Mitsubishi Eclipse / Eclipse Spyder (2000-2002). Service and repair manual — part 28

CYLINDER HEAD GASKET

TSB Revision

ENGINE MECHANICAL <2.4L ENGINE>

11A-29

REMOVAL SERVICE POINTS

<<A>> POWER STEERING OIL PUMP AND BRACKET

ASSEMBLY REMOVAL

Remove the power steering oil pump and bracket assembly

from the engine with the hose attached.

NOTE: Place the removed power steering oil pump in a place

where it will not be a hindrance when removing and installing

the cylinder head assembly, and secure it with a cord or wire.

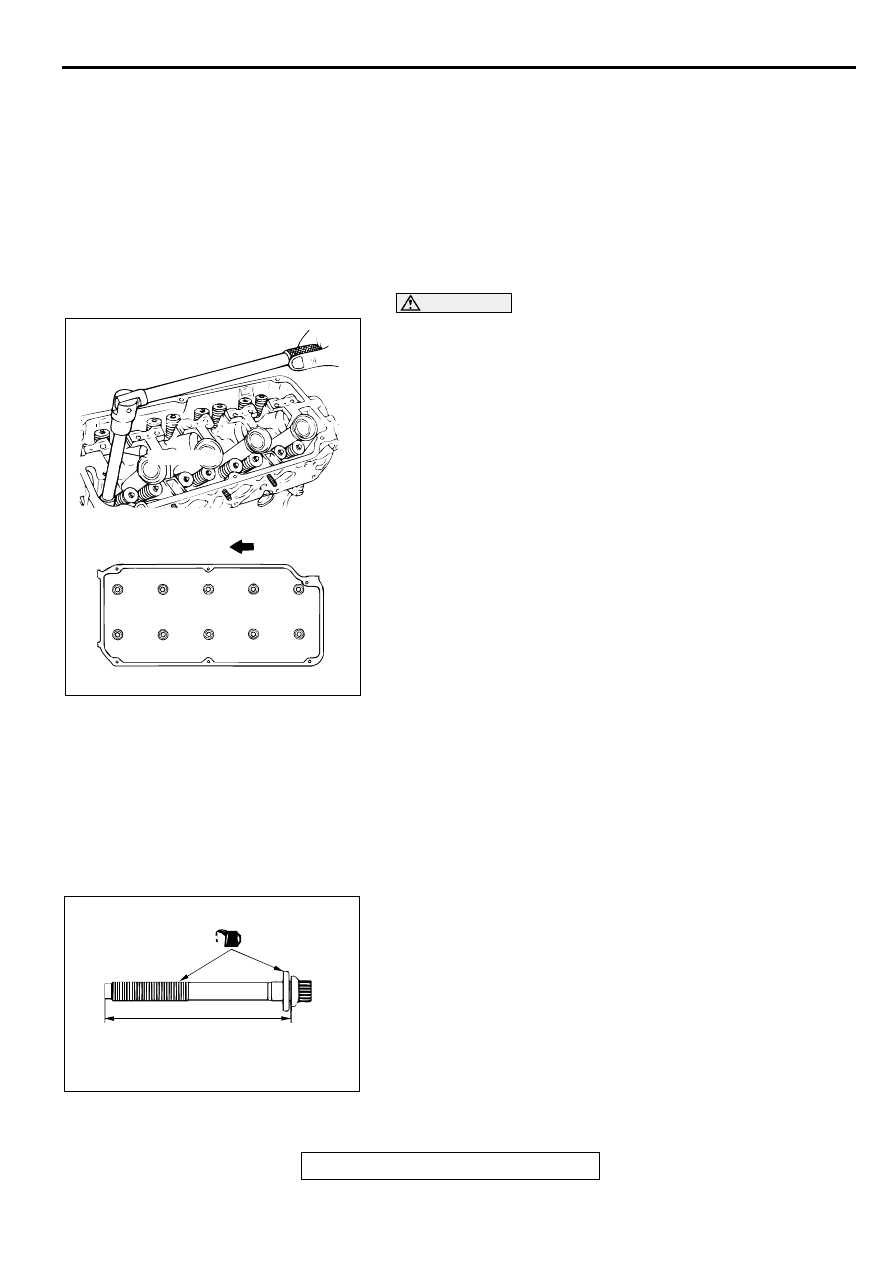

<<B>> CYLINDER HEAD ASSEMBLY REMOVAL

CAUTION

Be careful not to damage or deform the plug guides when

removing the cylinder head bolts. Plug guides cannot be

replaced separately.

Using special tool MB991654, loosen the bolts in two or three

steps in the order of the numbers shown in the illustration, then

remove the cylinder head assembly.

INSTALLATION SERVICE POINTS

>>A<< CYLINDER HEAD GASKET INSTALLATION

1. Wipe off all oil and grease from the gasket mounting

surface.

2. Match the shapes of the cylinder head holes with their

respective cylinder head gasket holes.

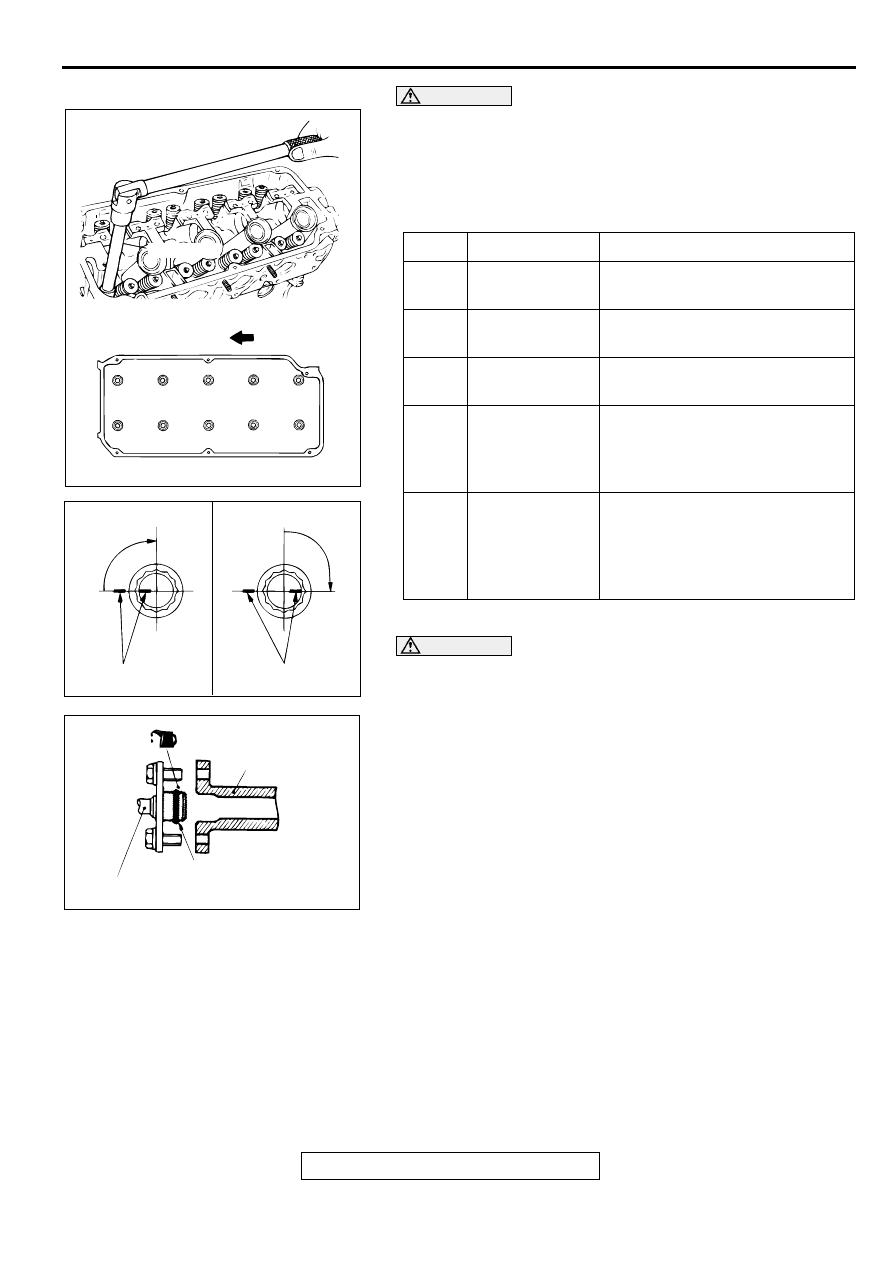

>>B<< CYLINDER HEAD ASSEMBLY INSTALLATION

1. When installing the cylinder head bolts, the length below the

head of the bolts should be within the limit.

If it is outside the limit, replace the bolts.

Limit (A): 99.4 mm (3.91 inches)

2. Apply a small amount of engine oil to the thread section and

the washer of the cylinder head bolt.

AC000142

INTAKE SIDE

EXHAUST SIDE

FRONT OF

ENGINE

AB

MB991654

1

2

3

5

10

8

7

9

6

4

AC000143

(ENGINE OIL)

AB

A

CYLINDER HEAD GASKET

TSB Revision

ENGINE MECHANICAL <2.4L ENGINE>

11A-30

CAUTION

•

Always tighten cylinder head bolts at a 90 degree angle.

If it is less than 90 degree angle, the bolt will loosen.

•

If it is more than 90 degree angle, remove the head bolt

and repeat the procedure from step 1.

3. Using special tool MB991654, tighten the bolts by the

following procedure.

>>C<< HIGH-PRESSURE FUEL HOSE INSTALLATION

CAUTION

Do not allow engine oil to enter the fuel rail.

1. Apply a small amount of new engine oil to the O-ring.

2. While turning the high-pressure fuel hose to the right and

left, install the fuel rail, while being careful not to damage the

O-ring. After installing, check that the hose turns smoothly.

3. If the hose does not turn smoothly, the O-ring is probably

being clamped. Disconnect the high-pressure fuel hose and

check the O-ring for damage.

4. Re-insert the fuel rail and confirm the hose turns smoothly.

STEP

OPERATION

REMARKS

(1)

Tighten to 79

±

4

N

⋅

m (58

±

3 ft-lb)

Tighten in the order shown in the

illustration.

(2)

Fully loosen.

Tighten in the reverse order of

that shown in the illustration.

(3)

Tighten to 20

±

2

N

⋅

m (15

±

1 ft-lb)

Tighten in the order shown in the

illustration.

(4)

Tighten 90

°

of a

turn.

Tighten in the order shown in the

illustration. Mark the head of the

cylinder head bolt and cylinder

head with a paint mark.

(5)

Tighten 90

°

of a

turn.

Tighten in the order shown in the

illustration. Check that the

painted mark of the head bolt is

aligned with that of the cylinder

head.

AC000142

INTAKE SIDE

EXHAUST SIDE

FRONT OF

ENGINE

AC

MB991654

10

9

8

6

1

3

4

2

5

7

AC000144

STEP (4)

STEP (5)

90˚

90˚

PAINTED MARKS

PAINTED MARKS

AB

AC000129 AB

FUEL RAIL

HIGH-PRESSURE

FUEL HOSE

O-RING

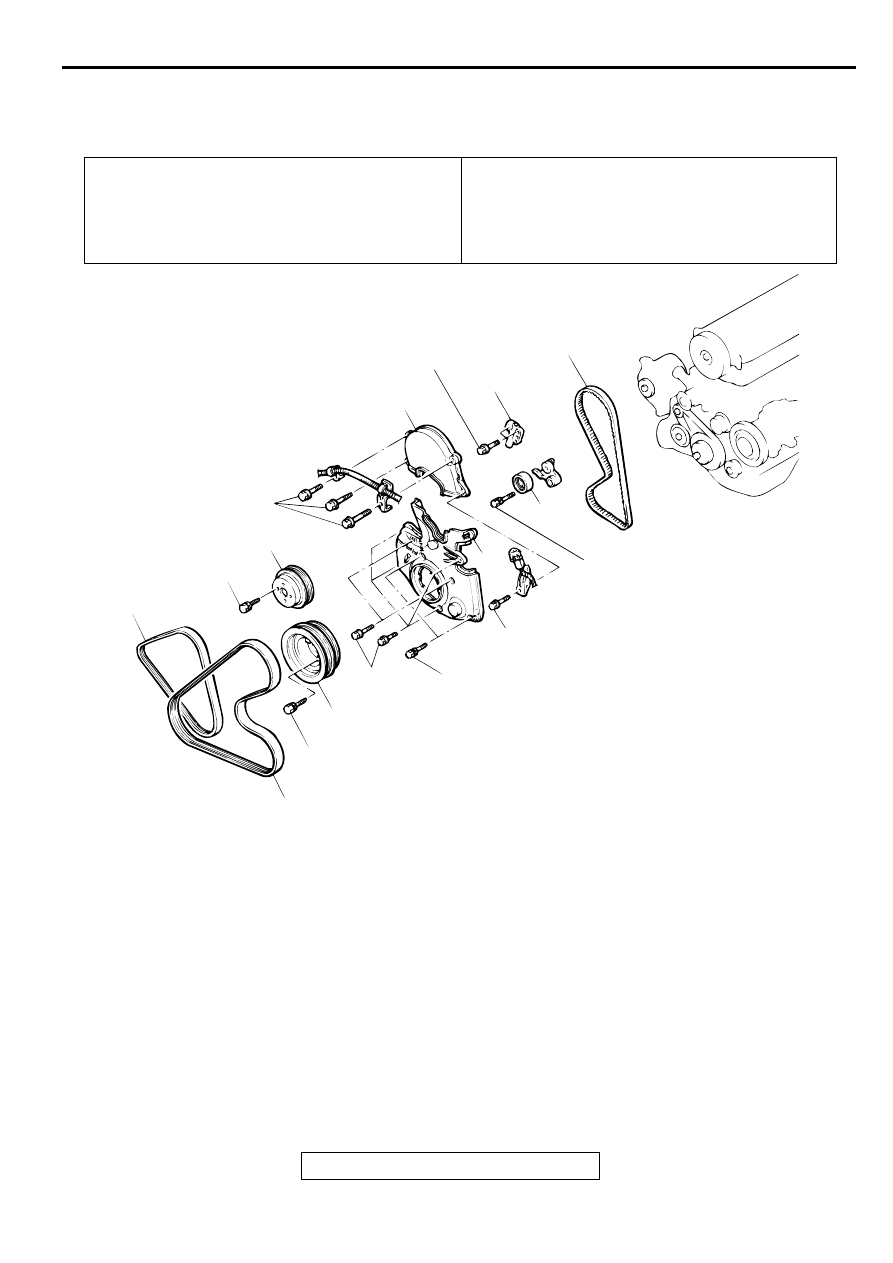

TIMING BELT

TSB Revision

ENGINE MECHANICAL <2.4L ENGINE>

11A-31

TIM IN G B ELT

REMOVAL AND INSTALLATION

M1112004300140

Required Special Tools:

•

MD998738: Adjusting Screw

•

MD998767: Tensioner Wrench

Pre-removal Operation

•

Engine Mount Bracket Removal (Refer to GROUP 32,

Engine Mounting

Post-installation Operation

•

Engine Mount Bracket Installation (Refer to GROUP 32,

Engine Mounting

•

Drive Belt Tension Adjustment [Refer to GROUP 00,

Maintenance Service

−

Drive Belts (Check Condition)

AC000145

23 ± 3 N·m

17 ± 3 ft-lb

48 ± 6 N·m

36 ± 4 ft-lb

25 ± 4 N·m

18 ± 4 ft-lb

11 ± 1 N·m

96 ± 8 in-lb

14 ± 1 N·m

117 ± 13 in-lb

8.8 ± 1.0 N·m

78 ± 9 in-lb

8.8 ± 1.0 N·m

78 ± 9 in-lb

11 ± 1 N·m

96 ± 8 in-lb

9

7

5

8

4

3

2

1

AB

6

REMOVAL STEPS

1.

DRIVE BELT (POWER STEERING

OIL PUMP AND A/C COMPRES-

SOR)

2.

DRIVE BELT (GENERATOR)

3.

WATER PUMP PULLEY

4.

CRANKSHAFT PULLEY

5.

TIMING BELT UPPER COVER AS-

SEMBLY

6.

TIMING BELT LOWER COVER

ASSEMBLY

>>C<<

•

TIMING BELT TENSION ADJUST-

MENT

<<A>>

>>B<<

7.

TIMING BELT

8.

TENSIONER PULLEY

>>A<<

9.

AUTO-TENSIONER

REMOVAL STEPS (Continued)

TIMING BELT

TSB Revision

ENGINE MECHANICAL <2.4L ENGINE>

11A-32

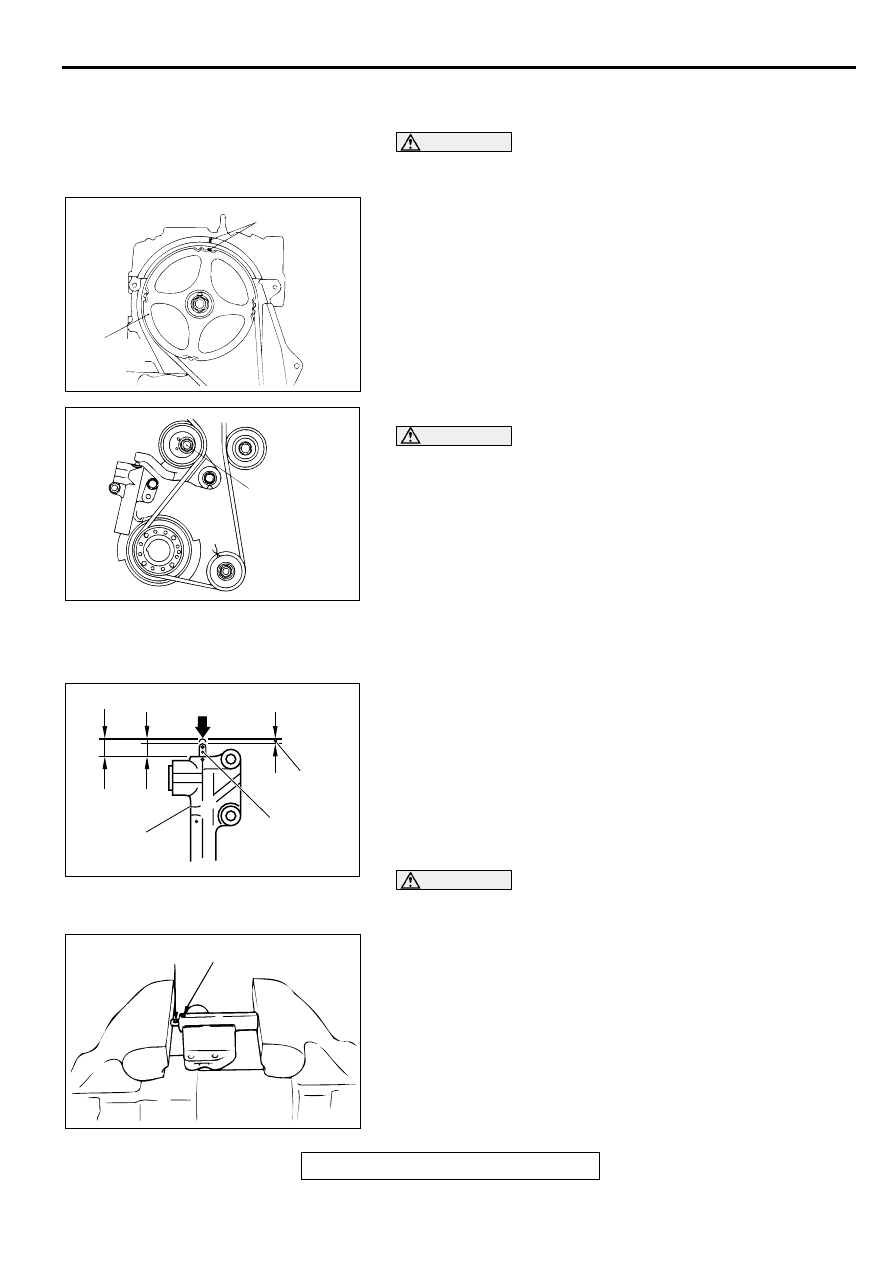

REMOVAL SERVICE POINT

<<A>> TIMING BELT REMOVAL

CAUTION

The crankshaft should always be turned in the forward

direction only.

1. Turn the crankshaft in the forward direction (to the right) to

align the camshaft sprocket timing marks.

2. Loosen the tension pulley fixing bolt.

CAUTION

If the timing belt is to be re-used, use chalk to mark (on its

flat side) an arrow indicating the clockwise direction.

3. Move the tension pulley to the water pump side, and then

remove the timing belt.

INSTALLATION SERVICE POINTS

>>A<< AUTO-TENSIONER INSTALLATION

1. Apply 98

−

196 N (22

−

44 pound) force to the pushrod of the

auto-tensioner by pressing it against a metal object (such as

the engine block) and measure the movement of the

pushrod.

Standard value: Within 1 mm (0.04 inch)

A: Length when it is free (not pressed)

B: Length when it is pressed

A

−

B: Movement

2. If it is outside the standard value, replace the auto-tensioner.

CAUTION

Never compress the pushrod too fast, or it may be

damaged.

3. Use a press or vise to gently compress the auto-tensioner

pushrod until pin hole A of the pushrod and pin hole B of the

tensioner cylinder are aligned.

AC000146AB

TIMING MARKS

CAMSHAFT

SPROKET

AC000147

FIXING BOLT

AB

ACX00306AC

A

B

AUTO-TENSIONER

AMOUNT

PUSHED IN

PUSHROD

98 – 196 N

(22 – 44 lb)

AC000148AB

A

B

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст