Acura RL (1996-2004 year). Manual — part 32

Repair Procedures

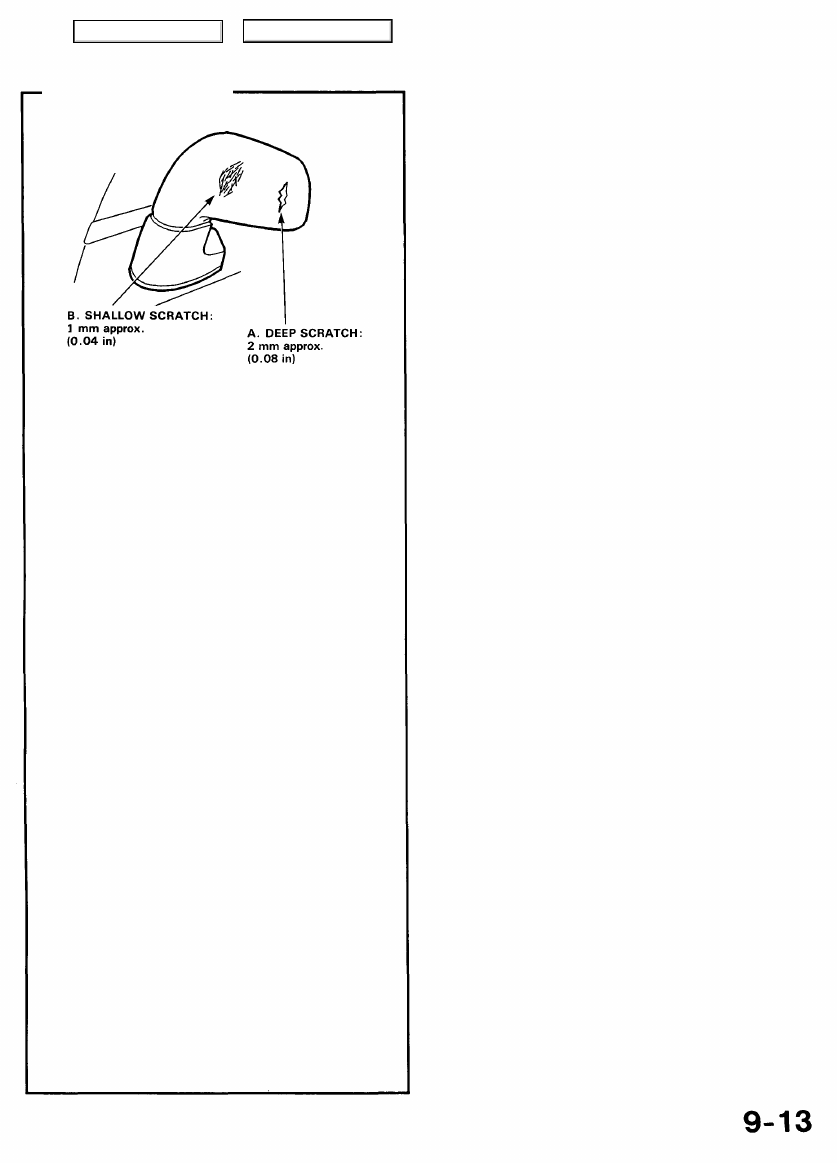

A. Deep scratches, when filling:

(1) Sand the damage section. (#120~#240)

(2) Apply the filler and dry.

(3) Sand the filler (#240~#400)

(4) Coat with the primer/primer surfacer and dry.

(5) Sand the primer surfacer. (#600~#800)

(6) Top coating.

B. Shallow scratches:

(1) Coat with the primer/primer surfacer.

(2) Sand the primer surfacer. (|600~#800)

(3) Top coating.

C. Repaint:

(1) Sand the primer surfacer. (#600~#800)

(2) Top coating.

Main Menu

Table of Contents

Refinishing Procedures

1. Base material reconditioning (sanding)

-1. Repaint and replacement part

Lightly sand the part with #400, #600 or #800.

-2. Slight scores or scratches

Use a flexible sanding block and wet sand the

damaged section with #400, #600.

NOTE: Sand level to remove damage.

-3. Deep scratches, when filling.

Use a flexible sanding block and wet sand the

damaged section with #240, #400.

2. Degreasing and cleaning

Clean the repaired area with wax and grease remover,

then blow with air dry.

• Do not use high air pressure; use only an ap-

proved, 210 kPa (2.1 kgf/cm

2

, 30 psi) air nozzle.

• Wear goggles or safety glasses to prevent eye

injury.

NOTE: Wipe dust off surface with a tack cloth.

3. Filling, drying and sanding

Apply the filler in several thin coats.

NOTE: Mix and apply the filler according to the

manufacturer's instructions.

-I. Dry the filler with an infrared dryer for 5 or 6

minutes.

Be sure to keep the dryer 40-50 cm (16-20 in) away

from the surface.

-2. Scratch the filled surface with your nail. If the

surface is white when scratched, dry sand and wet

sand with the #240-#400 paper. Be sure to sand

level.

4. Cleaning with compressed air, and degreasing

Blow the entire area to be coated with compressed air,

then clean with wax and grease remover.

• Do not use high air pressure; use only an ap-

proved, 210 kPa (2.1 kgf/cm

2

, 30 psi) air nozzle.

• Wear goggles or safety glasses to prevent eye

injury.

NOTE: Clean the whole surface to the help the masking

tape adhere securely.

(cont'd)

Main Menu

Table of Contents

ABS/PC Resin Parts

Refinishing Procedures (cont'd)

5. Masking

Use the masking tape and paper to mask the area that

should not be sprayed.

6. Coat with primer/primer surfacer, drying and sand-

ing.

• Spray the primer surfacer over the filled area.

8. Top coating

• Remove dust with a tack cloth before spraying.

• Spray the top coating. Spray until the primer sur-

facer is covered.

• The coating thickness should be 30-35 microns.

• Ventilate when spraying paint. Most paint

contains substances that are harmful if inhaled

or swallowed. Read the paint label before

opening the paint container.

• Avoid contact with skin. Wear an approved res-

pirator, gloves, eye protection and appropriate

clothing when painting.

• Paint is flammable. Store it in a safe place, and

keep it away from sparks, flames or cigarettes.

• Do not use high air pressure; use only an ap-

proved, 210 kPa (2.1kgf/cm

2

, 30 psi) air nozzle.

• Wear goggles or safety glasses to prevent eye

injury.

NOTE: For the recommended top coat paint, refer to

"Example of repair materials".

Solid color: Color enamel + color clear coat

Metallic: Metallic enamel + clear coat

Pearl: Pearl enamel + clear coat

9. Drying

After top coating for about 10 minutes, then dry with

an infrared dryer.

NOTE: Follow the paint manufacturer's specification to

dry properly.

• Ventilate when spraying paint. Most paint

contains substances that are harmful if inhaled

or swallowed. Read the paint label before

opening the paint container.

• Avoid contact with skin. Wear an approved res-

pirator, gloves, eye protection and appropriate

clothing when painting.

• Paint is flammable. Store it in a safe place, and

keep it away from sparks, flames or cigarettes.

• Do not use high air pressure; use only an ap-

proved, 210 kPa (2.1kgf/cm , 30 psi) air nozzle.

• Wear goggles or safety glasses to prevent eye

injury.

• The coating thickness should be 20-25 microns.

NOTE: Follow the primer/primer surfacer manufacturer's

instructions.

- 1 . Drying

• Let the primer surfacer dry naturally for 5 to 10

minutes, then dry with a infrared dryer.

Body parts being dried with an

industrial dryer can get hot enough to cause injury.

Do not touch parts being dried.

• Be sure to keep the dryer 40-50 cm (16-20 in)

away from the paint film.

-2. Sanding

Lightly dry sand the whole area to be painted with

#600, #800 sandpaper.

7. Blow off with compressed air, then clean with wax

and grease remover.

• Do not use high air pressure; use only an ap-

proved, 210 kPa (2.1kgf/crrv, 30 psi) air nozzle.

• Wear goggles or safety glasses to prevent eye

injury.

NOTE: Clean the whole surface to help the masking

tape adhere securely.

Main Menu

Table of Contents

9-15

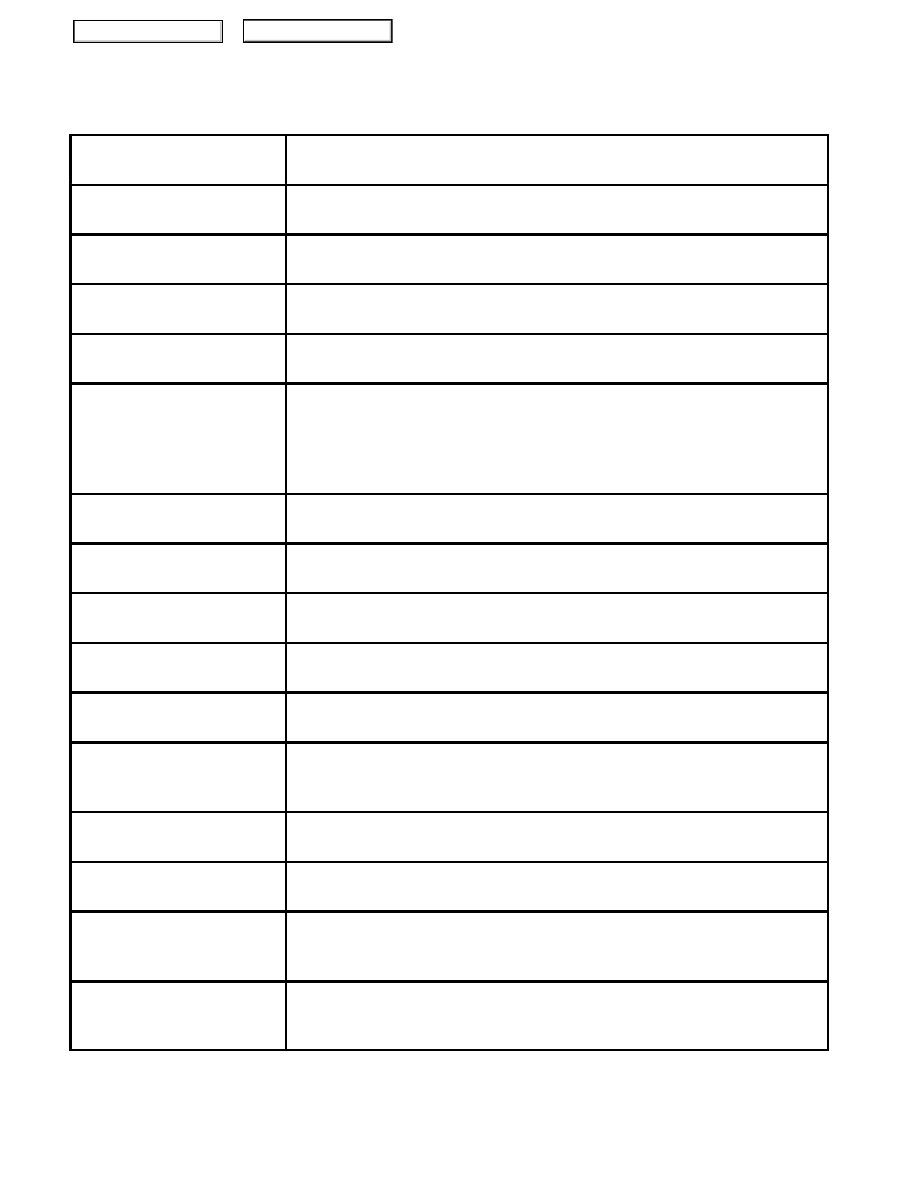

Glossary

All paint

Painting of complete surface.

Air blow

Using compressed air to blow away dust and debris.

Block paint

Painting a section only, such as a door.

Clear paint (clear coat)

Clear paint without dye (pigment).

Double coat

Application of two paint coats.

Dry coat

Paint which left the spray gun and dried partially before it reached the surface, thereby

making the painted surface rough. Dry coating is caused by too little paint being fed, too

high an air pressure, too much distance between the painted surface and the gun, or

moving the gun too fast.

Dry film

Paint which has dried completely.

Dust coat

Paint is applied thinner than a dry coat. Painted surface becomes rough.

ED painting

Electrostatic discharge painting.

Enamel

Finishing paint pigmented with dye.

Featheredging

Smoothing off the edges of painted surfaces.

Flash off

Evaporation of the paint solvent. (Flash off time is the period between paint coat

applications.)

Ford cup

A type of viscosity meter .

Gun stroke

Movement of the paint gun.

Hardener

Hardening agent of two-liquid type paint or fillers. Polycyanates and oxides are used

for hardeners.

Heat-hardening acrylic

resin paint

Composed of acrylic resin and meramine resin, and hardened (forms a paint film) by

baking.

Main Menu

Table of Contents

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст