Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 392

EMISSION CONTROL

TSB Revision

ENGINE AND EMISSION CONTROL

17-87

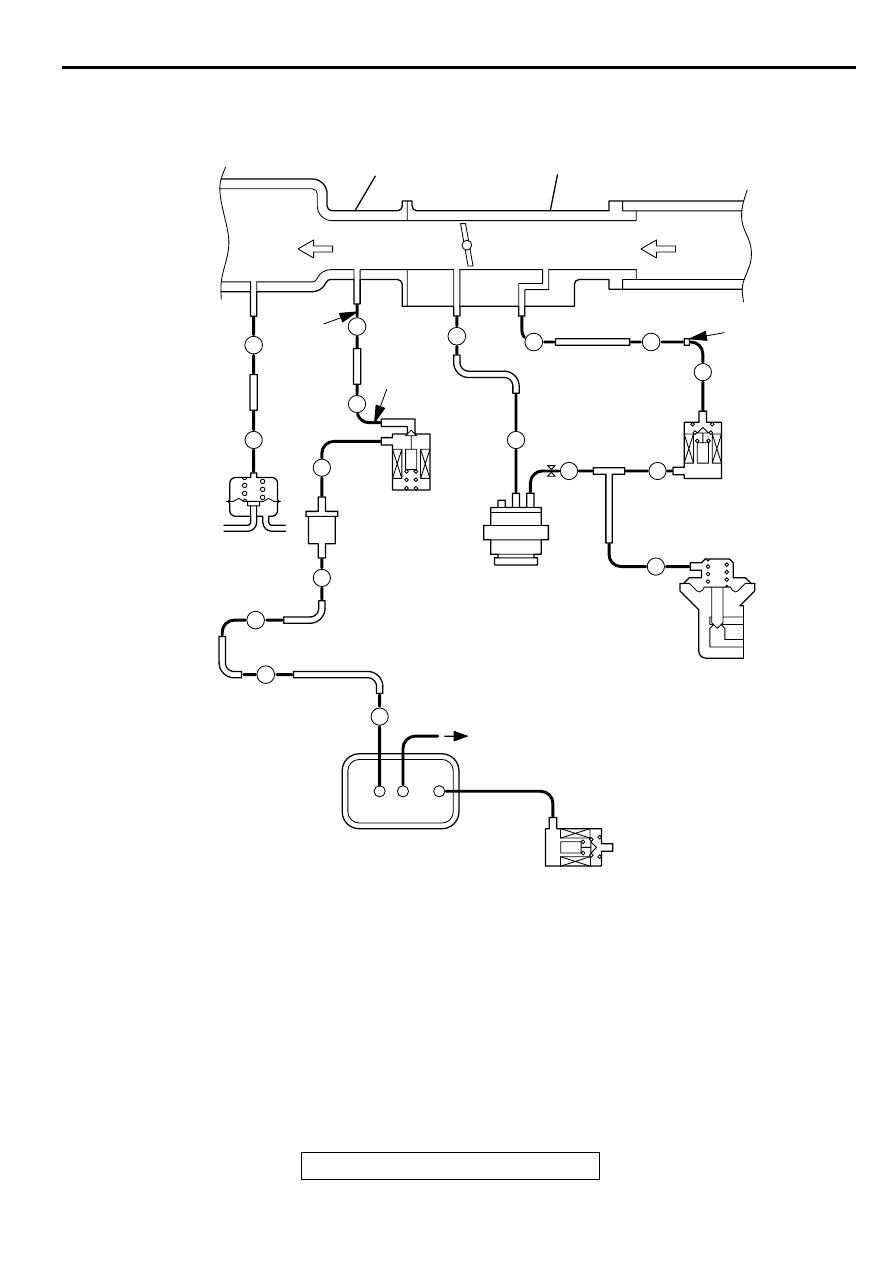

<3.0L ENGINE>

VACUUM HOSE INSTALLATION

M1173007200022

1. When connecting the vacuum hoses, they should be

securely inserted onto the nipples.

2. Connect the hoses correctly, using the VACUUM HOSE

ROUTING as a guide.

AKX01296

INTAKE MANIFOLD

THROTTLE BODY

TO COMB-

USTION

CHAMBER

FROM AIR

CLEANER

HOSE JOINT

EGR SOLENOID

(ON: CLOSE)

FUEL

PRESSURE

REGULATOR

EVAPORATIVE

EMISSION

PURGE

SOLENOID

(ON: OPEN)

CHAMBER

VACUUM

CONTROL

VALVE

EGR VALVE

FUEL

TANK

B: BLACK

G: GREEN

L: LIGHT BLUE

W: WHITE

Y: YELLOW

*1:RED PAINT MARK

*2:RESTRICTOR

EVAPORATIVE

EMISSION

CANISTER

EVAPORATIVE EMISSION

VENTILATION SOLENOID

(ON: CLOSE)

AB

B

B

B

B

B

B

B

B

B

B

L

G

G

G

Y

Y

W

*1

*1

*2

EMISSION CONTROL

TSB Revision

ENGINE AND EMISSION CONTROL

17-88

VACUUM HOSE CHECK

M1173007300029

1. Using the VACUUM HOSE ROUTING as a guide, check that

the vacuum hoses are correctly connected.

2. Check the connection of the vacuum hoses, (removed,

loose, etc.) and confirm that there are no sharp bends or

damage.

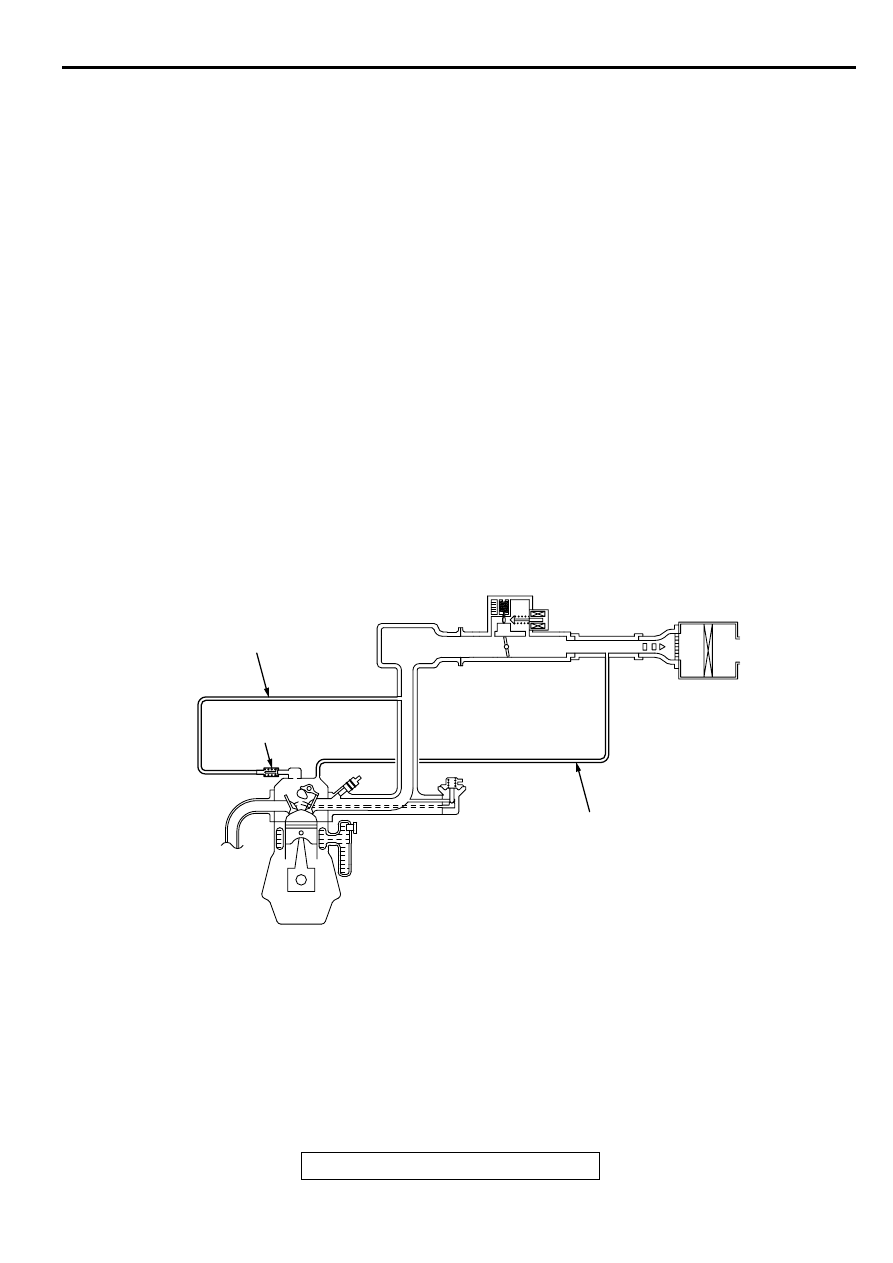

POSITIVE CRANKCASE VENTILATION SYSTEM

GENERAL DESCRIPTION (POSITIVE CRANKCASE VENTILATION SYSTEM)

M1173005000044

The positive crankcase ventilation system is a

system for preventing the escape of blow-by gases

from inside the crankcase into the atmosphere.

Fresh air is sent from the air cleaner into the

crankcase through the breather hose to be mixed

with the blow-by gas inside the crankcase.

The blow-by gas inside the crankcase is drawn into

the intake manifold through the positive crankcase

ventilation (PCV) valve.

The PCV valve is designed to lift the plunger

according to the intake manifold vacuum so as to

regulate the flow of blow-by gas properly.

In other words, the blow-by gas flow is regulated

during low load engine operation to maintain engine

stability, while the flow is increased during high load

operation to improve the ventilation performance.

SYSTEM DIAGRAM

<2.4L ENGINE>

AKX01297

VENTILATION HOSE

POSITIVE CRANKCASE

VENTILATION (PCV)

VALVE

BREATHER HOSE

AB

EMISSION CONTROL

TSB Revision

ENGINE AND EMISSION CONTROL

17-89

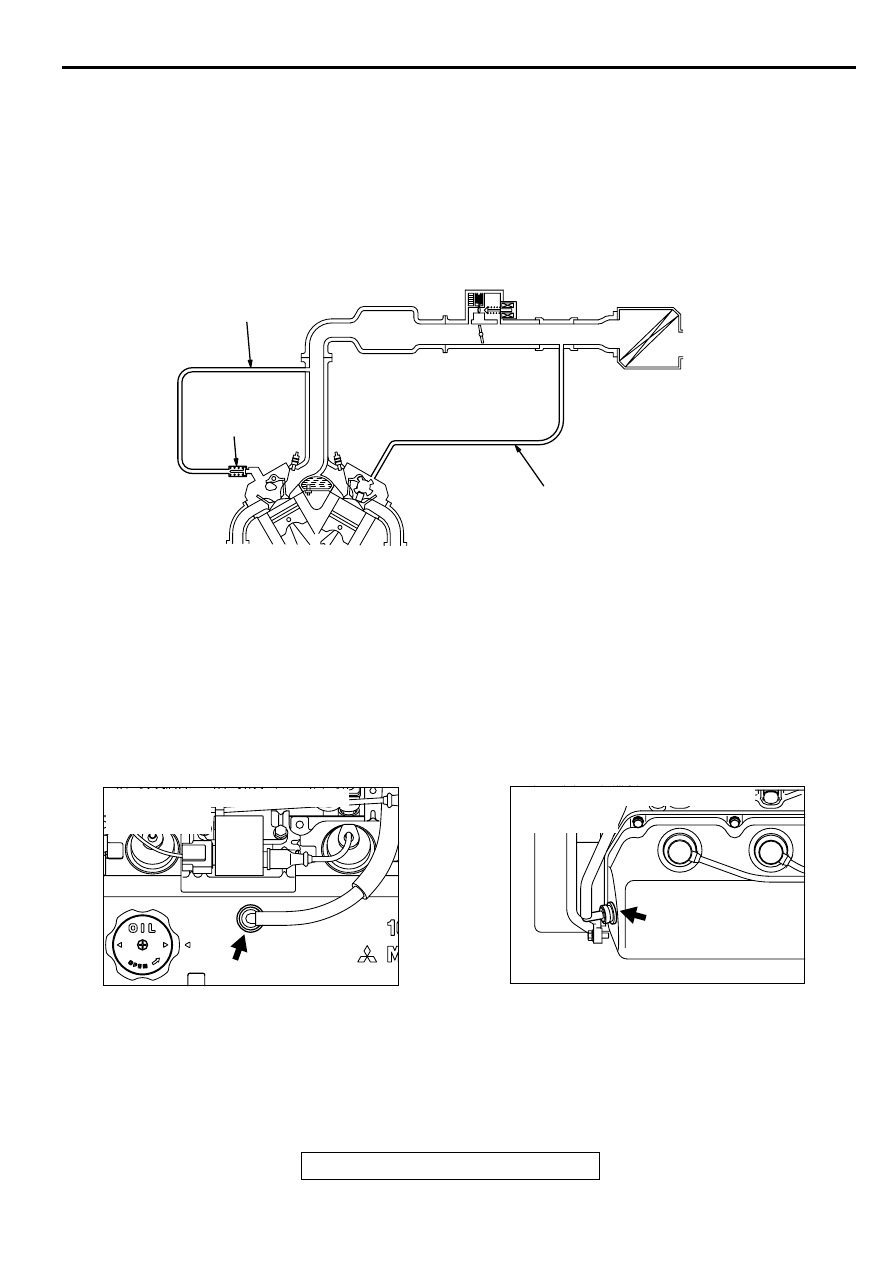

<3.0L ENGINE>

COMPONENT LOCATION

M1173007400026

AKX00334

BREATHER HOSE

VENTILATION HOSE

PCV VALVE

AB

AKX01299 AB

POSITIVE CRANKCASE VENTILATION

(PCV) VALVE

<2.4L ENGINE>

AKX01300AB

POSITIVE CRANKCASE VENTILATION

(PCV) VALVE

<3.0L ENGINE>

EMISSION CONTROL

TSB Revision

ENGINE AND EMISSION CONTROL

17-90

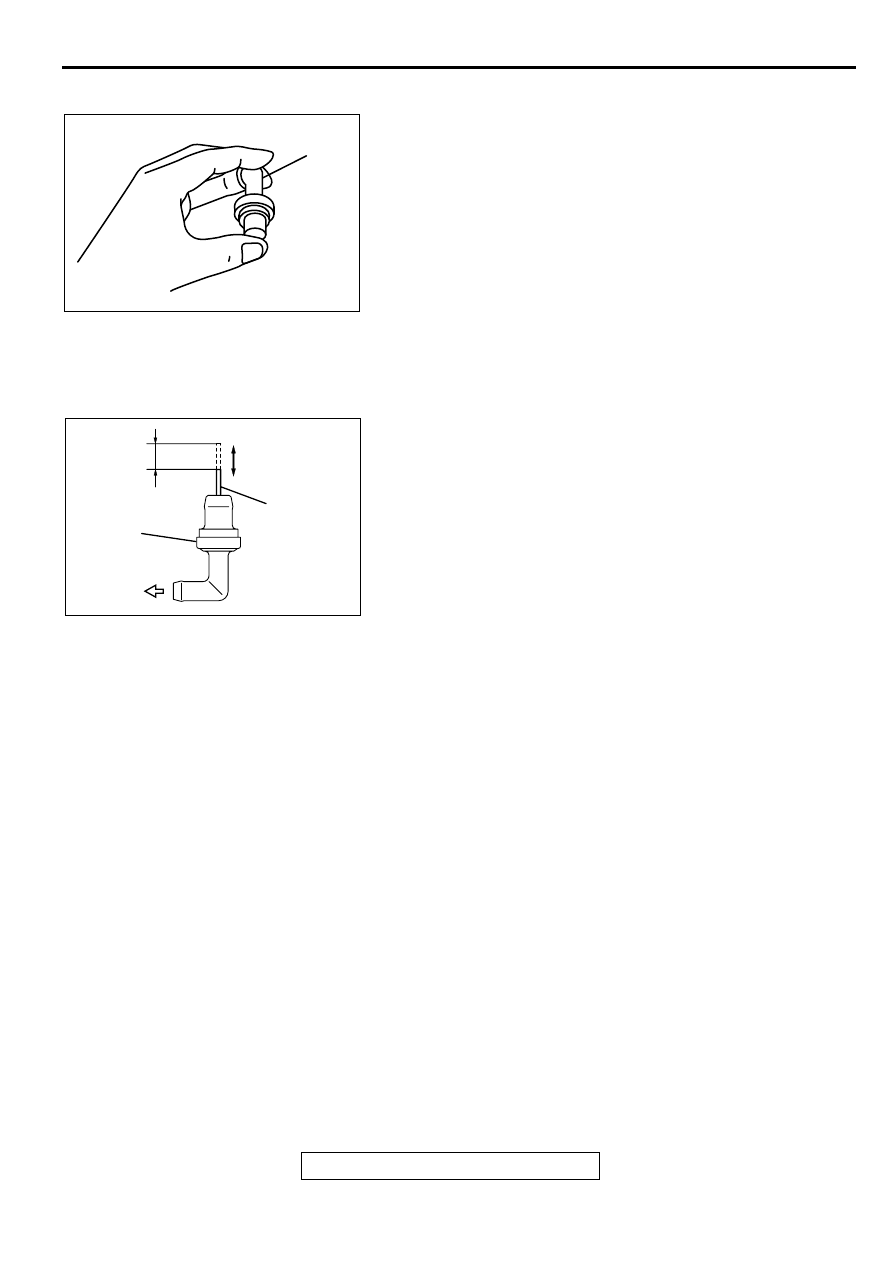

CRANKCASE VENTILATION SYSTEM CHECK

M1173001100049

1. Remove the positive crankcase ventilation (PCV) valve from

the rocker cover, then reconnect the PCV valve to the

vacuum supply hose.

2. With the engine idling, put your finger on the open end of the

PCV valve, and check for negative pressure (vacuum).

NOTE: At this time, the plunger in the PCV valve should

move back and forth as the open end is covered and

uncovered.

3. If negative pressure is not felt, clean or replace the PCV

valve. Inspect he vacuum supply hose and vacuum supply

hose port for restriction or plugged condition.

POSITIVE CRANKCASE VENTILATION (PCV)

VALVE CHECK

M1173001200046

1. Hold the PCV valve with the vacuum side down. Insert a thin

rod, and using light pressure, depress the end of the PCV

valve spring by 5

−

10 mm (0.2

−

0.3 inch). Release

pressure on the rod to see if the PCV valve spring will lift the

rod to its original position.

2. If the rod returns quickly to its original position, the PCV

valve is OK. If the stick does not return quickly. clean or

replace the PCV valve.

EVAPORATIVE EMISSION CONTROL SYSTEM

GENERAL DESCRIPTION

M1173005100041

The evaporative emission control system prevents

fuel vapors generated in the fuel tank from escaping

into the atmosphere.

Fuel vapors from the fuel tank flow through the vapor

pipe/hose to be stored temporarily in the evaporative

emission (EVAP) canister.

When the vehicle is in operation, fuel vapors stored

in the EVAP canister flow through the chamber, the

EVAP purge solenoid, purge port and intake manifold

plenum to the combustion chamber.

When the engine coolant temperature is low or when

the intake air quantity is small (when the engine is at

idle, for example), the engine control module brings

the EVAP purge solenoid into the OFF state to shut

off the fuel vapor flow to the intake manifold plenum.

This ensures driveability when the engine is cold or

running under low load and also stabilizes the

emission level.

An EVAP ventilation solenoid is provided between

the EVAP canister and atmosphere to monitor for

OBD-II EVAP leaks. This solenoid is normally OFF.

However, it turns ON when monitoring the OBD-II

EVAP leaks and shuts off the atmosphere flow to the

EVAP canister. Then the fuel tank differential

pressure sensor monitors the fuel vapor pressure to

detect OBD-II EVAP leaks. The fuel vent valve and

the leveling valve prevent fuel from being overfilled.

The fuel vent valve and the leveling valve prevents

fuel leaks just if the vehicle is rolled over in an

accident.

The vent valve releases the air from the fuel tank

through the evaporative emission canister into the

atmosphere when the fuel tank pressure increases

due to refueling, etc. The vent valve and the air filter

supply the atmospheric air to the evaporative

emission canister when the fuel tank pressure

decreases.

AKX00336

PCV VALVE

AB

AKX00337

5 - 10 mm

(0.2 - 0.3 in)

PCV VALVE

VACUUM SIDE

THIN ROD

(VERY

SMOOTH)

AB

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст