Discovery 2. Manual — part 403

ENGINE - TD5

DESCRIPTION AND OPERATION

12-1-9

1 Acoustic cover

2 Oil filler flap

3 Rear acoustic cover

4 Rear acoustic cover inserts (2 off)

5 Rear acoustic cover grommets (2 off)

6 Rear acoustic cover screws (2 off)

7 Acoustic cover grommets (3 off)

8 Acoustic cover bolts (3 off)

9 Camshaft cover isolators (13 off)

10 Camshaft cover flange screws (13 off)

11 Breather hose clip

12 Breather hose

13 Breather hose to breather valve clip

14 Breather valve

15 Camshaft cover seal

16 Oil separator plate

17 Oil separator plate gasket

18 Camshaft cover

19 Acoustic cover to camshaft cover seal

20 Oil filler cap and seal

ENGINE - TD5

12-1-10 DESCRIPTION AND OPERATION

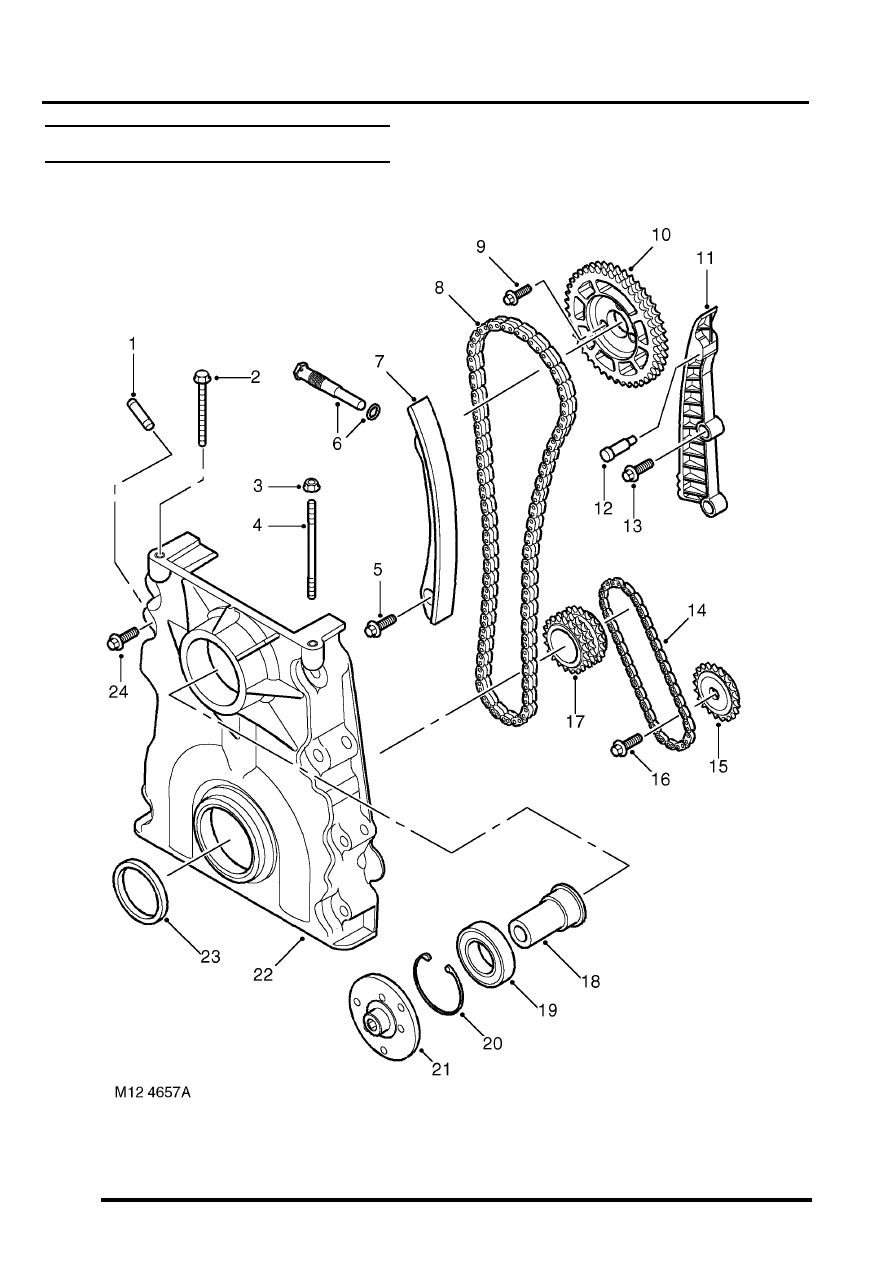

Camshaft timing chain components

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-11

1 Vacuum pump stub pipe

2 Cylinder head to timing chain cover bolt

3 Cylinder head to timing chain cover nut

4 Cylinder head to timing chain cover stud

5 Tensioner assembly pivot screw

6 Tensioner adjuster

7 Tensioner arm assembly

8 Duplex timing chain – crankshaft to camshaft

sprocket

9 Camshaft sprocket bolts (3 off)

10 Camshaft sprocket

11 Fixed chain guide

12 Fixed guide pin

13 Fixed chain guide to cylinder block screws

14 Oil pump drive chain

15 Oil pump sprocket

16 Oil pump sprocket screw

17 Crankshaft sprockets

18 Bearing to viscous fan shaft

19 Viscous fan to cover bearing

20 Circlip

21 Hub – viscous fan to bearing flange

22 Timing chain cover

23 Timing chain cover to crankshaft seal

24 Timing cover to cylinder head screws (8 off)

ENGINE - TD5

12-1-12 DESCRIPTION AND OPERATION

Description

General

The Td5 diesel engine is a 2.5 litre, 5 cylinder, in-line direct injection unit having 2 valves per cylinder, operated by a

single overhead camshaft. The engine emissions, on pre EU3 models, comply with ECD2 (European Commission

Directive) and on EU3 models, comply with ECD3 legislative requirements. Both models employ electronic engine

management control, positive crankcase ventilation and exhaust gas recirculation to limit the emission of pollutants.

The unit is water cooled and turbo-charged and is controlled by an electronic engine management system.

The engine is a monobloc cast iron construction with an aluminium stiffening plate fitted to the bottom of the cylinder

block to improve lower structure rigidity. The cylinder head and sump are cast aluminium. An acoustic cover is fitted

over the upper engine to reduce engine generated noise.

The engine utilises the following features:

l

Electronic Unit Injectors (EUI's) controlled by an Engine Management System for precise fuel delivery under

all prevailing operating conditions.

l

Turbocharging which delivers compressed air to the combustion chambers via an intercooler for improved

power output.

l

Fuel Cooler

l

Oil Cooler

l

Centrifuge Oil Filter

l

Hydraulic Lash Adjusters with independent finger followers

Cylinder block components

The cylinder block components are described below:

Cylinder Block

The cylinders and crankcase are contained in a single cast iron construction. The cylinders are direct bored and

plateau honed with lubrication oil supplied via lubrication jets for piston and gudgeon pin lubrication and cooling. It is

not possible to rebore the cylinder block if the cylinders become worn or damaged. Three metal core plugs are fitted

to the three centre cylinders on the right hand side of the cylinder block.

Lubrication oil is distributed throughout the block via the main oil gallery to critical moving parts through channels

bored in the block which divert oil to the main and big-end bearings via oil holes machined into the crankshaft. Oil is

also supplied from the cylinder block main gallery to the five lubrication jets which cool and lubricate the piston and

gudgeon pins. Plugs are used to seal both ends of the main oil gallery at front and rear of the engine block. An oil

cooler is fitted to the LH side of the engine block; ports in the oil cooler assembly mate with ports in the cylinder block

to facilitate coolant flow. Oil is diverted through the oil cooler, centrifuge filter and full-flow filter before supplying the

main oil gallery. A tapping in the oil filter housing provides a lubrication source for the turbocharger bearings and an

oil pressure switch is included in a tapping in the oil cooler housing which determines whether sufficient oil pressure

is available to provide engine lubrication and cooling.

Cylinder cooling is achieved by water circulating through chambers in the engine block casting. A threaded coolant

jacket plug is located at the front RH side of the cylinder block.

Cast mounting brackets are bolted to both sides of the engine block for mounting the engine to the chassis on the LH

and RH hydramount studs.

The gearbox bolts directly to the engine block; a gearbox shim plate is located between the adjoining faces of the

gearbox and the flywheel side of the engine block and is fixed to the rear of the engine block by two bolts. Two hollow

metal dowels locate the rear of the cylinder block to the gearbox shim plate. The gearbox casing provides the

mounting for the starter motor.

A port is included at the rear left hand side of the cylinder block which connects to the turbocharger oil drain pipe to

return lubrication oil to the sump.

A plug sealing the lubrication cross-drilling gallery is located at the front right hand side of the cylinder block and plugs

for the main lubrication gallery is included at the front and rear of the cylinder block.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст