Mitsubishi Colt Ralliart. Manual — part 348

SYMPTOM PROCEDURES

SMART WIRING SYSTEM (SWS) NOT USING SWS MONITOR

54B-136

DIAGNOSIS PROCEDURE

Step 1. Pulse check

Check the input signal from the tail lamp switch.

OK: The M.U.T.-III sounds or the voltmeter

needle fluctuates.

Q: Is the check result normal?

All the signals are received normally. :

Go to Step

2.

The ignition switch (IG1) signal is not received. :

Refer to Inspection Procedure N-2 "The

ignition switch (IG1) signal is not received

."

The tail lamp switch signal is not received. :

Refer

to Inspection Procedure N-4 "The column

switch (lighting and turn-signal lamp) signal

is not received

."

Step 2. Connector check: B-134 ETACS-ECU

connector.

Q: Is the check result normal?

YES :

Go to Step 3.

NO :

Repair the defective connector.

Step 3. Voltage measurement at B-134

ETACS-ECU connector.

(1) Remove the ETACS-ECU, and measure at the

junction block side.

(2) Voltage between B-134 ETACS-ECU connector

terminal No.16 and body earth

OK: System voltage

Q: Is the check result normal?

YES :

Go to Step 5.

NO :

Go to Step 4.

System switch

Check condition

Ignition switch (IG1)

When turned from ACC

to ON

Tail lamp switch

When the lighting switch

is turned to the TAIL

position

AC313872 AH

Connector: B-134

Harness side

Junction block (Rear view)

AC313872 AH

Connector: B-134

Harness side

Junction block (Rear view)

AC313972

Connector B-134

(Harness side)

AT

Main

Index

Group

TOC

SYMPTOM PROCEDURES

SMART WIRING SYSTEM (SWS) NOT USING SWS MONITOR

54B-137

Step 4. Check the wiring harness between B-134

ETACS-ECU connector terminal No.16 and the

fusible link (1).

NOTE:

Prior to the wiring harness inspection, check junction

block connector B-108, and repair if necessary.

• Check the power supply line for open circuit.

Q: Is the check result normal?

YES :

The trouble can be an intermittent

malfunction (Refer to GROUP 00

− How to

use Troubleshooting/inspection Service

Points

− How to Cope with Intermittent

).

NO :

Repair the wiring harness.

Step 5. Retest the system.

Check that the tail lamps illuminate normally.

Q: Is the check result normal?

YES :

The trouble can be an intermittent

malfunction (Refer to GROUP 00

− How to

use Troubleshooting/inspection Service

Points

− How to Cope with Intermittent

).

NO :

Replace the ETACS-ECU.

AC313872 AH

Connector: B-134

Harness side

Junction block (Rear view)

AC313870

Connector: B-108

BD

Junction block (Front view)

B-108(B)

Harness side

Main

Index

Group

TOC

SYMPTOM PROCEDURES

SMART WIRING SYSTEM (SWS) NOT USING SWS MONITOR

54B-138

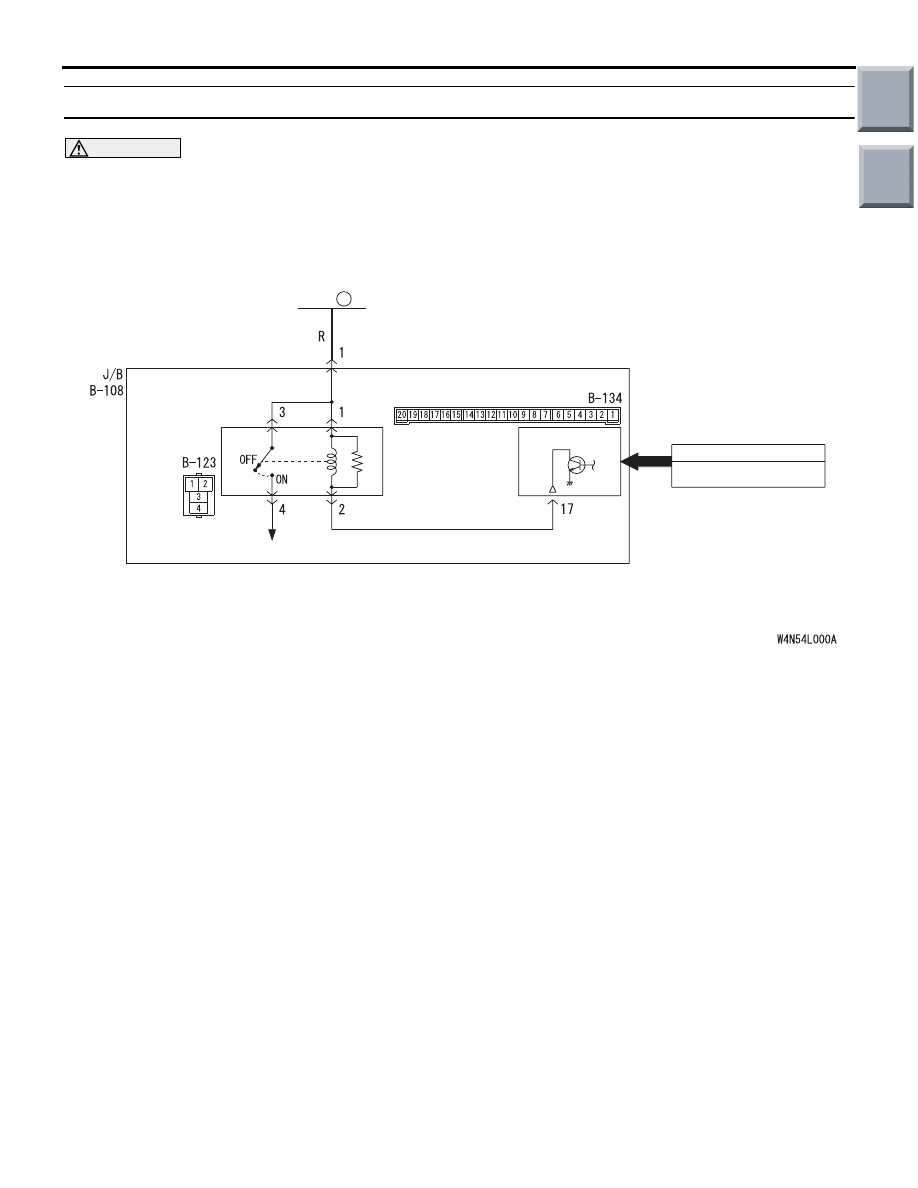

INSPECTION PROCEDURE J-2: The low-beam headlamps do not illuminate normally.

CAUTION

Whenever the ECU is replaced, ensure that the

input and output signal circuits are normal.

COMMENTS ON TROUBLE SYMPTOM

If the low-beam headlamps do not illuminate, the

headlamp switch input circuit, the headlamp relay

(LO) or the ETACS-ECU may be defective. If the

SWS monitor ECU check shows "NG", also check

the headlamp backup circuit (from column switch

connector terminal No.10 to ETACS-ECU connector

terminal No.60) and repair if necessary.

POSSIBLE CAUSES

• Malfunction of the headlamp relay (LO)

• Malfunction of the column switch

• Malfunction of the ETACS-ECU

• Damaged harness wires and connectors

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Gray R : Red P : Pink V : Violet

ETACS-ECU

HEADLAMP

RELAY (LO)

HAEDLAMP

FUSIBLE

LINK

1

HEADLAMP SWITCH

INPUT SIGNAL

J/B SIDE

Headlamp Relay (Low-Beam) Circuit

Main

Index

Group

TOC

SYMPTOM PROCEDURES

SMART WIRING SYSTEM (SWS) NOT USING SWS MONITOR

54B-139

DIAGNOSTIC PROCEDURE

Step 1. Pulse check

Check the input signal from the headlamp switch.

OK: The M.U.T.-III sounds or the voltmeter

needle fluctuates.

Q: Are the check result normal?

All the signals are received normally. :

Go to Step

2.

The ignition switch (IG1) signal is not received. :

Refer to Inspection Procedure N-2 "The

ignition switch (IG1) signal is not received

."

The headlamp switch signal is not received. :

Refer to Inspection Procedure N-4 "The

column switch (lighting and turn-signal lamp

switch) signal is not received

Step 2. Connector check: B-123 headlamp relay

(LO) connector

Q: Is the check result normal?

YES :

Go to Step 3.

NO :

Repair the defective connector.

Step 3. Check the headlamp relay (LO).

Refer to GROUP 54A

− Headlamp

Q: Is the check result normal?

YES :

Go to Step 4.

NO :

Replace the headlamp relay (LO).

Step 4. Voltage measurement at B-123 headlamp

relay (LO) connector.

(1) Remove the headlamp relay (LO), and measure

at the junction block side.

(2) Voltage between B-123 headlamp relay (LO)

connector terminal Nos.1, 3 and body earth

OK: System voltage

Q: Is the check result normal?

YES :

Go to Step 6.

NO :

Go to Step 5.

System switch

Check condition

Ignition switch (IG1)

When turned from ACC

to ON

Headlamp switch

When the lighting switch

is turned to the HEAD

position

AC313870 AD

Connector: B-123

Junction Block (Front view)

Harness side

AC313870 AD

Connector: B-123

Junction Block (Front view)

Harness side

AC313972AV

Connector B-123

(Harness side)

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст