Discovery 2. Manual — part 44

ENGINE - V8

OVERHAUL 12-2-49

Seal - crankshaft - rear - automatic

models

$% 12.21.20.01

Disassembly

1. Remove CKP sensor.

V8, REPAIRS, Sensor - crankshaft position

(CKP).

Note: Later engines are fitted with a modified

starter ring gear which incorporates the reluctor

plate, spacer and hub. The modified ring gear

may be fitted as a replacement to early

engines.

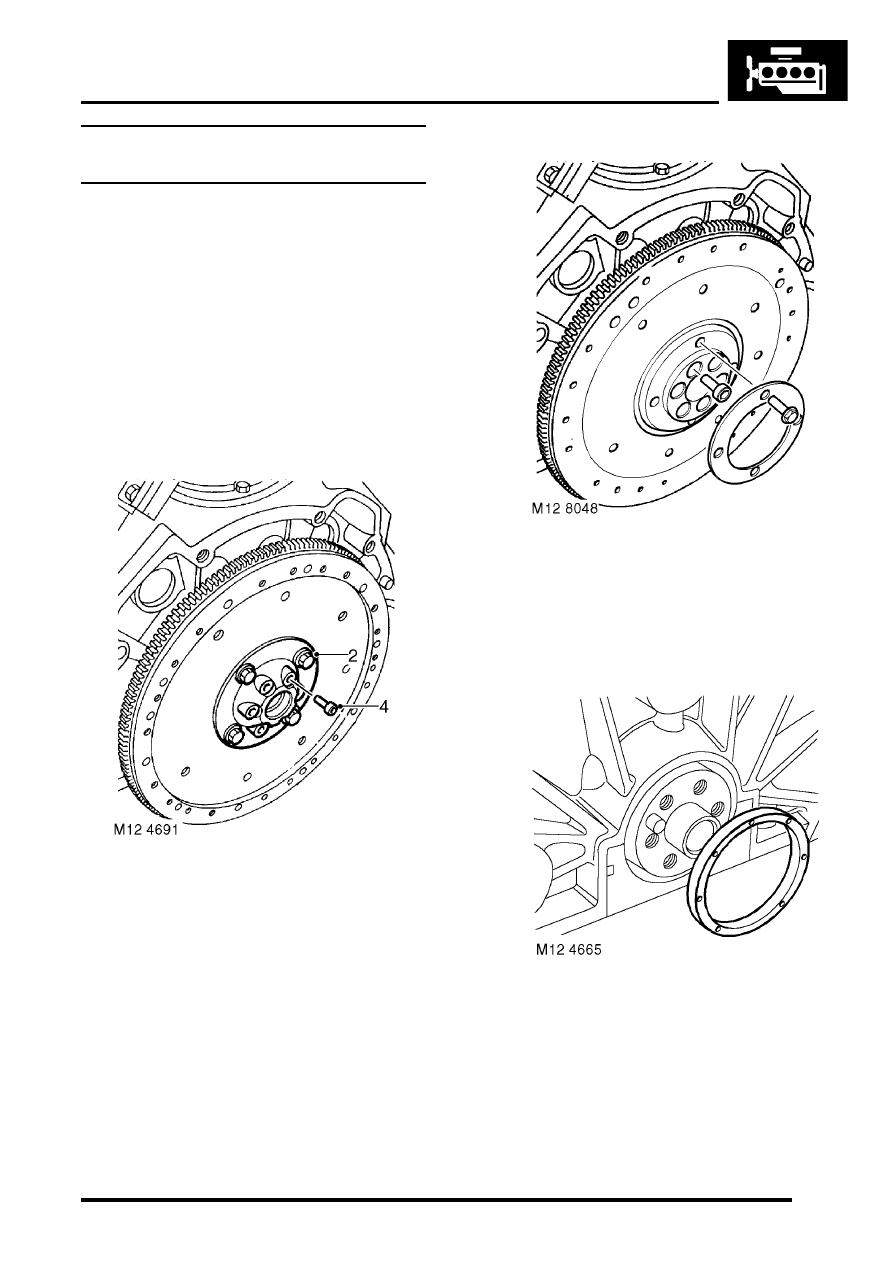

2. Early engines: Remove 4 bolts securing drive

plate clamp ring and remove ring.

3. Early engines: Remove drive plate from hub.

4. Early engines: Remove 6 Allen bolts securing

hub and starter ring gear, remove hub, starter

ring gear and collect spacer.

Note: On early engines, balance weights are on

engine side of drive plate, replacement drive

plates will have balance weights on torque

converter side of drive plate.

5. Later engines: Remove 4 bolts securing drive

plate clamp ring and remove ring.

6. Later engines: Remove drive plate.

7. Later engines: Remove 6 Allen bolts securing

starter ring gear to crankshaft, remove starter

ring gear.

8. Carefully remove oil seal from cylinder block to

avoid damage to seal location or running

surface on crankshaft.

ENGINE - V8

12-2-50 OVERHAUL

Reassembly

1. Ensure both seal location and running surface

on crankshaft are clean. Ensure that bolt holes

in crankshaft are clean and dry.

2. Lubricate replacement oil seal with engine oil.

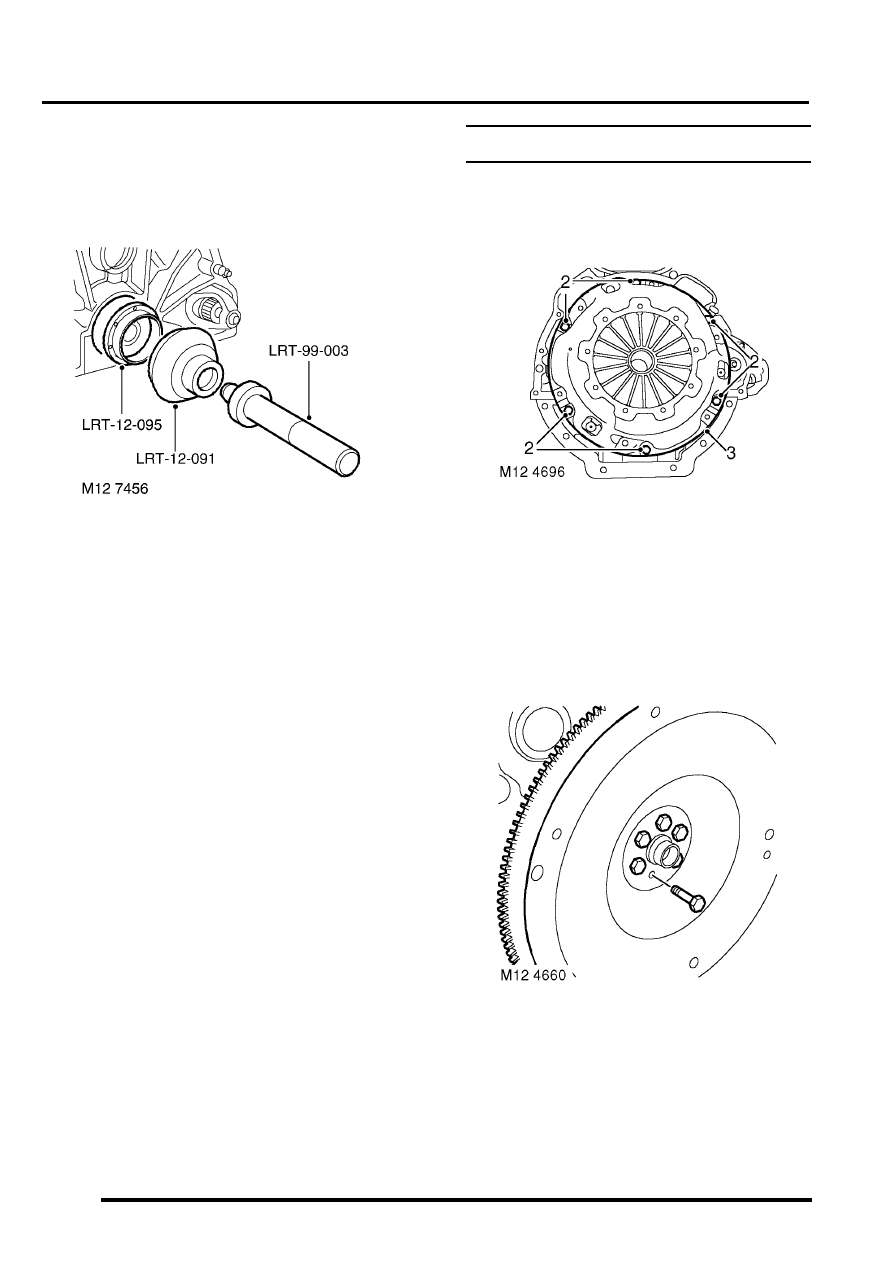

3. Lubricate seal guide LRT-12-095 with engine

oil and position guide to crankshaft.

4. Fit new seal squarely onto crankshaft and

remove guide LRT-12-095.

5. Fit seal into location using tools LRT-12-091

and LRT-99-003.

6. All engines: Ensure bolt holes in crankshaft

are clean and dry.

7. All engines: Clean all components.

8. All engines: Check that drive plate is free from

cracks and distortion.

9. Early engines: Fit hub, starter ring gear and

spacer to crankshaft, tighten Allen bolts to 78

Nm (58 lbf.ft).

10. Early engines: Fit drive plate and clamp ring,

tighten bolts to 45 Nm (35 lbf.ft).

11. Later engines: Fit starter ring gear, fit Allen

bolts and tighten to 85 Nm (63 lbf.ft).

12. Later engines: Fit drive plate and clamp ring,

fit bolts and tighten to 45 Nm (33 lbf.ft).

13. Fit CKP sensor.

V8, REPAIRS, Sensor - crankshaft position

(CKP).

Seal - crankshaft - rear - manual models

$% 12.21.20.01

Disassembly

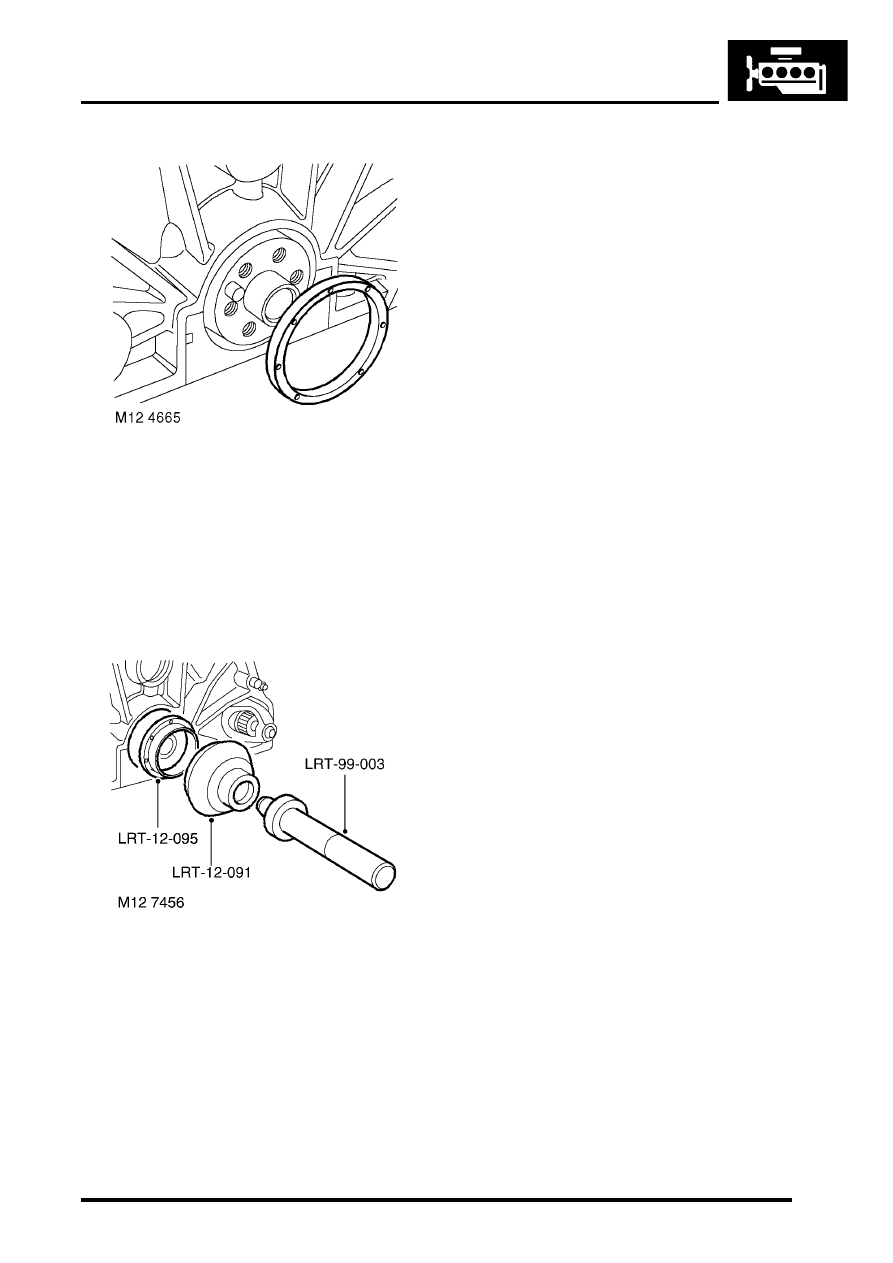

1. Restrain flywheel.

2. Working in sequence, loosen and remove 6

bolts securing clutch cover to flywheel.

3. Remove clutch cover.

4. Remove clutch plate.

5. Remove CKP sensor.

V8, REPAIRS, Sensor - crankshaft position

(CKP).

6. Remove 6 bolts securing flywheel.

7. Remove flywheel.

ENGINE - V8

OVERHAUL 12-2-51

8. Carefully remove oil seal from cylinder block to

avoid damage to seal location or running

surface on crankshaft.

Reassembly

1. Ensure both seal location and running surface

on crankshaft are clean. Ensure that bolt holes

are clean and dry.

2. Lubricate replacement oil seal with engine oil.

3. Lubricate seal guide LRT-12-095 with engine

oil and position to crankshaft.

4. Fit new seal squarely onto crankshaft and

remove guide LRT-12-095.

5. Fit seal into location using tools LRT-12-091

and LRT-99-003.

6. Clean mating faces of flywheel and crankshaft,

dowel and dowel hole.

7. Fit flywheel to crankshaft and, working in a

diagonal sequence, tighten bolts to 78 Nm (58

lbf.ft).

8. Fit CKP sensor.

V8, REPAIRS, Sensor - crankshaft position

(CKP).

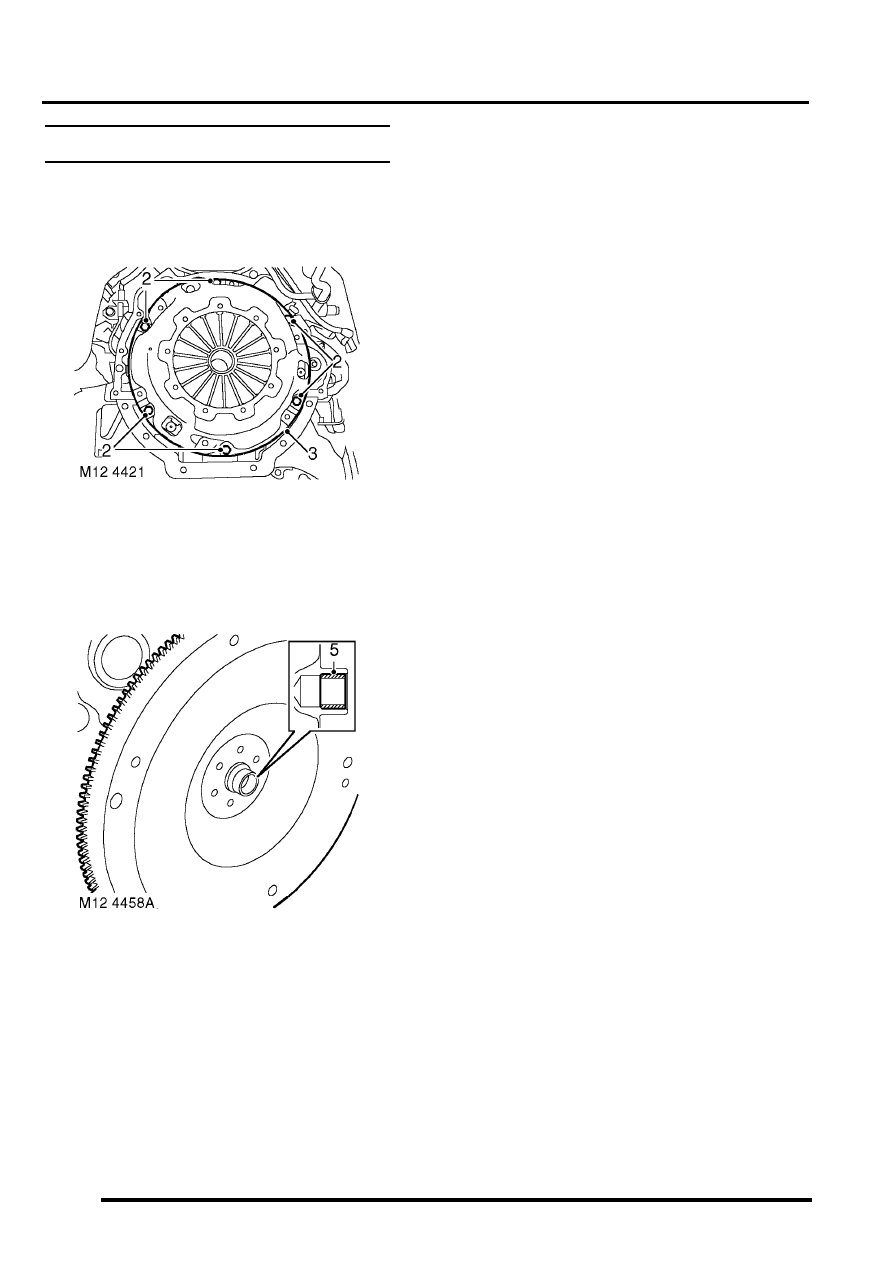

9. Clean clutch cover, drive plate and spigot bush

in end of crankshaft.

10. Renew worn components as necessary.

11. If refitting existing drive plate, apply Molycote

FB 108 to splines.

12. Fit LRT-12-001 alignment tool to spigot bearing

in crankshaft.

13. Fit drive plate onto alignment tool, ensure side

marked 'flywheel side' is against flywheel.

14. Fit clutch cover and locate on dowels.

15. Fit clutch cover bolts and tighten in diagonal

sequence to 40 Nm (30 lbf.ft).

ENGINE - V8

12-2-52 OVERHAUL

Bearing - spigot - crankshaft

$% 12.21.45.01

Disassembly

1. Remove 6 bolts securing clutch cover.

2. Remove clutch cover.

3. Tap a thread in spigot bush to accommodate a

suitable impulse extractor.

4. Fit extractor to bush.

5. Remove bush from crankshaft.

Reassembly

1. Clean bush register in rear of crankshaft.

2. Using a suitable drift, fit new bush to crankshaft

so that it is flush with or up to a maximum of 1.6

mm (0.06 in) below the end of the crankshaft.

3. Ream spigot bush to 19.117 + 0.025

−

0.00 mm

(0.75 + 0.001

−

0.00 in) .

4. Remove all traces of swarf on completion.

5. Clean mating faces of flywheel and crankshaft,

dowel and dowel hole.

6. Fit clutch cover to flywheel and tighten bolts by

diagonal slection to 40 Nm (30 lbf.ft).

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст