Mitsubishi Colt Ralliart. Manual — part 292

OUTPUT SHAFT

CONTINUOUSLY VARIABLE TRANSMISSION OVERHAUL

23B-41

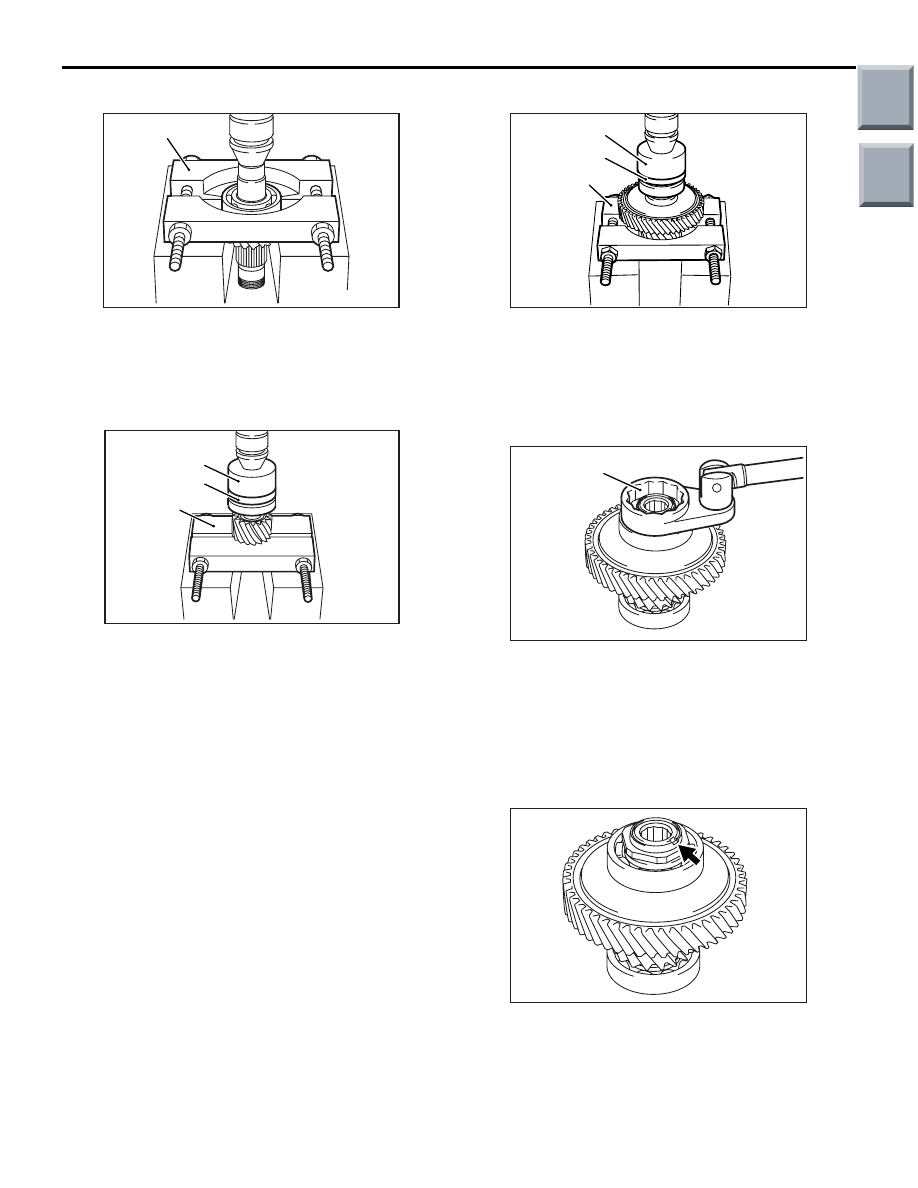

<<C>> BALL BEARING REMOVAL

AK401996

MD998801

AB

Use the special tool Bearing remover (MD998801) to

remove the ball bearing.

REASSEMBLY SERVICE POINTS

>>A<< BALL BEARING INSTALLATION

AK401997

MD998812

MD998801

MD998817

AC

Use the special tools to install the new ball bearing.

• Installer cap (MD998812)

• Installer adapter (MD998817)

• Bearing remover (MD998801)

>>B<< BALL BEARING INSTALLATION

AK401998

MD998812

MD998818

MD998801

AC

Use the special tools to install the new ball bearing.

• Installer cap (MD998812)

• Installer adapter (MD998818)

• Bearing remover (MD998801)

>>C<< LOCK NUT INSTALLATION

AK401994

MD998809

AC

1. Apply ATF to the thread portion of the lock nut

before installation.

2. Use the special tool Lock nut wrench (MD998809)

to tighten the lock nut to the specified torque of

190

± 20 N⋅m.

3. Loosen the lock nut one complete turn, then

tighten it again to the specified torque.

AK401993AC

4. Stake the lock nut securely into the notch in the

output shaft.

Main

Index

Group

TOC

DIFFERENTIAL

CONTINUOUSLY VARIABLE TRANSMISSION OVERHAUL

23B-42

DIFFERENTIAL

DISASSEMBLY AND REASSEMBLY

M1233213000110

AK202464

135 ± 5 N·m

1

2

6

5

3

4

7

10

6

8

9

9

7

AC

Apply automatic

transmission fluid

to all moving parts

before installation.

Disassembly steps

>>

E

1.

Differential drive gear

<<

A

>>

>>

D

<<

2.

Ball bearing

<<

B

>>

>>

C

<<

3.

Ball bearing

>>

B

<<

4.

Lock pin

>>

A

<<

5.

Pinion shaft

>>

A

6.

Pinion

>>

A

7.

Washer

>>

A

8.

Side gear

>>

A

9.

Spacer

10. Differential case

Disassembly steps (Continued)

Main

Index

Group

TOC

DIFFERENTIAL

CONTINUOUSLY VARIABLE TRANSMISSION OVERHAUL

23B-43

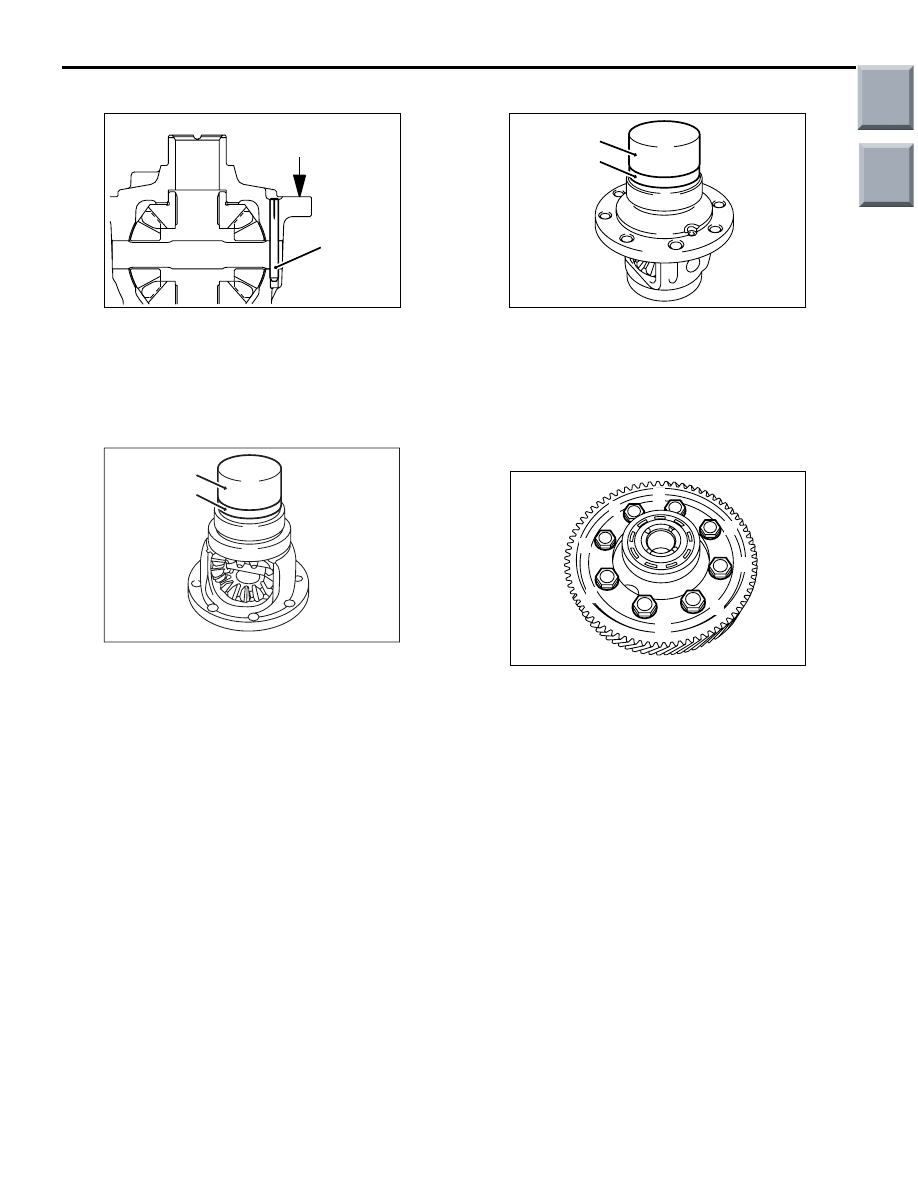

DISASSEMBLY SERVICE POINTS

<<A>> BALL BEARING REMOVAL

AK202466

MD998801

AC

Use the special tool Bearing remover (MD998801) to

remove the ball bearing from the differential case.

<<B>> BALL BEARING REMOVAL

AK202465

MD998801

AC

Use the special tool Bearing remover (MD998801) to

remove the ball bearing from the differential case.

REASSEMBLY SERVICE POINTS

>>A<< SPACER/SIDE

GEAR/WASHER/PINION/PINION SHAFT

INSTALLATION

AK102817

1. Fit the spacer on the back side of each side gear.

2. Install the side gears fitted with the spacers into

the differential case.

NOTE: . Use spacers of a thickness of 0.93

−

1.00

mm when installing new side gears.

AK102818

3. Fit the washer on the back side of each pinion.

Mesh both the pinions simultaneously with the

side gears, then bring the pinions into position

inside the differential case while rotating them.

4. Insert the pinion shaft into the differential case

while aligning the lock pin holes.

AK102819

5. Measure the backlash between each side gear

and the pinion.

Standard value: 0.025

− 0.150 mm

6. If the backlash deviates from the standard value,

replace the spacer of the side gear with a one of

an appropriate thickness and measure the

backlash again for confirmation.

NOTE: The backlash on one side gear should be

equal to that on the other after adjustments.

Main

Index

Group

TOC

DIFFERENTIAL

CONTINUOUSLY VARIABLE TRANSMISSION OVERHAUL

23B-44

>>B<< LOCK PIN INSTALLATION

AK202467

Differential drive gear

mounting surface

Lock pin

AC

Insert the lock pins into the differential case using a

press with a force larger than 5 kN until their top

ends are lower than the differential drive gear mount-

ing surface.

>>C<< BALL BEARING INSTALLATION

AK202468

MD998812

MD998819

AC

Use the special tools to install the new ball bearing

on the differential case.

• Installer cap (MD998812)

• Installer adapter (40) (MD998819)

>>D<< BALL BEARING INSTALLATION

AK202469

MD998812

MD998819

AC

Use the special tools to install the new ball bearing

on the differential case.

• Installer cap (MD998812)

• Installer adapter (40) (MD998819)

>>E<< DIFFERENTIAL DRIVE GEAR

INSTALLATION

AK102822AC

8

1

3

5

7

2

4

6

1. Place the differential drive gear in position on the

differential case.

2. Apply ATF to each of the bolt and tighten the bolts

in the numbered sequence to the specified torque

of 135

± 5 N⋅m.

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст