Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 610

POWER STEERING GEAR BOX ASSEMBLY

TSB Revision

POWER STEERING

37A-35

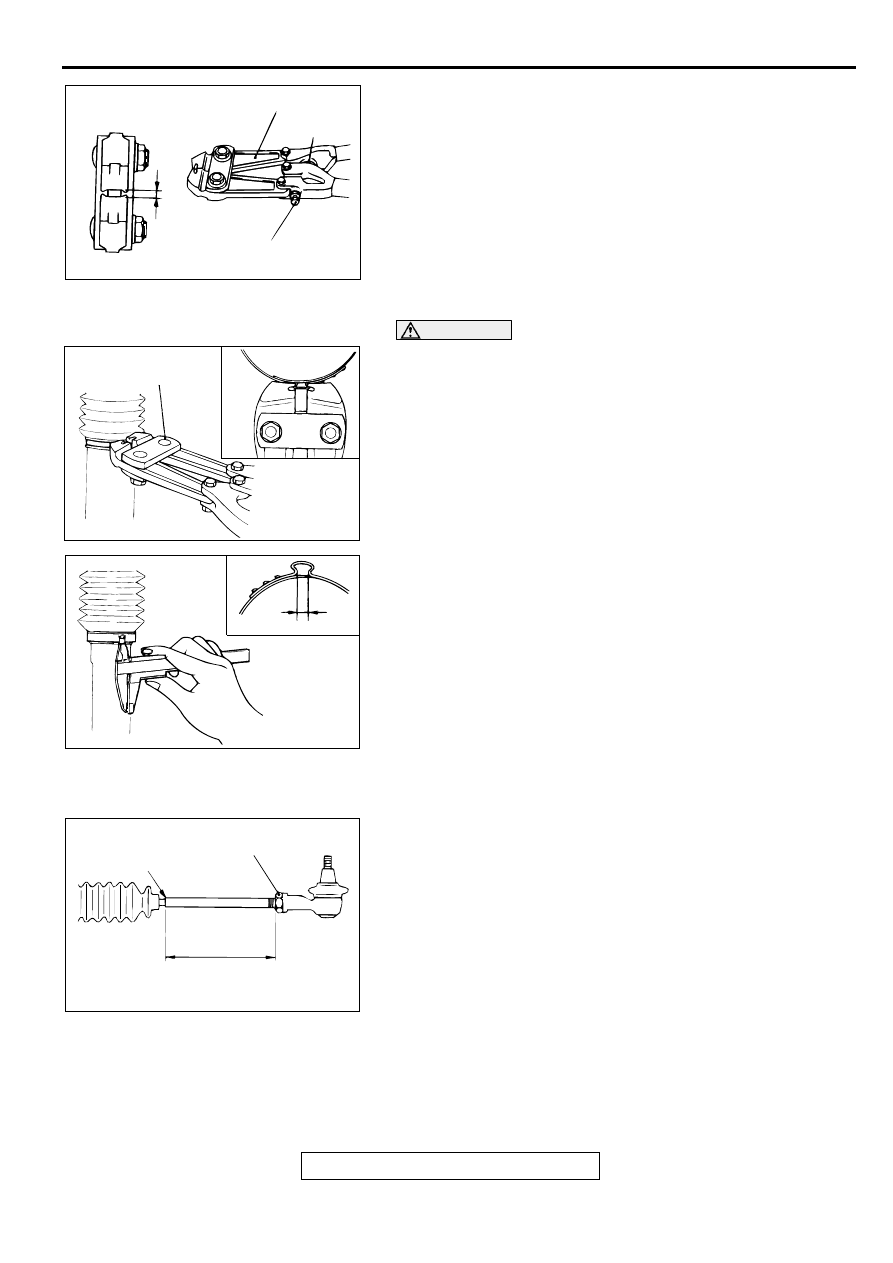

>>N<< BELLOWS BAND INSTALLATION

1. Turn the adjusting bolt of special tool MB991561 to adjust

the opening dimension (W) to the standard value.

NOTE: The dimension (W) is adjusted by approximately 0.7

mm (0.03 inch) per one turn.

NOTE: Do not turn the adjusting bolt more than one turn.

Standard value (W): 1.9 mm (0.07 inch)

<When more than 1.9 mm (0.07 inch)>: Screw in the

adjusting bolt.

<When less than 1.9 mm (0.07 inch)>: Loosen the

adjusting bolt.

CAUTION

•

Hold the rack housing, and use special tool MB991561

to crimp the bellows band securely.

•

Crimp the bellows band until special tool MB991561

touches the stopper.

2. Use special tool MB991561 to crimp the bellows band.

3. Check that crimped width (A) is within the standard value.

Standard value (A): 1.4

−

1.8 mm (0.06

−

0.07 inch)

<When more than 1.8 mm (0.07 inch)>: Readjust the

dimension (W) of step (1) to the value calculated by

the following equation, and repeat step (2).

W = 5.5 mm (0.22 inch)

−

A [Example: if (A) is 1.9 mm

(0.07 inch), (W) is 3.6 mm (0.14 inch).]

<When less than 1.4 mm (0.06 inch)>: Remove the

bellows band, readjust the dimension (W) of step (1) to

the value calculated by the following equation, and

use a new bellows band to repeat steps (2) to (3).

W = 5.5 mm (0.22 inch)

−

A [Example: if (A) is 1.3 mm

(0.05 inch), (W) is 4.2 mm (0.17 inch).]

>>O<< TIE ROD END/TIE ROD END JAM NUT

INSTALLATION

Screw in the tie rod end to achieve the right and left length as

illustrated. Lock with the jam nut.

ACX01164 AB

W

MB991561

ADJUSTING BOLT

STOPPER

ACX01165 AB

MB991561

ACX01166 AB

A

AC001011AC

JAM NUT

EDGE OF BELLOWS

ASSEMBLY GROOVE

2.4L ENGINE: 192 mm (7.6 in)

3.0L ENGINE <ECLIPSE>: 200 mm (7.9 in)

3.0L ENGINE <ECLIPSE SPYDER>: 197 mm (7.8 in)

POWER STEERING GEAR BOX ASSEMBLY

TSB Revision

POWER STEERING

37A-36

INSPECTION

M1372004400051

RACK

•

Check the rack tooth surfaces for damage or wear.

•

Check the oil seal contact surfaces for uneven wear.

•

Check the rack for bends.

PINION AND VALVE ASSEMBLY

•

Check the pinion gear tooth surfaces for damage or wear.

•

Check for worn or defective seal ring.

BEARING

•

Check for roughness or abnormal noise during bearing

operation.

•

Check the bearing for play.

•

Check the needle roller bearings for roller slip-off.

OTHERS

•

Check the cylinder inner surface of the rack housing for

damage.

•

Check the boots for damage, cracking or deterioration.

•

Check the rack support for uneven wear or dents.

•

Check the rack bushing for uneven wear or damage.

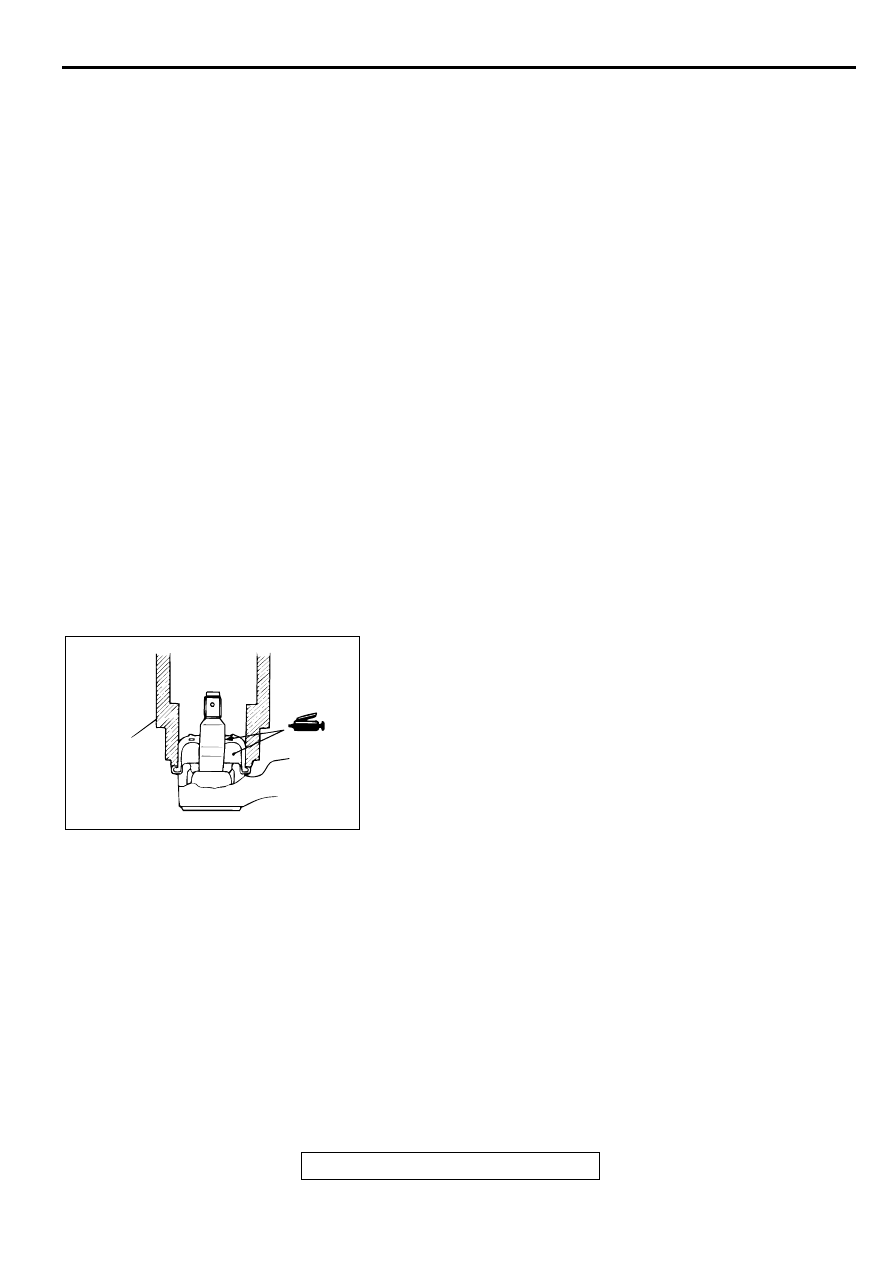

TIE ROD END BALL JOINT DUST COVER

REPLACEMENT

M1372008200093

If the dust cover is damaged accidentally during service work,

replace the dust cover as follows:

1. Apply grease to the lip and inside of the dust cover.

2. Drive in the dust cover with special tool MB990776 until it is

fully seated.

3. Check the dust cover for cracks or damage by pushing it

with your finger.

AC001012AB

MB990776

POWER STEERING OIL PUMP ASSEMBLY

TSB Revision

POWER STEERING

37A-37

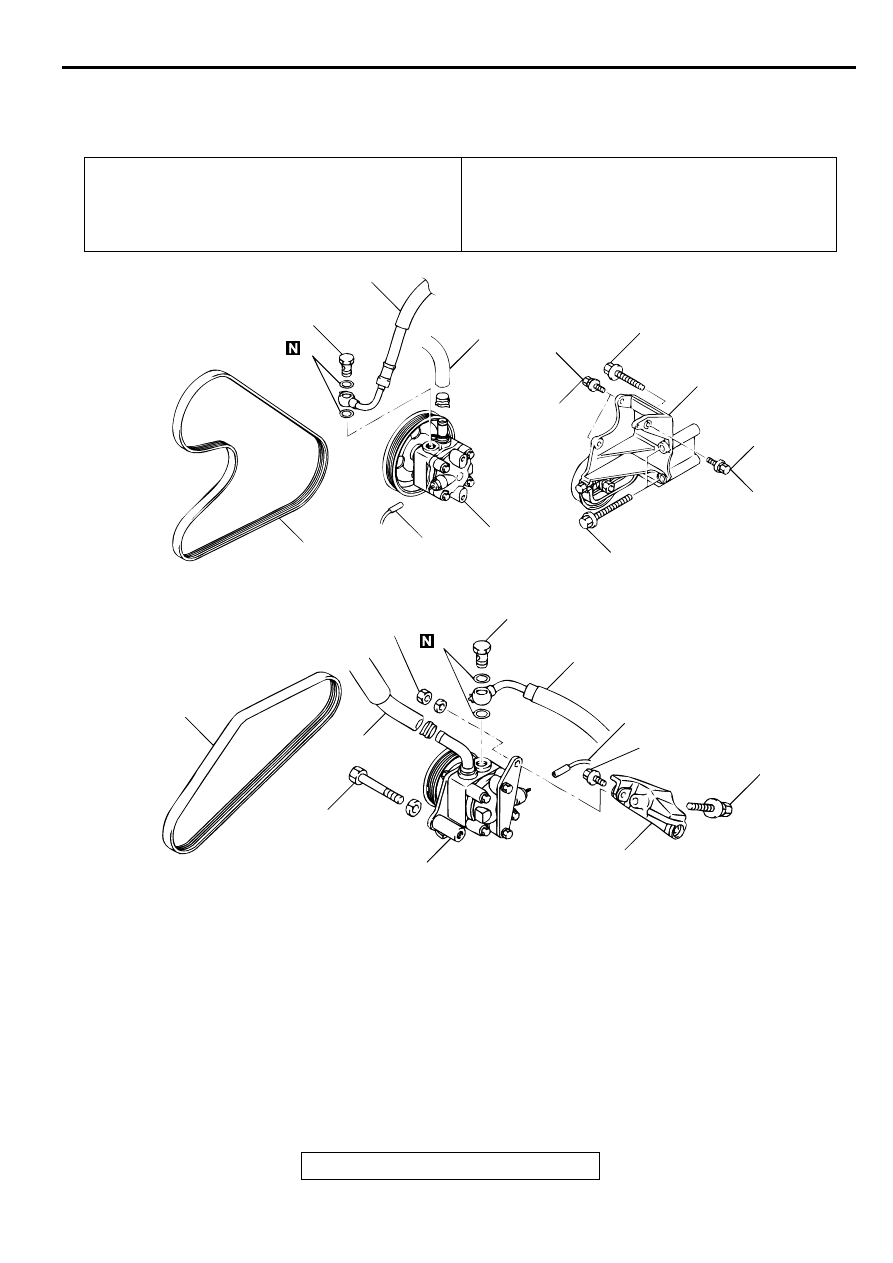

PO W ER STEER IN G O IL PU M P A SSEM BLY

REMOVAL AND INSTALLATION

M1372005200072

INSPECTION

M1372005300057

Check the drive belt for cracks.

Check the driveshaft assembly for uneven rotation.

Pre-removal Operation

•

Power Steering Fluid Draining (Refer to

Post-installation Operation

•

Power Steering Fluid Level Check (Refer to

.)

•

Drive Belt Tension Check (Refer to

.)

•

Power Steering Fluid Line Bleeding (Refer to

•

Oil Pump Pressure Test (Refer to

.)

AC001013

1

10

9

8

7

6

5

4

3

2

57 ± 7 N·m

42 ± 5 ft-lb

1

9

5

4

3

2

57 ± 7 N·m

42 ± 5 ft-lb

29 ± 3 N·m

21 ± 3 ft-lb

29 ± 3 N·m

21 ± 3 ft-lb

49 ± 10 N·m

36 ± 7 ft-lb

42 ± 7 N·m

31 ± 5 ft-lb

42 ± 7 N·m

31 ± 5 ft-lb

23 ± 4 N·m

17 ± 3 ft-lb

44 ± 10 N·m

33 ± 7 ft-lb

<2.4L ENGINE>

<3.0L ENGINE>

AB

49 ± 10 N·m

36 ± 7 ft-lb

REMOVAL STEPS

1.

DRIVE BELT

2.

PRESSURE SWITCH CONNECTOR

3.

SUCTION HOSE

4.

PRESSURE HOSE

5.

GASKET

6.

BOLT

7.

BOLT

8.

POWER STEERING PUMP

BRACKET

9.

OIL PUMP

10.

OIL PUMP BRACKET

REMOVAL STEPS (Continued)

POWER STEERING OIL PUMP ASSEMBLY

TSB Revision

POWER STEERING

37A-38

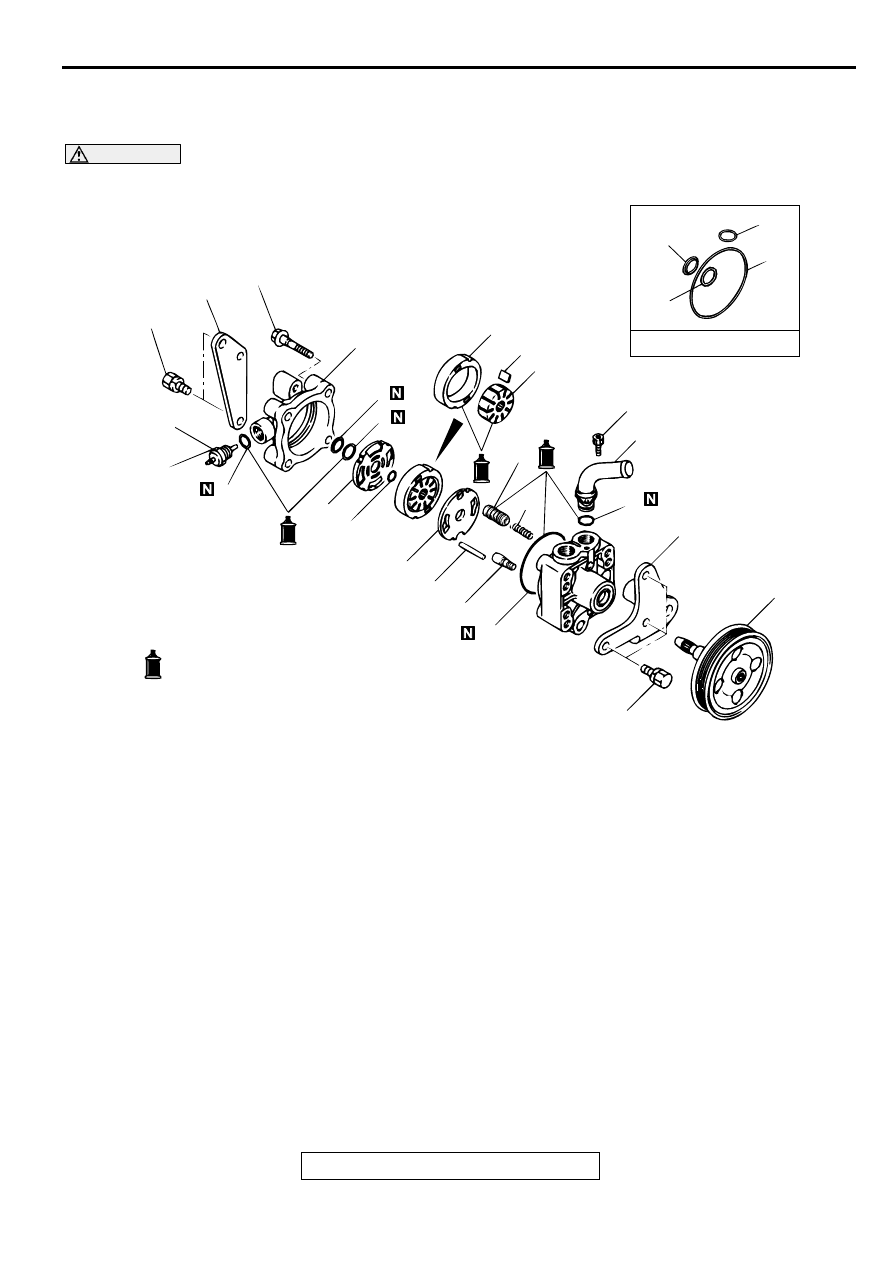

DISASSEMBLY AND ASSEMBLY

M1372005400087

CAUTION

Do not disassemble the pressure switch assembly and valve subassembly.

AC001014

OIL PUMP SEAL KIT

1

13

12

11

10

8

7

6

5

4

3

2

14

15

18

17

16

19

20

21

6

5

16

21

27 ± 2 N·m

21 ± 1 ft-lb

16 ± 2 N·m

12 ± 1 ft-lb

20 ± 3 N·m

15 ± 2 ft-lb

3.7 ± 0.3 N·m

33 ± 2 in-lb

16 ± 2 N·m

12 ± 1 ft-lb

AD

9

: MITSUBISHI POWER STEERING FLUID

DISASSEMBLY STEPS

1.

PRESSURE SWITCH ASSEMBLY

2.

O-RING

3.

REAR BRACKET <3.0L ENGINE>

4.

REAR COVER

5.

BACKUP RING

>>A<<

6.

O-RING

7.

SIDE PLATE (REAR)

8.

SNAP RING

9.

DRIVESHAFT ASSEMBLY

10.

FRONT BRACKET <3.0L ENGINE>

>>D<<

11.

VANE

>>C<<

12.

CAM RING

>>B<<

13.

ROTOR

14.

SIDE PLATE (FRONT)

15.

LOCK PIN

16.

O-RING

17.

VALVE SUBASSEMBLY

18.

SPOOL ASSEMBLY

19.

SPRING

20.

SUCTION PIPE

>>A<<

21.

O-RING

DISASSEMBLY STEPS (Continued)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст