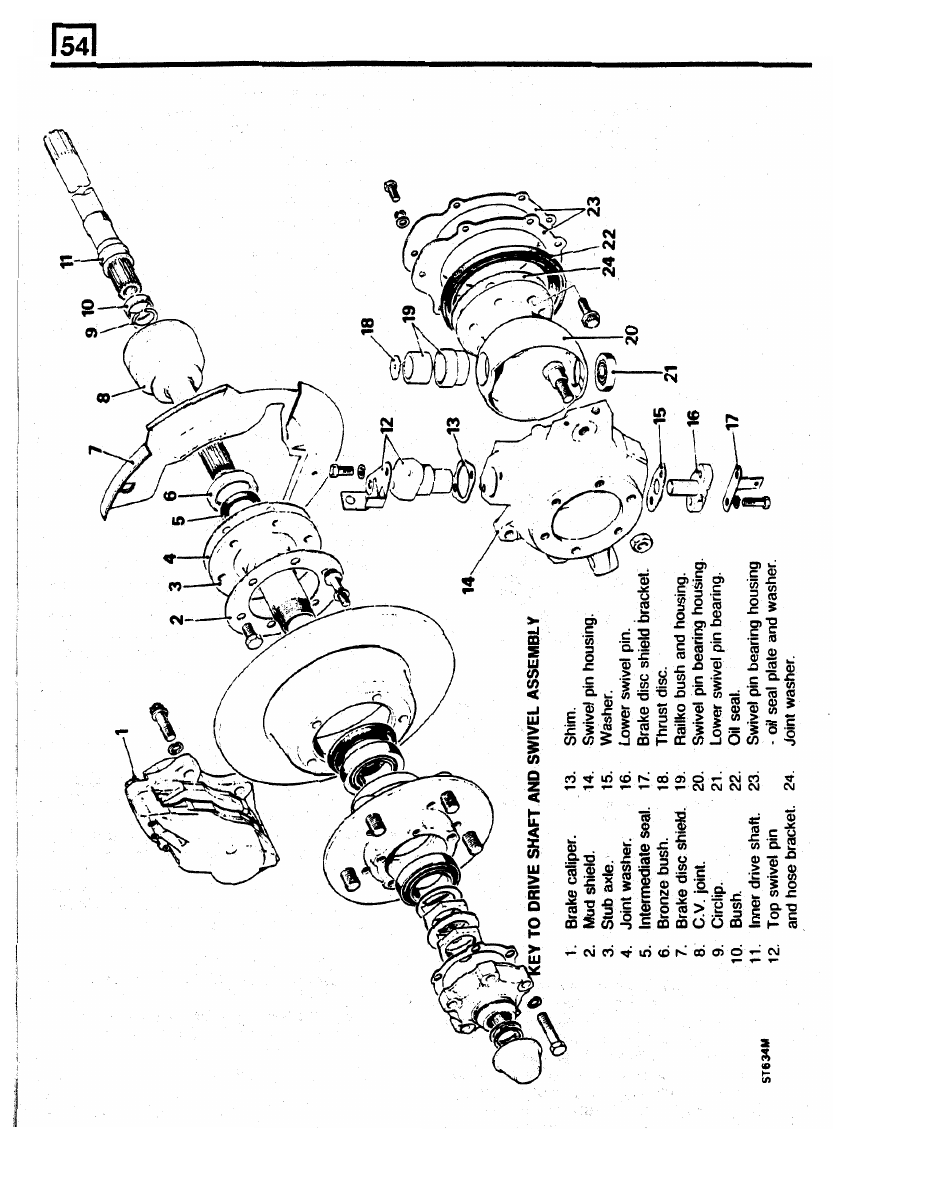

Defender (1993+). Manual — part 65

FRONT AXLE

AND FINAL DRIVE

29. Slacken off the adjusting nut until an end-play

OVERHAUL

STUB

AXLE,

AXLE

SHAFT,

30. Fit a new keyed lock tab washer.

ASSEMBLY

31. Fit and tighten the hub adjusting nut and

of

0,1270

to

0,1016

mm

is

obtained.

CONSTANT VELOCITY JOINT

AND SWIVEL

re-check the end-play before bending the lock

Special tool:

18G284AAH/LRT-37-004

bush

tab over.

extractor

32. Fit a new joint washer to the driving member

and fit the member

to

the hub and secure with

the five bolts tightening evenly to 60 to 70

33. Fit the original drive shaft shim and secure

1.

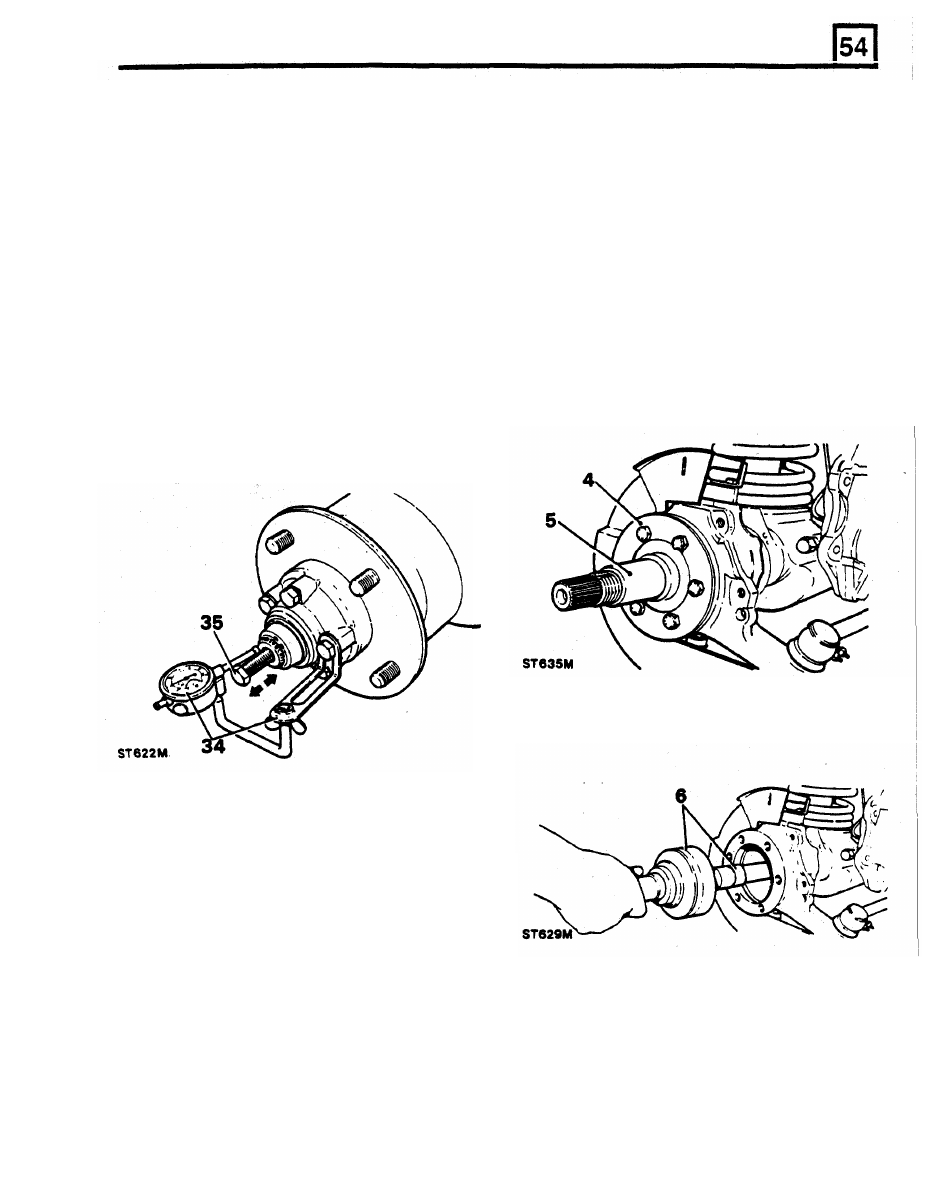

Remove the hub complete as described in the

operation to overhaul the hub assembly

34. To check the drive shaft end-play mount a dial

instructions

1

to

14.

guage using a bracket RO530106 and rest the

2. Drain the swivel pin housing and refit plug.

stylus in a loaded condition on the end of the

3. Remove the six bolts retaining the stub axle

to

the swivel housing.

35. Fit a suitable bolt to the threaded end

of

the

4.

Remove the mud shield.

5.

Remove the stub axle and joint washer.

Remove stub axle, axle shaft and constant

velocity joint

drive shaft and using a pair of pliers move the

drive shaft back and forth noting the dial

guage reading. The end-play should be

6.

Pull-out the axle shaft and constant velocity

joint from the axle casing.

36.

If

the end-play requires adjustment, remove

the circlip, measure the shim thickness and fit

an appropriate selective shim to give the

required end-play.

37. Remove the bolt

from

the drive shaft, fit the

circlip and dust cap.

38. Fit the brake caliper and tighten the two bolts

to the correct torque.

39.

Locate

the

jump

hose

in

the bracket and

tighten the locknuts or see caution below.

CAUTION:

If the jump nose was disconnected as

is

necessary

on

later vehicles the brake hydraulic

system must

be

bled.

40.

Fit the road wheel, remove the axle stand and

finally tighten the road wheel nuts.

41.

Operate the footbrake several times to locate

the brake pads before taking the vehicle on

the road.

Nm.

with the circlip.

drive shaft.

between 0,127 to 0,254 mm.

FRONT

AXLE AND FINAL DRIVE

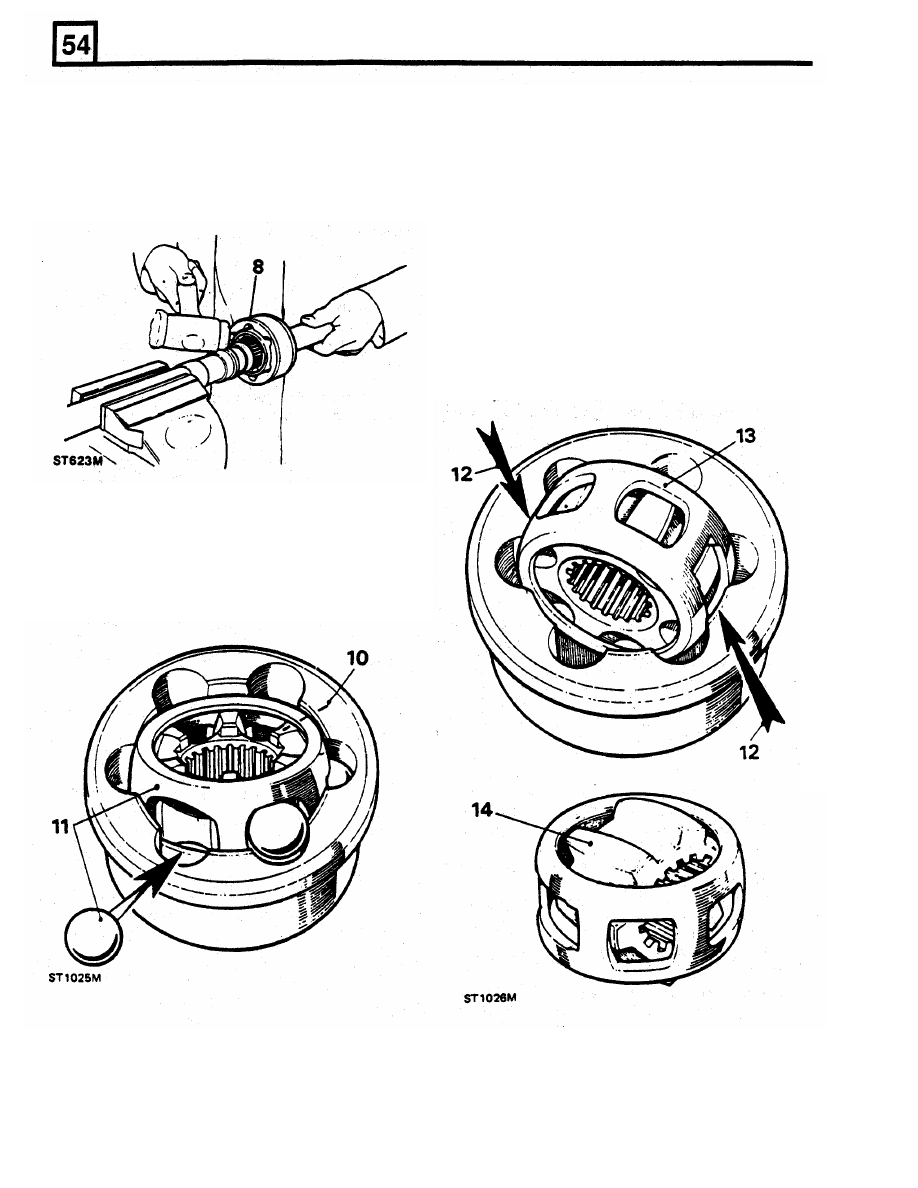

Remove constant velocity joint from axle shaft

12.

Swivel the cage into line with the axis of the

joint and turn it until two opposite windows

coincide with two lands of the joint housing.

7.

Hold the axle shaft firmly in a

soft

jawed vice

8.

Using

a

soft mallet drive the constant velocity

13.

Withdraw the cage.

joint from the shaft.

9.

Remove the circlip and collar from the axle

shaft.

14.

Turn the inner track at right angles to the

cage with

two

of the lands opposite the cage

openings and withdraw the inner race.

15.

Degrease and examine all components for

general wear and condition.

16.

Examine the inner and outer track, cage balls

and bearing surfaces of the constant velocity

joint for damage and excessive wear.

17.

To

assemble the constant velocity joint,

reverse the dismantling instructions and

lubricate with a recommended

EP

oil.

18.

Check that the end-float of the assembled

joint does not exceed 0,64 mm.

Dismantle the constant velocity joint

10.

Mark the relative positions

of

the constant

velocity joint inner and outer race and the

cage for correct reassembly.

11.

Tilt and swivel the cage and inner race

to

remove the balls.

FRONT AXLE

AND FINAL DRIVE

30.

Remove the top swivel pin retaining

bolts

complete with the brake jump hose bracket.

31.

Withdraw the top swivel pin and shims.

retrieving the lower taper bearing.

33. If the swivel

pin

housing

is

to

be renewed,

remove the drain and level plugs and

lock-stop bolt and nut.

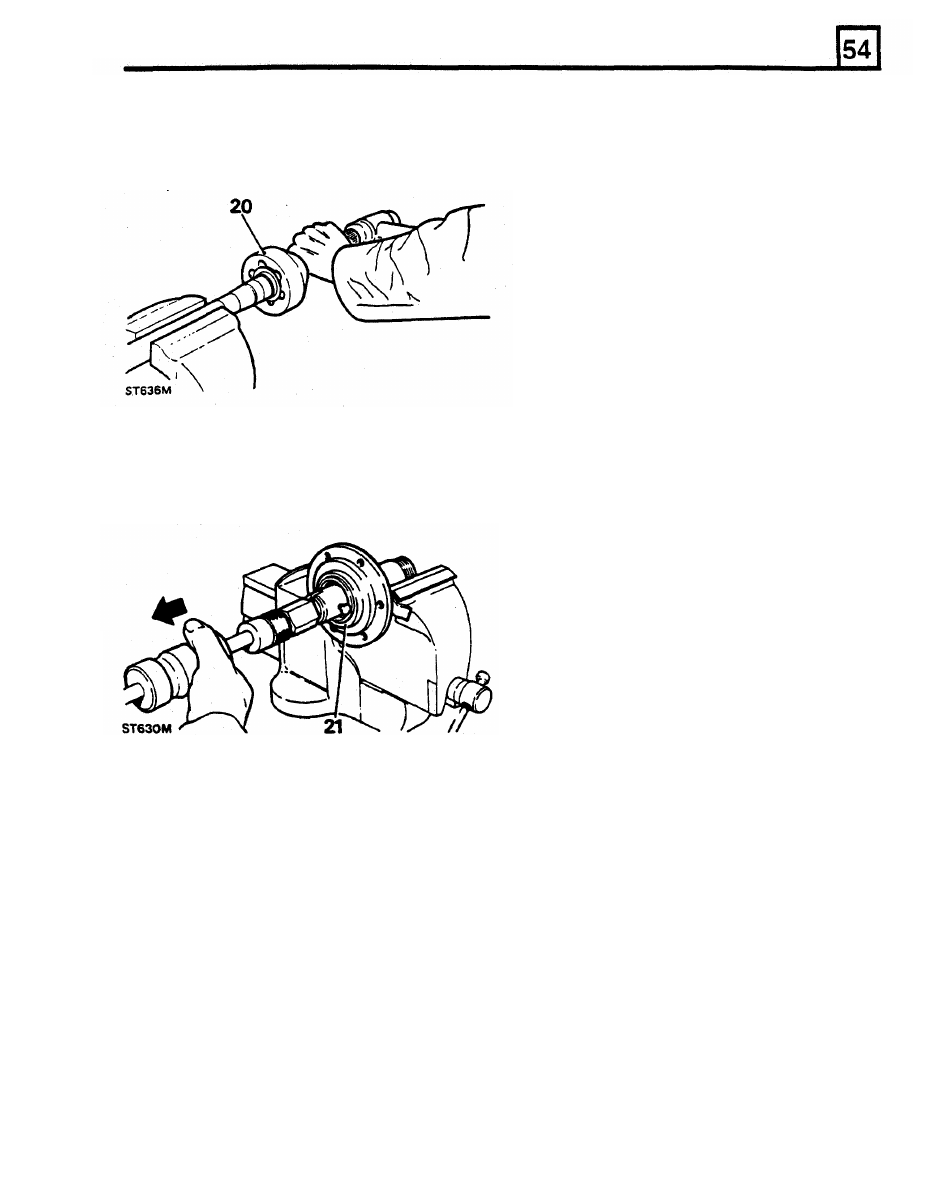

Fit constant velocity joint t o axle

19.

Fit the collar and a new circlip.

20. Engage the constant velocity joint on the axle

32. Remove the swivel pin housing whilst

shaft splines and using a soft mallet, drive the

joint home.

Remove swivel pin bearing housing

34. Remove the seven bolts securing the swivel

pin bearing housing to the axle case and

remove the housing and joint washer.

35.

Remove and discard the swivel pin oil seal

and joint washer.

Overhaul swivel pin bearing housing

36. Prise-out the oil seal from the back

of

the

housing.

37. Drift-out the lower swivel pin bearing track.

21. To remove the bronze brush and oil seal use

38. Press-out the upper swivel pin in Railko bush

housing.

special tool 18G284AAH and

a

slide hammer.

Ensure that the fingers

of the tool locate

39. If worn, pitted or damaged, renew the

housing.

behind the bush, not the oil seal. Drive-out the

40.

Press-in the lower swivel pin bearing track.

bush, then extract the oil seal.

41. Press-in the Railko bush housing ensuring

that the machined flat is towards the back of

the housing, ie when the housing is fitted to

the axle, the flat faces inboard.

42. With the cavity side trailing press the axle

shaft oil seal into the housing and grease.

43. Fit the thrust disc into the bottom

of

the Railko

bush housing and check that

it

is

still

in

position when the swivel pin is fitted.

Renew stub axle intermediate oil seal and bush

Fit swivel p i n bearing housing t o axle

casing bolts with Loctite 270.

45.

Coat both sides

of

a joint washer and place in

position on the swivel pin bearing housing

to

axle mating face.

46.

Hang me swivel pin bearing housing oil seal,

retainer and joint washer over the back

of

the

47. Fit and secure the swivel pin bearing housing

to

the axle with the seven bolts tightening

evenly to 65

to 80

Nm.

22. Lubricate the seal and lip with EP 90 oil and

44. Coat the

swivel

pin bearing housing to axle

with the cavity side leading press-in a new

intermediate oil seal using

a

suitable tube.

23. Using a suitable block, press or drive-in the

bush up

to

the shoulder.

Remove swivel p i n housing

24. Remove the brake disc shield secured by one

housing.

nut and bolt at the bottom front and one

single

bolt,

behind the shield, in the swivel

housing.

25. Disconnect the track-rod end ball joint from

the housing.

26. Disconnect the drag-link ball joint.

27.

Remove the seven

bolts

securing the swivel

pin housing

o

il

seal

and retaining plate and

joint washer and release the assembly from

the swivel pin housing. Note that whilst the

joint washer can be removed at this stage, the

oil

seal and retaining plate must remain until

the swivel pin bearing housing is removed.

28. Remove the two bolts, complete with the

brake disc shield bracket, securing the lower

swivel pin to the housing.

29. Withdraw the lower swivel pin and joint

Fit swivel pin housing

48. Grease and fit the lower swivel pin bearing to

the bearing housing.

49. Place the swivel pin housing in position over

the swivel in bearing housing.

FRONT AXLE AND FINAL

DRIVE

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст