Discovery 2. Manual — part 469

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-19

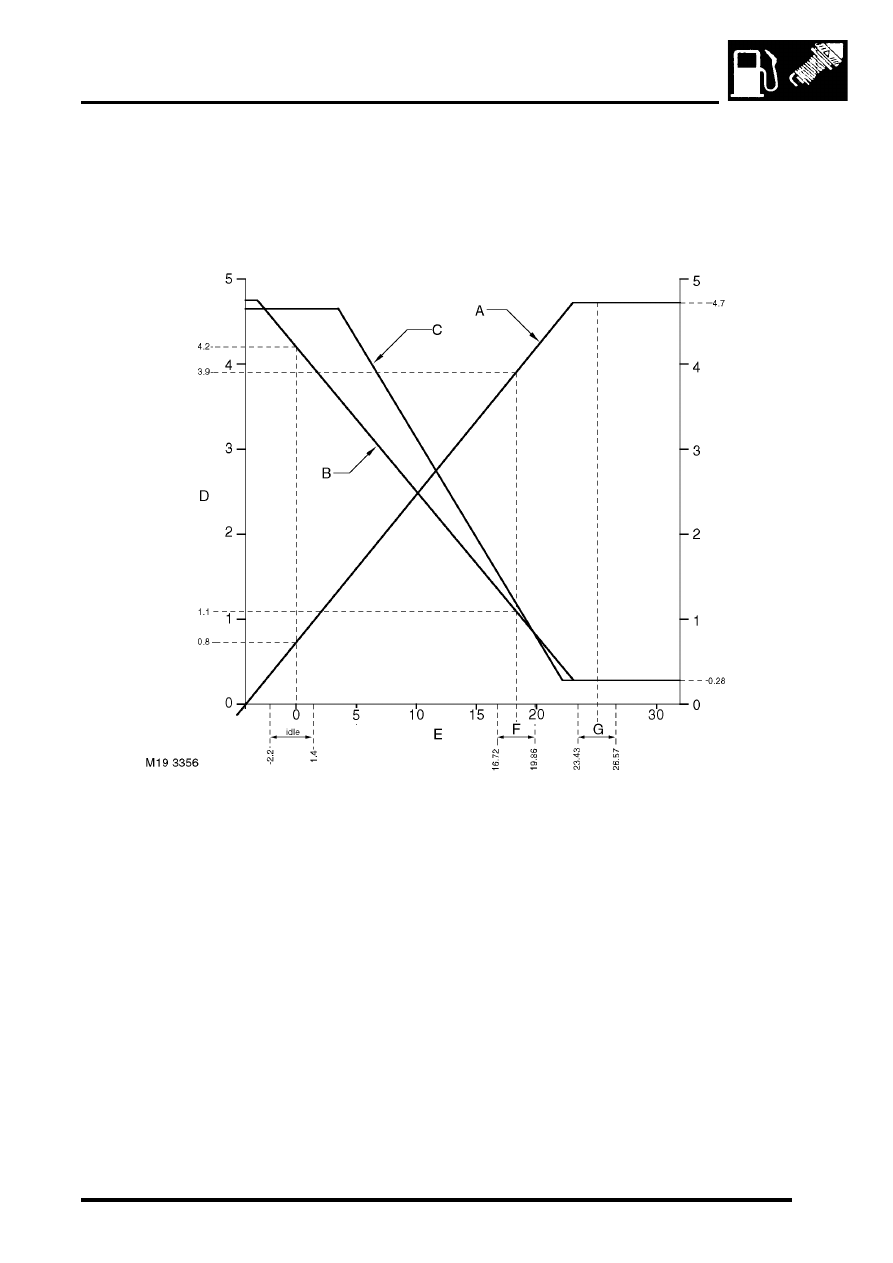

Throttle Position (TP) sensor – From VIN 297137

Discovery Series II vehicles from VIN 297137 use three track thick film potentiometers. No idle speed sender switch

is used on this type of sensor because the ECM can compare the two or three sets of signals to implement idle speed

control and over-run fuel shut-off. The two potentiometers are known as track 1 and 2 potentiometers. The track 3

potentiometer on later models is used to improve the resolution of the pedal. The ECM provides a 5V supply and

receives a signal from each of the potentiometer tracks.

a = Track 1

b = Track 2

c = Track 3

d = Voltage

e = Pedal angle (degrees)

f = Wide open throttle stop tolerance band

g = Not applicable for Discovery Series II.

With reference to the above graph, at idle (throttle released), track 2 returns a signal of 4.2V to the ECM and track 1

returns a signal of 0.8V. The ECM calculates the sum of these two figures which totals 5.0V.

At wide open throttle, track 2 returns a signal of 1.1V and track 1 returns a signal of 3.9V to the ECM. The ECM

calculates the sum of these two figures which totals 5.0V. The ECM uses this strategy to error check the TP sensor

signal and ensure that the requested throttle position is applied. The third potentiometer track measures the tolerance

of tracks 1 and 2 and provides an improved functionality check of the pedal angle.

NOTE: Three track TP sensors cannot be fitted as replacements on vehicles previously fitted with two track TP

sensors. Replacement ECM's are configured for two track TP sensors and can be fitted to all Td5 models. When

replacement ECM's are fitted to vehicles using three track TP sensors, TestBook or T4 must be used to configure the

ECM for three track TP sensor use.

If the TP sensor fails, the ECM will illuminate the MIL and the engine will operate at normal idle speed only.

ENGINE MANAGEMENT SYSTEM - TD5

18-1-20 DESCRIPTION AND OPERATION

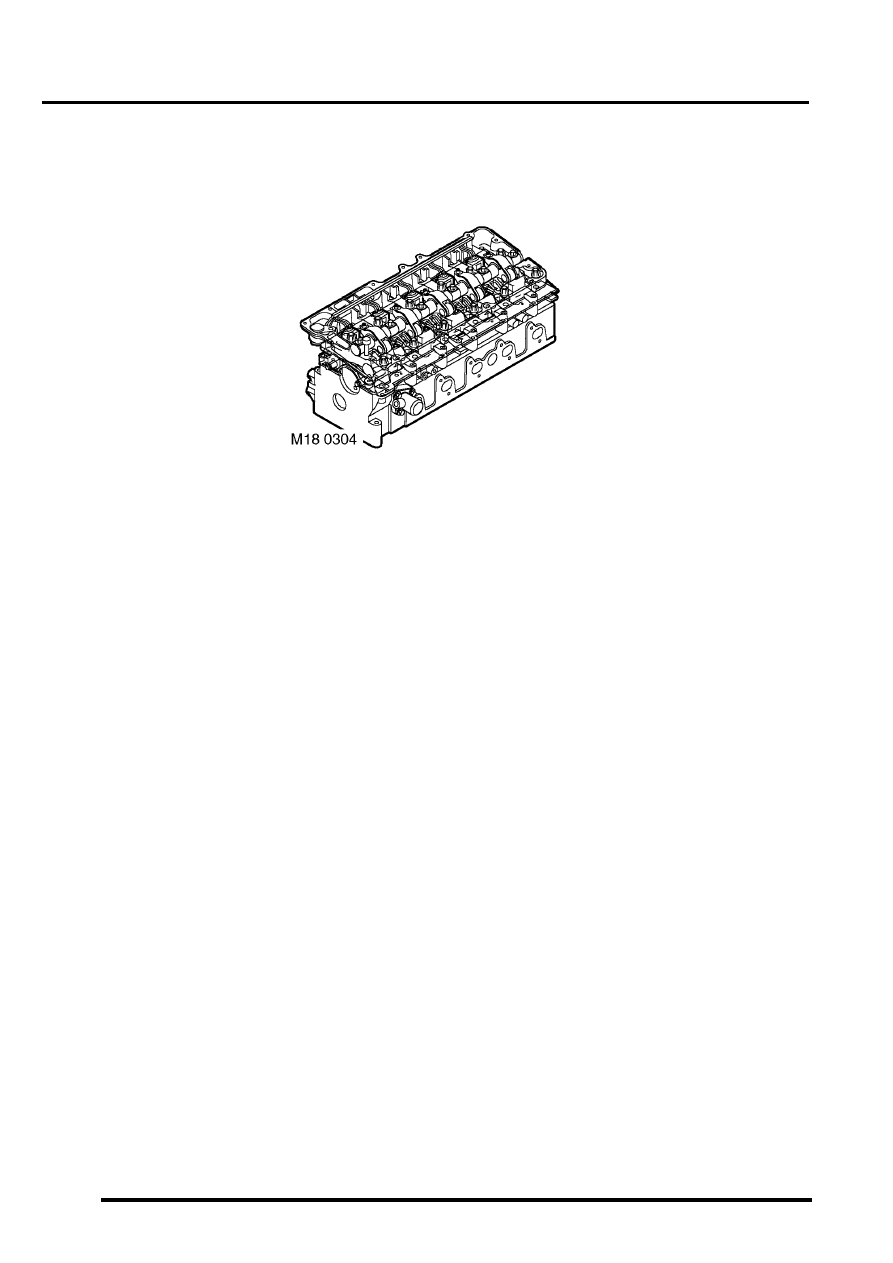

Electronic Unit Injector (EUI)

The EUI's are located in the top of the engine inside the camshaft cover. There is one EUI per cylinder. They inject

finely atomised fuel directly into the combustion chamber. Each EUI has its own electrical connection, which is linked

to a common harness also located under the camshaft cover. Each of the EUI has its own 5 letter grading code. This

code is used so that greater EUI precision is achieved.

The ECM provides the earth path for the EUI. Using an injection-timing map within its memory and information from

the crankshaft speed and position sensor the ECM is able to determine precise crankshaft angle. When the ECM

determines the crankshaft speed and position it closes the spill valve within the EUI. Fuel pressure rises inside the

EUI to a predetermined limit of, 1500 bar (22,000 lbf.in

2

) on pre EU3 models, and 1750 bar (25,500 lbf.in

2

) on EU3

models, at this limit the pintle lifts off its seat allowing the fuel to inject into the combustion chamber. The ECM de-

energises the spill valve to control the quantity of fuel delivered. This causes a rapid pressure drop within the EUI

which allows the EUI return spring to re-seat the pintle ending fuel delivery.

The electrical circuit that drives the EUI works in two stages depending on battery voltage. If battery voltage is

between 9 and 16 volts the EUI's will provide normal engine performance. If however battery voltage falls to between

6 and 9 volts, on pre EU3 models, EUI operation is restricted to a limit of 2100 rev/min, on EU3 models EUI operation

is restricted to idle.

If the vehicle is fitted with a new ECM, the EUI grades for that specific vehicle must be downloaded to the new ECM

using TestBook. In the event of the engine failing to rev above 3000 rev/min it is probable that the EUI grading has

not been completed.

Input/Output

Input to the EUI takes the form of both mechanical and electrical signals. The mechanical input to the EUI is diesel

fuel via the fuel pump operating at approximately 4 to 5 bar (58 to 72 lbf.in

2

). Each of the EUI's is operated

mechanically by an overhead camshaft to enable injection pressures of up to 1500 bar (22,000 lbf.in

2

) on pre EU3

models, and 1750 bar (25,500 lbf.in

2

) on EU3 models, to be achieved. The ECM controls the EUI's to ensure that fuel

delivery is precise and as intended.

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-21

The EUI's earth paths are as follows:

l

EUI 1 via pin 25 of the ECM connector C0158.

l

EUI 2 via pin 26 of the ECM connector C0158.

l

EUI 3 via pin 27 of the ECM connector C0158.

l

EUI 4 via pin 24 of the ECM connector C0158.

l

EUI 5 via pin 1 of the ECM connector C0158.

The EUI can fail as follows:

l

Open circuit.

l

Short circuit to voltage supply.

l

Short circuit to vehicle earth.

l

Wiring loom fault.

l

Connector water ingress.

l

Connector failure due to excess heat.

In the event of a fuel injector failure any of the following symptoms may be observed:

l

Engine misfire.

l

Idle faults.

l

Reduced engine performance.

l

Reduced fuel economy.

l

Difficult cold start.

l

Difficult hot start.

l

Excess smoke.

ENGINE MANAGEMENT SYSTEM - TD5

18-1-22 DESCRIPTION AND OPERATION

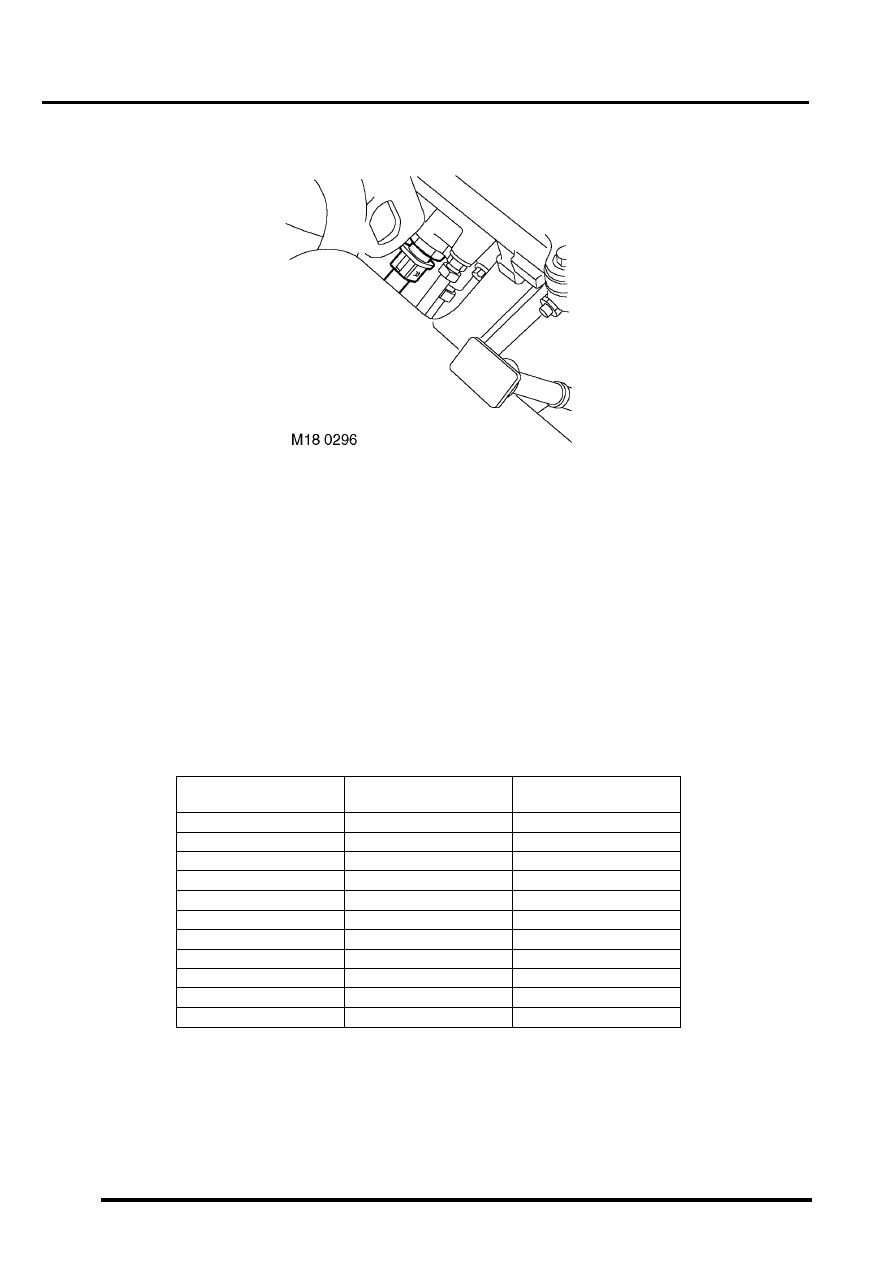

Fuel Temperature (FT) sensor

The FT sensor is located at the rear of the engine in the fuel rail with the tip of the sensor inserted at least 10 mm into

the fuel flow. This allows the sensor to respond correctly to changes in fuel density in relation to fuel temperature.

The FT sensor works as a NTC sensor. As fuel temperature rises the resistance in the sensor decreases. As

temperature decreases the resistance in the sensor increases. The ECM is able to compare the voltage signal to

stored values and compensates fuel delivery as necessary for hot engine start.

The operating range of the sensor is -40 to 130

°

C (-40 to 266

°

F).

Input/Output

The inputs and outputs for the FT sensor are 5 volt supply and signal out. In the event of component failure the ECM

reverts to a fixed value of 60

°

C stored in its memory.

The output signal is measured via pin 19 of the ECM connector C0158. The earth path is via pin 5 of ECM connector

C0158.

FT sensor temperature to resistance table.

Temperature,

°

C

Temperature,

°

F

Resistance, ohms

(nominal)

-10

14

9397

0

32

5896

10

50

3792

20

68

2500

30

86

1707

40

104

1175

50

122

834.0

60

140

595.5

80

176

322.5

100

212

186.6

125

257

100.2

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст