Mazda Training manual — part 269

Air Conditioning Fundamentals

TC070-05-01S

7 – REFRIGERANTS

50

In the mid-1980s, scientists discovered that chemicals called

chloro-fluorocarbons (CFCs) were destroying the ozone in the

atmosphere. Ozone protects the earth from harmful ultraviolet rays

released by the sun.

One of the major contributors to CFCs in the atmosphere was R-12,

which often leaked into the atmosphere during servicing of A/C systems.

In 1987, the United States and 22 other countries signed an

international agreement calling for the gradual phase-out of CFCs.

In 1990, the United States revised the federal Clean Air Act, adding

stricter CFC standards than the international agreement. As a result,

R-12 was phased out of most automotive A/C systems in about 1990.

By the year 2000, R-12 will be banned completely.

HFC134a (R-134a)

Because of the environmental damage caused by R-12, scientists

developed an alternative refrigerant called R-134a. Most vehicles

manufactured from 1990 to the present use R-134a as an A/C

refrigerant.

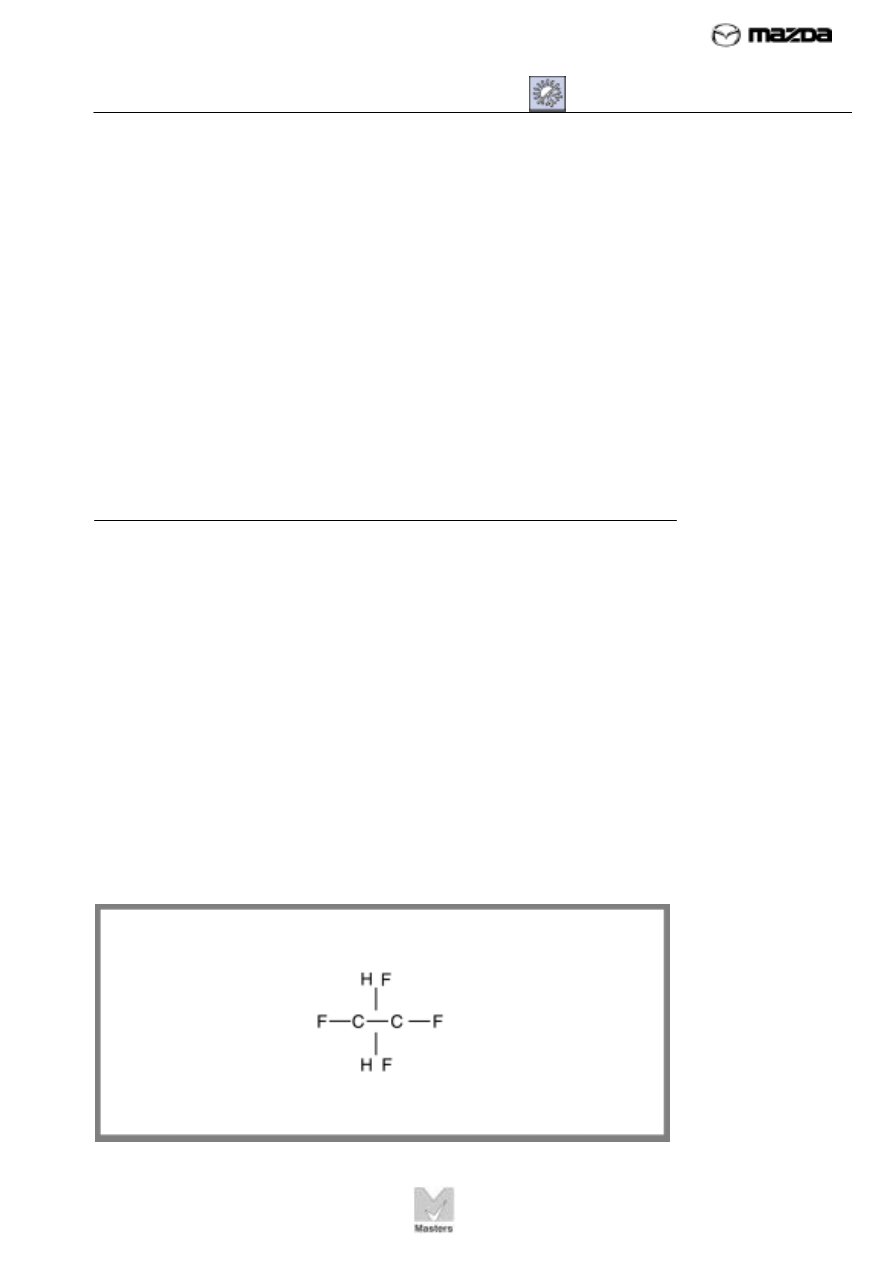

Chemical Structure

R-134a is the common name for Tetrafluoroethane-134a (HFC-134a),

whose chemical formula is CH2FCF3. Unlike R-12, R-134a does not

contain CFCs. Instead, it contains hydrofluorocarbons (HFCs), which do

not damage the ozone layer.

Figure 29 shows the chemical structure of R-134a, which contains two

carbon atoms, two hydrogen atoms, and four fluorine atoms.

FIGURE 29. R-134

contains carbon,

hydrogen, and

fluoride atoms. It is

used as a refrigerant

in most vehicles built

from 1990 to the

present.

Air Conditioning Fundamentals

TC070-05-01S

7 – REFRIGERANTS

51

Properties of R-134a

Like R-12, R-134a has chemical properties that make it ideal for use as a refrigerant. These

include:

•

Low boiling point of -15° F (-26° C) at sea level.

•

Ability to change temperature readily in response to changes in pressure.

R-134a provides most of the benefits of R-12 without the harmful atmospheric effects. The

absence of chlorine in R-134a makes it environmentally “friendly,” but R-134a can be

flammable under certain pressures and concentrations. For more information about these

conditions, see “Safety Procedures” on page 57.

DIFFERENCES BETWEEN REFRIGERANTS

A/C systems that use one type of refrigerant cannot use the other type. For example, you

cannot use R-134a to charge an older A/C system designed to use R-12. (Some older

systems can be retrofit to use the new refrigerant, but these are special cases. See

“Retrofitting” on page 56.)

Under no circumstances can you mix R-12 and R-134a in the same system. Mixing

refrigerants is called cross-contamination, and it can seriously damage the A/C system. In

addition, identifying contaminated refrigerant during normal diagnosis is difficult.

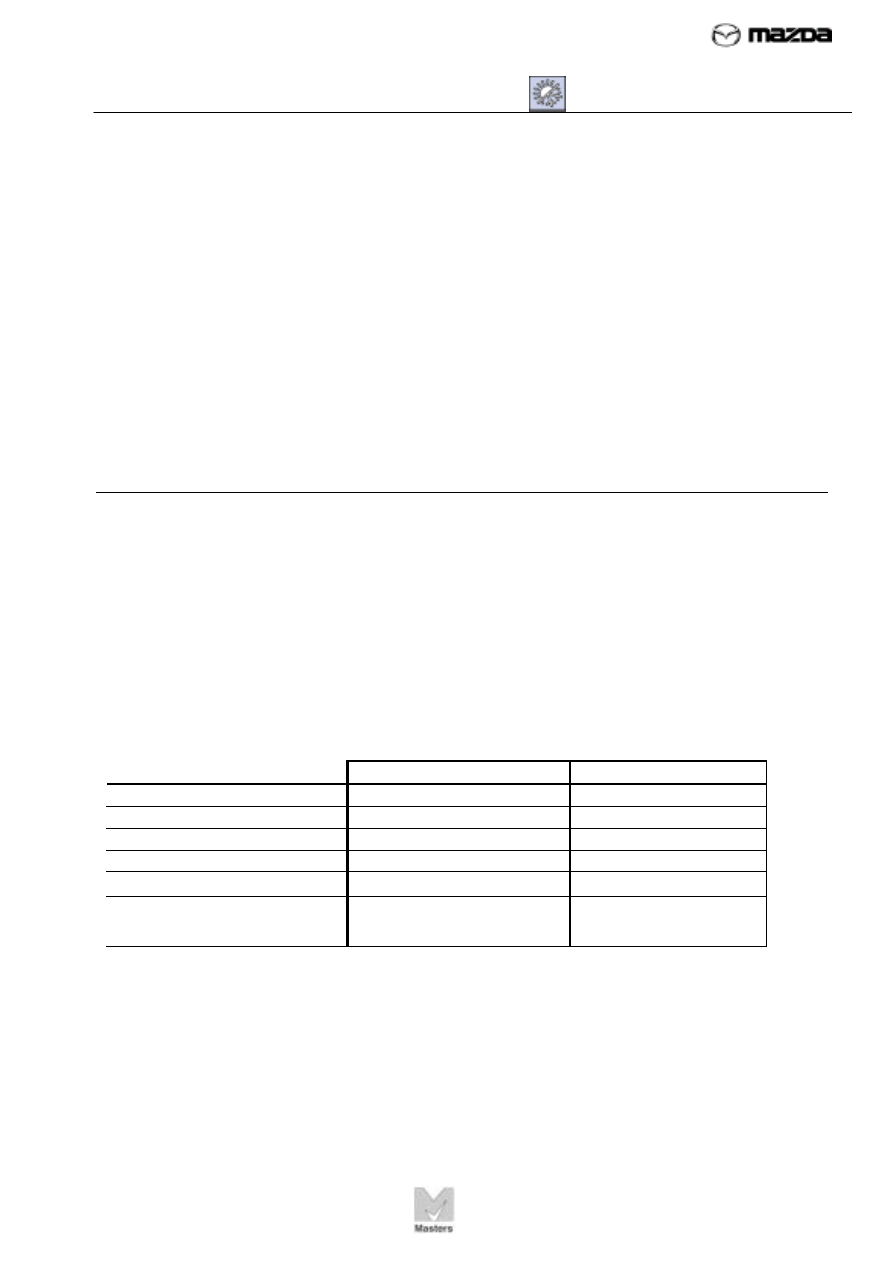

The chart below outlines the differences between the two refrigerants. Whenever you work

on an A/C system, you must determine the refrigerant type.

R-12

R-134a

Container color

White

Light blue

Container marking

R-12 R-134a

Container fitting size

7/16" - 20; 1/4" flare

1/2" - 16 ACME

Chemical name

Dichlorodifluoromethane

Tetrafluoroethane

Boiling point

-21.62° F (-29.70° C)

-15.07° F (-25.15° C)

Latent heat of vaporization

36.43 BTUs @ 32° F (0°

C)

47.19 BTUs @ 32° F

(0° C)

Air Conditioning Fundamentals

TC070-05-01S

7 – REFRIGERANTS

52

To prevent cross-contamination, always observe the following rules:

1. Refer to the tags or bands around the lines and tubes to identify the refrigerant used in

the system.

2. Do not mix R-12 and R-134a service equipment.

3. Do not use adapters to cross from one refrigerant to the other.

4. You may use new R-134a rubber seals and hoses on an R-12 system. However, you

may not use R-12 rubber seals and hoses on an R-134a system.

RECYCLED, RECLAIMED, AND EXTRACTED REFRIGERANT

Technicians often remove (discharge) refrigerants from an A/C system during service.

Depending on how these refrigerants are processed after removal, they are called recycled,

reclaimed, or extracted.

Recycled Refrigerant

Recycled refrigerant is cleaned to remove contaminants produced during normal operation

of a mobile A/C system. Mixing recycled refrigerant from a non-mobile system — a building

A/C system, for example — will contaminate recycled mobile refrigerant.

Reclaimed Refrigerant

Reclaimed refrigerant is processed to the same standards and purity as new refrigerant.

This process requires expensive equipment not ordinarily found in dealership service

departments.

Reclaimed and recycled refrigerant will perform equally well in all mobile A/C systems.

Air Conditioning Fundamentals

TC070-05-01S

7 – REFRIGERANTS

53

FIGURE 30. A

container filled to 60

percent capacity at

50° F (10° C) poses

no safety hazard.

However, the same

container at 90° F

(32° C) reaches its

maximum capacity.

At 100° F (38° C),

high pressure in the

container can cause

an explosion.

Extracted Refrigerant

Extracted refrigerant is simply removed and stored in an approved

container, without any filtering or processing. Before you return

extracted refrigerant to a vehicle A/C system, you should recycle it to

remove impurities.

STORING RECYCLED REFRIGERANT

Both R-12 and R-134a are gases at normal room temperature, and they

can be hazardous if stored improperly. New refrigerant stored in its

original, properly filled container usually poses no safety hazard.

However, recycled refrigerant can be dangerous if it is stored in the

wrong type of container or in an overfilled container.

To prevent accidents when handling recycled refrigerant, always follow

the rules below:

1.

Never save disposable refrigerant containers for reuse. Remove all

refrigerant and dispose of the containers properly.

2. Use only containers approved by the U.S. Department of

Transportation. Approved containers are marked “DOT4BA” or

DOT4BW.”

3. Never fill a container to more than 60 percent of its capacity.

4. Never store refrigerant containers in direct sun or heat. High

temperature causes the gas to expand, which increases the

pressure in the container. Figure 30 shows what can happen if a

properly filled container reaches a temperature of 100° F (38° C).

50° F

90° F

100° F

60% capacity 100% capacity

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст