Mitsubishi Colt Ralliart. Manual — part 217

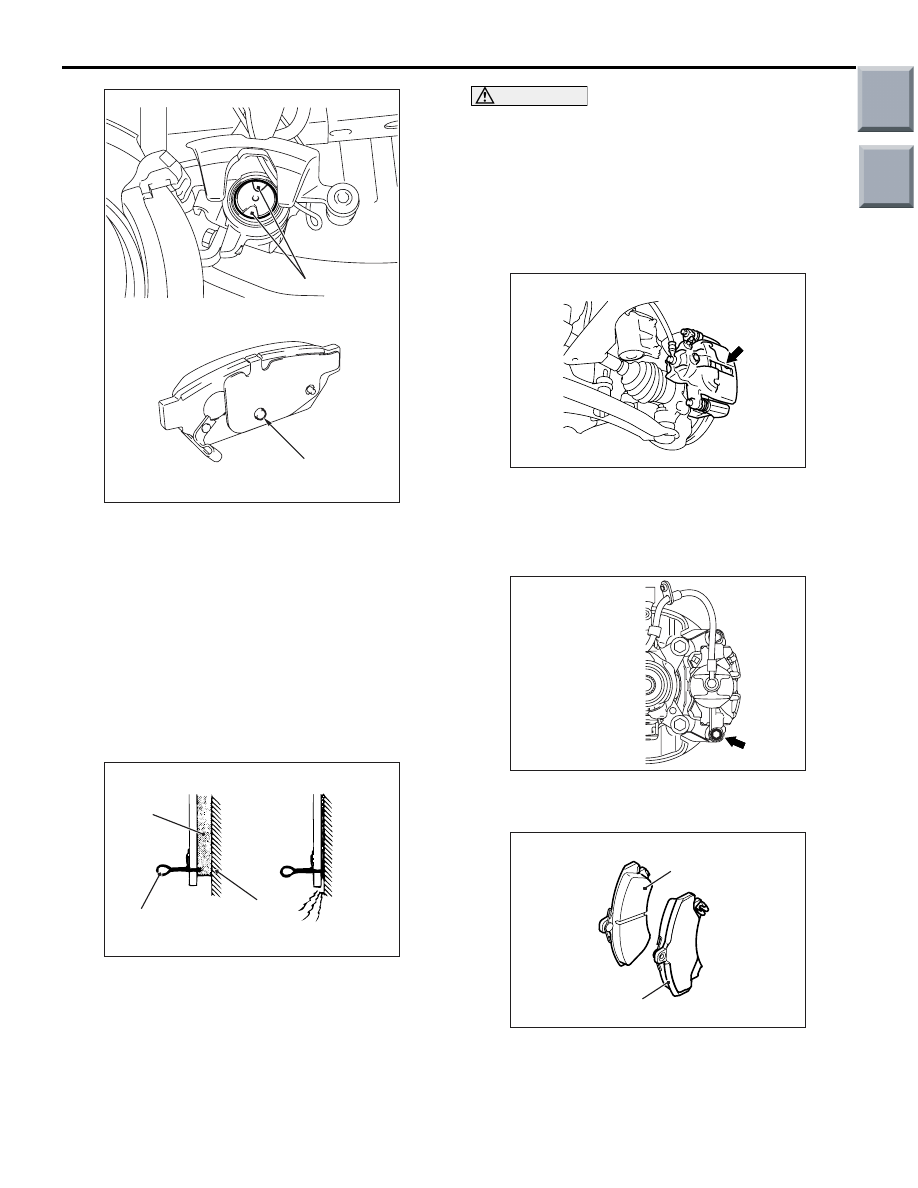

AC403232AB

Stopper groove

Protrusion

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM

35A-14

8. Set as shown so that the protrusion on the pad

assembly rear face is engaged in the piston

stopper groove.

9. Install the pad and caliper assembly, and check

the brake drag force (Refer to

).

DISC BRAKE PAD CHECK AND

REPLACEMENT <RALLIART

VERSION-R>

M1351002300859

<FRONT>

NOTE:

AC000879

When new

When worn

AD

Pad

Wear indicator

Brake

disc

The brake pads have indicators that contact the

brake disc when the brake pad thickness becomes

1.5 mm, and emit a squealing sound to warn the

driver.

CAUTION

• Whenever a pad must be replaced, replace

both LH and RH wheel pads as a set to pre-

vent the vehicle from pulling to one side when

braking.

• If there is a significant difference in the thick-

ness of the pads on the left and right sides,

check the sliding condition of the piston and

slide pins.

AC601033AC

1. Check the brake pad thickness through the caliper

body check port.

Standard value: 10.5 mm

Minimum limit: 1.5 mm

AC601051AC

2. Remove the bolt. Pivot the caliper assembly and

hold it with wires.

AC601035AC

1

2

3. Remove the following parts from caliper

assembly.

(1) Pad assembly <RH> or Pad and wear

indicator assembly <LH>

(2) Pad assembly

Main

Index

Group

TOC

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM

35A-15

4. In order to measure the brake drag force after pad

installation, measure the rotary-sliding resistance

of the hub with the pads removed <Refer to

5. Install the pads and caliper assembly, and then

check the brake drag force <Refer to

>.

<Rear>

AC601034AD

1. Visually check the thickness of brake pad from the

inspection hole of the caliper body.

Standard value: 10.0 mm

Limit value: 1.5 mm

2. When the thickness is lower than the limit value,

replace the both brake pads (right and left) as a

set.

3. Disengage the connection between the rear brake

caliper and rear parking brake cable.

AC601034AE

4. Remove the bolt, and swivel the caliper assembly

upward to retain with a wire or other similar

material.

AC601036AC

1

2

5. Remove the following parts from the caliper

assembly.

(1) Pad assembly <RH> or Pad and wear

indicator assembly <LH>

(2) Pad assembly

6. In order to measure the brake drag force after pad

installation, measure the hub sliding torque with

no pad attached (Refer to

CAUTION

Keep grease or other fouling off the pad and

brake disc friction surface.

AC402607AD

MB996049

7. Clean the piston, and press the piston into the

cylinder using the special tool, rear disc brake

piston driver (MB996049).

8. Install the pad and caliper assembly, and check

the brake drag force (Refer to

Main

Index

Group

TOC

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM

35A-16

DISC BRAKE ROTOR CHECK

M1351002900594

CAUTION

Disc brakes must be kept within the allowable

service values in order to maintain normal brake

operation.

Before turning the brake disc, the following condi-

tions should be checked.

Inspection item

Remark

Scratches, rust, saturated lining materials and wear

• If the vehicle is not driven for a long period of

time, sections of the discs that are not in contact

with the pads will become rusty, causing noise

and shuddering.

• If grooves and scratches resulting from excessive

disc wear are not removed prior to installing a new

pad assembly, there will be inadequate contact

between the disc and the lining (pad) until the

pads conform to the disc.

Run-out

Excessive run-out of the discs will increase the pedal

depression resistance due to piston kick-back.

Change in thickness (parallelism)

If the thickness of the disc changes, this will cause

pedal pulsation, shuddering and surging.

Inset or warping (flatness)

Overheating and improper handling while servicing

will cause warping or distortion.

BRAKE DISC THICKNESS CHECK

ACX00668

1. Using a micrometer, measure disc thickness at

eight positions, approximately 45 degrees apart

and 10 mm in from the outer edge of the disc.

Standard value:

<Front (LS, VR)> 20.0 mm

<Front (VR-X)> 24.0 mm

<Front (RALLIART Version-R)> 25.8 mm

<Rear> 10.0 mm

Limit value:

<Front (LS, VR)> 18.4 mm

<Front (VR-X)> 22.4 mm

<Front (RALLIART Version-R)> 23.5 mm

<Rear (VR-X)> 8.4 mm

<Rear (RALLIART Version-R)> 8.0 mm

NOTE: Thickness variation (at least 8 positions)

should not be more than 0.015 mm.

Main

Index

Group

TOC

ON-VEHICLE SERVICE

BASIC BRAKE SYSTEM

35A-17

CAUTION

• After a new brake disc is installed, always

grind the brake disc with on-the-car type

brake lathe. If this step is not carried out, the

brake disc run-out exceeds the specified

value, resulting in judder.

•

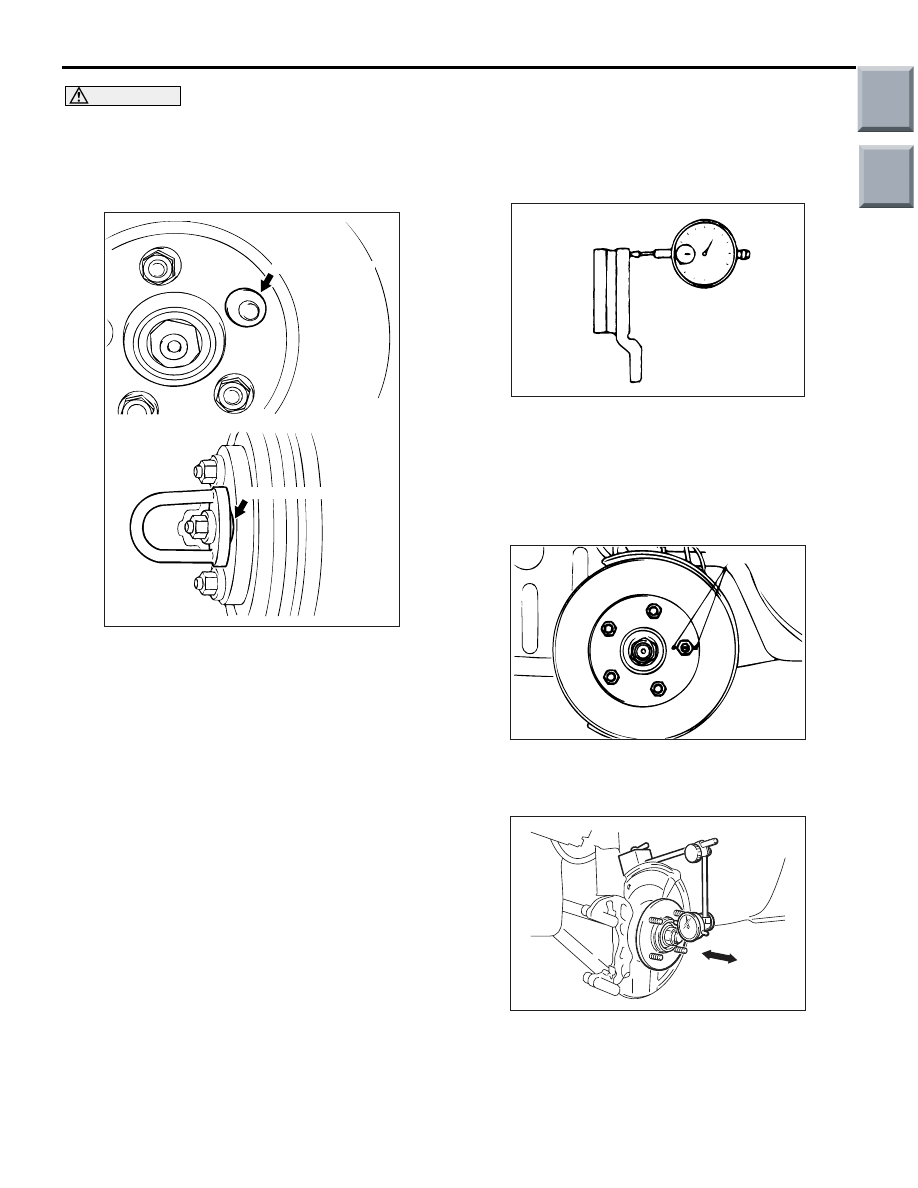

AC006226AD

M12 Flat washer

M12 Flat washer

When the on-the-car type lathe is used, first

install M12 flat washer on the stud bolt in the

brake disc side according to the figure, and

then install the adapter. If the adapter is

installed with M12 flat washer not seated, the

brake disc rotor may be deformed, resulting

in inaccurate grinding.

• Grind the brake disc with all wheel nuts diag-

onally and equally tightened to the specified

torque 100 N

⋅m. When all numbers of wheel

nuts are not used, or the tightening torque is

excessive or not equal, the brake disc rotor or

drum may be deformed, resulting in judder.

2. If the disc thickness is less than the limits, replace

it with a new one.

If thickness variation exceeds the specification,

turn rotor with an on-the-car type brake lathe

("MAD, DL-8700PF" or equivalent). If the

calculated final thickness after turning the rotor is

less than the standard value, replace the disc.

FRONT BRAKE DISC RUN-OUT CHECK

AND CORRECTION

1. Remove the brake assembly, and then hold it with

wire.

2. Temporarily install the disc with the hub nut.

ACX00669

3. Place a dial gauge approximately 5 mm from the

outer circumference of the brake disc, and

measure the run-out of the disc.

Limit: 0.06 mm

4. If the brake disc run-out exceeds the limit, correct

it as follows:

AC201323AC

Chalk marks

(1) Chalk phase marks on the wheel stud and the

brake disc, which run-out is excessive as

shown.

AC314229AB

(2) Remove the brake disc. Then place a dial

gauge as shown, and measure the axial play

by pushing and pulling the wheel hub.

Limit: 0.05 mm

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст