Mitsubishi Colt Ralliart. Manual — part 267

CAMSHAFT

ENGINE OVERHAUL <4A9>

11B-32

INSPECTION

M1113027000091

CAMSHAFT

AK304883

Measure the cam height. If the measured value

exceeds the limit, replace the camshaft.

Standard value:

Intake: 44.71 mm

Exhaust: 44.28 mm

Limit:

Intake: 44.21 mm

Exhaust: 43.78 mm

VALVE TAPPET

AK304938

AB

Wall

thickness

1. Measure the valve tappet at the illustrated

location. If the measured valve is discord to

instruction valve by identification mark and

following table, replace the tappet.

AK305693

Identification mark

AB

2. Every valve tappet has an identification mark

stamped at the illustrated location.

Valve tappets are available in 31 sizes, at 0.02

mm intervals in the 2.70

− 3.30 mm range, as

shown in the following table.

Thickness mm ID mark

Thickness mm ID mark

Thickness mm ID mark

2.70

70

2.92

92

3.14

14

2.72

72

2.94

94

3.16

16

2.74

74

2.96

96

3.18

18

2.76

76

2.98

98

3.20

20

2.78

78

3.00

00

3.22

22

2.80

80

3.02

02

3.24

24

2.82

82

3.04

04

3.26

26

2.84

84

3.06

06

3.28

28

2.86

86

3.08

08

3.30

30

2.88

88

3.10

10

2.90

90

3.12

12

Main

Index

Group

TOC

CYLINDER HEAD AND VALVES

ENGINE OVERHAUL <4A9>

11B-33

CYLINDER HEAD AND VALVES

REMOVAL AND INSTALLATION

M1113006900992

AK402342

AC

7

10

11

8

1

6

5

4

3

9

24.5 ± 2 N·m

→ +180˚ to 184˚

21

19

20

17

18

16

15

14

13

12

2

Apply engine oil to

all moving parts

before installation.

Removal steps

>>

C

<< 1. Cylinder head bolt

2. Cylinder head bolt washer

3. Cylinder head assembly

4. Cylinder head gasket

<<

A

>> >>

B

<< 5. Retainer lock

6. Valve spring retainer

7. Valve spring

8. Intake valve

<<

A

>> >>

B

<< 9. Retainer lock

10.Valve spring retainer

11. Valve spring

12.Exhaust valve

>>

A

<< 13.Valve stem seal

14.Valve spring seat

>>

A

<< 15.Valve stem seal

16.Valve spring seat

17.Valve guide

18.Valve guide

19.Intake valve seat

20.Exhaust valve seat

21.Cylinder head

Removal steps (Continued)

Main

Index

Group

TOC

CYLINDER HEAD AND VALVES

ENGINE OVERHAUL <4A9>

11B-34

REMOVAL SERVICE POINTS

<<A>> RETAINER LOCK REMOVAL

AK304941AB

MD999597

While compressing the valve spring using the special

tool Valve spring compressor (MD999597), remove

the retainer lock.

NOTE: To facilitate reassembly, the valve, spring and

other parts removed should be kept together and

attached with a tag showing where it has been

assembled including the cylinder number.

INSTALLATION SERVICE POINTS

>>A<< VALVE STEM SEAL INSTALLA-

TION

AK304886AB

MB991994

Valve

stem

seal

1. Install the valve spring seat.

CAUTION

• The valve stem seal should not be reused.

• A new valve stem seal should be installed

correctly using the special tool. Incorrectly

installed valve stem seal will allow engine oil

to leak through into the combustion chamber.

2. Lightly coat a new valve stem seal with engine oil.

3. Insert the new valve stem seal into the valve

guide using the special tool Valve stem seal

installer (MB991994).

NOTE: . Use the special tool, on which the

number "MB991994A" is stamped.

>>B<< RETAINER LOCK INSTALLATION

AK304941AB

MD999597

While compressing the valve spring using the special

tool Valve spring compressor (MD999597), install the

retainer lock.

>>C<< CYLINDER HEAD BOLT

INSTALLATION

AK401051

15 mm

29 mm

40 mm

A

B

AB

1. Inspect all reused cylinder bolts according to the

following procedure.

(1) Measure the outside diameter shown in the

illustration (arrow "A").

(2) Measure the smaller outside diameter shown

in the illustration (arrow "B").

(3) When the difference between the smaller

outside diameters (arrow "A" and "B") exceeds

the standard value, replace the cylinder head

bolt.

Standard value: 0

− 0.15 mm

2. Install the cylinder head bolt and washer

assembly onto the cylinder head.

Main

Index

Group

TOC

AK305406AB

Timing chain side

6

3

4

7

8

9

2

1

5

10

CYLINDER HEAD AND VALVES

ENGINE OVERHAUL <4A9>

11B-35

3. In accordance with the installation order, tighten

them to the specified torque of 24.5

± 2 N⋅m in

several steps.

4. Make sure all bolts reach the specified torque.

AK304945

Paint mark

Paint mark

AB

180

˚

to 184

˚

5. Put paint marks on the bolt heads and the cylinder

as illustrated.

CAUTION

• If the head bolt is tightened less than the

specified lower limit of 180 degree angle, the

bolt may become loose. Be sure to tighten

correctly.

• If the head bolt is tightened in excess of the

specified upper limit of 184 degree angle,

loosen the bolt completely and repeat the

entire procedures.

6. Tighten the bolts in the correct sequence by 180

to 184 degree angle.

Ensure that the paint marks on the bolt heads and

the cylinder are aligned in a straight line.

INSPECTION

M1113007000862

CYLINDER HEAD

1. Before cleaning, check the cylinder head for

leakage of coolant or exhaust gas as well as

cracks or other damage.

2. Remove oil, scale, sealant, carbon and other

residues completely. Clean the oil passages and

blow compressed air through them to verify that

they are free of restriction.

AK304943

CAUTION

The grinding limit for the cylinder head and block

combined is 0.2 mm.

3. Using a straight edge and a thickness gauge,

measure the flatness of the cylinder head bottom

surface. If the distortion exceeds the limit, correct

it by grinding.

Bottom face distortion

Standard value: 0.03 mmor less

Limit: 0.2 mm

Grinding limit: 0.2 mm

Cylinder head height (standard value for new

part): 113.0 mm

VALVE

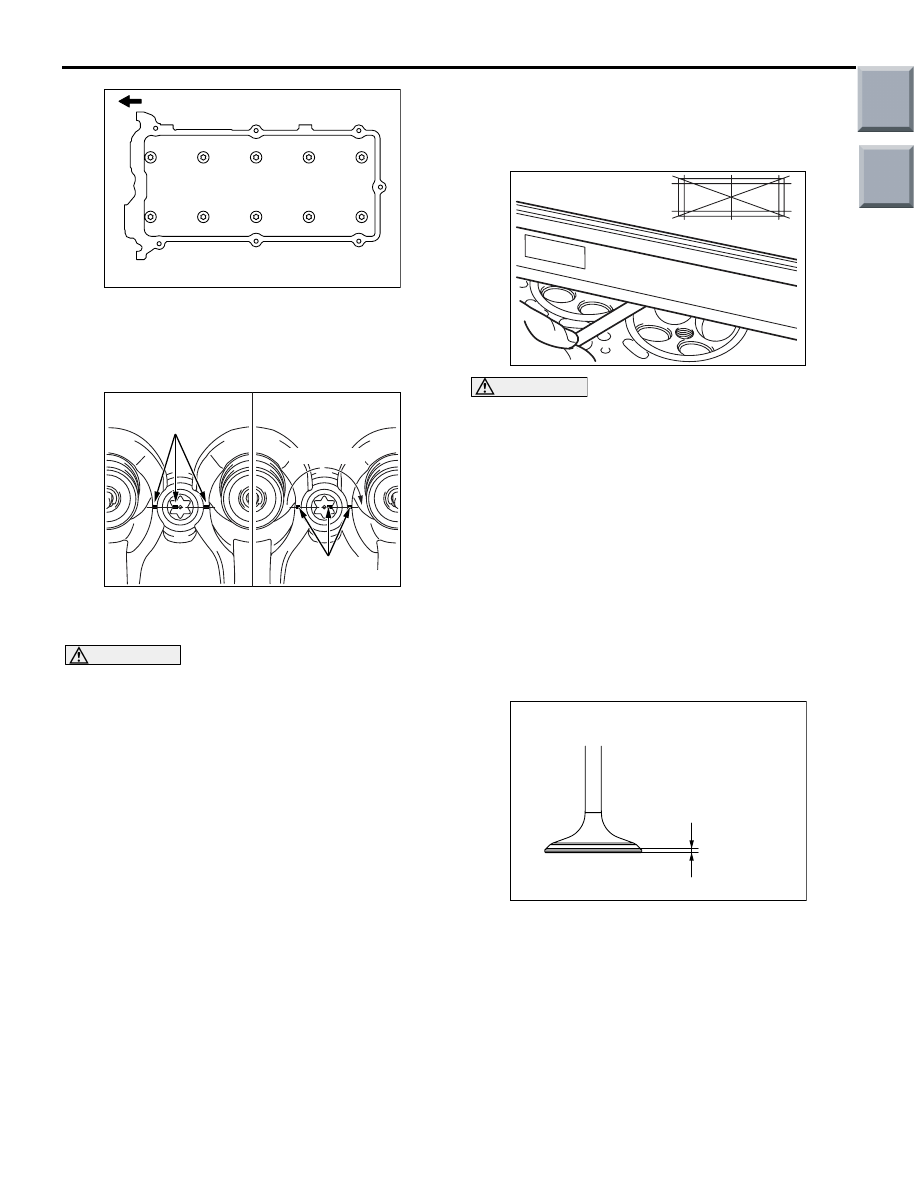

AK305408AB

Margin

The bottom of valve

seat contact facet

1. If the valve face-to-seat contact is uneven or

interrupted, correct the valve seat.

2. Measure the valve head margin. If the measured

value exceeds the limit, replace with a new valve.

Standard value:

Intake 1.35 mm

Exhaust 1.85 mm

Limit:

Intake 0.85 mm

Exhaust 1.35 mm

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст