Mazda Training manual — part 282

AIR CONDITIONING

SG01 - Basic System

SG01-7

TC070-15-01H

Condenser

• The figure below shows a sub cool condenser. It is a multi-flow condenser which is

equipped with a sub cooling part and integrated with a receiver/drier.

• The sub cool condenser separates liquid-gas refrigerant initially cooled at the

condenser via the receiver/drier, where it returns again to the condenser sub cooling

part and is cooled, accelerating liquefaction and improving cooling capacity.

Refrigerant life

• The pipes in the refrigerant lines are made of aluminum alloy and the hoses are

made of rubber (flexible hose).

• A high-pressure charging valve is located on the cooler hose (HI) and a low-

pressure charging valve is located on the cooler hose (LO).

Z6

AIR CONDITIONING

SG01 - Basic System

SG01-8

TC070-15-01H

LF

Spring-lock Coupling

• Spring-lock coupling is used for pipe-to-pipe connections. As a result, pipes can be

connected easily, maintenance of torque is unnecessary, and serviceability is

improved.

• There is a garter spring in the cage on the male side (cooler pipe or cooler hose

(LO)) of spring-lock coupling type and the end of the pipe on the female side (A/C

unit) is flared. When the pipes are being connected, the flared end of the female

side forces the garter spring on the female side to expand, and by fully inserting the

male side into the female side, the flared end is locked by the garter spring. When

the cooler pipe or cooler hose (LO) is replaced, the additional indicator ring comes

out after connecting; indicating that the flared end is locked.

AIR CONDITIONING

SG01 - Basic System

SG01-9

TC070-15-01H

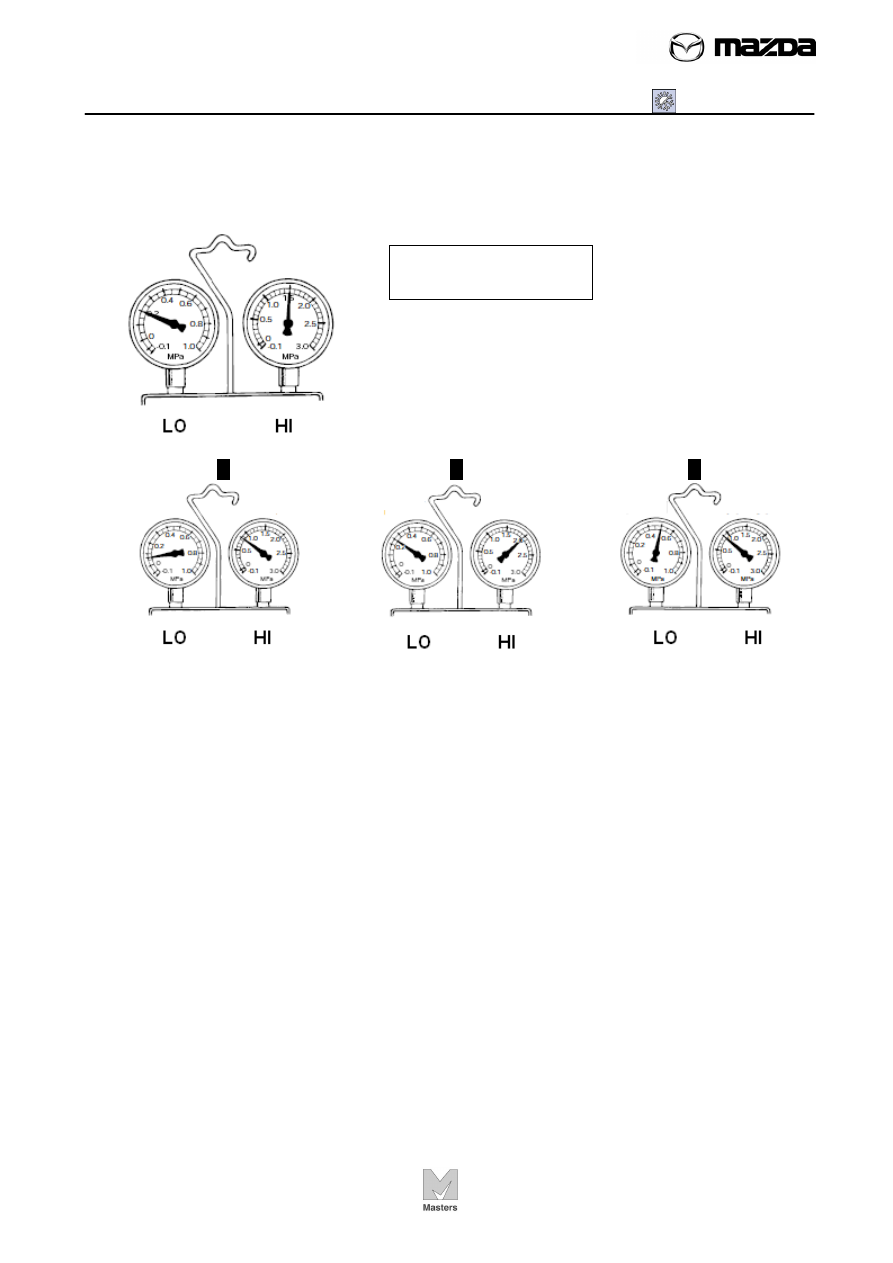

Gauge manifold reading

Normal

LO: 0.15 – 0.25 MPa

HI: 1.37 – 1.57 MPa

It may vary under the different condition.

A

B

C

A: Insufficient refrigerant

B: Excessive refrigerant or insufficient cooling

C: Compressor failure

AIR CONDITIONING

SG01 - Basic System

SG01-10

TC070-15-01H

Refrigerant System Service Warnings (Reference)

Handling Refrigerant

• Avoid breathing air conditioning refrigerant or lubricant vapor. Exposure may irritate

eyes, nose and throat. Also, due to environmental concerns, we urge use of

recovery/recycling/recharging equipment when draining R-134a from the air

conditioning system. If accidental system discharge occurs, ventilate work area

before resuming service.

• Do not perform pressure test or leak test for R-134a service equipment and/or

vehicle air conditioning system using compressed air. Some mixtures of air and R-

134a have been shown to be combustible at elevated pressures. These mixtures, if

ignited, may cause injury or property damage. Additional health and safety

information may be obtained from refrigerant manufacturers.

• Do not allow the refrigerant to leak near fire or any kind of heat. A poisonous gas

may be generated if the refrigerant gas contacts fire or heat such as from cigarettes

and heaters. When carrying out any operation that can cause refrigerant leakage,

extinguish or remove the above-mentioned heat sources and maintain adequate

ventilation.

• Handling liquid refrigerant is dangerous. A drop of it on the skin can result in

localized frostbite. When handling the refrigerant, wear gloves and safety goggles. If

refrigerant splashes into the eyes, immediately wash them with clean water and

consult a doctor.

Storing Refrigerant

• The refrigerant container is highly pressurized. If it is subjected to high heat, it could

explode, scattering metal fragments and liquid refrigerant that can seriously injure

you. Store the refrigerant at temperatures below 40 °C {104 °F}.

Refrigerant System Service Cautions

Handling Insufficient Refrigerant Level

• If an insufficient refrigerant level is detected at troubleshooting, do not charge (add)

the refrigerant. Because an accurate amount of refrigerant cannot be determined

from the pressure indicated on the manifold gauge, never charge the refrigerant. If

there is too much or too little refrigerant from the refilling, there may be secondary

problems such as damage to the refrigerant cycle parts, or a decrease of cooling

performance. Therefore, if it is determined that the refrigerant level is insufficient,

completely remove refrigerant from the refrigerant cycle and refill with refrigerant to

the specified amount.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст