Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 603

POWER STEERING DIAGNOSIS

TSB Revision

POWER STEERING

37A-7

INSPECTION PROCEDURE 5: Squealing Noise

DIAGNOSIS

STEP 1. Check the belt tension.

Refer to GROUP 00, Maintenance Service

−

Drive

Belts

.

Q: Is the belt tension incorrect?

YES :

Adjust the belt tension. (Refer to GROUP

00, Maintenance Service

−

Drive Belts

NO :

Go to Step 2.

STEP 2. Check for seizure in the oil pump.

Q: Is there seizure?

YES :

Replace the part. Then go to Step 3.

NO :

Go to Step 3.

STEP 3. Check symptoms.

Confirm that no noise is generated.

Q: Is there noise?

YES :

Repeat from Step 1.

NO :

Diagnosis is complete.

INSPECTION PROCEDURE 6: Hissing Noise

DIAGNOSIS

STEP 1. Check for entry of air.

Q: Has air entered?

YES :

Bleed the air (Refer to

.). Then go

to Step 4.

NO :

Go to Step 2.

STEP 2. Check each hose for crushing or

twisting.

Q: Is there fault?

YES :

Repair or replace the hose. Then go to Step

NO :

Go to Step 3.

STEP 3. Check the steering gear box for damage.

Q: Is there damage?

YES :

Repair or replace the part. Then go to Step

NO :

Go to Step 4.

STEP 4. Check symptoms.

Confirm that no noise is generated.

Q: Is there noise?

YES :

Repeat from Step 1.

NO :

Diagnosis is complete.

INSPECTION PROCEDURE 7: Droning Noise

DIAGNOSIS

STEP 1. Check the oil pump or oil pump bracket

installation.

Q: Is the oil pump or oil pump bracket installation

correct?

YES :

Go to Step 2.

NO :

Repair it. Then go to Step 3.

STEP 2. Check the oil pump for damage.

If a slight "beat noise" is produced by the oil pump

when the steering wheel is turned fully and held in

that position, this is not a malfunction.

Q: Is there damage?

YES :

Replace the oil pump. Then go to Step 3.

NO :

Go to Step 3.

STEP 3. Check symptoms.

Confirm that no noise is generated.

Q: Is there noise?

YES :

Repeat from Step 1.

NO :

Diagnosis is complete.

POWER STEERING DIAGNOSIS

TSB Revision

POWER STEERING

37A-8

INSPECTION PROCEDURE 8: Squeaking Noise

DIAGNOSIS

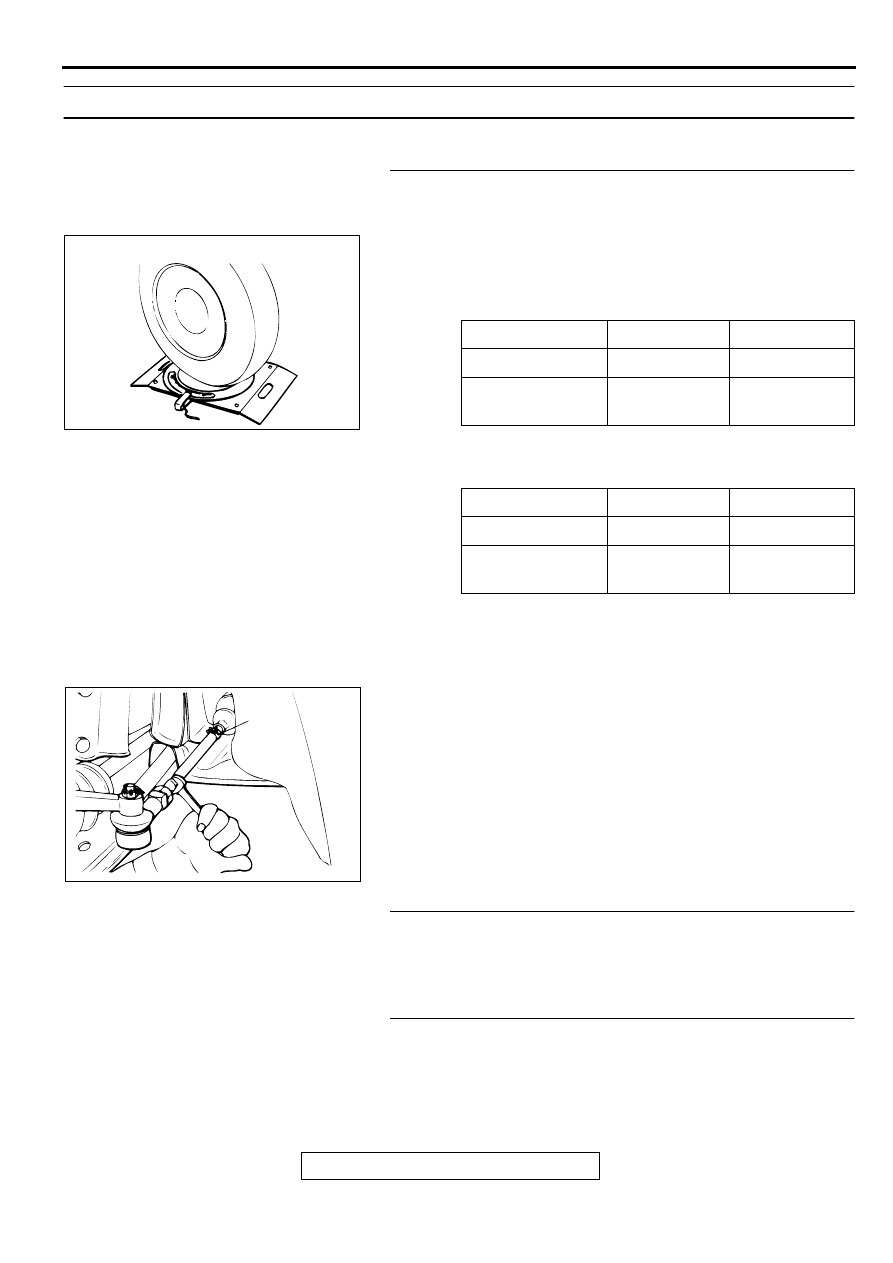

STEP 1. Check for interference of the wheel and vehicle

body.

If interfering, adjust the steering angle.

(1) Place the front wheel on a turning radius gauge and

measure the steering angle.

Standard value:

<ECLIPSE>

<ECLIPSE SPYDER>

(2) If the steering angle is not within the standard value, adjust

the toe-in.

Standard value: 0

±

3 mm (0

±

0.12 inch)

(3) Adjust the toe-in by undoing the clip and turning the left and

right tie rod turnbuckles by the same amount (in opposite

directions).

NOTE: The toe will move out as the left turnbuckle is turned

toward the front of the vehicle and the right turnbuckle is

turned toward the rear of the vehicle.

Q: Is the steering angle normal?

YES : Go to Step 2.

NO : Adjust the steering angle. Then go to Step 3.

STEP 2. Check the steering gear box for damage.

Q: Is there damage?

YES : Repair or replace the part. Then go to Step 3.

NO : Go to Step 3.

STEP 3. Check symptoms.

Confirm that no noise is generated.

Q: Is there noise?

YES : Repeat from Step 1.

NO : Diagnosis is complete.

ITEMS

2.4L ENGINE

3.0L ENGINE

Inside wheel

36

°

12'

±

2

°

00'

31

°

00'

±

2

°

00'

Outside wheel

(reference)

30

°

24'

27

°

00'

ITEMS

2.4L ENGINE

3.0L ENGINE

Inside wheel

36

°

12'

±

2

°

00'

33

°

60'

±

2

°

00'

Outside wheel

(reference)

30

°

24'

28

°

30'

AC000756AB

AC001078 AB

CLIP

POWER STEERING DIAGNOSIS

TSB Revision

POWER STEERING

37A-9

INSPECTION PROCEDURE 9: Vibration

NOTE: A slight vibration may be felt when the stationary steering effort is made due to the condition of the

road surface. To check whether the vibration actually exists or not, test-drive the vehicle on a dry concrete or

asphalt surface. Moreover, a very slight amount of vibration is not a malfunction.

DIAGNOSIS

STEP 1. Check for entry of air.

Q: Has air entered?

YES :

Bleed the air (Refer to

.). Then go

to Step 3.

NO :

Go to Step 2.

STEP 2. Check the steering gear box for damage.

Q: Is there damage?

YES :

Repair or replace the part. Then go to Step

NO :

Go to Step 3.

STEP 3. Check symptoms.

Confirm that no noise is generated.

Q: Is there noise?

YES :

Repeat from Step 1.

NO :

Diagnosis is complete.

INSPECTION PROCEDURE 10: Oil Leakage from Hose Connection

DIAGNOSIS

STEP 1. Check for loosening of the flare nut.

Q: Is the flare nut loose?

YES :

Tighten it to 15

±

3 N

⋅

m (11

±

2 ft-lb). Then

go to Step 3.

NO :

Go to Step 2.

STEP 2. Check the insertion of the hose and the

clamp installation state.

Q: Are they correct?

YES :

Go to Step 3.

NO :

Repair or replace the part. Then go to Step

3.

STEP 3. Check symptoms.

Check that no oil is leaking.

Q: Is there oil leakage?

YES :

Repeat from Step 1.

NO :

Diagnosis is complete.

INSPECTION PROCEDURE 11: Oil Leakage from Hose Assembly

DIAGNOSIS

STEP 1. Check the hose for damage or clogging.

Q: Is the hose damaged or clogged?

YES :

Repair or replace it. Then go to Step 2.

NO :

Go to Step 2.

STEP 2. Check symptoms.

Check that no oil is leaking.

Q: Is there oil leakage?

YES :

Repeat from Step 1.

NO :

Diagnosis is complete.

POWER STEERING DIAGNOSIS

TSB Revision

POWER STEERING

37A-10

INSPECTION PROCEDURE 12: Oil Leakage from Oil Reservoir

DIAGNOSIS

STEP 1. Check the oil reservoir for damage.

Q: Is there damage?

YES :

Repair or replace it. Then go to Step 3.

NO :

Go to Step 2.

STEP 2. Check for overflowing.

Q: Is there overflowing?

YES :

Adjust fluid level. Then go to Step 3.

NO :

Go to Step 3.

STEP 3. Check symptoms.

Q: Is there oil leakage?

YES :

Repeat from to Step 1.

NO :

Diagnosis is complete.

INSPECTION PROCEDURE 13: Oil Leakage from Oil Pump

DIAGNOSIS

STEP 1. Check the oil pump body for damage.

Q: Is there damage?

YES :

Replace the part. Then go to Step 3.

NO :

Go to Step 2.

STEP 2. Check the O-ring or oil seal for damage.

Q: Is there damage?

YES :

Replace the part. Then go to Step 3.

NO :

Go to Step 3.

STEP 3. Check symptoms.

Check that no oil is leaking.

Q: Is there oil leakage?

YES :

Repeat from Step 1.

NO :

Diagnosis is complete.

INSPECTION PROCEDURE 14: Oil Leakage from Gear Box

DIAGNOSIS

STEP 1. Check the gear box housing for damage.

Q: Is there damage?

YES :

Replace the part. Then go to Step 3.

NO :

Go to Step 2.

STEP 2. Check the oil-ring or oil seal for damage.

Q: Is there damage?

YES :

Replace the part. Then go to Step 3.

NO :

Go to Step 3.

STEP 3. Check symptoms.

Check that no oil is leaking.

Q: Is there oil leakage?

YES :

Repeat from Step 1.

NO :

Diagnosis is complete.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст