Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 8

GENERAL DATA AND SPECIFICATIONS

TSB Revision

GENERAL <BODY AND CHASSIS>

00-29

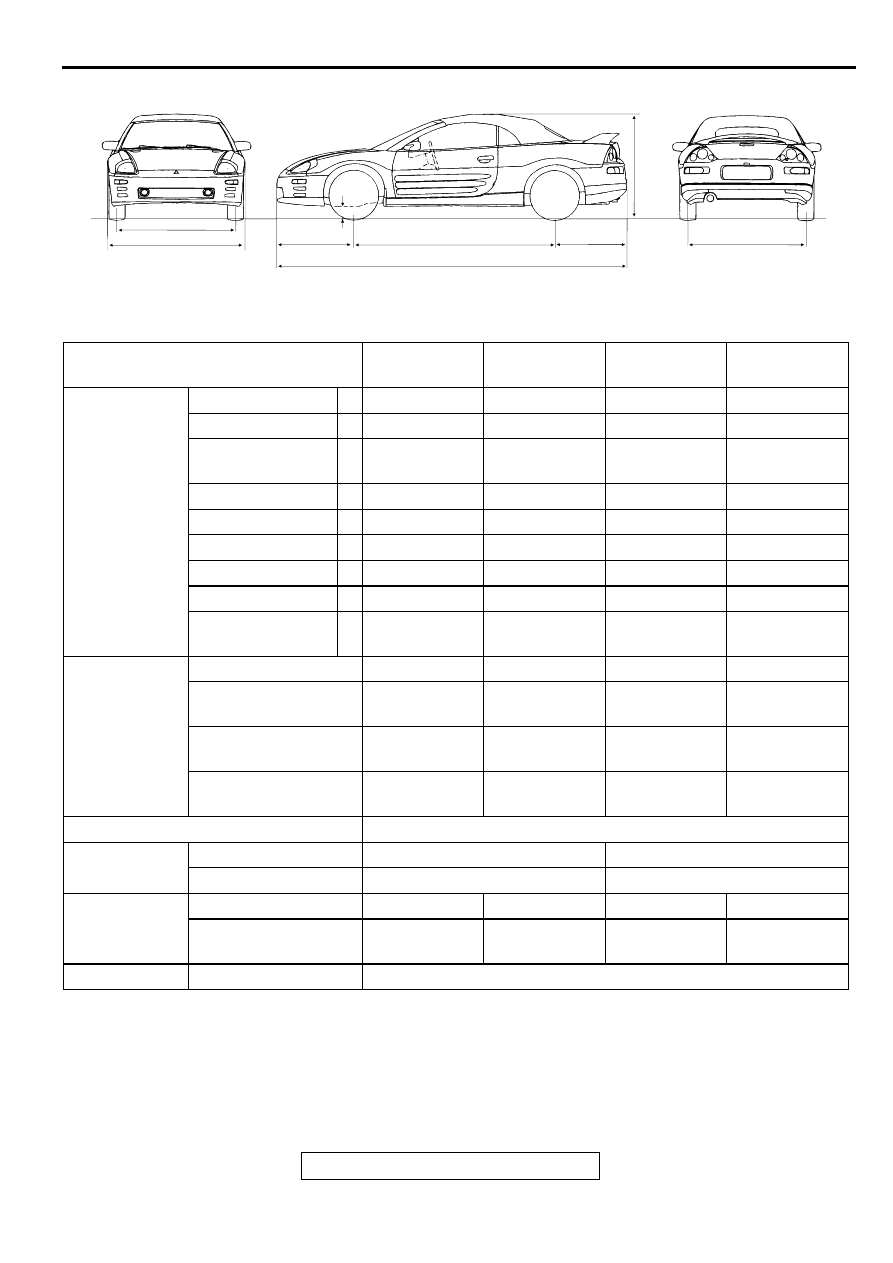

<ECLIPSE SPYDER>

GENERAL SPECIFICATIONS

AC002712

5

2

1

4

3

6

7

8

9

A

ITEMS

GS

HNHEL 4D

GS

HRHEL 4D

GT

NGEL4M

GT

RGEL4M

Vehicle

dimension mm

(in)

Overall length

1

4,455 (175.4)

4,455 (175.4)

4,455 (175.4)

4,455 (175.4)

Overall width

2

1,750 (68.9)

1,750 (68.9)

1,750 (68.9)

1,750 (68.9)

Overall height

(unladen)

3

1,340 (52.8)

1,340 (52.8)

1,340 (52.8)

1,340 (52.8)

Wheelbase

4

2,560 (100.8)

2,560 (100.8)

2,560 (100.8)

2,560 (100.8)

Tread-front

5

1,510 (59.4)

1,510 (59.4)

1,510 (59.4)

1,510 (59.4)

Tread-rear

6

1,510 (59.4)

1,510 (59.4)

1,510 (59.4)

1,510 (59.4)

Overhang-front

7

975 (38.4)

975 (38.4)

975 (38.4)

975 (38.4)

Overhang-rear

8920 (36.2)

920 (36.2)

920 (36.2)

920 (36.2)

Minimum running

ground clearance

9

163 (6.4)

163 (6.4)

165 (6.5)

165 (6.5)

Vehicle weight

kg (lb)

Curb weight

1,395 (3,075)

1,425 (3,142)

1485 (3,274)

1515 (3,340)

Gross vehicle weight

rating

1,770 (3,903)

1,770 (3,903)

1,855 (4,090)

1,855 (4,090)

Gross axle weight

rating-front

1,010 (2,227)

1,010 (2,227)

1,085 (2,392)

1,085 (2,392)

Gross axle weight

rating-rear

810 (1,786)

810 (1,786)

820 (1,808)

820 (1,808)

Seating capacity

4

Engine

Model No.

4G64

6G72

Piston displacement

2.4L

3.0L

Transaxle

Model No.

F5M42

F4A42

F5M51

F4A51

Type

5-speed

manual

4-speed

automatic

5-speed

manual

4-speed

automatic

Fuel system

Fuel supply system

Electronic controlled multiport fuel injection

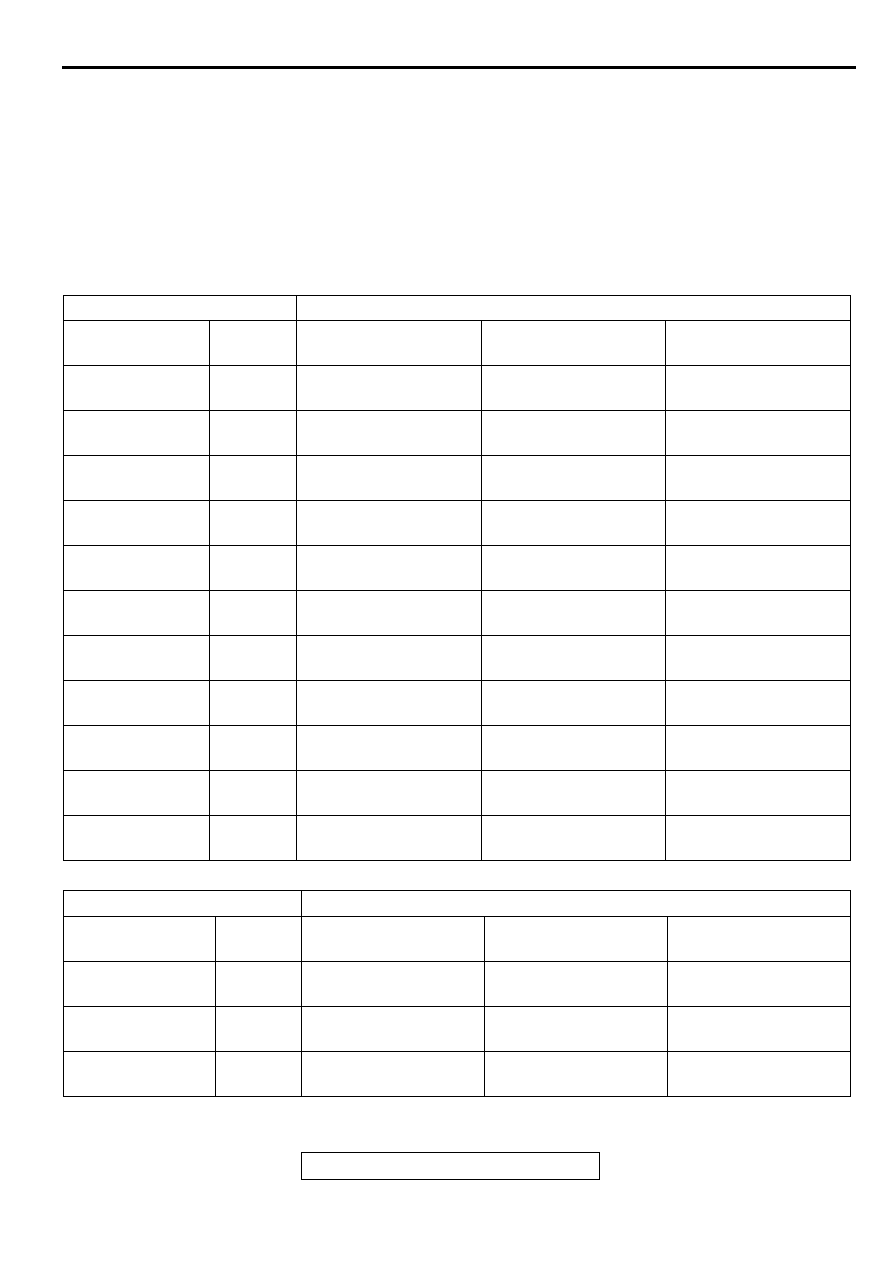

TIGHTENING TORQUE

TSB Revision

GENERAL <BODY AND CHASSIS>

00-30

TIG H TEN IN G TO R Q U E

M1001001100094

Each torque value in the table is a standard value for

tightening under the following conditions.

1. Bolts, nuts and washers are all made of steel and

plated with zinc.

2. The threads and bearing surface of bolts and

nuts are all in dry condition.

The values in the table are not applicable:

1. If toothed washers are inserted.

2. If plastic parts are fastened.

3. If bolts are tightened to plastic or die-cast

inserted nuts.

4. If self-tapping screws or self-locking nuts are

used

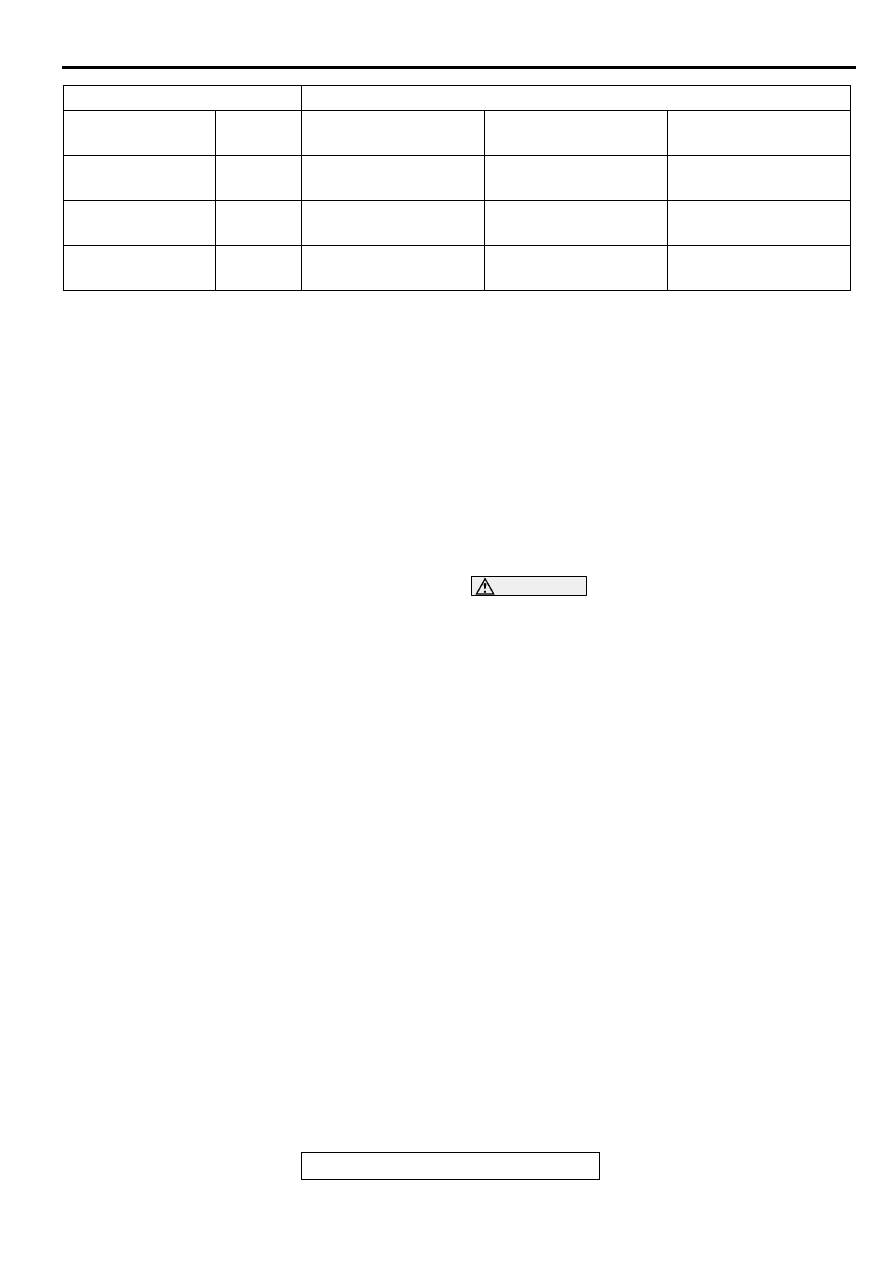

Standard bolt and nut tightening torque

Flange bolt and nut tightening torque

THREAD SIZE

STANDARD TIGHTENING TORQUE

NOMINAL BOLT

DIAMETER (mm)

PITCH

(mm)

HEAD MARK "4"

HEAD MARK "7"

HEAD MARK "8"

M5

0.82.5

±

0.5 N

⋅

m

(23

±

4 in-lb)

5.0

±

1.0 N

⋅

m

(44

±

9 in-lb)

6.0

±

1.0 N

⋅

m

(53

±

9 in-lb)

M6

1.0

5.0

±

1.0 N

⋅

m

(44

±

9 in-lb)

9.0

±

2.0 N

⋅

m

(79

±

18 in-lb)

10

±

2 N

⋅

m

(89

±

17 in-lb)

M81.25

12

±

2 N

⋅

m

(107

±

17 in-lb)

22

±

4 N

⋅

m

(16

±

3 ft-lb)

25

±

4 N

⋅

m

(18

±

3 ft-lb)

M10

1.25

24

±

4 N

⋅

m

(18

±

3 ft-lb)

44

±

10 N

⋅

m

(33

±

7 ft-lb)

53

±

7 N

⋅

m

(39

±

5 ft-lb)

M12

1.25

41

±

8 N

⋅

m

(30

±

6 ft-lb)

83

±

12 N

⋅

m

(61

±

9 ft-lb)

98

±

12 N

⋅

m

(72

±

9 ft-lb)

M14

1.5

73

±

12 N

⋅

m

(54

±

9 ft-lb)

140

±

20 N

⋅

m

(104

±

14 ft-lb)

155

±

25 N

⋅

m

(115

±

18 ft-lb)

M16

1.5

110

±

20 N

⋅

m

(81

±

15 ft-lb)

210

±

30 N

⋅

m

(155

±

22 ft-lb)

235

±

35 N

⋅

m

(174

±

25 ft-lb)

M181.5

165

±

25 N

⋅

m

(122

±

18 ft-lb)

300

±

40 N

⋅

m

(222

±

29 ft-lb)

340

±

50 N

⋅

m

(251

±

37 ft-lb)

M20

1.5

225

±

35 N

⋅

m

(166

±

26 ft-lb)

410

±

60 N

⋅

m

(303

±

44 ft-lb)

480

±

70 N

⋅

m

(354

±

52 ft-lb)

M22

1.5

300

±

40 N

⋅

m

(222

±

29 ft-lb)

555

±

85 N

⋅

m

(410

±

62 ft-lb)

645

±

95 N

⋅

m

(476

±

70 ft-lb)

M24

1.5

395

±

55 N

⋅

m

(292

±

40 ft-lb)

735

±

105 N

⋅

m

(543

±

77 ft-lb)

855

±

125 N

⋅

m

(631

±

92 ft-lb)

THREAD SIZE

STANDARD TIGHTENING TORQUE

NOMINAL BOLT

DIAMETER (mm)

PITCH

(mm)

HEAD MARK "4"

HEAD MARK "7"

HEAD MARK "8"

M6

1.0

5.0

±

1.0 N

⋅

m

(44

±

9 in-lb)

10

±

2 N

⋅

m

(89

±

17 in-lb)

12

±

2 N

⋅

m

(107

±

17 in-lb)

M81.25

13

±

2 N

⋅

m

(111

±

22 in-lb)

24

±

4 N

⋅

m

(18

±

3 ft-lb)

27

±

5 N

⋅

m

(20

±

4 ft-lb)

M10

1.25

26

±

4 N

⋅

m

(19

±

3 ft-lb)

49

±

9 N

⋅

m

(36

±

7 ft-lb)

58

±

7 N

⋅

m

(43

±

5 ft-lb)

LUBRICATION AND MAINTENANCE

TSB Revision

GENERAL <BODY AND CHASSIS>

00-31

LU B R IC ATIO N A N D M A IN TEN A N C E

M1001001200091

Maintenance and lubrication service

recommendations have been compiled to provide

maximum protection for the vehicle owner's

investment against all reasonable types of driving

conditions. Since these conditions vary with the

individual vehicle owner's driving habits, the area in

which the vehicle is operated and the type of driving

to which the vehicle is subjected, it is necessary to

prescribe lubrication and maintenance service on a

time frequency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by the

Society of Automotive Engineers (SAE), the

American Petroleum Institute (API) and the National

Lubricating Grease Institute (NLGI).

MAINTENANCE SCHEDULES

Information for service maintenance is provided in

the "SCHEDULED MAINTENANCE TABLE." Three

schedules are provided; one for "Required

Maintenance." one for "General Maintenance and "

and one for "Severe Usage Service."

The item numbers in "SCHEDULED MAINTENANCE

TABLE" correspond to the section numbers in

"MAINTENANCE SERVICE."

SEVERE SERVICE

Vehicles operating under severe service conditions

will require more frequent service.

Component service information is included in

appropriate units for vehicles operating under one or

more of the following conditions:

1. Trailer towing or police, taxi or commercial type

operation.

2. Operation of Vehicle

(1) Short-trip operation at freezing temperature

(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city traffic

during hot weather above 32

°

C (90

°

F)

(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

(7) Driving off-road

ENGINE OIL

CAUTION

Test results submitted to EPA have shown that

laboratory animals develop skin cancer after

prolonged contact with used engine oil.

Accordingly, the potential exists for humans to

develop a number of skin disorders, including

cancer, from such exposure to used engine oil.

Therefore, when changing engine oil, be careful

not to touch it as much as possible. Protective

clothing and gloves, that cannot be penetrated

by oil, should be worn. The skin should be

thoroughly washed with soap and water, or use

waterless hand cleaner, to remove any used

engine oil. Do not use gasoline, thinners, or

solvents.

Either of the following engine oils should be used:

1. Engine oil displaying ILSAC certification mark.

2. Engine oil conforming to the API classification SJ

EC or SJ/CD EC.

For further details, refer to "LUBRICANTS

SELECTION."

LUBRICANTS AND GREASES

Semi-solid lubricants bear the NLGI designation and

are further classified as grades 0, 1, 2, 3, etc.

Whenever "Chassis Lubricant" is specified,

Multipurpose Grease, NLGI grade Number 2, should

be used.

M10

1.5

24

±

4 N

⋅

m

(18

±

3 ft-lb)

45

±

8 N

⋅

m

(33

±

6 ft-lb)

55

±

10 N

⋅

m

(41

±

7 ft-lb)

M12

1.25

46

±

8 N

⋅

m

(34

±

6 ft-lb)

95

±

15 N

⋅

m

(70

±

11 ft-lb)

105

±

15 N

⋅

m

(78

±

11 ft-lb)

M12

1.75

43

±

8 N

⋅

m

(32

±

6 ft-lb)

83

±

12 N

⋅

m

(61

±

9 ft-lb)

98

±

12 N

⋅

m

(72

±

9 ft-lb)

THREAD SIZE

STANDARD TIGHTENING TORQUE

NOMINAL BOLT

DIAMETER (mm)

PITCH

(mm)

HEAD MARK "4"

HEAD MARK "7"

HEAD MARK "8"

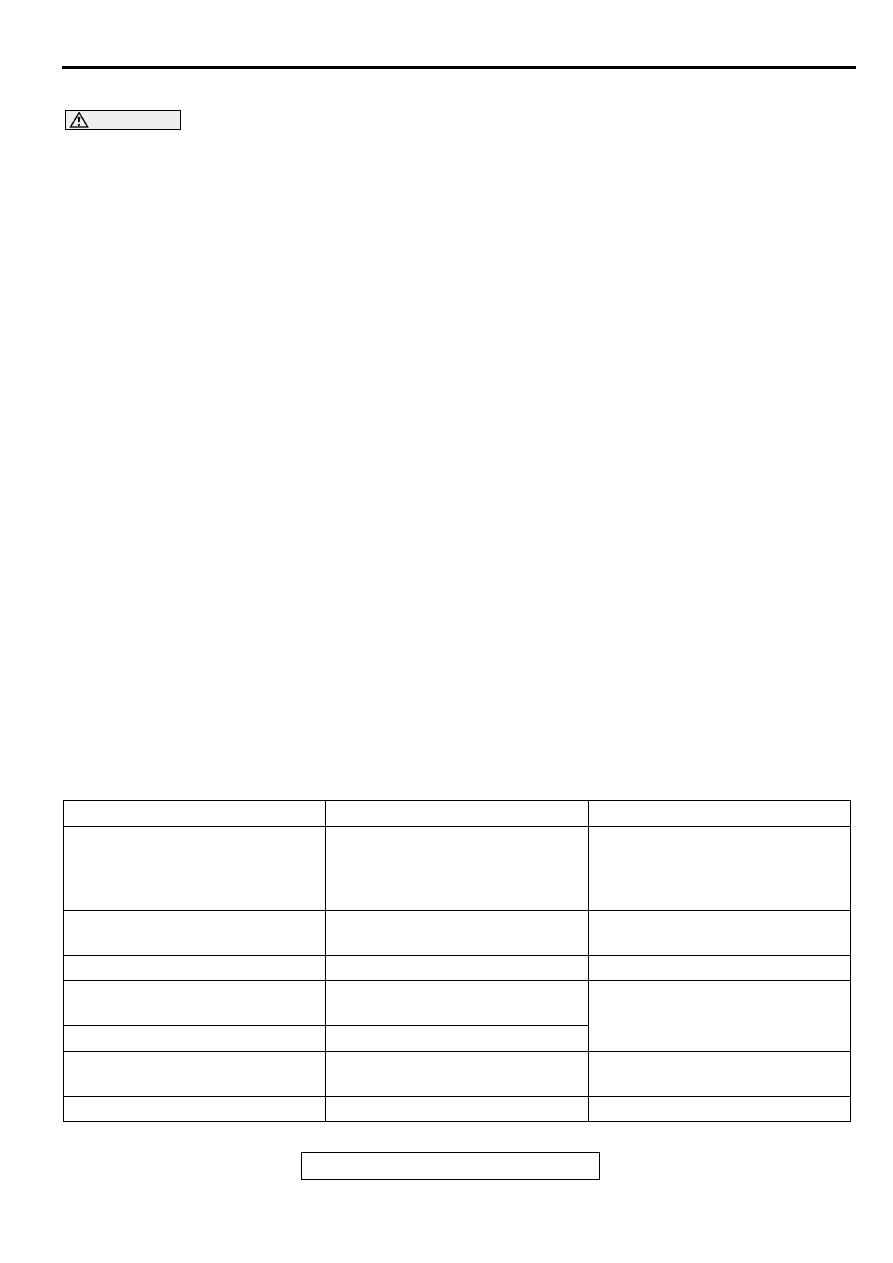

RECOMMENDED LUBRICANTS AND LUBRICANT CAPACITIES TABLE

TSB Revision

GENERAL <BODY AND CHASSIS>

00-32

FUEL USAGE STATEMENT

CAUTION

Using leaded gasoline in your car will damage

the catalytic converters and heated oxygen

sensors, and affect the warranty coverage

validity.

This vehicle must use unleaded gasoline only.

This vehicle has a fuel filler tube which is especially

designed to accept only the smaller-diameter

unleaded gasoline dispensing nozzle.

2.4L model is designed to operate on unleaded

gasoline having a minimum octane rating of 87

[(MON + RON)/2], or 91 RON.

3.0L model is designed to operate on premium grade

unleaded gasoline having a minimum octane rating

of 91 [(MON + RON)/2], or 95 RON. If premium

grade unleaded gasoline is not available, unleaded

gasoline having an octane rating of 87 [(MON +

RON)/2], or 91 RON may be used. However, the

performance level may be reduced.

MON: Motor Octane Number

RON: Research Octane Number

GASOLINE CONTAINING ALCOHOL

Some gasoline sold at service stations contain

alcohol although they may not be so identified.

Using fuels containing alcohol is not recommended

unless the nature of the blend can be determined as

being satisfactory.

Gasohol: A mixture of 10% ethanol (grain alcohol)

and 90% unleaded gasoline may be used in your

vehicle. If driveability problems are experienced as a

result of using gasohol, it is recommended that the

vehicle be operated on gasoline.

Methanol: Do not use gasoline containing

methanol (wood alcohol). Using this type of alcohol

can result in vehicle performance deterioration and

damage critical parts in the fuel system components.

Fuel system damage and performance problems

resulting from the use of gasoline containing

methanol may not be covered by the new vehicle

warranty.

GASOLINE CONTAINING METHY TERTIARY

BUTYL ETHER (MTBE)

Unleaded gasoline containing 15% or less MTBE

may be used in your vehicle. (Fuel containing MTBE

over 15% in volume may cause reduced engine

performance and produce vapor lock or hard

starting.

MATERIALS ADDED TO FUEL

Indiscriminate use of fuel system cleaning agents

should be avoided. Many of these materials intended

for gum and varnish removal may contain highly

active solvents or similar ingredients that can be

harmful to gasket and diaphragm materials used in

fuel system component parts.

REC O M M EN D ED LUB RIC A N TS AN D LU BR IC A N T

C A PA C ITIES TA B LE

M1001001300098

RECOMMENDED LUBRICANTS

PARTS

SPECIFICATIONS

REMARKS

Engine oil

Engine oil displaying ILSAC

certification mark ("Starburst"

symbol) conforming the API

classification SJ EC or SJ/CD EC

For further details, refer to

"LUBRICANTS SELECTION"

section.

Manual transaxle

API classification GL-4

SAE grade number:SAE75W-90

or 75W/85W

Automatic transaxle

-

-

Power steering

MITSUBISHI POWER STEERING

FLUID

-

Brakes

Conforming to DOT 3 or DOT 4

Engine coolant

MITSUBISHI genuine coolant or

an equivalent

-

Door hinges, back door hinges

Engine oil

-

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст