Acura RL (1996-2004 year). Manual — part 472

3.0 mm (0.12 in) MAX

6.0 mm (0.24 in) MAX

Reassembly (cont'd)

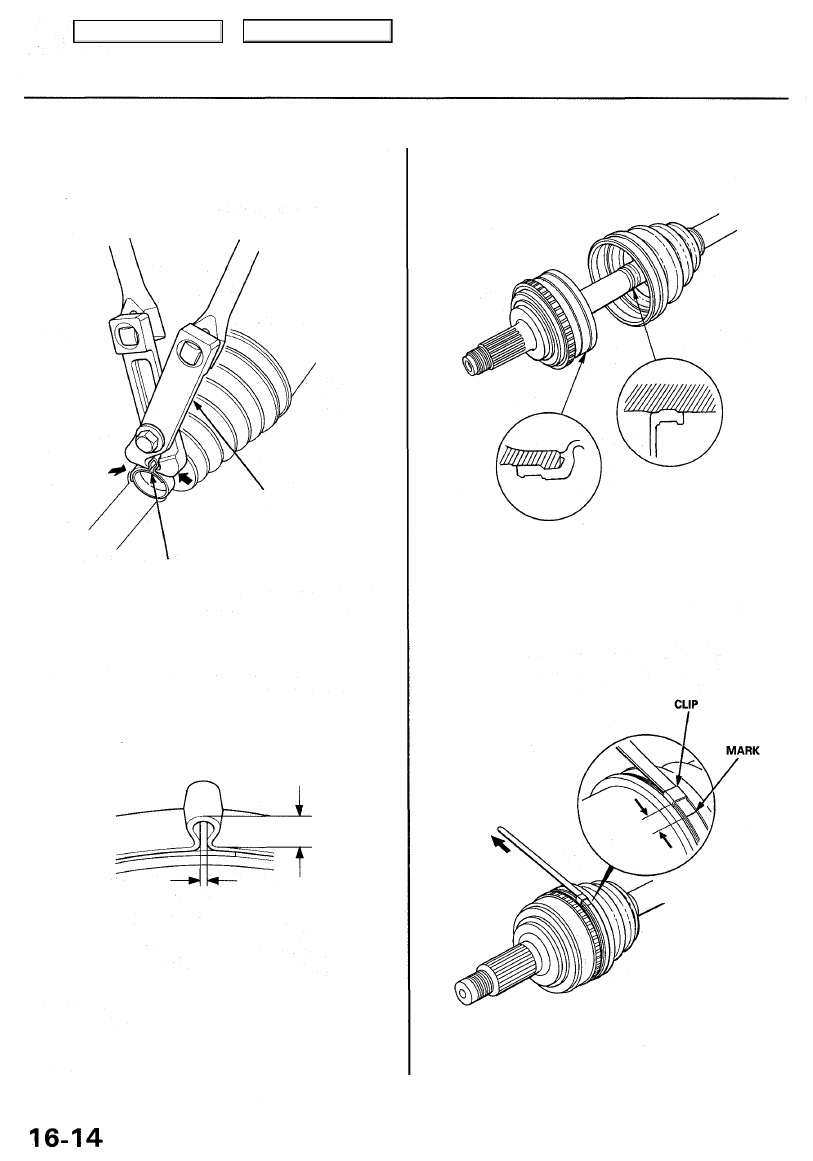

11. Close the ear portion of the band with a commercially

available boot band pincers Kent-Moore J-35910 or

equivalent.

Driveshafts

13. Fit the boot ends onto the driveshaft and the

outboard joint.

14. Fit the double loop boot bands onto the boot ends.

15. Pull up the slack in the band by hand.

16. Mark a position on the band 10 - 14 mm (0.4 - 0.6

in.) from the clip.

12. Check the clearance between the closed ear portion

of the band. If the clearance is not within the stan-

dard, close the ear portion of the band further.

BOOT BAND PINCERS

Kent-Moore J-35910

or equivalent

EAR PORTION

Main Menu

Table of Contents

17. Thread the free end of the band through the nose

section of the commercially available boot band

tool KD-3191 or equivalent, and into the slot on the

winding mandrel.

BOOT BAND TOOL

(Commercially available)

KD-3191 or equivalent

Mark spot.

WINDING

MANDREL

18. Place a wrench on the winding mandrel of the boot

band tool, and tighten the band until the marked

spot on the band meets the edge of the clip.

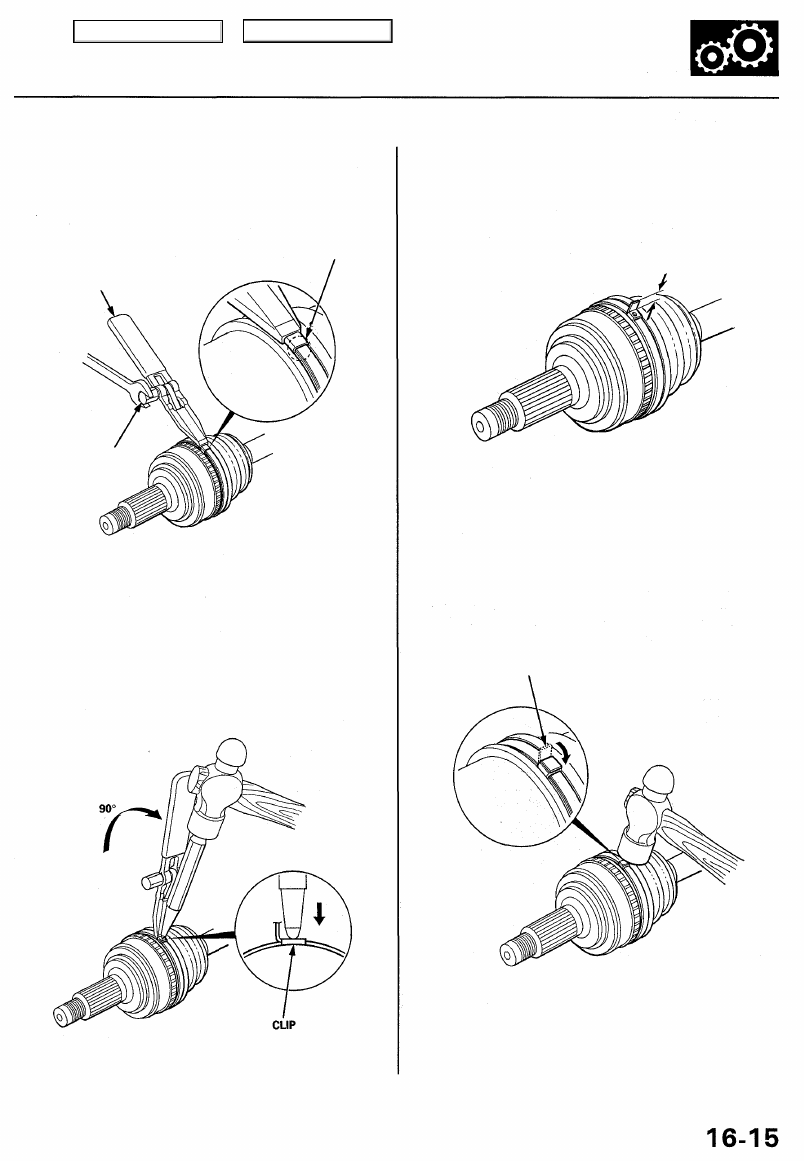

19. Lift up the boot band tool to bend the free end of

the band 90° to the clip. Center punch the clip, then

fold over the remaining tail onto the clip.

21. Bend the band by tapping it down with a hammer.

NOTE: Make sure the band and the clip do not

interfere with anything, and the band does not

move. Remove any grease remaining in the sur-

rounding surfaces.

20. Unwind the boot band tool, and cut off the excess

free end of the band to leave a 5 - 10 mm (0.2 - 0.4

in) tail protruding from the clip.

BAND END

(0.2 - 0.4 in)

Main Menu

Table of Contents

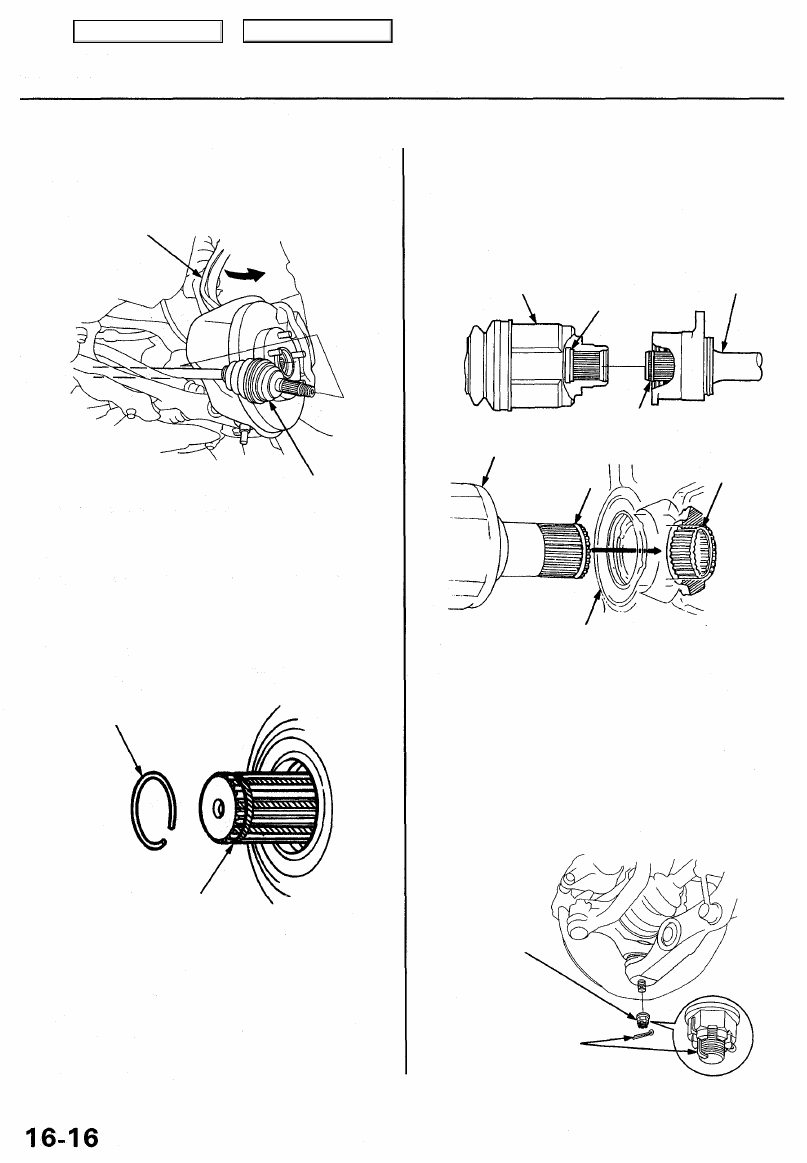

3. Install a new set ring onto the driveshaft or interme-

diate shaft groove.

CAUTION: Always use a new set ring whenever

the driveshaft is being installed.

SET RING GROOVE

Driveshafts

Installation

1. Install the outboard joint into the knuckle.

KNUCKLE

4. Insert the inboard end of the driveshaft into the dif-

ferential or intermediate shaft until the set ring

locks in the groove.

NOTE: Clean the areas where the driveshaft con-

tacts the differential thoroughly with solvent or car-

buretor cleaner, and dry with compressed air.

INTERMEDIATE SHAFT

GROOVE

INBOARD JOINT

SET RING

Replace.

INBOARD JOINT

SET RING

Replace.

GROOVE

DIFFERENTIAL

5. Install the knuckle onto the lower arm, then tighten

the castle nut, and install a new cotter pin.

NOTE: Wipe off the grease before tightening the

nut at the ball joint.

CAUTION:

• Be careful not to damage the ball joint boot.

• Torque the castle nut to the lower torque speci-

fication, then tighten it only far enough to align

the slot with the pin hole. Do not align the nut

by loosening it. Install a new cotter pin.

CASTLE NUT

14 x 2.0 mm

69 - 78 N-m

(7.0 - 8.0 kgf-m,

51 - 58 Ibf-ft)

COTTER PIN

Replace.

On reassembly,

bend the cotter pin

as shown.

2. Apply 0.5 - 1.0 g (0.02 - 0.04 oz) of grease to the

whole splined surface of the intermediate shaft.

NOTE: After applying grease, remove the grease

from the splined grooves at intervals of 2 - 3 splines

and from the set ring groove so air can bleed from

the inboard joint.

SET RING

Replace.

OUTBOARD JOINT

Main Menu

Table of Contents

6. Install the damper fork over the driveshaft and onto

the lower arm. Install the damper in the damper

fork so the aligning tab is aligned with the slot in

the damper fork.

ALIGNING TAB

DAMPER FORK

FLANGE BOLT

10 x 1.25 mm

43 N-m (4.4 kgf-m, 32 Ibf-ft)

SELF-LOCKING NUT

12 x 1.25 mm

69 N-m (7.0 kgf-m, 51 Ibf-ft)

Replace.

7. Loosely install the flange bolts and the new self-

locking nut.

NOTE: The bolts and nut should be tightened with

the vehicle's weight on the damper.

8. Apply engine oil to the seating surface of the new

spindle nut.

WHEEL NUT 12 x 1.5 mm

108 N-m (11.0 kgf-m, 80 Ibf-ft)

SPINDLE NUT 24 x 1.5 mm

245 N-m (25.0 kgf-m, 181 Ibf-ft) Replace.

NOTE: After tightening, use a drift to

stake the spindle nut shoulder against the driveshaft.

9. Install a new spindle nut, then tighten the nut.

10. Install the front wheel with the wheel nuts.

NOTE: Before installing the wheel, clean the mating

surfaces of the brake disc and the wheel.

11. Tighten the flange bolts and the new self-locking

nut with the vehicle's weight on the damper.

12. Refill the differential with recommended oil (see

).

13. Check the front wheel alignment, and adjust it if

necessary (see

).

FRONT WHEEL

Main Menu

Table of Contents

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст