Mazda Training manual — part 27

Powertrain Engines

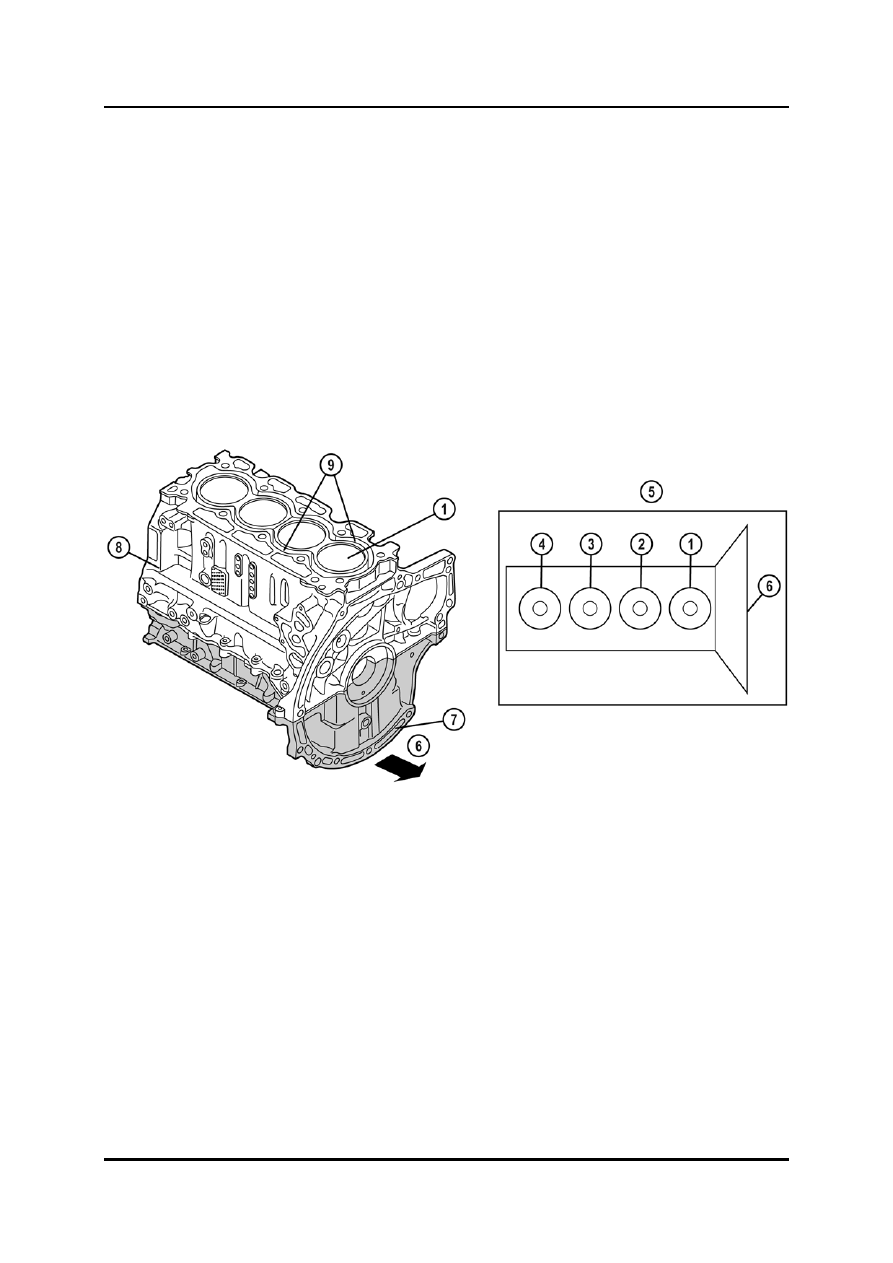

Cylinder Block

•

The cylinder block is equipped with cylinder liners, the coolant jackets of which are open

towards the top.

•

The cylinder block is composed of an upper and a lower cylinder block, in which the

main bearing caps are integrated. Upper and lower cylinder block are matched to each

other, i.e. they cannot be replaced separately. If one of the components exceeds the

specification, the cylinder block must be replaced as a complete unit.

NOTE: Bolt and stud repairs using thread inserts in the area of the cylinder head bolts and

main bearing bolts are not permitted.

•

The cylinder no.1 is located on the transmission side (French-style cylinder numbering).

L1001.4_01087

1

Cylinder no.1

6

Transmission side

2

Cylinder no.2

7

Lower cylinder block

3

Cylinder no.3

8

Upper cylinder block

4

Cylinder no.4

9

Coolant jackets

5

French style cylinder numbering

Curriculum Training

01-95

Engines Powertrain

Pistons

•

The pistons have valve recesses for the intake and exhaust valves.

•

The piston skirt is coated to reduce friction between the piston and the cylinder.

•

The connecting rods are fracture-split on the big end to ensure a perfect fit between

connecting rod and connecting rod bearing cap. For this reason, the pairs of connecting

rods and connecting rod bearing caps must be kept together during removal.

L1001.4_01088

1

Valve recesses

2

Arrow indicating the installation direction

•

There is no positioning tab for locating the lower bearing in the connecting rod big end.

For installing the lower connecting rod bearing shell two alignment tools (SST) are

required (refer to the workshop manual for details).

L1001.4_01144

1

Alignment tools (SST)

01-96 Curriculum

Training

Powertrain Engines

Crankshaft

•

The crankshaft is equipped with a key for the installation of the crankshaft timing pulley

and the crankshaft pulley.

•

The crankshaft timing pulley has a magnetic pulse wheel for the CKP sensor signals.

NOTE: When removing or installing the crankshaft timing pulley care must be taken, since

scratches or impacts can de-magnetize the magnetic pulse wheel.

•

To ensure optimum bearing clearance of the crankshaft, main bearing shells with

different thickness and hence different tolerance class are fitted in one engine. The

upper main bearing shells are only available in one tolerance class and feature a black

color coding on the edge.

•

The lower main bearing shells are available in three different tolerance classes (A, B and

C) and feature one of the following color codings on the edge:

–

Blue (tolerance class A)

–

Black (tolerance class B)

–

Green (tolerance class C)

•

To determine the tolerance class for the lower bearing shell of each main bearing, the

diameter classes of the main bearings and of the main journals have to be verified.

•

The diameter class of the main bearings can be verified by the engraved letters (A to Z)

on the cylinder block, whereas the first letter is equivalent to the diameter class of main

bearing no.5 (the symbol ^ locates the timing belt side).

•

The diameter class of the main journals can be verified by the printed letters (A to Z) on

the crankshaft, whereas the first letter is equivalent to the diameter class of main journal

no.5 (the symbol ^ locates the timing belt side).

Curriculum Training

01-97

Engines Powertrain

L1001.4_01090

1

Diameter classes of the main journals

2

Diameter classes of the main bearings

•

The correct tolerance class for the lower bearing shell of each main bearing can be

determined by the diagram shown below.

L1001.4_01091

1

Diameter class of main journal

4

Black (tolerance class B)

2

Diameter class of main bearing

5

Green (tolerance class C)

3

Blue (tolerance class A)

01-98 Curriculum

Training

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст