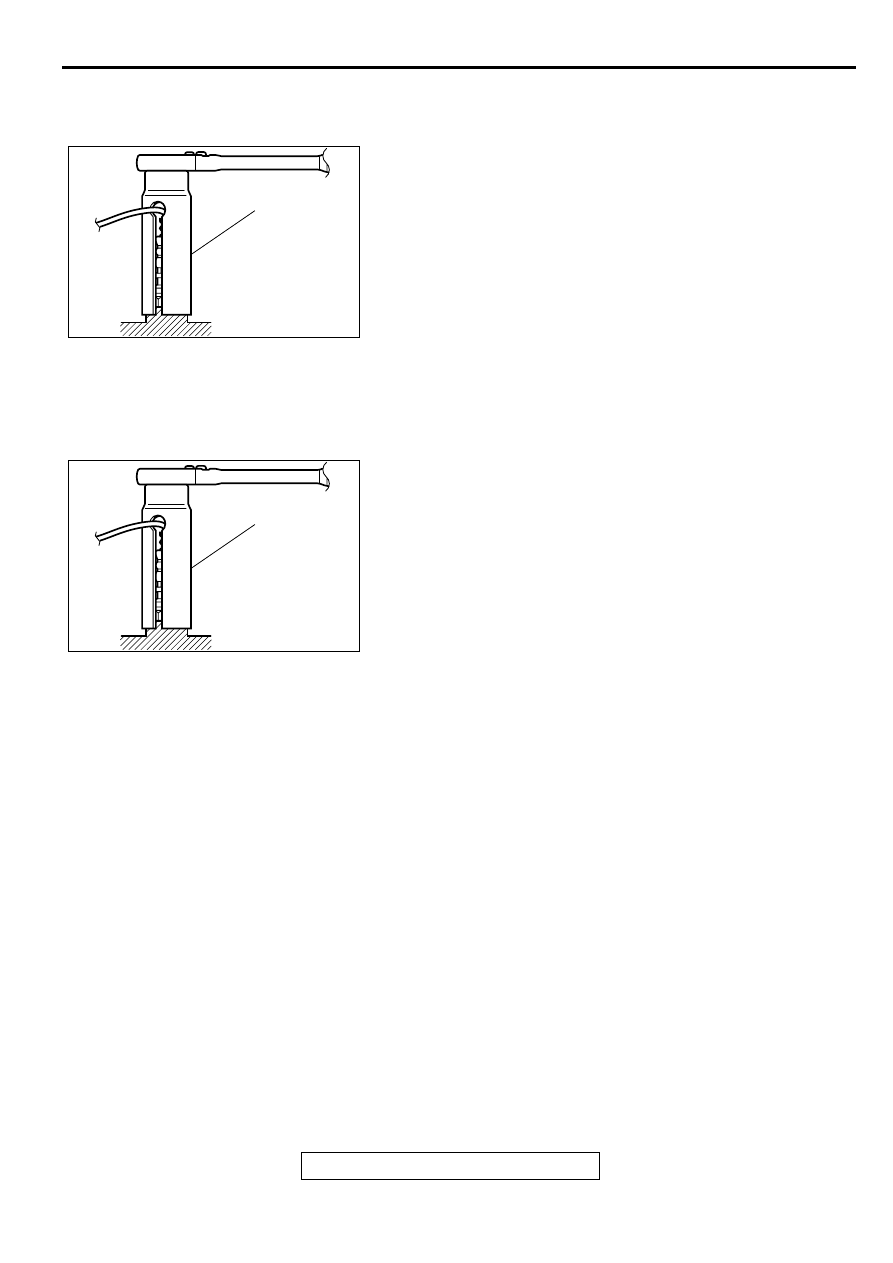

REMOVAL SERVICE POINT

<<A>> HEATED OXYGEN SENSOR (FRONT) REMOVAL

Use special tool MD998770 to remove the oxygen sensor.

INSTALLATION SERVICE POINT

>>A<< HEATED OXYGEN SENSOR (FRONT)

INSTALLATION

Use special tool MD998770 to installation the oxygen sensor.

INSPECTION

M1151003400101

Check the following points; replace the part if a problem is

found.

EXHAUST MANIFOLD CHECK

1. Check for damage or cracking of any part.

2. Using a straight edge and a feeler gauge, check for

distortion of the cylinder head installation surface.

Standard value: 0.15 mm (0.006 inch) or less

Limit: 0.20 mm (0.008 inch)

ACX02426 AB

MD998770

ACX02426 AB

MD998770

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст