DAF 95XF. Manual — part 417

4

XE ENGINE FUEL SYSTEM

Removal and installation

95

XF series

4-2

Installing the injection lines

1.

Purge the injection lines with dry

compressed air.

2.

Check whether the injector side connection

is tightened to the specified tightening

torque, see main group “Technical data”.

3.

Fit the injection lines.

4.

Note:

When tightening the injection-line unions,

hold the injector’s side connection back

using an open-end spanner.

Tighten the union nuts of the injection lines

to the specified tightening torque, see main

group “Technical data”.

5

©

0008

4

95

XF series

Removal and installation

XE ENGINE FUEL SYSTEM

4-3

4.2

REMOVAL AND INSTALLATION OF INJECTORS

Because there is overpressure in

the fuel tank, fuel may penetrate the

cylinders when the injectors are

removed. Therefore, when removing

injectors, always take off the

fuel-tank cap first. Collect any fuel

leaving the injectors.

Note:

If the engine has been fitted with a DEB, the

latter must be removed before the injectors can

be removed.

While the DEB is being installed, both the DEB

clearance and the valve clearance must be

adjusted.

Removing the injectors

1.

Remove the injection lines.

2.

Remove the valve covers.

3.

Remove the DEB, if fitted.

4.

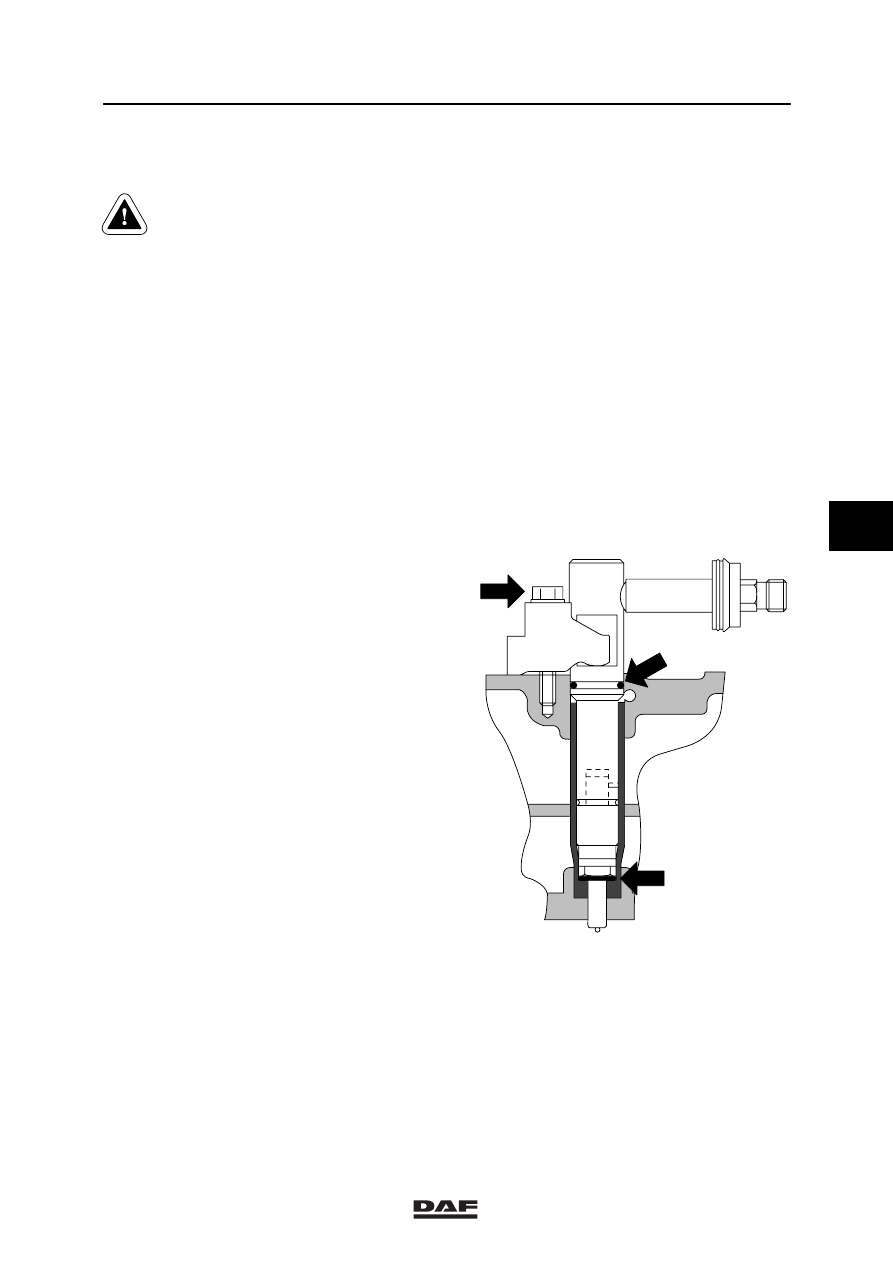

Remove the attachment bolt (3) of the

injector clamp.

5.

To remove the injector and the clamp, only

use the special tools (DAF no. 1329412 and

DAF no. 0694928).

Note:

If during removal one or more copper shims (1)

remain in the injector sleeve, the injector will be

reinstalled in a higher position.

-

As a result, instead of spraying into the

combustion chamber of the piston, the fuel

will be sprayed onto the piston ring. This

may seriously damage the piston.

-

There will be inadequate sealing between

the O-ring (2) of the injector and the cylinder

head. Fuel leaking from the injector can

freely flow into the engine and dilute the

lubricating oil.

3

2

1

I 400191

5

©

0008

4

XE ENGINE FUEL SYSTEM

Removal and installation

95

XF series

4-4

Installing the injectors

1.

Clean the injector sleeve, see chapter

“Cleaning”.

2.

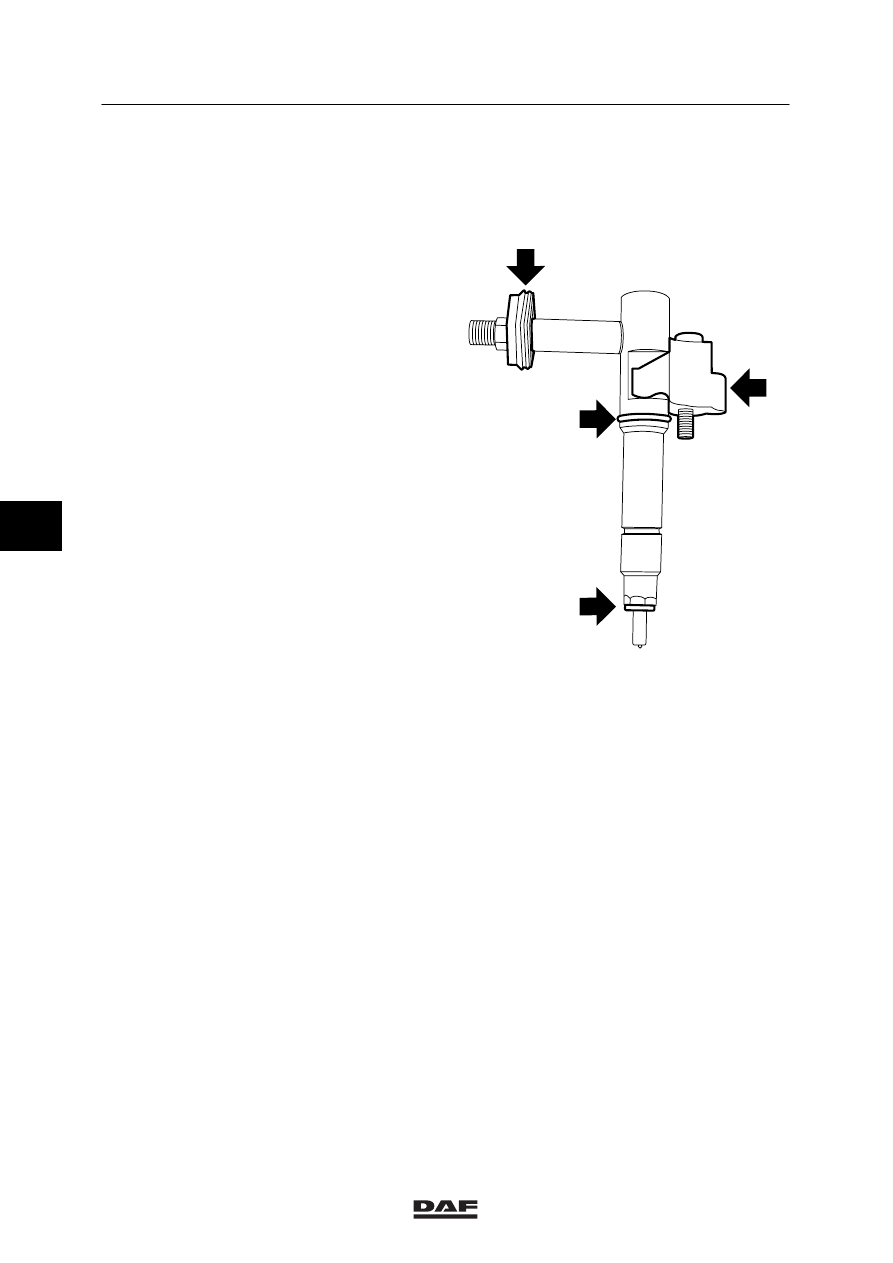

Fit a new O-ring (1) and a new copper

shim (2) on the injector. Apply a little

acid-free grease to both rings.

3.

Check the valve-sleeve sealing ring (3) of

the injector. Replace it if leaking and/or

damaged.

4.

Note:

Make sure that the injector clamp (4) is

installed correctly.

Install the injector together with the injector

clamp (4) and tighten the attachment bolt to

the specified tightening torque, see main

group “Technical data”.

5.

Fit the injection lines.

6.

Check the injector seals for leaks, see

“Checking and adjustment”.

7.

Install the DEB, if present.

8.

Fit the valve covers.

i 400183

3

4

1

2

5

©

0008

4

95

XF series

Removal and installation

XE ENGINE FUEL SYSTEM

4-5

4.3

REMOVAL AND INSTALLATION OF INJECTOR SLEEVES

Removing the injector sleeve

1.

Drain part of the engine coolant.

2.

Remove the injection lines.

3.

Remove the injector.

4.

Insert a ball of crumpled paper into the

injector sleeve to prevent metal particles

from entering the engine.

5.

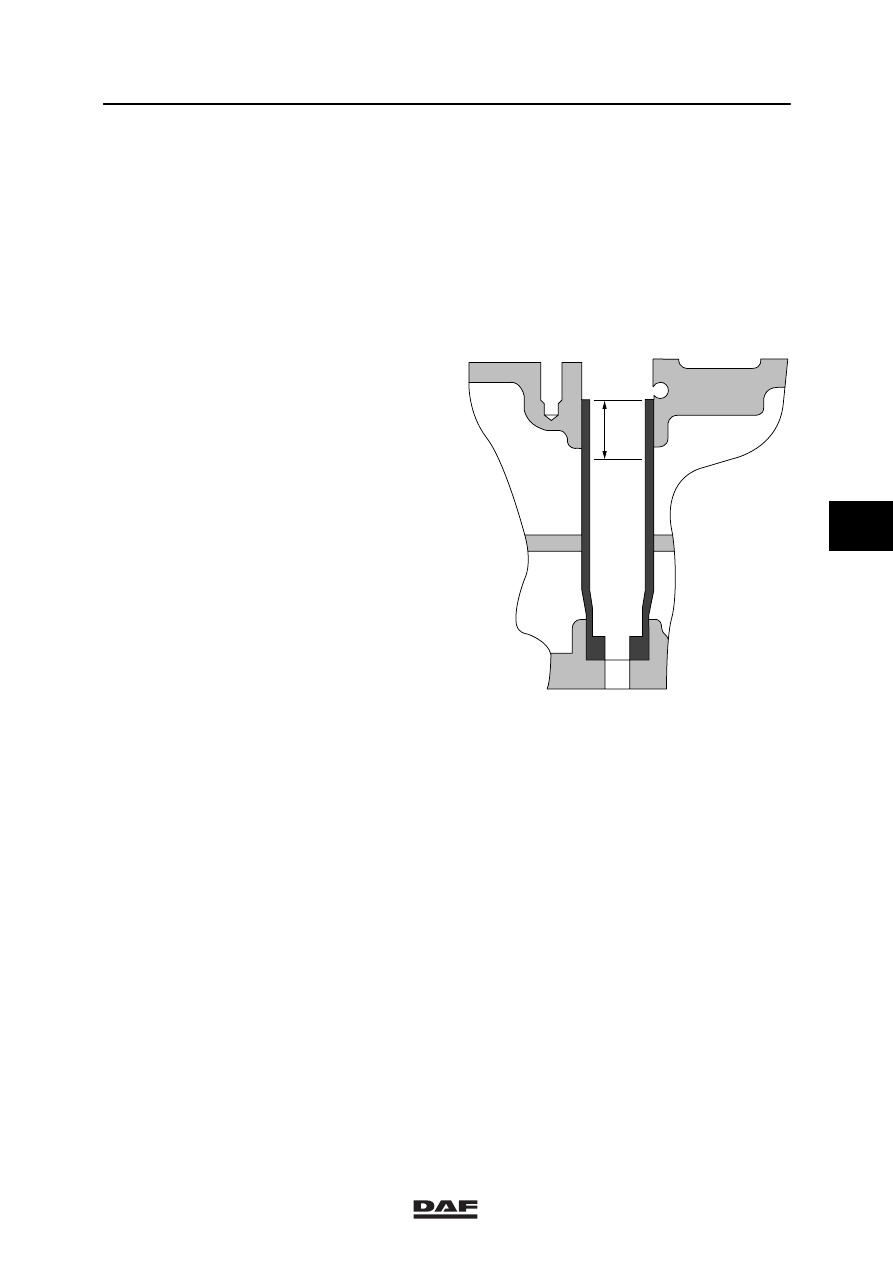

Cut thread (M22

1.5) in the injector

sleeve to be removed over a length (A) of

approx. 20 mm.

6.

Insert the special tool (DAF no. 1310425)

into the injector sleeve and use the special

tool (DAF no. 0694928) to remove the

injector sleeve.

Installing the injector sleeve

1.

Clean the injector-sleeve opening

thoroughly.

2.

Note:

Install the injector sleeve dry into the

cylinder head.

Use the special tool (DAF no. 1329305) to

tap the injector sleeve into the cylinder

head.

3.

Install the injector.

4.

Fit the injection lines.

5.

Fill the cooling system.

A

I 400195

5

©

0008

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст