Great Wall Hover. Manual — part 68

b. Adhere the measuring meter base on the end surface of reducer

housing; the measuring head contacts the tooth surface; rotate

the driven gear by hand and measure the engagement clearance be

tween the drive and driven gear.

c. If the engagement clearance does not meet the requirement, use

the special tools to adjust the left and right adjusting ring until it

meets the requirement.

d. Recheck the engagement clearance between the drive and driven

gear.

Engagement clearance: 0.13-0.18mm

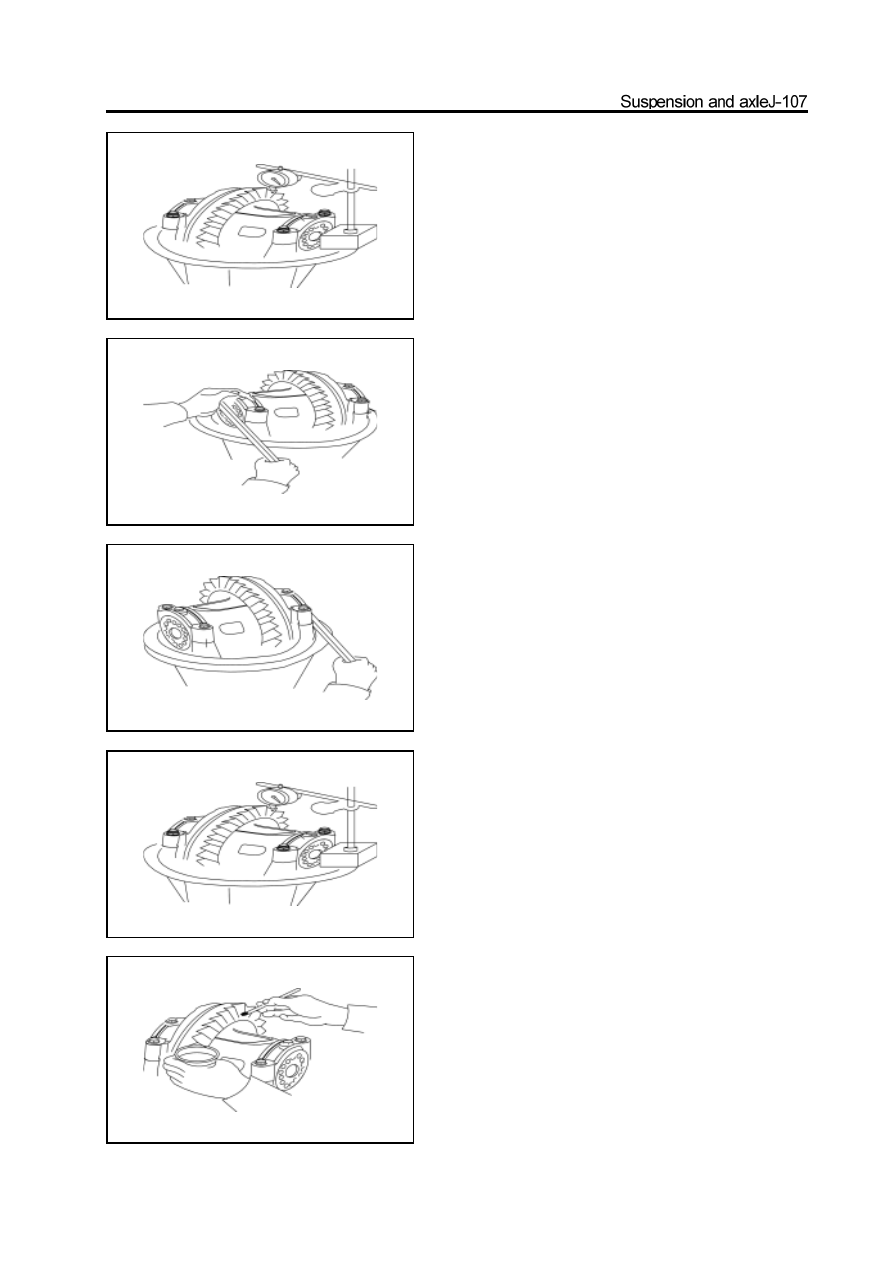

14. Check the meshing mark of drive and driven bevel

gear.

a. Paint 3-4 teeth with the red lead in three different positions of

driven bevel gear.

b. Rotate the driven bevel gear in clockwise and anticlockwise by

hand.Check the engagement of gear.

sound contact

toe contact

dedendum contact

arge end contact

small end contact

select the shim which can make the small drive gear

close to the driven bevel gear

select the shim which can make the small drive gear away from the driven bevel gear

Select the proper washer from the table for correction if the intertooth

contacting status is bad. The thickness tolerance of washer is

0.01mm.

15. Install the stop washer and stop plate

a. If the drive and driven gear engagement mark meets the requirement,

then use the hand hammer and punch to lock the stop washer.

b. Install the stop plate, spring shim and bolt; tighten the bolt.

Tightening force: 18-25N

m

c. Use the punch and hand hammer to knock the lower end of stop

plate in the adjusting ring hole.

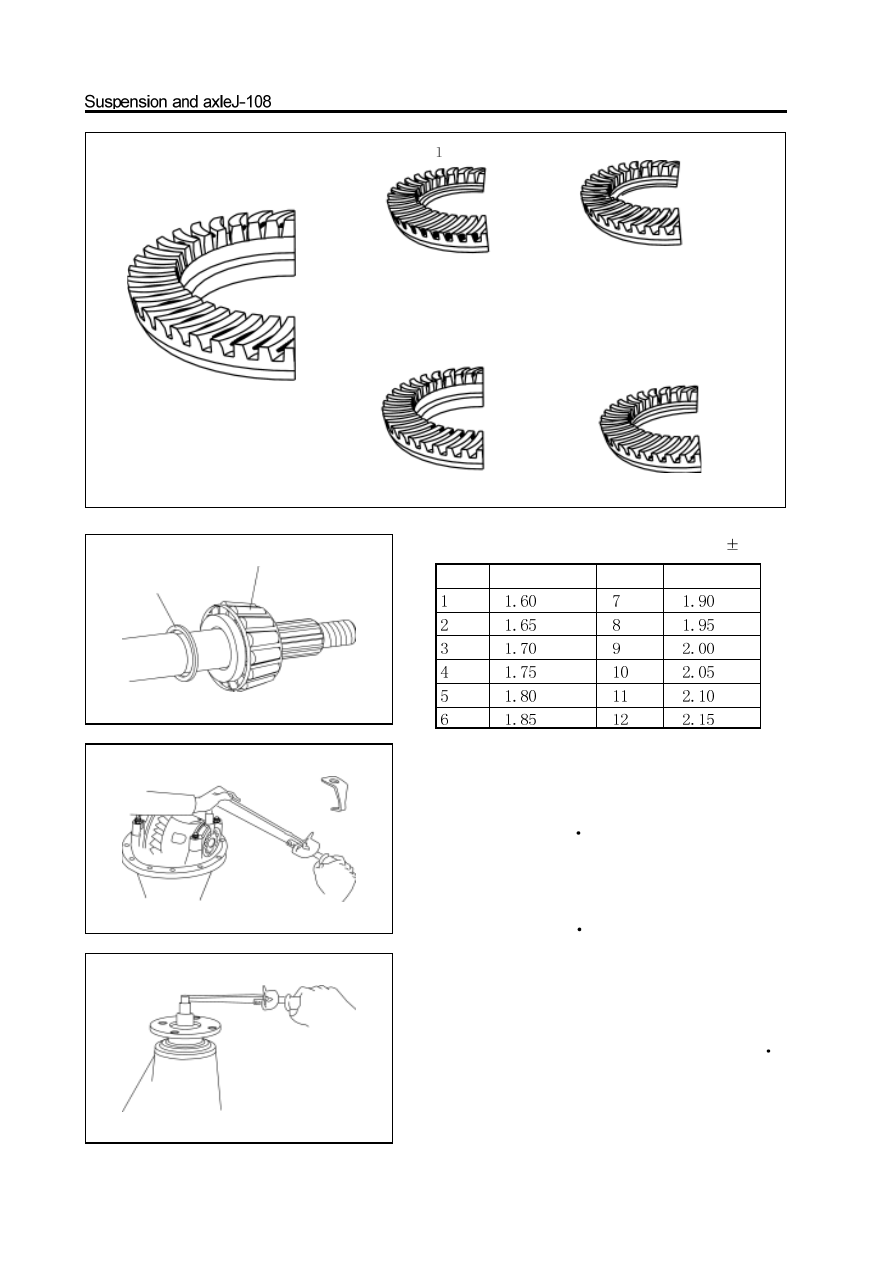

Set NO. Thickness

Set NO. Thickness

16. Measure the total pre-applied load

Pre-applied load : 1.8-2.4N

m

If the pre-applied load is beyond the specified; it should replace the

shim between the spacer and rear bearing until meet the requirement.

a. It should replace the adjusting washer if the pre-applied load is

more than specified value.

b. If the pre-applied load is less than specified value, it can retighten

the nut slowly and the torque should be no more than 160N

m.

Caution: When tighten the nut, if is beyond the Max. torque, re-

place the adjusting washer and repeat the pre-applied load process.

Do not reduce the pre-applied load by the method of screw off the

drive gear nut to loose.

washer

rear bearing

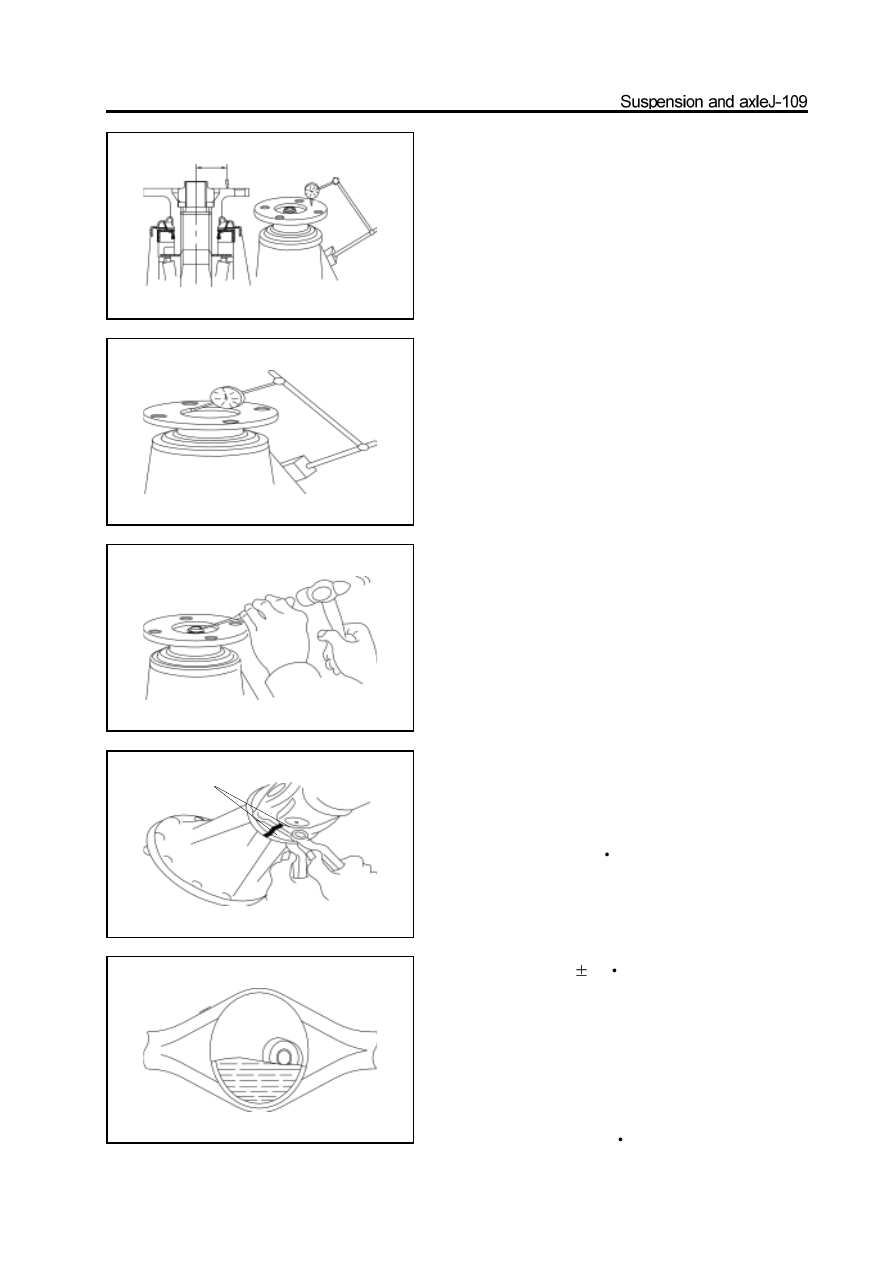

17. Check and adjust the run-out of flange.

a.Adhere the dial indicator base on the reducer housing; make the

probe of dial indicator contact with the end surface of flange;

rotate the flange and watch the rotation range of the dial.

Full run-out tolerance of end surface: 0.10mm

b.Adhere the dial indicator base on the reducer housing; make the

probe of the dial indicator contact with the inner diameter of

flange; rotate the flange by hand , and watch the rotation range of

the dial.Radial full run-out tolerance: 0.10mm

18. Rivet the nut of drive bevel gear

Installation of reducer and differential assembly

1.Install the new stiffening ring

2.Install the reducer and differential assembly

Install the reducer and differential assembly in the rear axle housing;

place the washer and nut. Tighten the nut to the specified torque.

Tightening force: 18-25N

m

3.Install the reducer and differential assembly flange

on the drive shaft flange and align the assembly

mark; use four bolts and nuts to connect them.

Tighten the bolt and nut to the specified torque.

Tightening force: 78

5N

m

4.Install the oil drain plug; fill the differential with the

gear oil

oil number : GL-5 hyperbolic gear oil

Viscosity: SAE80W/90

Amount: Filled with oil until the oil flow out from the oil filling

port.

Tighten the oil filling plug.

Tightening force: 140-150N

m

assembly mark

Differential

Differential

1

Remove the reducer and differential assembly

(Refer to “Removal of reducer”)

2

Remove the differential from the reducer and dif

ferential assembly.

(Refer to “Disassembly of reducer”)

Replacement of differential components

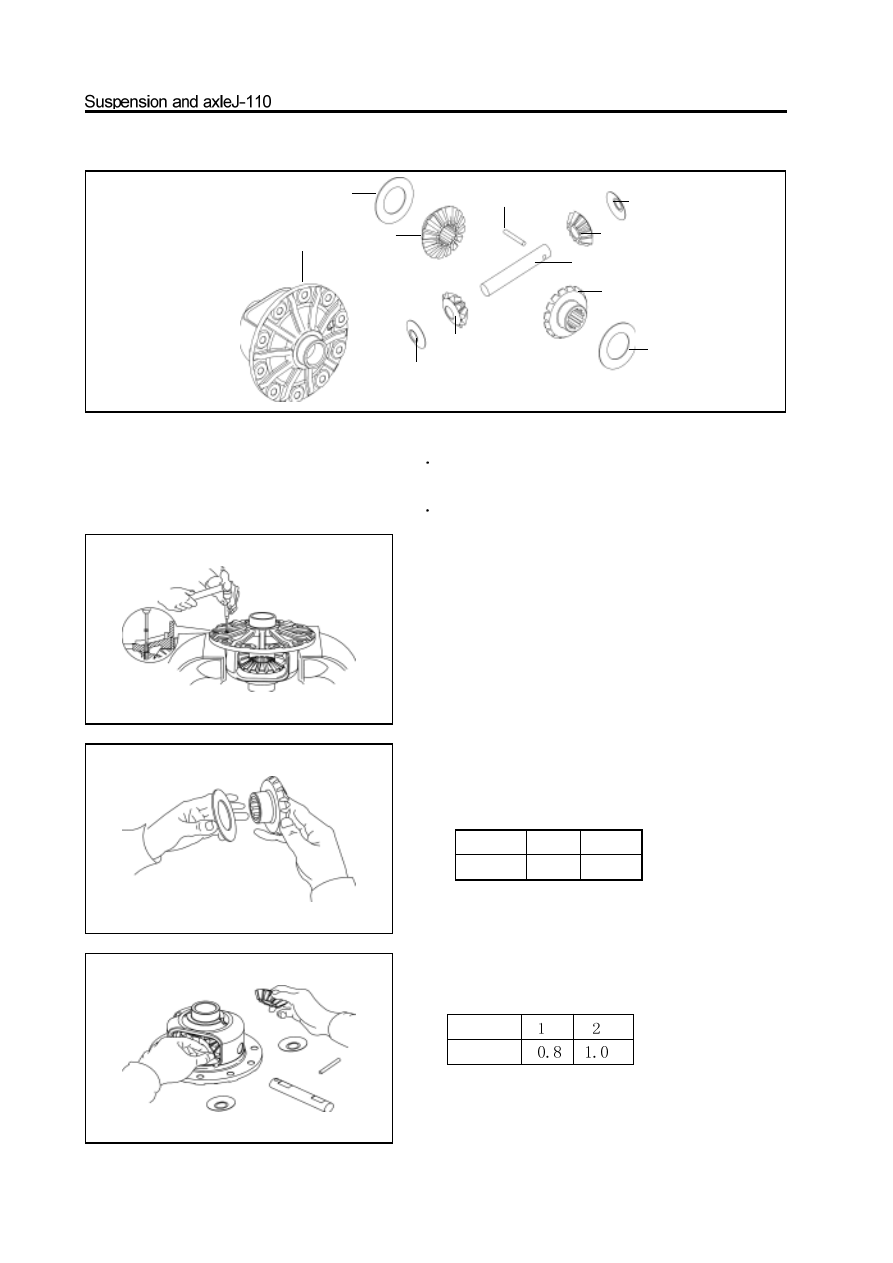

1.Disassembly of differential

Use the hammer and punch to knock out the pin. Remove the

planetary gear shaft, two half axle gears, two planetary gears and

two lock washers, two thrust plates.

2. Assembly of differential

a.Install the half axle gear and thrust plate of axle shaft gear

(Unit: mm)

b.Install the planetary gear and planetary gear lock washer in the

differential by rolling. (Unit: mm)

differential housing

thrust plate

half axle

gear

straight pin

planetary gear

lock washer

half axle

gear

thrust plate

planetary gear

lock washer

planetary gear shaft

Set NO. 1 2

Thickness 1.2 1.5

Set NO.

Thickness

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст