Great Wall Hover. Manual — part 20

Automatic transmission-11

Diagnosis input

solenoid valve

1and 2

S1 and S2 is the normal open solenoid valve, which is used to set the gear-position with other switch

solenoid valve. It determines the static gear-position by operating the gear shift valve. Refer to Table 3.5,

S1 and S2 also send the pressure single to allow or prohibit the engagement with rear brake belt.

solenoid valve

3and 4

S3 and S4 are the normal-opened solenoid valve which is used to control the shifting quality and sequence in

combination. S3 control the open or close of the clutch. S4 is used to control the on and off of the front brake

belt regulating valve.

solenoid valve 5

S5 is the variable pressure solenoid valve which can release the pressure of gear-position shifting. It provides

the pressure signal to the clutch and brake belt regulator and controls the shifting pressure. S5 also provides

the pressure single to the torque converter clutch regulating valve.

solenoid valve 6

S6 is the normal-opened solenoid valve, which is used to the set the H/L level of pipeline pressure. The

pipeline pressure is high when the solenoid valve is closed.

solenoid valve 7

S7 is the normal-opened solenoid valve which is used to control the engagement status of torque converter

licking clutch. It makes the clutch to generate the action when the S7 is in opened status.

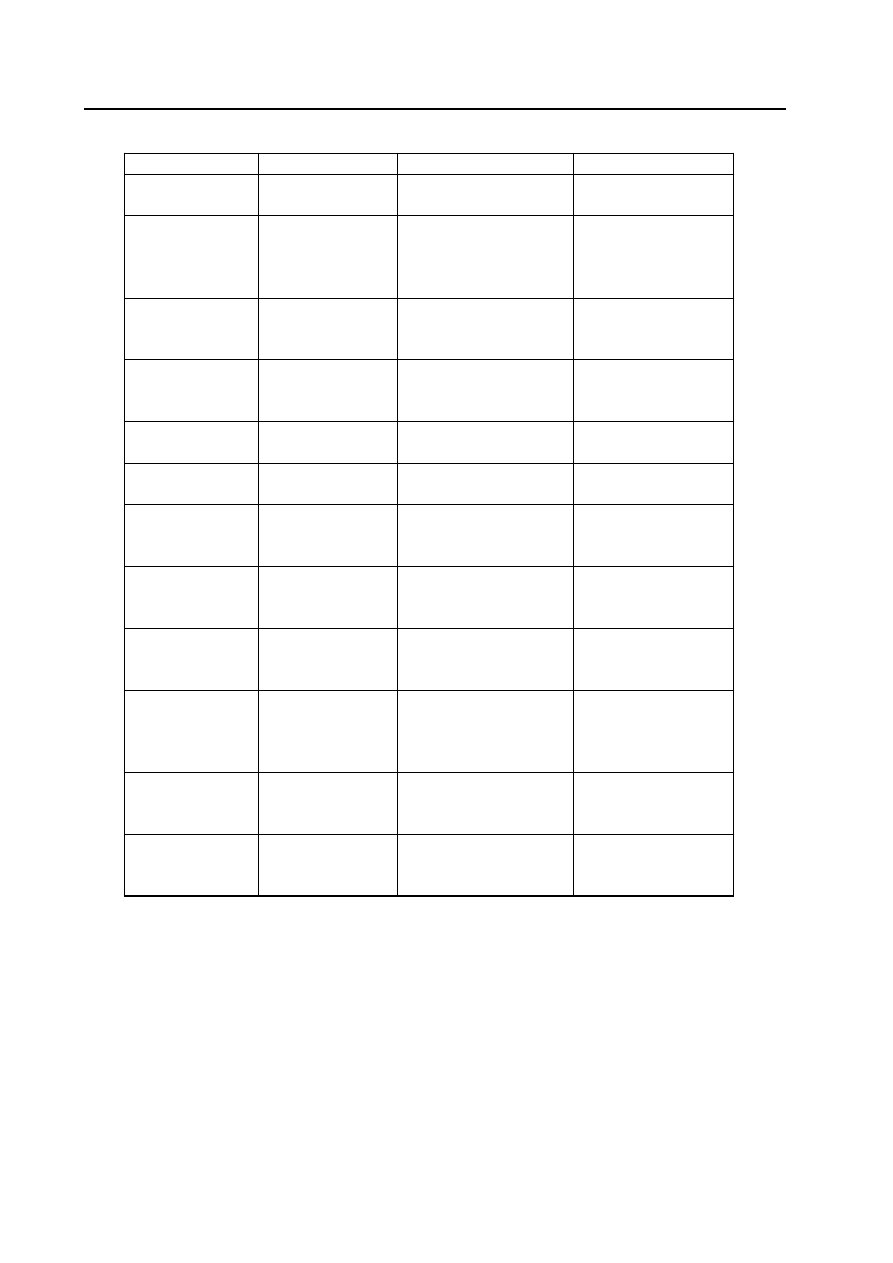

Table 3.4 Status and function of solenoid valve

Gear-position S1

S2

1

st

-Gear On On

2

nd

-Gear Off On

3

rd

-Gear Off Off

4

th

-Gear On Off

R-Gear

One of them is in On position

at least.

N-Gear Off Off

P-Gear Off Off

Table 3.5 Logic status of solenoid valve in static gear-position

Automatic transmission-12

Shifting

Initial shifting status

Current variation of S5

Finished shifting status

1-2

S1 Off

S4 On

950mA-650mA

S4 Off

1-3

S1 Off

S2 Off

S3 On

S4 On

900mA-400mA

S3 Off

S4 Off

1-4

S2 Off

S3 On

S4 On

850mA-750mA

S3 Off

S4 Off

2-3

S2 Off

S3 On

S4 On

700mA-200mA

S3 Off

S4 Off

3-4

S1 On

S4 On

950mA-550mA

S4 Off

4-3 S4

On

950mA-700mA

S1 Off

S4 Off

4-2 S3

On

800mA-500mA

S1 Off

S2 On

S3 Off

4-1

S3 On

S4 On

1000mA-600mA

S2 On

S3 Off

S4 Off

3-2

S2 On

S4 On

550mA-400mA @ 20kph

800mA-600mA@60kph

1000mA-800mA@100kph

S4 Off

3-1

S3 On

S4 On

1000mA-750mA

S1 On

S2 On

S3 Off

S4 Off

2-1 S4

On

1000mA-500mA

S1 On

S4 Off

Torque converter clutch

On

Off

S7 On

1000mA-500mA

900mA-600mA

S7 Off

Table 3.6 Operation of solenoid valve during shifting period

Automatic transmission-13

Symbol of solenoid valve (On/off solenoid valve)

Figure 3.5 Normal-opened type

1.Variable pressure regulating valve regulating system

The shifting pressure of abrasion unit is controlled by the variable pressure regulating valve.

The line pressure is independent of the shifting pressure and determined by the thro

position, shifting status and engine speed.

S5 is a proportional or variable pressure regulating valve which provides the pressure signal control shifting pressure for

the clutch and brake belt regulating valve.

In automatic shifting period, it process the integral times enlarging and contracting

regulation for the clutch regulating valve, brake belt regulating valve, torque converter regulating valve and VPS.

The hydraulic pressure generated by variable pressure regulating valve is in inverse ratio with current. During the shifting, TCU

will increase or decrease the current of solenoid valve according to the program. The current is variable in the range of 200mA

to 1000mA. The increasing of the current will decrease the S5 output pressure; the decreasing of current will increase the output

pressure of S5.

Lin 500 pressure (about 440 to 560kPa) is the reference pressure of VPS, meanwhile, the VPS output pressure equals to the

pressure on line 500 always.

When the VPS is in waiting status, it means there is not the generation of shifting action. VPS current is 200mA. At this time,

it gives the maximum output pressure.

In stable status, the brake belt and clutch regulating solenoid valve is in closed status. In this condition, the pressure of line 500

is applied on the piston. For the line 500 pressure is more than S5 pressure always, so it pushed the oil in S5 to the place

between the regulating valve and piston. At this time, oil pressure applied on the friction unit equals to the product of pressure

on line 500 and magnification factor.

During the starting of shifting, the used on/off solenoid valve is in opened status which cut off the oil loop supply from line 500

to piston.

At the same time, VPS pressure is decreased to starting pressure valve, pressure set by regulating valve and pressure setting

value required by execution of VPS by pushing the piston from the valve. The shifting is finished through the on/off solenoid

valve, VPS returns to the waiting status

Pointed to each gear-position, the system can make the brake belt; clutch or both realize

the electronic control.

Mode indicator lamp: the mode indicator lamp can be used to indicate the current selected and whether the overpeed status

exists. The mode indicator lamp is located in instrument panel generally. (Refer to Part 2.3)

Automatic transmission-14

The main box includes:

BIR blow-off valve

1. Valve

Figure 3.7 shows the valve unit in the view of transmission fluid tank. Figure 3.8 illustrates the pump cover.

2. Manual-operated valve

The manual-operated valve (refer to Figure 3.9) is connected to the car gear selection mechanism. It controls the transmission

fluid flow to the forward or reverse loop. Except in manual 1st-Gear position, the function of manual-operated valve is same

in all forward gear. In manual 1st-Gear, the transmission fluid will enter into the shift valve 1 2 to make the rear brake belt

and C4 overspeed gear clutch is engaged respectively.

The hydraulic control system is located in the valve, pump and main box.

The valve includes the following types:

Manual-operated valve

Three shift valves

sequence valve electromagnetic pressure control valve

line pressure control valve

clutch connection regulating valve

brake belt connection regulating valve

solenoid valve 1 to solenoid valve 6

reverse lock valve

The pump includes the following types:

primary regulating valve (control line pressure)

torque converter clutch regulating valve

torque converter clutch control valve

solenoid valve 7

Hydraulic control system

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст