Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 13

MAINTENANCE SERVICE

TSB Revision

GENERAL <BODY AND CHASSIS>

00-49

12. MANUAL TRANSMISSION OIL

M1001002800074

Check oil level

Inspect each component for evidence of leakage, and check

the oil level by removing the filler plug. If the oil is

contaminated, replace with new oil.

1. Remove the filler plug.

2. Check that the oil is not noticeably dirty, and that it has a

suitable viscosity.

3. Tighten the filler plug to the specified torque.

Tightening torque: 32

±

2 N

⋅

m (24

±

1 ft-lb)

Change oil

1. Remove the filler plug.

2. Remove the drain plug and drain the oil.

3. Tighten the drain plug to the specified torque.

Tightening torque: 32

±

2 N

⋅

m (24

±

1 ft-lb)

4. Fill with Hypoid gear oil SAE 75W-90 or 75W-85W

conforming to API classification GL-4 until the level comes

to the lower portion of filler plug hole.

Quantity:

<2.4L Engine> 2.2 dm

3

(2.3 quarts)

<3.0L Engine> 2.8 dm

3

(3.0 quarts)

5. Tighten the filler plug to the specified torque.

Tightening torque: 32

±

2 Nm (24

±

1 ft-lb)

13. AUTOMATIC TRANSMISSION FLUID

M1001002900093

Checking A/T fluid level

1. Drive the vehicle until the A/T fluid temperature rises to the

normal temperature [70

−

80

°

C (158

−

176

°

F)].

NOTE: The A/T fluid temperature is measured with MUT-II.

NOTE: If it takes some amount of time until the A/T fluid

reaches its normal operating temperature [70

−

80

°

C (158

−

176

°

F

)

], check the A/T fluid level by referring to the left

diagram.

2. Park the vehicle on a level surface.

3. Move the selector lever through all positions to fill the torque

converter and the hydraulic circuits with A/T fluid, and then

move the selector lever to the "N" position.

4. After wiping off any dirt around the dipstick, remove the

dipstick and check the condition of the A/T fluid.

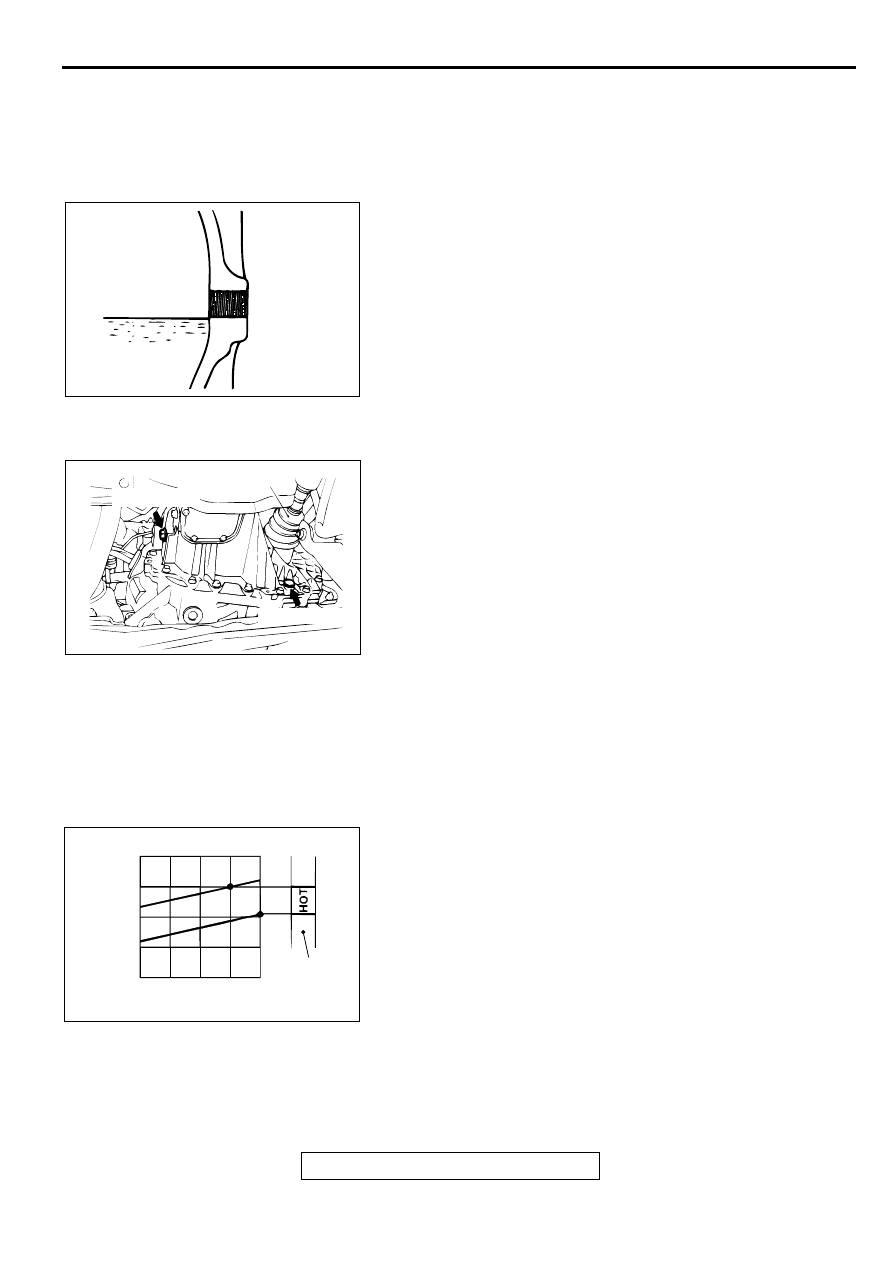

AC000094

TRANSMISSION

OIL

AB

AC000095AB

DRIVE SHAFT <LH>

FILLER PLUG

DRAIN PLUG

AC002477

80

DIPSTICK

60

40

(176)

(140)

(104)

FLUID TEMPERATURE [˚C (˚F)]

– 30 (– 1.2)

– 20 (– 0.8)

– 10 (– 0.4)

0 (0)

10 (0.4)

FLUID LEVEL [mm (in)]

AB

MAINTENANCE SERVICE

TSB Revision

GENERAL <BODY AND CHASSIS>

00-50

NOTE: If the fluid smells as if it is burnt, it means that the A/

T fluid has been contaminated by fine particles from the

bushings and friction materials, a transaxle overhaul and

flashing the cooler line flushing may be necessary.

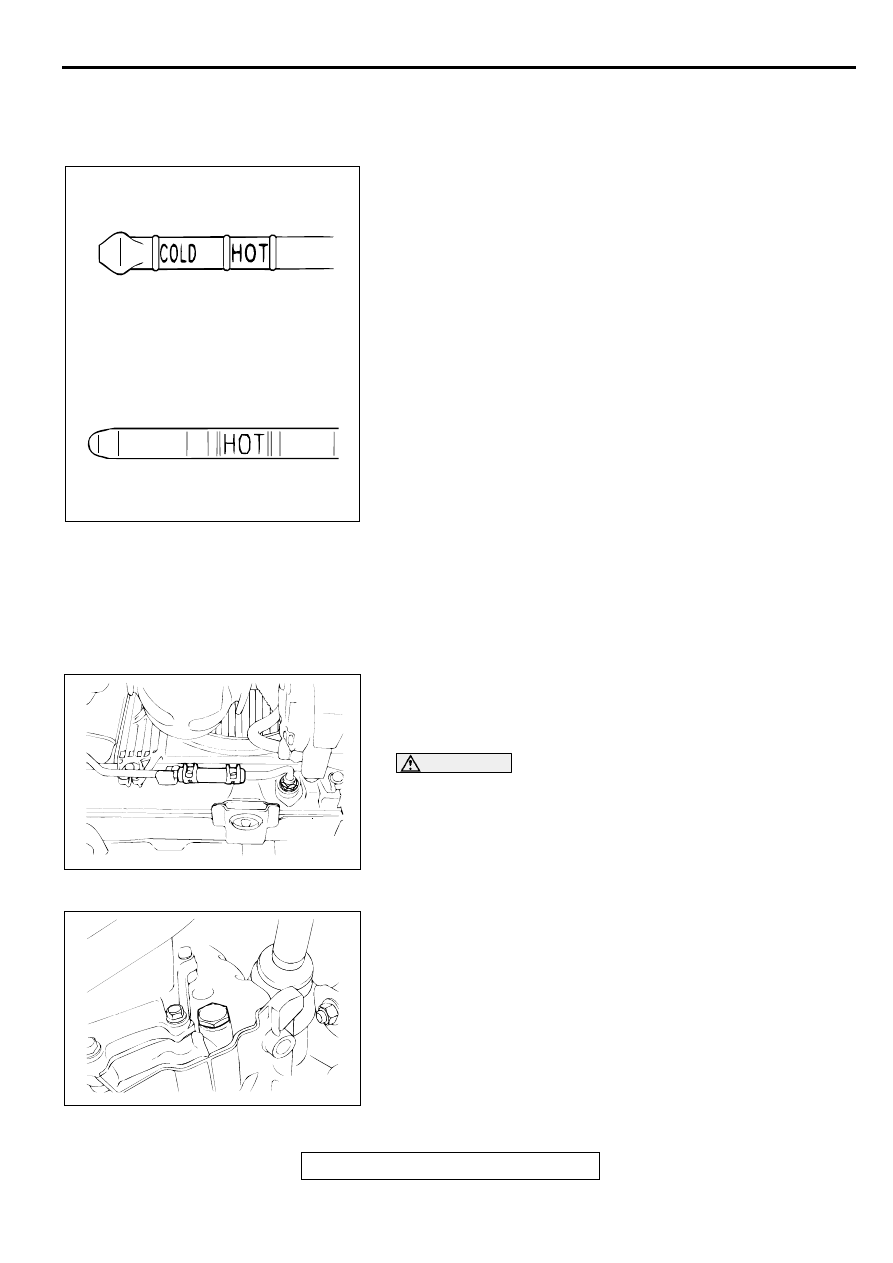

5. Check that the A/T fluid level is at the "HOT" mark on the

dipstick. If the A/T fluid level is lower than this, pour in more

DIAMOND ATF SP-II M or SP-III or equivalent until the level

reaches the "HOT" mark.

NOTE: If the A/T fluid level is too low, the oil pump will draw

in air along with the A/T fluid, which will cause bubbles to

form. This will in turn cause the hydraulic pressure to drop,

which will result in late shifting and slipping of the clutches

and brakes.

In either case, air bubbles can interfere with normal valve,

clutch, and brake operation. Foaming can cause A/T fluid to

escape from the transaxle vent, in which case it may be

mistaken for a leak.

6. Securely insert the dipstick.

NOTE: The A/T fluid should always be replaced when:

.

•

When trouble shooting the transaxle

•

When overhauling the transaxle

•

When the oil is noticeably dirty or burnt (vehicle was

driven under severe conditions)

Change A/T fluid

If you have a A/T fluid changer, use this changer to replace the

A/T fluid. If you do not have a A/T fluid changer, replace the A/T

fluid by the following procedure.

1. Disconnect the hose shown in the illustration which

connects the transaxle and the oil cooler (inside the

radiator). Place a container under the hose to collect the

discharge.

CAUTION

The engine should be stopped within one minute after it is

started. If the A/T fluid has all drained out before then, the

engine should be stopped at that point. Discharge volume:

Approximately 3.5 dm

3

(3.7 quarts)

2. Start the engine and let the A/T fluid drain out.

Running conditions: "N" range with engine idling

3. Remove the drain plug from the bottom of the transaxle case

to drain the A/T fluid.

Discharge volume: Approximately 2.0 dm

3

(2.1 quarts)

4. Install the drain plug with a new gasket, and tighten it to the

specified torque.

Tightening torque: 32

±

2 N

⋅

m (24

±

1 ft-lb)

5. Pour new AT fluid in through the oil filler tube.

Adding volume: Approximately 5.5 dm

3

(5.8 quarts)

AC000098

<2.4L ENGINE>

<3.0L ENGINE>

AB

AC000099

AC000100

MAINTENANCE SERVICE

TSB Revision

GENERAL <BODY AND CHASSIS>

00-51

CAUTION

Stop pouring if the full volume of A/T fluid cannot be

poured in.

6. Repeat the procedure in Step 2. (to pump out the rest of the

contaminated A/T fluid)

7. Pour the new A/T fluid in through the oil filler tube.

NOTE: Check the A/T fluid for contamination or burnt smell.

If A/T fluid is still contaminated or burnt, repeat Steps 6 and

7 before proceeding to Step 8.

8. Reconnect the hose which was disconnected in step 1

above, and firmly replace the dipstick.

9. Start the engine and run it at idle for 1

−

2 minutes.

10. Move the selector lever through all positions, and then

move it to the "N" position.

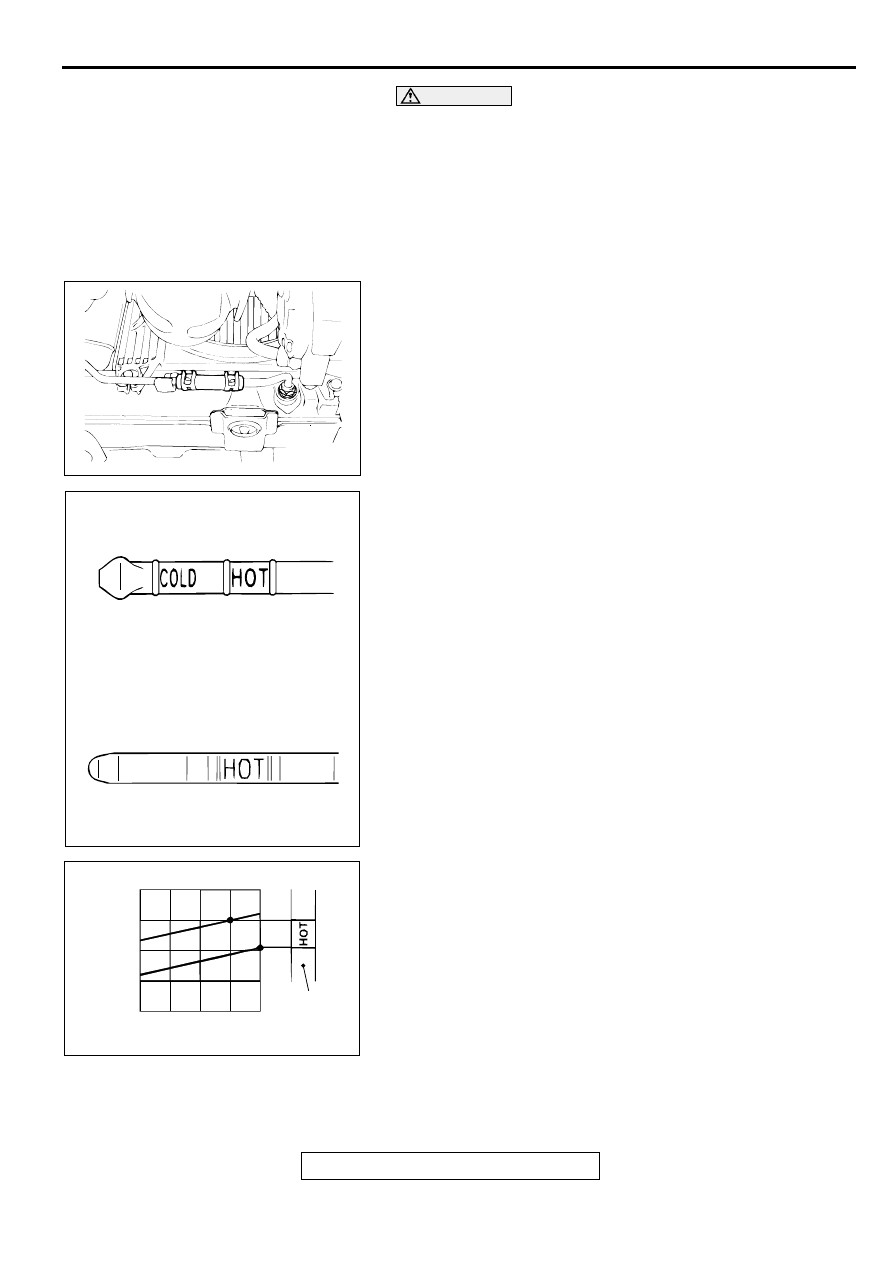

11.Check that the A/T fluid level is at the "COLD" mark on the

dipstick. If the level is lower than this, pour in more A/T fluid.

12.Drive the vehicle until the A/T fluid temperature rises to the

normal temperature [70

−

80

°

C (158

−

176

°

F)], and then

check the A/T fluid level again. If it takes some amount of

time until the A/T fluid reaches its normal operating

temperature [70

−

80

°

C (158

−

176

°

F)], check the A/T fluid

level by referring to the diagram at left. The A/T fluid level

must be at the "HOT" mark.

NOTE: The A/T fluid temperature is measured with scan tool

(MUT-II). The "COLD" level is for reference only; the "HOT"

level should be regarded as the standard level.

NOTE: If it takes some amount of time until the A/T fluid

reaches its normal operating temperature [70

−

80

°

C

(158 -

176

°

F

)

], check the A/T fluid level by referring to the left

diagram.

13. Firmly insert the dipstick into the oil filler tube.

AC000101

AC000098

<2.4L ENGINE>

<3.0L ENGINE>

AB

AC002477

80

DIPSTICK

60

40

(176)

(140)

(104)

FLUID TEMPERATURE [˚C (˚F)]

– 30 (– 1.2)

– 20 (– 0.8)

– 10 (– 0.4)

0 (0)

10 (0.4)

FLUID LEVEL [mm (in)]

AB

MAINTENANCE SERVICE

TSB Revision

GENERAL <BODY AND CHASSIS>

00-52

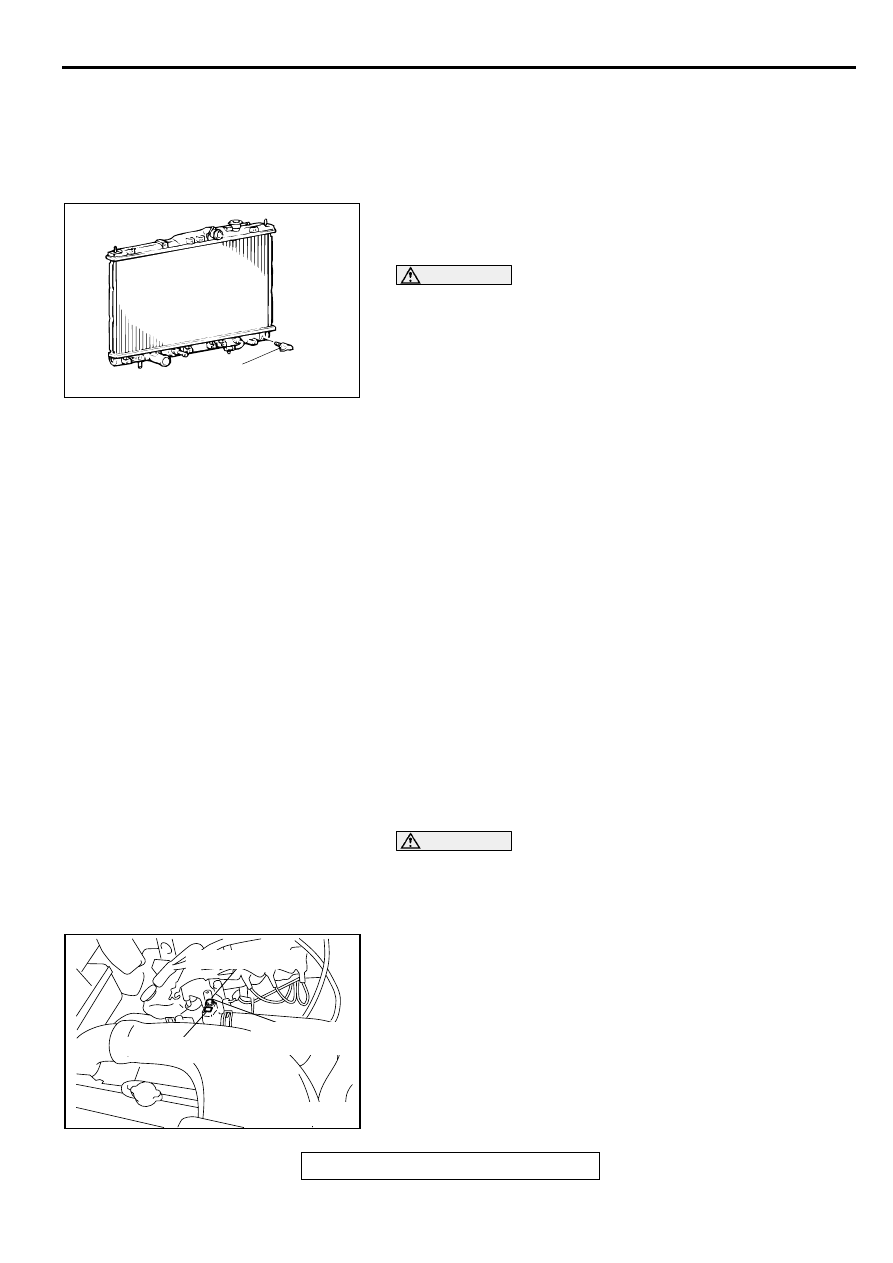

14. ENGINE COOLANT (CHANGE)

M1001003100090

Check the cooling system parts such as the radiator, heater

and oil cooler hoses, thermostat and the connections for

leakage and damage.

Changing Coolant

1. Set the temperature control knob to the "HOT" position.

2. Let the engine operate until the engine coolant warms, and

then stop the engine.

CAUTION

When removing the radiator cap, use care to avoid contact

with hot coolant or steam. Place a shop towel over the cap

and turn the cap counterclockwise a little to let the

pressure escape through the vinyl tube. After relieving the

steam pressure, remove the cap by slowly turning it

counterclockwise.

3. Remove the radiator cap, radiator drain plug and engine

drain plug to drain the coolant.

4. Remove the reserve tank and drain the coolant.

5. After completely draining the coolant, reinstall the drain

plugs and flush the engine and radiator using a radiator

cleaning fluid.

6. After the flushing is completed, completely drain the

cleaning fluid and install the radiator and engine drain plugs.

7. By referring to the section on coolant, select an appropriate

concentration for safe operation for safe operating

temperature within the range of 30 to 60%. Refill the coolant

at the selected concentration. A convenient mixture is a 50%

water and 50% antifreeze solution [freezing point:

−

31

°

C (

−

32.8

°

F)].

Recommended antifreeze:

MITSUBISI GENUINE Part NO.MD970389 or equivalent

Quantity:

<2.4L Engine> 7.0 dm

3

(7.4 quarts)

<3.0L Engine> 8.0 dm

3

(8.5 quarts)

CAUTION

Do not use alcohol or methanol anti-freeze or any engine

coolants mixed with alcohol or methanol anti-freeze. The

use of an improper anti-freeze can cause the corrosion of

the aluminum components.

8. Reinstall the radiator cap.

9. Start the engine and let it warm up until the thermostat

opens.

10.After repeatedly revving the engine up to 3,000 r/min

several times, then stop the engine.

11.Remove the radiator cap after the engine has become cold,

and pour in coolant up to the brim. Reinstall the cap.

AC000106

DRAIN

PLUG

AB

ACX01422 AB

CAUTION LABEL

AIR BLEED BOLT

14 ±1 N·m

120 ± 13 in-lb

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст