Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 189

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-455

8478

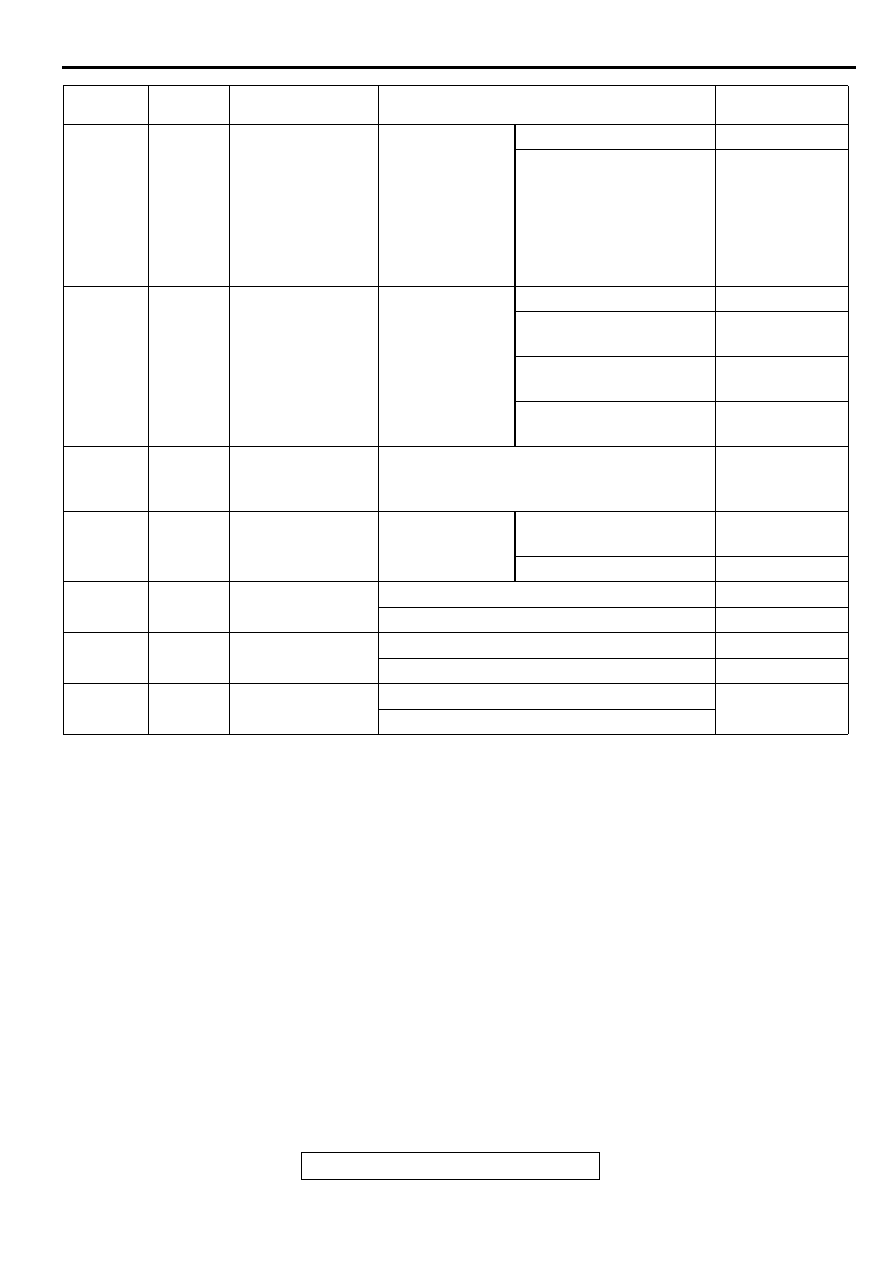

Throttle position

sensor

Ignition switch:

"ON" (check for

smooth voltage

increase as

throttle is moved

from idle position

to wide open

throttle)

Idle

0.535

−

0.735 V

Wide open throttle

4.5

−

5.5 V

85

55

Barometric

pressure sensor

Ignition switch:

"ON"

When altitude is 0 m (0 ft) 3.7

−

4.3 V

When altitude is 600 m

(1,969 ft)

3.4

−

4.0 V

When altitude is 1,200 m

(3,937 ft)

3.2

−

3.8 V

When altitude is 1,800 m

(5,906 ft)

2.9

−

3.5 V

86

80

Vehicle speed

sensor

•

Ignition switch: "ON"

•

Move the vehicle slowly forward

0

⇔

8 -12 V

(changes

repeatedly)

87

79

Idle position signal Ignition switch:

"ON"

Set throttle valve to idle

position

0

−

1 V

Open throttle slightly

4 V or more

88

56

Camshaft position

sensor

Engine: cranking

0.4

−

3.0 V

Engine: idling

1.5

−

3.0 V

89

45

Crankshaft

position sensor

Engine: cranking

0.4

−

4.0 V

Engine: idling

1.5

−

2.5 V

90

65

Volume air flow

sensor

Engine: idling

2.2

−

3.2 V

Engine: 2,500 r/min

TERMINAL

NO. <M/T>

TERMINAL

NO. <A/T>

INSPECTION ITEM

INSPECTION CONDITION (ENGINE CONDITION)

NORMAL

CONDITION

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-456

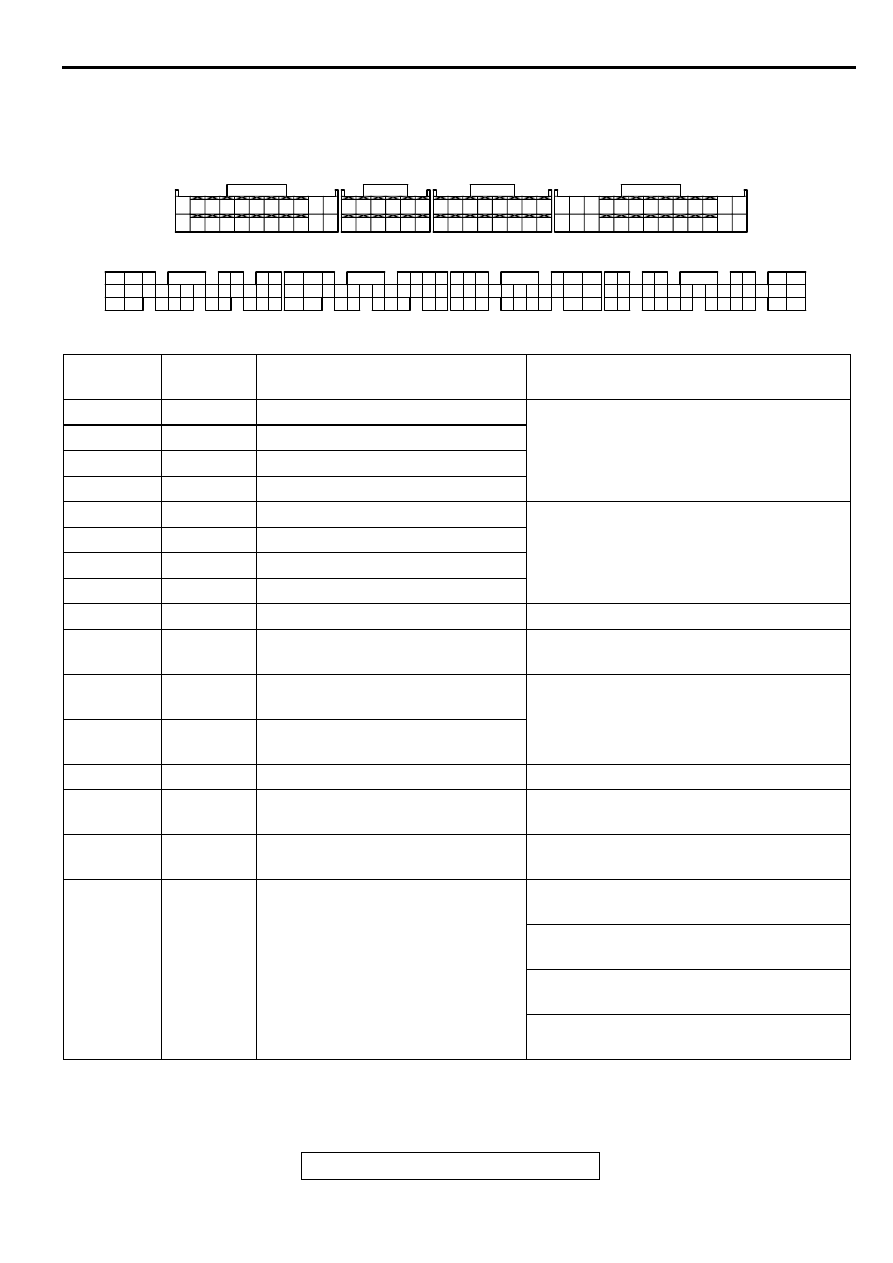

TERMINAL RESISTANCE AND CONTINUITY CHECK

AK000058

ECM <M/T> or PCM <A/T> Connector Terminal Arrangement

AB

<M/T>

<A/T>

13 12 11 10

9

8

7

6

5

4

3

2

1

26 25 24 23 22 21 20 19

38 37 36

35 34

33 32 31

35 34 33 32 31

46 45 44 43 42 41

56 55 54 53 52 51

62 61 60 59 58

75 74 73 72 71

80

81

79 78 77 76

86 85 84 83 82

91

92

90 89 88 87

57

40 39

18 17 16 15 14

13 12 11 10

9

8

7

6

5

4

3

2

1

26

27

28

29

30

25

24

23

58

59

60

61

62

63

64

65

66

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

90

91

92

93

94

95

96

97

98

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

101

102

103

104

105

106

107

108

121

122

123

124

125

126

127

128

129

130

109

110

111

112

113

114

115

116

117

118

119

120

22 21 20 19 18 17 16

14

15

TERMINAL

NO.

TERMINAL

NO.

INSPECTION ITEM

NORMAL CONDITION (INSPECTION

CONDITION)

1

−

12

1

−

41

No.1 injector

13

−

16

Ω

[at 20

°

C (68

°

F)]

14

−

12

9

−

41

No.2 injector

2

−

12

24

−

41

No.3 injector

15

−

12

2

−

41

No.4 injector

4

−

12

14

−

41

Stepper motor coil (A1)

28

−

33

Ω

[at 20

°

C (68

°

F)]

17

−

12

28

−

41

Stepper motor coil (A2)

5

−

12

15

−

41

Stepper motor coil (B1)

18

−

12

29

−

41

Stepper motor coil (B2)

6

−

12

6

−

41

EGR solenoid

29

−

35

Ω

[at 20

°

C (68

°

F)]

9

−

12

34

−

41

Evaporative emission purge

solenoid

30

−

34

Ω

[at 20

°

C (68

°

F)]

13

−

Body

ground

42

−

Body

ground

ECM or PCM ground

Continuity (0

Ω

)

26

−

Body

ground

48

−

Body

ground

ECM or PCM ground

54

−

12

26

−

41

Heated oxygen sensor heater (rear) 11

−

18

Ω

[at 20

°

C (68

°

F)]

55

−

12

35

−

41

Evaporative emission ventilation

solenoid

17

−

21

Ω

[at 20

°

C (68

°

F)]

60

−

12

3

−

41

Heated oxygen sensor heater

(front)

4.5

−

8.0

Ω

[at 20

°

C (68

°

F)]

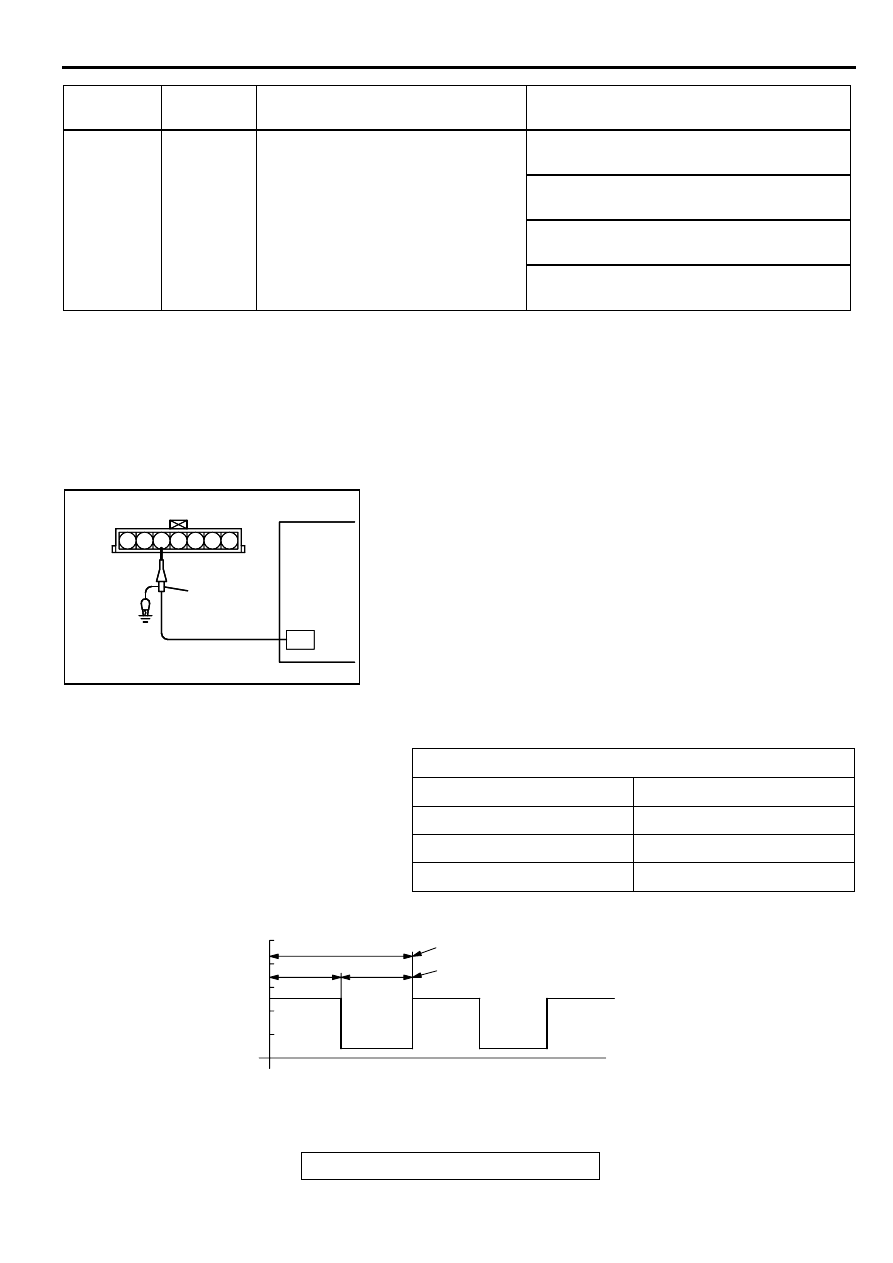

72

−

92

57

−

64Intake air temperature sensor

5.3

−

6.7 k

Ω

[when intake air temperature

is 0

°

C (32

°

F)]

2.3

−

3.0 k

Ω

[when intake air temperature

is 20

°

C (68

°

F)]

1.0

−

1.5 k

Ω

[when intake air temperature

is 40

°

C (104

°

F)]

0.30

−

0.42 k

Ω

[when intake air

temperature is 80

°

C (176

°

F)]

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-457

INSPECTION PROCEDURE USING AN

OSCILLOSCOPE

M1131009300166

VOLUME AIR FLOW SENSOR

Required Special Tool:

MB991709: Test Harness

Measurement Method

1. Disconnect the volume air flow sensor connector, and

connect the test harness special tool (MB991709) in

between. (All terminals should be connected.)

2. Connect the oscilloscope probe to volume air flow sensor

connector terminal 3.

Alternate method (Test harness not available)

<M/T>

1. Connect the oscilloscope probe to ECM terminal 61.

<A/T>

1. Connect the oscilloscope probe to PCM terminal 65.

Standard Wave Pattern

83

−

92

44

−

57

Engine coolant temperature sensor 5.1

−

6.5 k

Ω

[when engine coolant

temperature is 0

°

C (32

°

F)]

2.1

−

2.7 k

Ω

[when engine coolant

temperature is 20

°

C (68

°

F)]

0.9

−

1.3 k

Ω

[when engine coolant

temperature is 40

°

C (104

°

F)]

0.26

−

0.36 k

Ω

[when engine coolant

temperature is 80

°

C (176

°

F)]

TERMINAL

NO.

TERMINAL

NO.

INSPECTION ITEM

NORMAL CONDITION (INSPECTION

CONDITION)

Observation conditions

Function

Special pattern

Pattern height

Low

Pattern selector

Display

Engine r/min

Idle speed

AKX01594

OSCILLOSCOPE

OSCILLOSCOPE

PLOBE

4 5 6

1 2 3

7

AKX01594AB

AKX01595

THE TIME (CYCLE TIME) T IS REDUCED WHEN THE

AMOUNT OF INTAKE AIR INCREASES.

TIMES T

1

AND T

2

ARE EQUAL

T

T

1

T

2

10

0

(V)

TIME

AB

Standard wave pattern

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-458

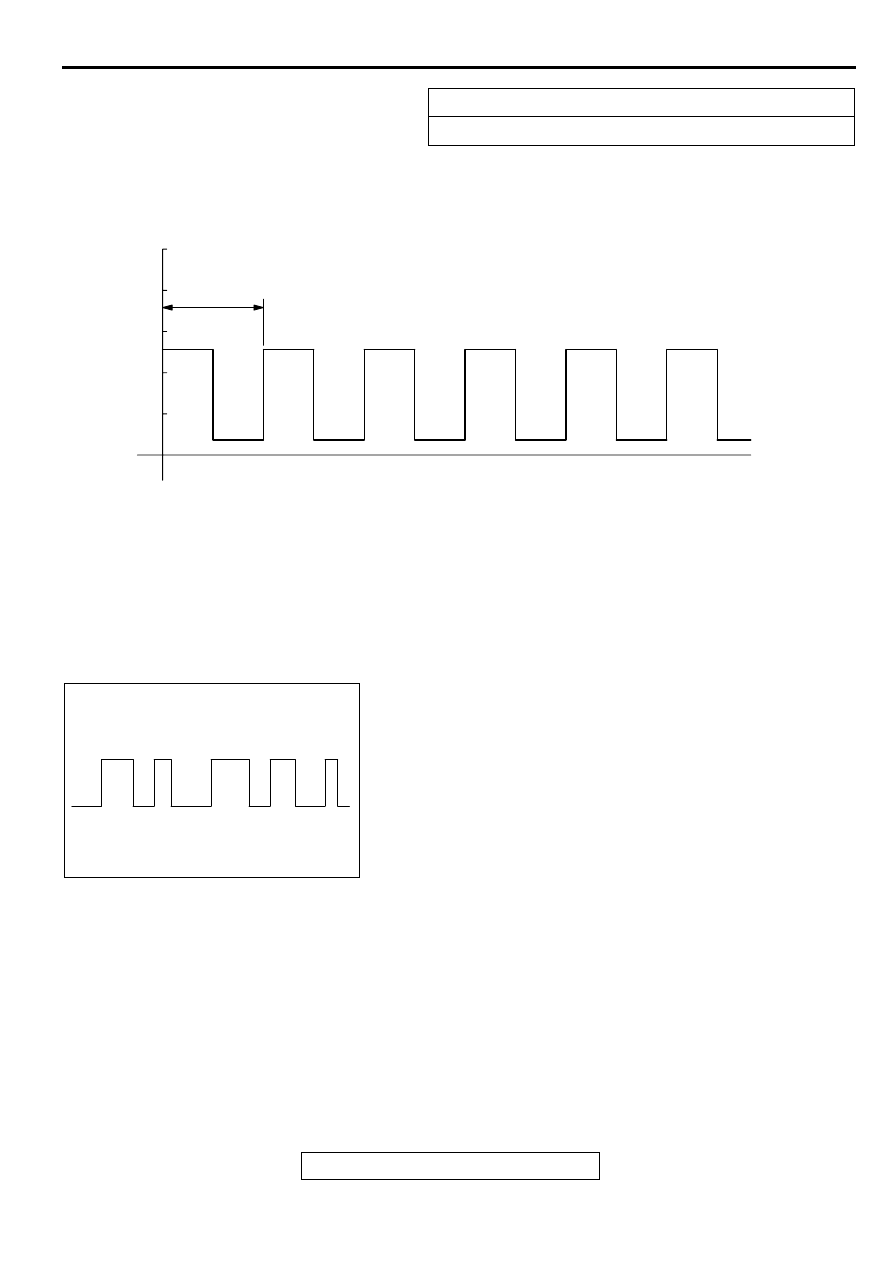

Wave Pattern Observation Points

1. Check that cycle time T becomes shorter and the frequency

increases when the engine speed is increased.

Examples of Abnormal Wave Patterns

Example 1

•

Cause of problem

Sensor interface malfunction.

•

Wave pattern characteristics

Rectangular wave pattern is output even when the engine is

not started.

Example 2

•

Cause of problem

Damaged rectifier or vortex generation column.

•

Wave pattern characteristics

Unstable wave pattern with non-uniform frequency. An

ignition leak will distort the wave pattern temporarily, even if

the volume air flow sensor is normal.

Observation conditions

Rev engine, observe T1 and T2 remain equal.

AKX01596

10

0

(V)

T

TIME

AB

Standard wave pattern

AKX01597

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст