Mitsubishi Colt Ralliart. Manual — part 270

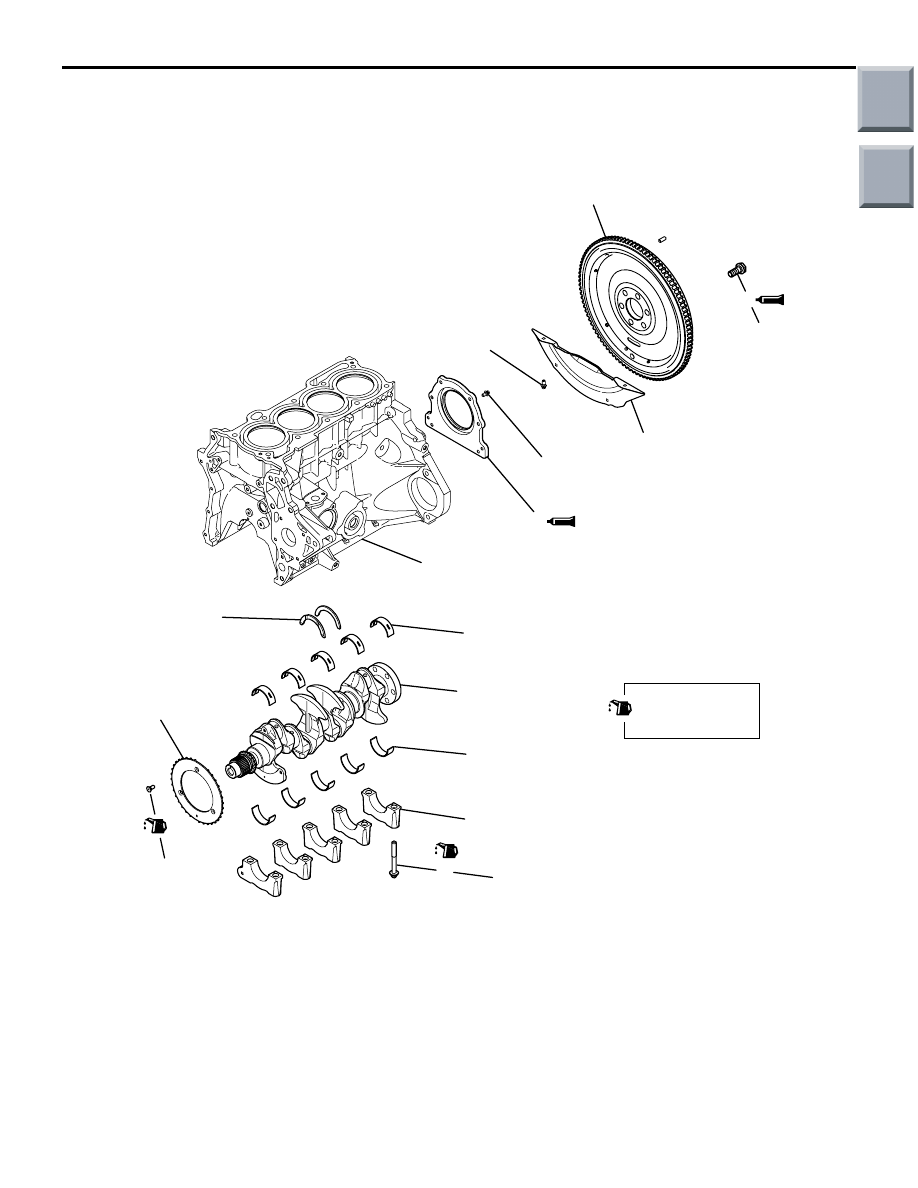

CRANKSHAFT AND CYLINDER BLOCK

ENGINE OVERHAUL <4A9>

11B-44

CRANKSHAFT AND CYLINDER BLOCK

REMOVAL AND INSTALLATION

M1113008701801

<M/T>

AK600324AB

Apply engine oil to

all moving parts

before installation.

7

10

11

8

1

6

5

4

3

2

9

35 ± 2 N·m

→ +60˚ to 64˚

12

100 ± 5 N·m

6.7 ± 1.3 N·m

9.0 ± 1.0 N·m

7.6 ± 0.6 N·m

Removal steps

<<

A

>> >>

G

<< 1. Fly wheel bolt

2. Fly wheel

3. Bell housing cover

4. Oil seal case

>>

F

<< 5. Crank shaft bearing cap bolt

>>

E

<< 6. Crankshaft bearing cap

>>

E

<< 7. Crankshaft bearing, lower

>>

D

<< 8. Crankshaft

9. Crankshaft bearing, upper

>>

C

<< 10.Thrust bearing

>>

B

<< 11.Crankshaft sensing ring

>>

A

<< 12.Cylinder block

Removal steps (Continued)

Main

Index

Group

TOC

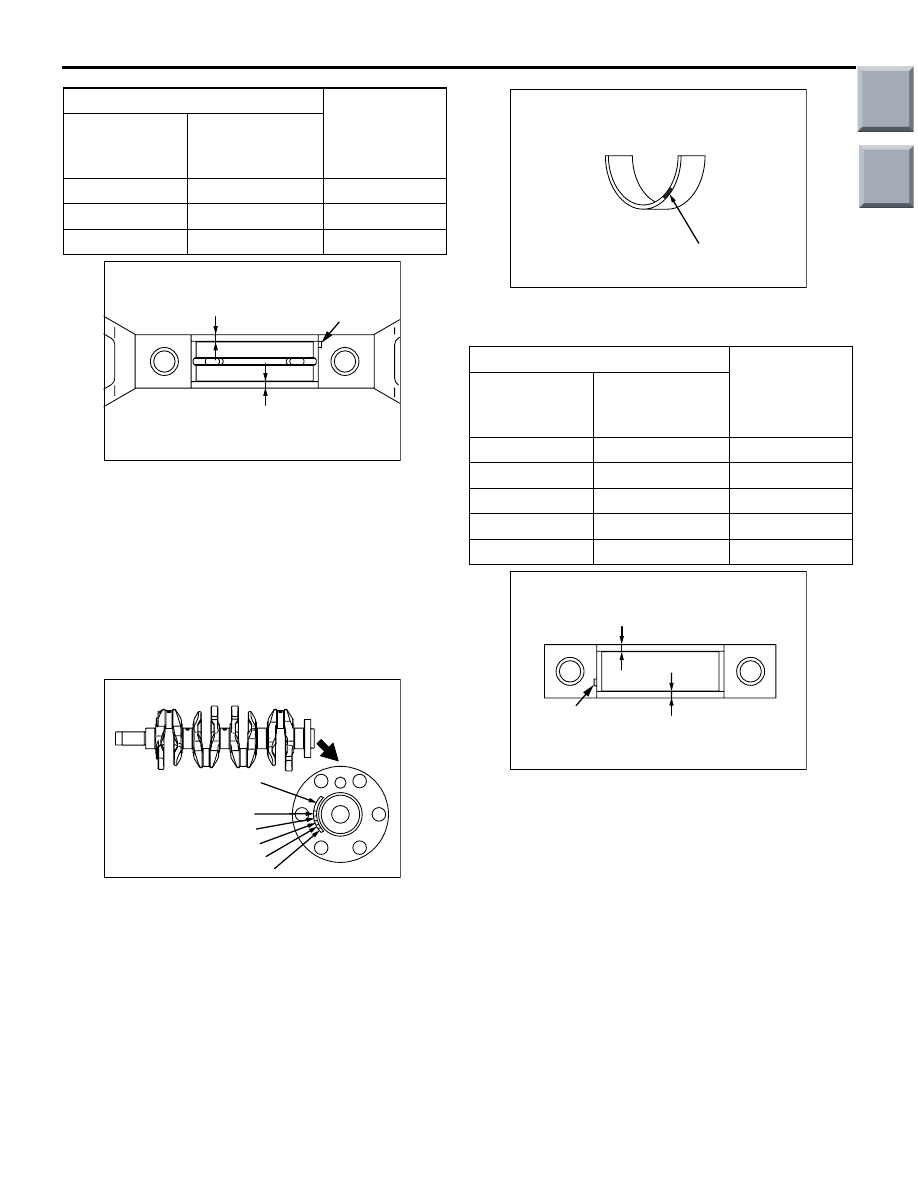

CRANKSHAFT AND CYLINDER BLOCK

ENGINE OVERHAUL <4A9>

11B-45

<CVT>

AK401772 AC

Apply engine oil to

all moving parts

before installation.

7

10

11

8

1

6

5

4

3

2

9

35 ± 2 N·m

→ +60˚ to 64˚

13

12

100 ± 5 N·m

6.7 ± 1.3 N·m

9.0 ± 1.0 N·m

7.6 ± 0.6 N·m

Removal steps

<<

A

>> >>

G

<< 1. Drive plate bolt

2. Adapter plate

3. Drive plate

4. Bell housing cover

>>

F

<< 5. Oil seal case

>>

E

<< 6. Crankshaft bearing cap bolt

>>

E

<< 7. Crankshaft bearing cap

>>

D

<< 8. Crankshaft bearing, lower

9. Crankshaft

>>

C

<< 10.Crankshaft bearing, upper

>>

B

<< 11.Thrust bearing

>>

A

<< 12.Crankshaft sensing ring

13.Cylinder block

Removal steps (Continued)

Main

Index

Group

TOC

CRANKSHAFT AND CYLINDER BLOCK

ENGINE OVERHAUL <4A9>

11B-46

REMOVAL SERVICE POINTS

<<A>> DRIVE PLATE BOLT/FLYWHEEL

BOLT REMOVAL

AK600410AC

MB991883

<M/T>

AK600407

MD998781

Cylinder block

Drive plate

AB

<CVT>

1. Lock the drive plate or the flywheel using the

special tool Flywheel stopper.

2. Remove the drive plate bolt.

• Flywheel Stopper (MD998781)

• Flywheel Stopper (MB991883)

INSTALLATION SERVICE POINTS

>>A<< CRANKSHAFT SENSING RING

INSTALLATION

AK305710

AB

1

3

2

Pin

1. Apply engine oil to the crankshaft sensing ring

screw.

2. Tighten the crankshaft sensing ring screws to 9.0

± 1.0 N⋅m in the steps given in the illustrated.

>>B<< THRUST BEARING INSTALLATION

1. Install the thrust bearing onto the cylinder block

side of the No. 4 bearing. Apply engine oil to the

thrust bearing to facilitate installation.

AK305429AB

Groove

2. The thrust bearing should be installed such that its

groove faces the crankshaft weight.

>>C<< CRANKSHAFT BEARING UPPER

INSTALLATION

AK305609AB

Timing chain side

No.1

No.2

No.5

No.4

No.3

1. The crankshaft bearing upper should be selected

based on the identification mark on the bottom

face of the cylinder block (illustrated) and the table

shown below.

AK305606AB

Groove

Identification

color

2. Every crankshaft bearing upper is identified by the

paint mark at the illustrated location.

Main

Index

Group

TOC

Cylinder block

Crankshaft

bearing paint

color

Identification

mark

Journal

diameter

mm

1

50.000

− 50.005 Blue

2

50.005

− 50.010 Black

3

50.010

− 50.015 Red

AK305700

AC

A

B

CRANKSHAFT AND CYLINDER BLOCK

ENGINE OVERHAUL <4A9>

11B-47

3. Select and install the crankshaft bearing upper.

4. Measure the illustrated location. The error should

be within 0.5 mm.

In case of the service part, install it aligning the

bearing projection with the places shown in

Figure.

>>D<< CRANKSHAFT BEARING LOWER

INSTALLATION

AK306103

No.1

AF

No.4

No.3

No.2

Production date

No.5

1. The crankshaft bearing lower should be selected

based on the identification mark on the crankshaft

rear flange (illustrated) and the table shown

below.

AK305607AB

Identification

color

2. Every crankshaft bearing lower is identified by the

paint mark at the illustrated location.

Crankshaft

Crankshaft

bearing paint

color

Identification

mark

Journal

diameter

mm

P

46.024

− 46.029 Blue

Y

46.019

− 46.024 Yellow or Black

N

46.014

− 46.019 Red

W

46.009

− 46.014 White

B

46.004

− 46.009 Purple

AK305695

AC

A

B

3. Select and install the crankshaft bearing lower.

4. Measure the illustrated location. The error should

be within 0.5 mm.

In case of the service part, install it aligning the

bearing projection with the places shown in

Figure.

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст