Mitsubishi Colt Ralliart. Manual — part 96

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4A9>

13A-338

CAUTION

When shifting the select lever to D range, the brakes should be applied so that the vehicle does not

move forward

NOTE: *1: On the new vehicle (mileage: 500 km or less), injector drive time may be longer by approximately

10%.

NOTE: *2: When service data in check mode is selected, the data is not displayed.

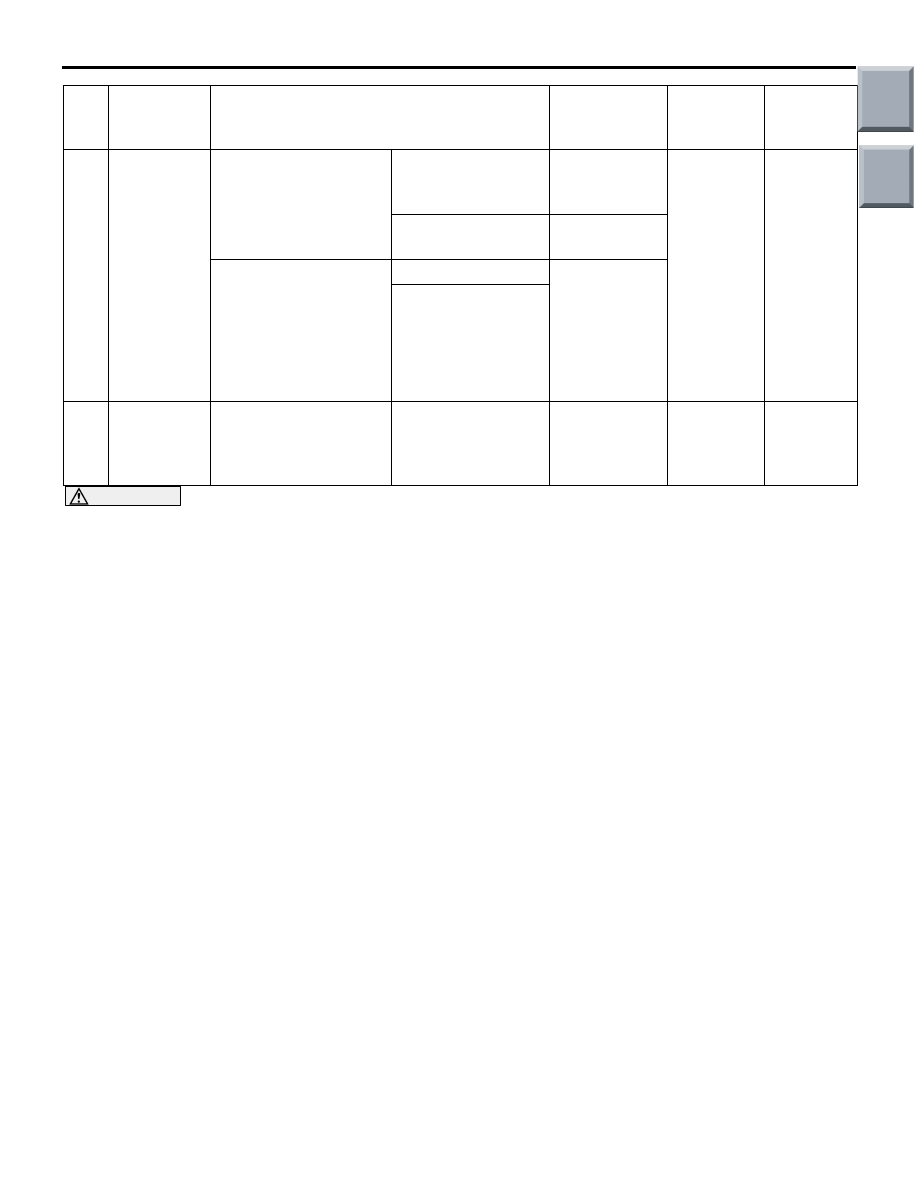

A1

*2

Oxygen

sensor

(front)

Engine: After warm-up

(leaner by deceleration,

richer by acceleration)

Excessive

deceleration from

4,000 r/min

0.2 V or less

Code No.

P0130

At excessive

acceleration

0.6

− 1.0 V

Engine: After warm-up

(using oxygen sensor,

check air-fuel ratio as

well as control status

by engine-ECU <M/T>

or engine-CVT-ECU

<CVT>

Idle operation

0.4 V or less

⇔ 0.6 − 1.0 V

2,500 r/min

A2

*2

Oxygen

sensor

(rear)

Engine: After warm-up At excessive

acceleration

0.2

− 0.8 V

(After several

seconds have

elapsed)

Code No.

P0136

Item

No.

Inspection

item

Inspection condition

Normal

condition

Inspection

procedure

No.

Reference

page

Main

Index

Group

TOC

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4A9>

13A-339

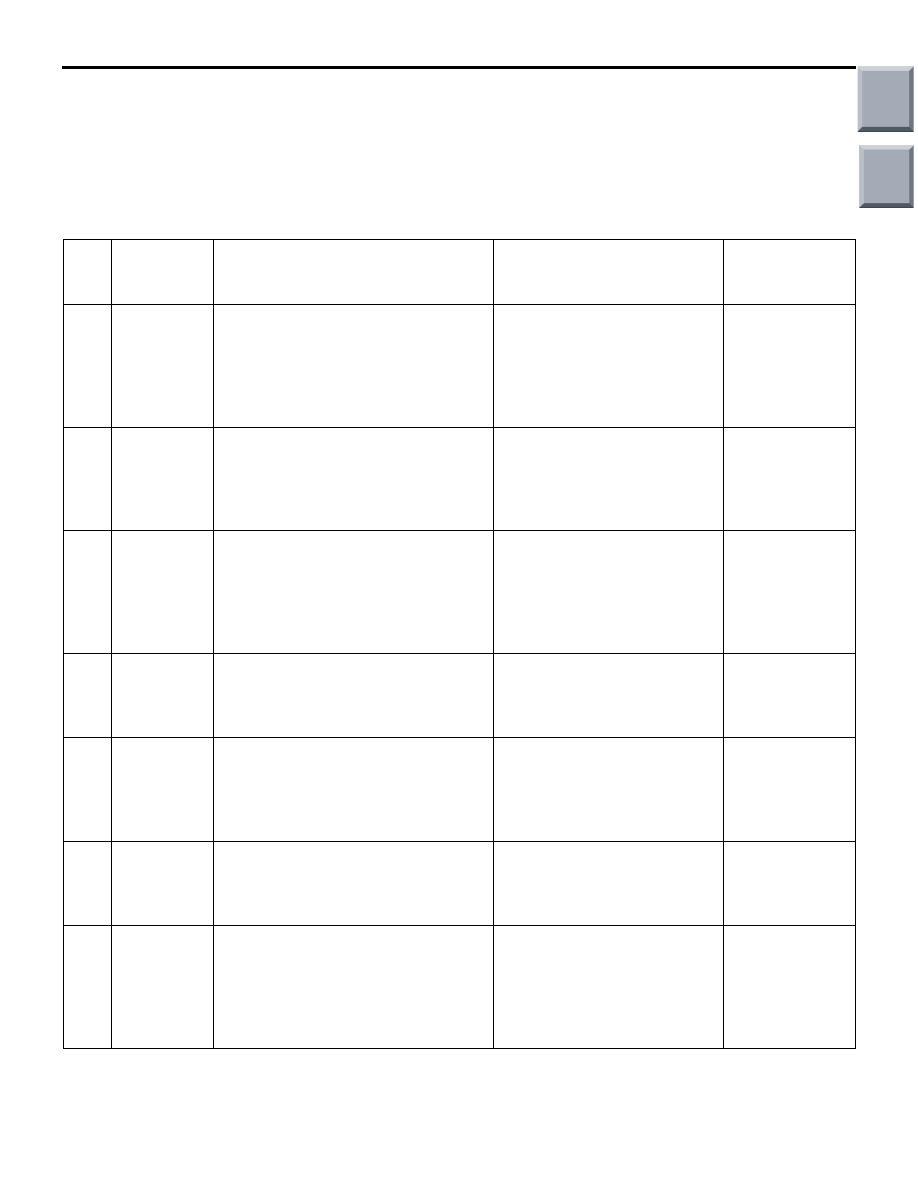

Engine-ECU <M/T> or Engine-CVT-ECU <CVT> Monitor Item

• Items useful for grasping the engine control condition by the engine-ECU <M/T> or engine-CVT-ECU

<CVT> are provided in this monitor item section.

• Values of these monitor items vary greatly depending on marginal difference of measurement conditions,

difference of the environment, aged deterioration of vehicles and so on, and it is difficult to show the pre-

cise specification values. Therefore, check conditions, display range and movement of values are

described.

Item

No.

Inspection

item

Explanation of M.U.T. display

Guideline for inspection

Display range,

numerical

value

5A

Air-fuel ratio

learning

value of B

zone (Low

speed load)

• Shows compensation value that

corrects air-fuel ratio feedback

control under mid-to-high load

• Minus side shows that injection

amount decreases and plus side

shows that it increases

Engine: After warm-up, drive

at 40 km/h

−25 to 25%

5B

Idle speed

control

position

learned

value

• Shows compensation value that

corrects idle speed control

opening (throttle valve opening)

• Minus side shows closed side and

plus side shows open side

Ignition switch: ON

−128 to

127STEP

5C

Idle speed

control

position

learned

value (A/C

load)

• Shows compensation value that

corrects idle speed control

opening (throttle valve opening)

when A/C is ON

• Minus side shows closed side and

plus side shows open side

Ignition switch: ON

−128 to

127STEP

6A

Knock

retard

• Shows retard amount of ignition

timing controlled by detonation

sensor output

Engine: Sudden acceleration

after warm-up

Retards in

response to

accelerator

opening

6B

Learned

knock retard

• Shows compensation value that

corrects ignition timing from

detonation sensor output

• 0% side shows retard and 100%

side shows advance

Ignition switch: ON

0

− 100%

6C

Target idle

speed

• Shows target idle speed

Engine: Idle operation

Changes in

response to

engine coolant

temperature

9B

Air-fuel ratio

learning

value of A

zone (Low

load)

• Shows compensation value that

corrects air-fuel ratio feedback

control under light load

• Minus side shows that injection

amount decreases and plus side

shows that it increases

Engine: After warm-up, 2,500

r/min without any load

−25 to 25%

Main

Index

Group

TOC

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4A9>

13A-340

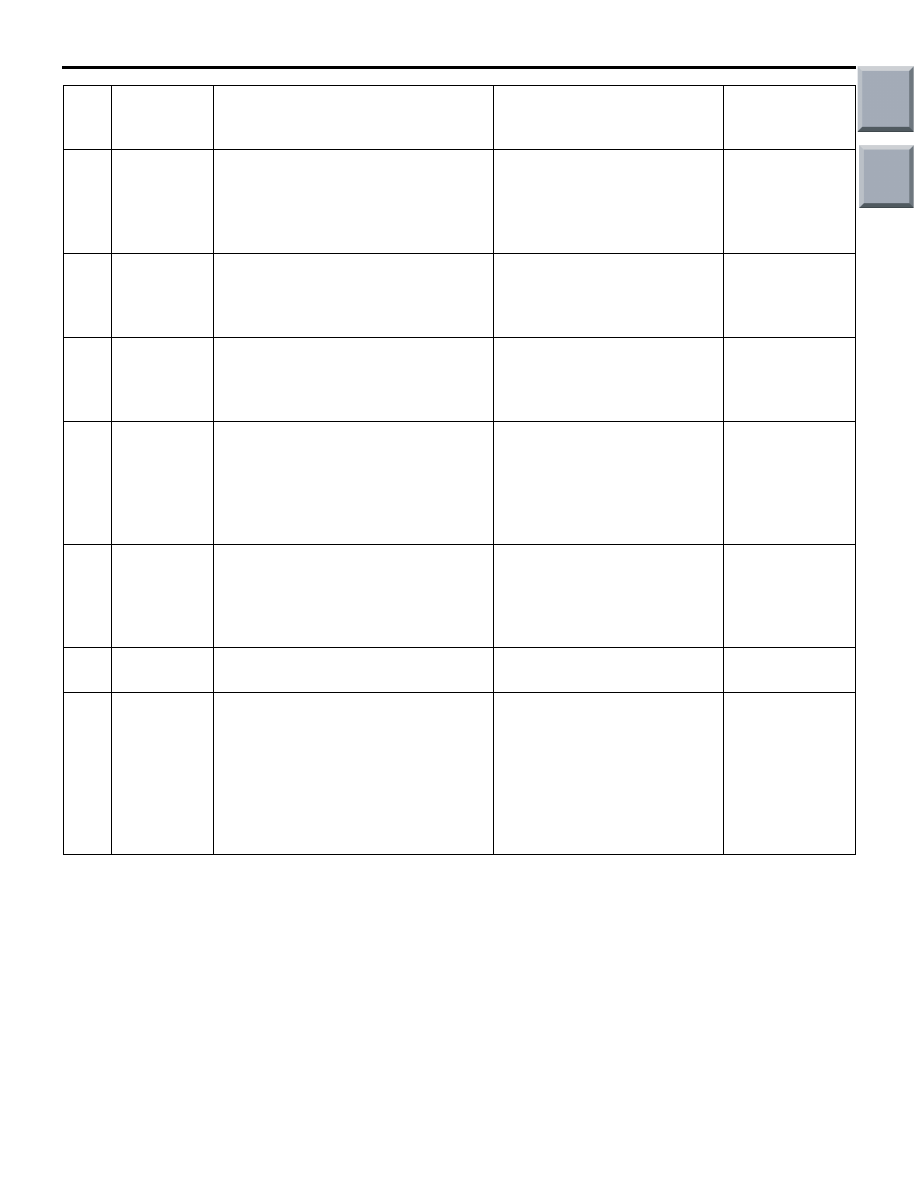

NOTE: *: This item is not displayed when the data list in check mode is selected.

9D

Air-fuel ratio

feedback

integration

• Shows feedback amount of

air-fuel ratio

• Minus side shows that injection

amount decreases and plus side

shows that it increases

Engine: After warm-up, 2,500

r/min without any load

−25 to 25%

B2

Alternator G

terminal

duty

• Shows duty ratio to alternator G

terminal

• Engine: After warm-up

• Headlamp switch: When

electrical load increases

such as from OFF to ON

Increases

B3

Purge

control

solenoid

valve duty

• Shows duty ratio to purge control

solenoid valve

Engine: After warm-up

0

− 100%

81

*

Long-term

fuel

compensati

on

• Shows compensation value that

corrects ait-fuel ratio feedback

control under mid-to-high load

• Minus side shows that injection

amount decreases and plus side

shows that it increases

Engine: After warm-up, 2,500

r/min without any load

(Air-fuel ratio feedback

control)

−25 to 25%

82

*

Short-term

fuel

compensati

on

• Shows feedback amount of

air-fuel ratio

• Minus side shows that injection

amount decreases and plus side

shows that it increases

Engine: After warm-up, 2,500

r/min without any load

(Air-fuel ratio feedback

control)

−25 to 25%

87

*

Calculation

load value

• Shows magnitude of engine load

Engine: After warm-up

0

− 100%

88

*

Fuel control

condition

• Shows air-fuel ratio feedback

control status

OL: Open loop, CL: Closed loop

OL-DRV: OL depending on driving

condition

OL-SYS: OL due to system failure

CL-HO2: CL only for front oxygen

sensor (rear oxygen abnormal)

Engine: After warm-up

Changes

depending on

driving condition

Item

No.

Inspection

item

Explanation of M.U.T. display

Guideline for inspection

Display range,

numerical

value

Main

Index

Group

TOC

TROUBLESHOOTING

MULTIPORT FUEL INJECTION (MPI) <4A9>

13A-341

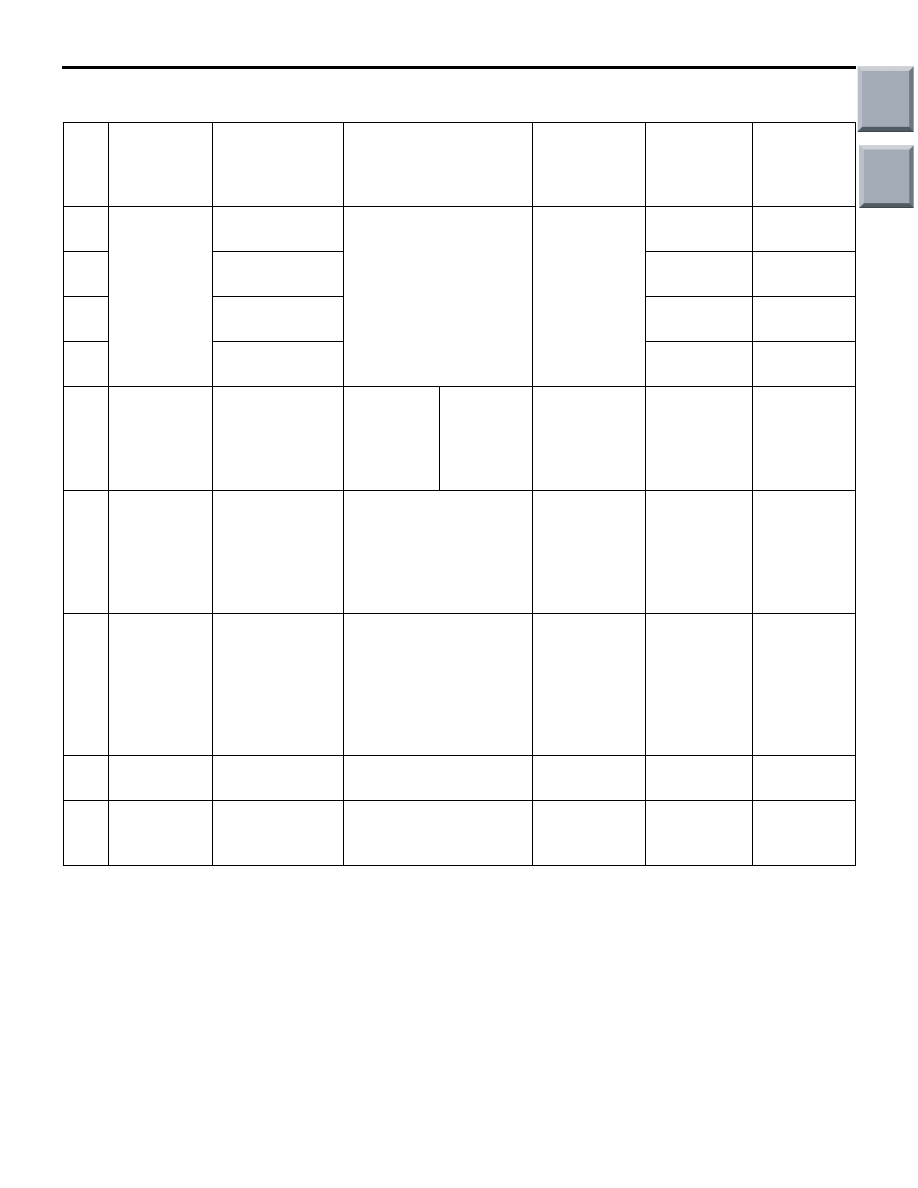

Actuator Test Reference Table

M1131152501636

Item

No.

Inspection

item

Drive content

Inspection conditions

Normal

condition

Code No.

/Inspection

procedure

No.

Reference

page

01

Injector

Cut off No. 1

injector

Engine: After warm-up,

idle operation (Cut off

injectors sequentially to

check for a cylinder that

does not change engine

in idle status.

Engine is

changed

(becomes

unstable or

stalled)

Code No.

P0201

02

Cut off No. 2

injector

Code No.

P0202

03

Cut off No. 3

injector

Code No.

P0203

04

Cut off No. 4

injector

Code No.

P0204

07

Fuel pump

Drive fuel pump

to circulate fuel

Ignition

switch: ON

Check for

pump

operating

noise near

fuel tank

Operating

noise audible

Procedure

No. 24

08

Purge

control

solenoid

valve

Switch solenoid

valve from OFF

to ON

Ignition switch: ON

When the

valve is

actuated,

operating

noise is

audible

Procedure

No. 29

17

Basic

ignition

timing

Switch

engine-ECU

<M/T> or

engine-CVT-EC

U <CVT> to

ignition timing

adjusting mode

• Engine: Idle

operation

• Install timing light

5

° BTDC

−

−

20

Cooling fan

motor

Fan motor is

driven

Ignition switch: ON

Fan motor

rotates

Procedure

No. 25

34

Throttle

valve control

servo

Stop the throttle

valve control

servo

Ignition switch: ON

Throttle valve

is opened

slightly

Code No.

P0638

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст