Mitsubishi Colt Ralliart. Manual — part 312

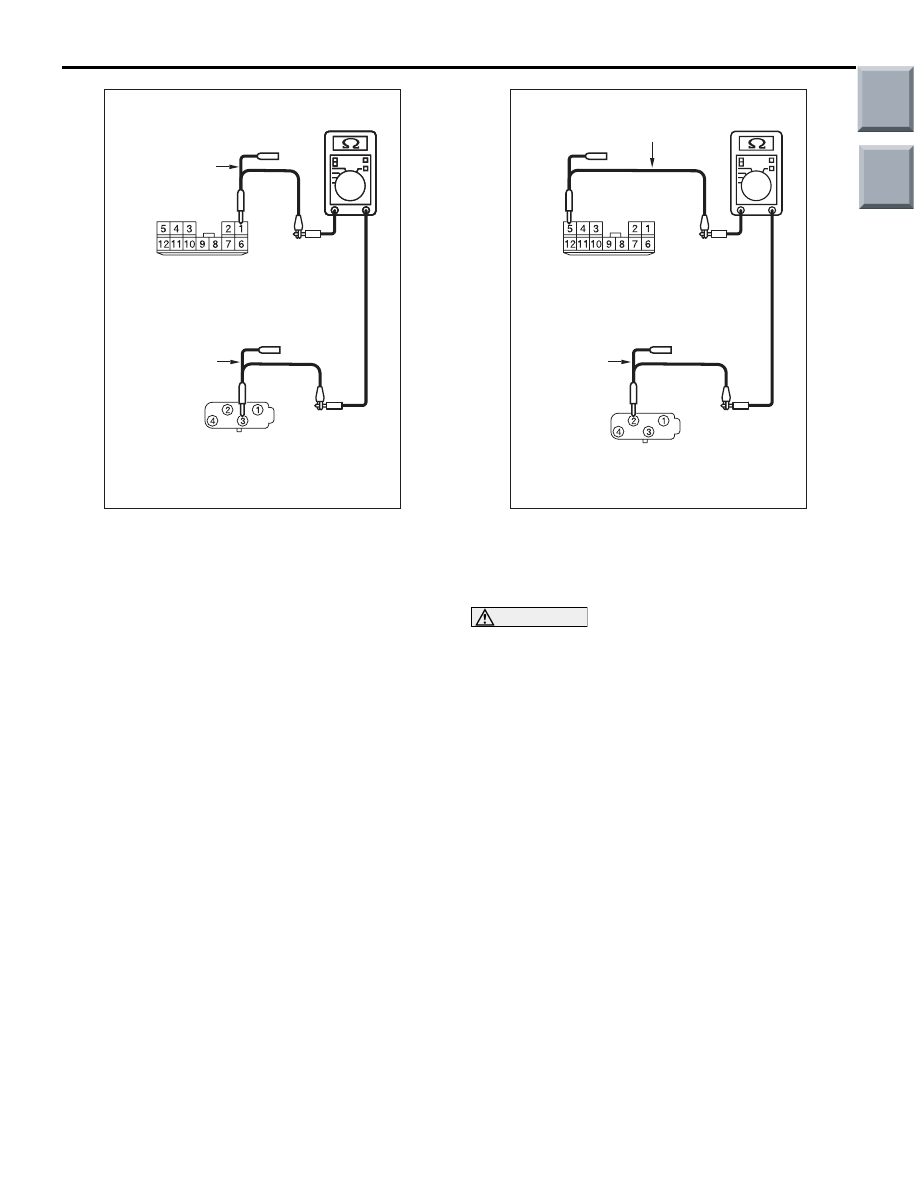

AC313937AT

Harness side: B-01

Harness side: B-37

Test

harness

Test

harness

TROUBLESHOOTING

CONTROLLER AREA NETWORK (CAN)

54D-77

(4) Continuity between B-01 joint connector (CAN2)

terminal No.8 and B-37 EPS-ECU connector

terminal No.8

OK: Continuity (2

Ω or less)

AC313937AU

Harness side: B-01

Harness side: B-37

Test

harness

Test

harness

(5) Continuity between B-01 joint connector (CAN2)

terminal No.11 and B-37 EPS-ECU connector

terminal No.3

OK: Continuity (2

Ω or less)

CAUTION

Strictly observe the specified wiring harness

repair procedure. For details refer to

Q: Is the check result normal?

YES :

<All the resistances measure 2

Ω or less>

Power supply to the EPS-ECU may be

suspected. Diagnose the EPS. Refer to

GROUP 37

− Troubleshooting

.

NO :

<Either or all of the resistances measure

more than 2

Ω> Repair the wiring harness

between the joint connector (CAN2) and the

EPS-ECU connector.

Main

Index

Group

TOC

TROUBLESHOOTING

CONTROLLER AREA NETWORK (CAN)

54D-78

Diagnostic Item 11: Diagnose when the M.U.T.-III cannot receive the data sent by G and yaw rate

sensor.

CAUTION

When servicing a CAN bus line, earth yourself by touching a metal object such as an unpainted water

pipe. If you fail to do, a component connected to the CAN bus line may be broken.

COMBINATION

METER

ENGINE-ECU

Wire colour code

B : Black LG : Light green G : Green L : Blue W : White Y : Yellow SB : Sky blue

BR : Brown O : Orange GR : Grey R : Red P : Pink V : Violet PU : Purple

G AND YAW

RATE SENSOR

FUNCTION

The diagnostic result demonstrates that "Diagnose

when the M.U.T.-III cannot receive the data sent by

G and yaw rate sensor" when the M.U.T.-III checks

the periodically sent data from each ECU and cannot

receive the G and yaw rate sensor data only.

TROUBLE JUDGEMENT CONDITIONS

M.U.T.-III judges the trouble when the periodically

sent data from G and yaw rate sensor cannot be

received and sent.

Main

Index

Group

TOC

TROUBLESHOOTING

CONTROLLER AREA NETWORK (CAN)

54D-79

PROBABLE CAUSES

• Damaged harness wires and connectors

• Power supply circuit malfunction of the G and

yaw rate sensor

• Malfunction of the G and yaw rate sensor

DIAGNOSIS PROCEDURE

STEP 1. Connector check: B-01 joint connector

(CAN2) and C-43 G and yaw rate sensor

connector

AC601064

AB

C-43 (B)

Connector: C-43

Harness side

AC313820AF

Connector: B-01

CAUTION

The strand end of the twist wire should be within

10 cm from the connector. For details refer to

.

When checking the joint connector, ensure that its

wiring harness side and its short pins are not dam-

aged.

Q: Is the check result normal?

YES :

Go to Step 2.

NO :

Repair a defective connector or replace the

joint connector.

STEP 2. Resistance measurement at B-01 joint

connector (CAN2) and C-43 G and yaw rate

sensor connector.

CAUTION

A digital multimeter should be used. For details

refer to

CAUTION

The test wiring harness should be used. For

details refer to

.

AC601064

AB

C-43 (B)

Connector: C-43

Harness side

AC313820AF

Connector: B-01

(1) Disconnect the joint connector (CAN2) and the G

and yaw rate sensor connector, and measure at

the wiring harness side.

(2) Turn the ignition switch to the OFF (LOCK)

position.

CAUTION

When measuring the resistance, disconnect the

negative battery terminal. For details refer to

.

(3) Ensure that the negative battery terminal is

disconnected.

Main

Index

Group

TOC

AC204740

AC204740

AC204740JC

Harness side: C-43

Test harness

Harness side: B-01

Test harness

TROUBLESHOOTING

CONTROLLER AREA NETWORK (CAN)

54D-80

(4) Continuity between B-01 joint connector (CAN2)

terminal No.1 and C-43 G and yaw rate sensor

connector terminal No.3

OK: Continuity (2

Ω or less)

AC204740JD

Harness side: B-01

Test harness

Test harness

Harness side: C-43

(5) Continuity between B-01 joint connector (CAN2)

terminal No.5 and C-43 G and yaw rate sensor

connector terminal No.2

OK: Continuity (2

Ω or less)

CAUTION

Strictly observe the specified wiring harness

repair procedure. For details refer to

Q: Is the check result normal?

YES :

<All the resistances measure 2

Ω or less>

Power supply to the G and yaw rate sensor

may be suspected. Diagnose the ASC

system. Refer to GROUP 35C

−

Troubleshooting

NO :

<Either or all of the resistances measure

more than 2

Ω> Repair the wiring harness

between the joint connector (CAN2) and the

G and yaw rate sensor connector.

Main

Index

Group

TOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст