Mazda Training manual — part 16

Powertrain Engines

•

Due to the large bathub shaped combustion chambers the rotary engine is equipped with

two spark plugs per rotor housing, improving combustion efficiency and exhaust

emissions

NOTE: Two different spark plugs (leading and trailing) with different lengths are mounted in

each rotor housing. If a wrong spark plug is used the engine may be damaged (e.g. a

spark plug which is too long may contact the rotor).

•

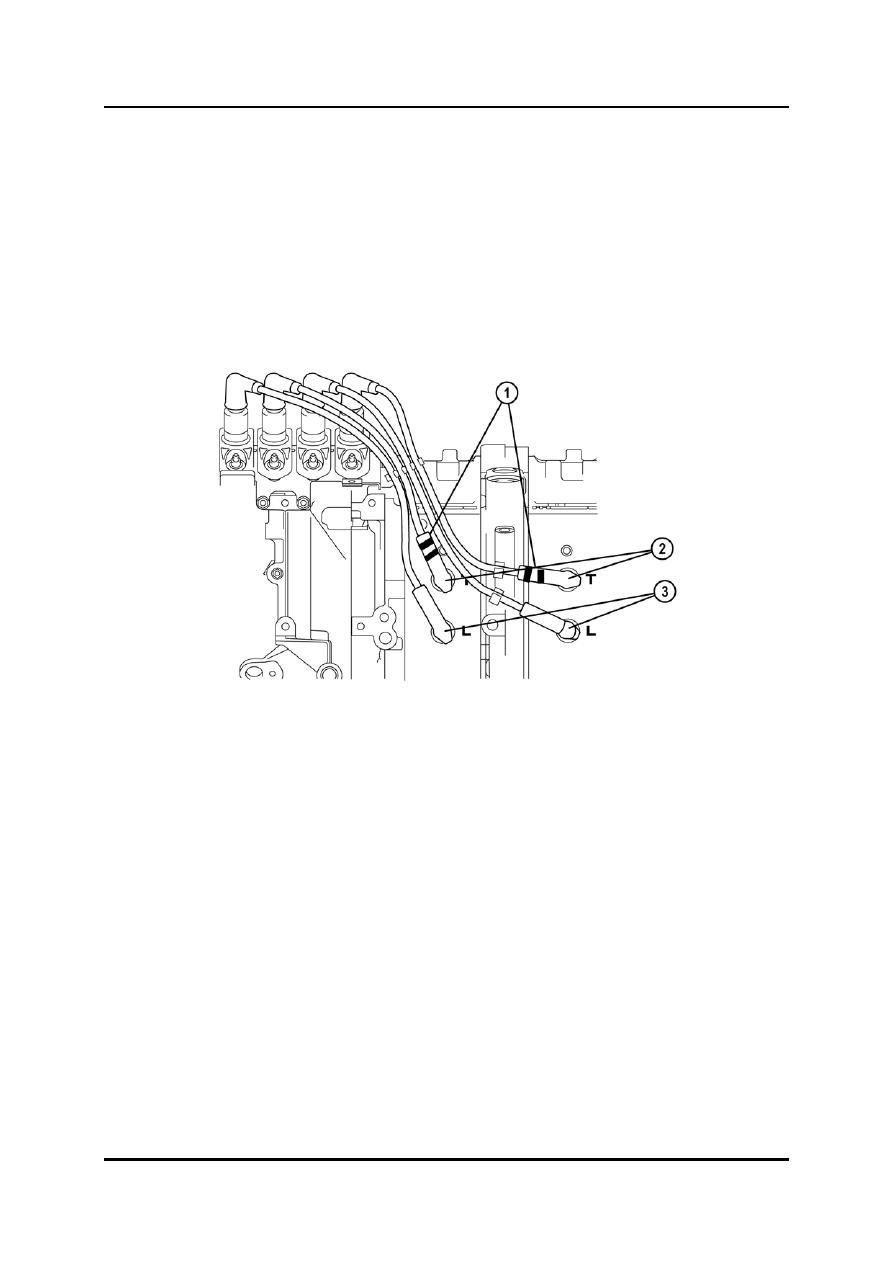

The high tension leads for the trailing spark plugs are marked with blue and green tape

to prevent incorrect installation.

L1001.4_01137

1

Blue and green tape

3

Leading spark plugs

2

Trailing spark plugs

Curriculum Training

01-51

Engines Powertrain

Operating Principle

•

In the rotary engine, each of the three faces of the rotor forms a chamber. These three

chambers are not interconnected and their combustion cycles vary as described below.

•

In much the same way as the four-stroke reciprocating engine, the air/fuel mixture in a

rotary engine is subjected to combustion and expansion within the engine, thus

converting heat energy to output power.

•

However, while the reciprocating engine uses the vertical movement of the pistons and a

complex valve mechanism to allow gas exchange, a rotary engine uses the rotation of

the rotor to open and close intake and exhaust ports on either side of it.

•

Because each rotor has three working chambers, this means that for every single

rotation of the rotor three full working cycles (intake, compression, combustion, exhaust)

are completed, resulting in three power pulses being delivered to the eccentric shaft for

one rotation of the rotor (see explanation on following pages).

L1001.4_01116

01-52 Curriculum

Training

Powertrain Engines

Intake Stroke

•

The volume of the operating chamber in position 1 is at its minimum, thus corresponding

with intake TDC (Top Dead Center) of a reciprocating engine. As the rotor continues to

turn from 2 through to 4, the intake ports become increasingly larger and draw in the

air/fuel mixture as the intake stroke begins. At the same time, the intake operating

chamber increases in capacity, reaching its maximum at 5. At this time, the rotor position

corresponds with BDC (Bottom Dead Center) of the intake stroke on a reciprocating

engine.

Compression Stroke

•

After 5, the intake ports are covered by the rotor, ending the intake stroke. The operating

chamber’s capacity gradually becomes smaller, compressing the air/fuel mixture as the

compression stroke begins. As the rotor turns, the operating chamber capacity becomes

smaller and smaller from 6 through to 9, and at 10 when the compression is almost

complete, the mixture is ignited by the spark plugs. At 10, the operating chamber’s

capacity is at its minimum. This is TDC of the compression stroke.

Combustion Stroke

•

The mixture ignited at 10 is burnt, pressure and volume increase, and expansion in the

operating chamber continues from 11 through to 13. During this time, the combustion

energy of the air/fuel mixture is applied to the rotor’s surface, and via the eccentric shaft

it is converted to rotational energy and used as motive power. At 15, the operating

chamber’s capacity reaches its maximum as it approaches BDC of the combustion

stroke.

Exhaust Stroke

•

After completion of combustion, burnt gases are expelled from the exhaust ports as the

capacity of the operating chamber decreases from 15 through 18. This is the exhaust

stroke, and when this stroke ends there is a return to 1, from where the cycle starts

again.

Curriculum Training

01-53

Engines Powertrain

•

The above is a description for only one chamber; the other two operate in exactly the

same way. As a result of these actions by only one chamber, the rotor makes one

rotation (during which the eccentric shaft turns three times), resulting in an intake of the

gas mixture followed by compression, combustion and exhaust. Also, because there are

three chambers on one rotor, there are three combustion (output) cycles for each

revolution of the rotor. In other words, one combustion cycle takes place for each

revolution of the eccentric shaft.

•

Concerning gas exchange, the cycles of the rotary engine are the same as those of a

four-stroke reciprocating engine, but combustion cycles per revolution of the output shaft

are the same as on a two-stroke reciprocating engine. Consequently, the rotary engine is

a special type of engine that neither falls into the four-stroke nor two-stroke category.

01-54 Curriculum

Training

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст