Mitsubishi Colt Ralliart. Manual — part 227

REAR DRUM BRAKE <LS, VR>

BASIC BRAKE SYSTEM

35A-54

REASSEMBLY SERVICE POINT

>>A<< PISTON CUP/PISTON INSTALLA-

TION

1. Use alcohol or brake fluid DOT 3 or DOT 4 to

clean the wheel cylinder and the piston.

AC000929AL

MB991008

Piston

Lip must face upwards.

CAUTION

In order to keep the piston cup from becoming

twisted or slanted, slide the piston cup down

special tool installer (MB991008) slowly and care-

fully, without stopping.

2. Apply brake fluid DOT 3 or DOT 4 to the piston

cups and special tool installer (MB991008).

3. Set the piston cup on special tool with the lip of

the cup facing up. Fit the cup onto special tool,

and then slide it down the outside of special tool

into the piston groove.

Main

Index

Group

TOC

GROUP 35B

ANTI-SKID

BRAKING SYSTEM

(ABS)

CONTENTS

GENERAL INFORMATION . . . . . . . .

SERVICE SPECIFICATIONS. . . . . . .

SPECIAL TOOLS. . . . . . . . . . . . . . . .

TROUBLESHOOTING . . . . . . . . . . . .

STANDARD FLOW OF DIAGNOSTIC

TROUBLESHOOTING . . . . . . . . . . . . . . . .

NOTES WITH REGARD TO DIAGNOSIS .

ABS AND BRAKE WARNING LAMP

INSPECTION . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS FUNCTION. . . . . . . . . . . . . . .

INSPECTION CHART FOR

DIAGNOSIS CODE. . . . . . . . . . . . . . . . . . .

DIAGNOSIS TROUBLE CODE

PROCEDURES. . . . . . . . . . . . . . . . . . . . . .

INSPECTION CHART FOR TROUBLE

SYMPTOMS . . . . . . . . . . . . . . . . . . . . . . . .

INSPECTION PROCEDURE FOR

TROUBLE SYMPTOMS . . . . . . . . . . . . . . .

DATA LIST REFERENCE TABLE. . . . . . . .

ACTUATOR TEST REFERENCE TABLE . .

CHECK AT ABS-ECU . . . . . . . . . . . . . . . . .

ON-VEHICLE SERVICE . . . . . . . . . . .

HYDRAULIC UNIT CHECK . . . . . . . . . . . . .

IN THE EVENT OF A DISCHARGED

BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . .

HYDRAULIC UNIT . . . . . . . . . . . . . . .

REMOVAL AND INSTALLATION . . . . . . . .

ABS SENSOR. . . . . . . . . . . . . . . . . . .

REMOVAL AND INSTALLATION . . . . . . . .

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . .

Main

Index

Group

TOC

GENERAL INFORMATION

ANTI-SKID BRAKING SYSTEM (ABS)

35B-2

GENERAL INFORMATION

M1352000100636

FEATURES

The 4ABS ensures directional stability and controlla-

bility during hard braking.

For vehicles with this type of ABS, 4 sensors (4

channels) are installed on front and rear wheels

allowing independent left and right control.

The system has the following features:

• EBD (Electronic Brake-force Distribution system)

control has been added to provide the ideal brak-

ing force for the rear wheels.

• Magnetic encoder for detecting wheel speed has

been installed as a wheel speed sensor instead

of the rotor.

• For wiring harness saving and secure data com-

munication, CAN

*

bus has been adopted as a

tool of communication with another ECU.

NOTE:

*

For more information about CAN (Controller

Area Network), refer to GROUP 54D, General Infor-

mation

.

EBD CONTROL

In ABS, electronic control is used so the rear wheel

brake hydraulic pressure during braking is regulated

by rear wheel control solenoid valves in accordance

with the vehicle's rate of deceleration, and the front

and rear wheel slippage which are calculated from

the signals received from the various Wheel speed

sensors. EBD control is a control system which pro-

vides a high level of control for both vehicle braking

force and vehicle stability. The system has the follow-

ing features:

• Because the system provides the optimum rear

wheel braking force regardless of vehicle load

conditions and the condition of the road surface,

the system reduces the required pedal depres-

sion force, particularly when the vehicle is heavily

loaded or driven on road surfaces with high fric-

tional coefficients.

• Because the duty placed on the front brakes is

reduced, the increases in pad temperature can

be controlled during brakes application to

improve the wear resistance characteristics of the

pad.

• Control valves such as the proportioning valve

are no required.

SPECIFICATIONS

Item

Specification

ABS control method

4-sensor, 4-channel

Wheel speed

sensor

Magnetic encoder

Front

86 (N pole:43, S pole:43)

Rear

86 (N pole:43, S pole:43)

Type

Semiconductor

Main

Index

Group

TOC

GENERAL INFORMATION

ANTI-SKID BRAKING SYSTEM (ABS)

35B-3

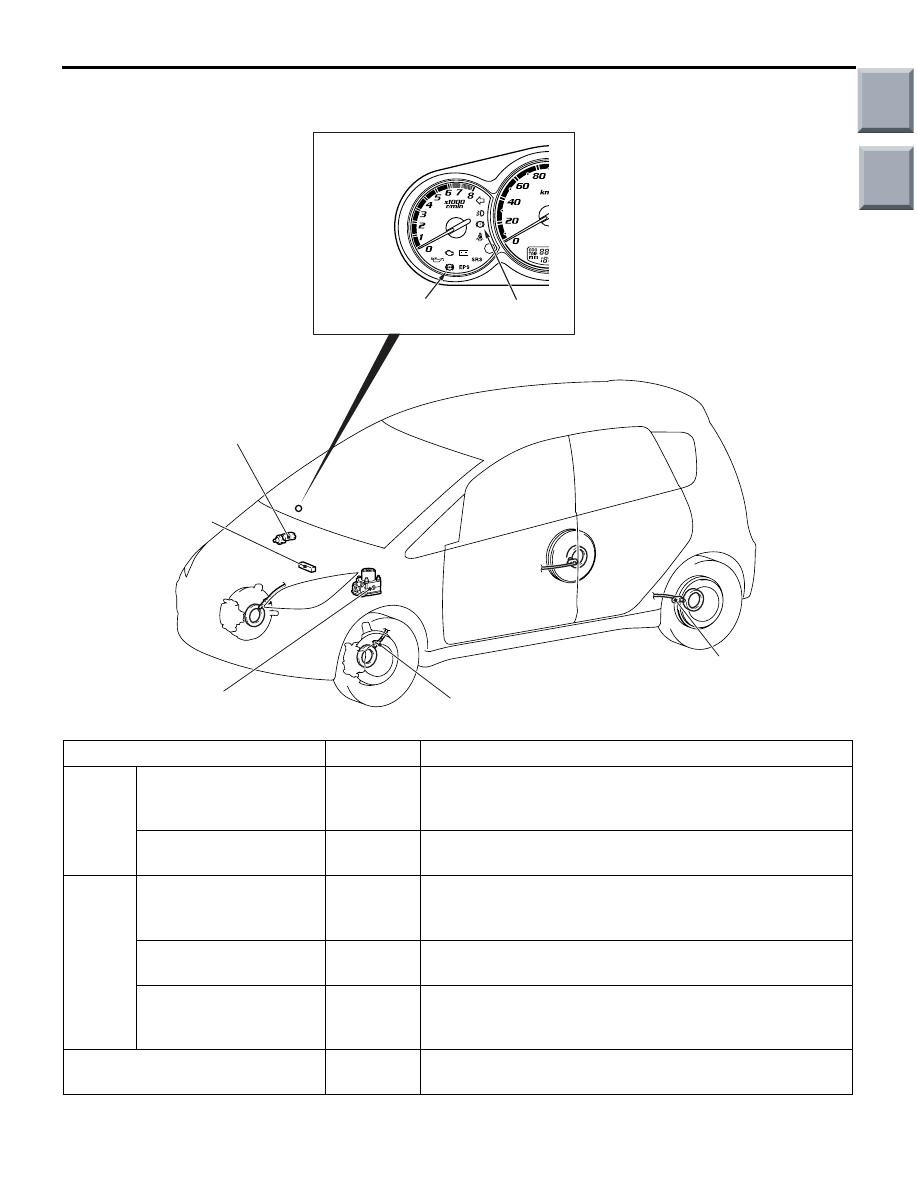

CONSTRUCTION DIAGRAM

AC400129AB

1

2

3, 7

1

4

5

6

Name of part

Number

Outline of function

Sensor

Wheel speed sensor

1

Sends alternating current signals at frequencies which are

proportional to the rotation speeds of each wheel to the

ABS-ECU.

Stop lamp switch

2

Sends a signal to the ABS-ECU to indicate whether the

brake pedal is depressed or and pump motor.

Actuator Hydraulic unit

3

Drives the solenoid valves and pump motor according to

signals from the ABS-ECU in order to control the brake

hydraulic pressure for each wheel.

ABS warning lamp

4

Illuminates in response to signals from the ABS-ECU

when a problem develops in the system.

Brake warning lamp

5

Illuminates in response to signals from the ABS-ECU

when a problem develops in the EBD system or the brake

fluid level is low.

Diagnosis connector

6

Outputs the diagnosis codes and allows communication

with the M.U.T.-III.

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст