Defender (1993+). Manual — part 92

AIR

CONDITIONING

(h) The compressor shaft must not be rotated

Evaporator

until the system is entirely assembled and

contains a charge of refrigerant.

Examine the refrigeration connections at the unit.

If

( j ) A new compressor contains an initial charge

of

the system should develop a fault, or

if

erratic

312,5 ml (11 UK fluid ozs) of oil when

operation is noticed, refer to the fault diagnosis

received, part

of

which

is

distributed

chart.

throughout the system when

it

has been run.

The compressor contains a holding charge of

gas when received which should be retained

until the hoses are connected.

component connected to the system to ensure

optimum dehydration and maximum moisture

protection of the system.

(I)

All

precautions must be taken to prevent

damage

to

fittings and connections. Slight

Stem type Service valves allow for the isolation

of

damage could cause a leak with the high

the compressor from other parts

of

the system,

pressures used in the system.

When these valves are used in conjunction with the

(m) Always use

two

spanners

of

the correct size,

liquid line quick-disconnect fittings, the three major

one on each hexagon, when releasing and

assemblies

of

the system can be removed from the

tightening refrigeration unions.

vehicle with a minimal

loss

of

refrigerant. In addition,

(n) Joints and ' O ' rings should be coated with

it

is

possible to remove major assemblies for repair

refrigeration oil to aid correct seating. Fittings

of

components which are not part of the refrigeration

which are not lubricated with refrigerant oil are

system,

or

provide access

to

parts

of

the vehicle

almost certain to leak.

which are obstructed by the air conditioning system,

(o) All lines must be

free of

kinks. The efficiency

without fully discharging the system. A thorough

of the system is reduced by a single kink

or

understanding

of

the stem type service valve is

restriction.

necessary before undertaking servicing

or

repair

(p) Flexible hoses should not

be

bent

to

a radius

less than ten times the diameter

of

the hoses.

(q) Flexible connections should not

be

within 50

mm

of

the exhaust manifold.

(r) Completed assemblies must be checked tor

refrigeration lines touching sheet metal panels.

Any direct contact

of

lines and

sheet

transmits

noise and must be eliminated.

Service valves

There are

two

types of service valves in operation:

(k) The

receiver/drier

should be the last

'Stem' and 'Schrader'. To identify where the different

operations occur, stem type will be boxed.

Stem type

involving

the

air conditioning system.

PERIODIC MAINTENANCE

Routine servicing apart from visual checks, is not

necessary. The visual inspections are as follows:

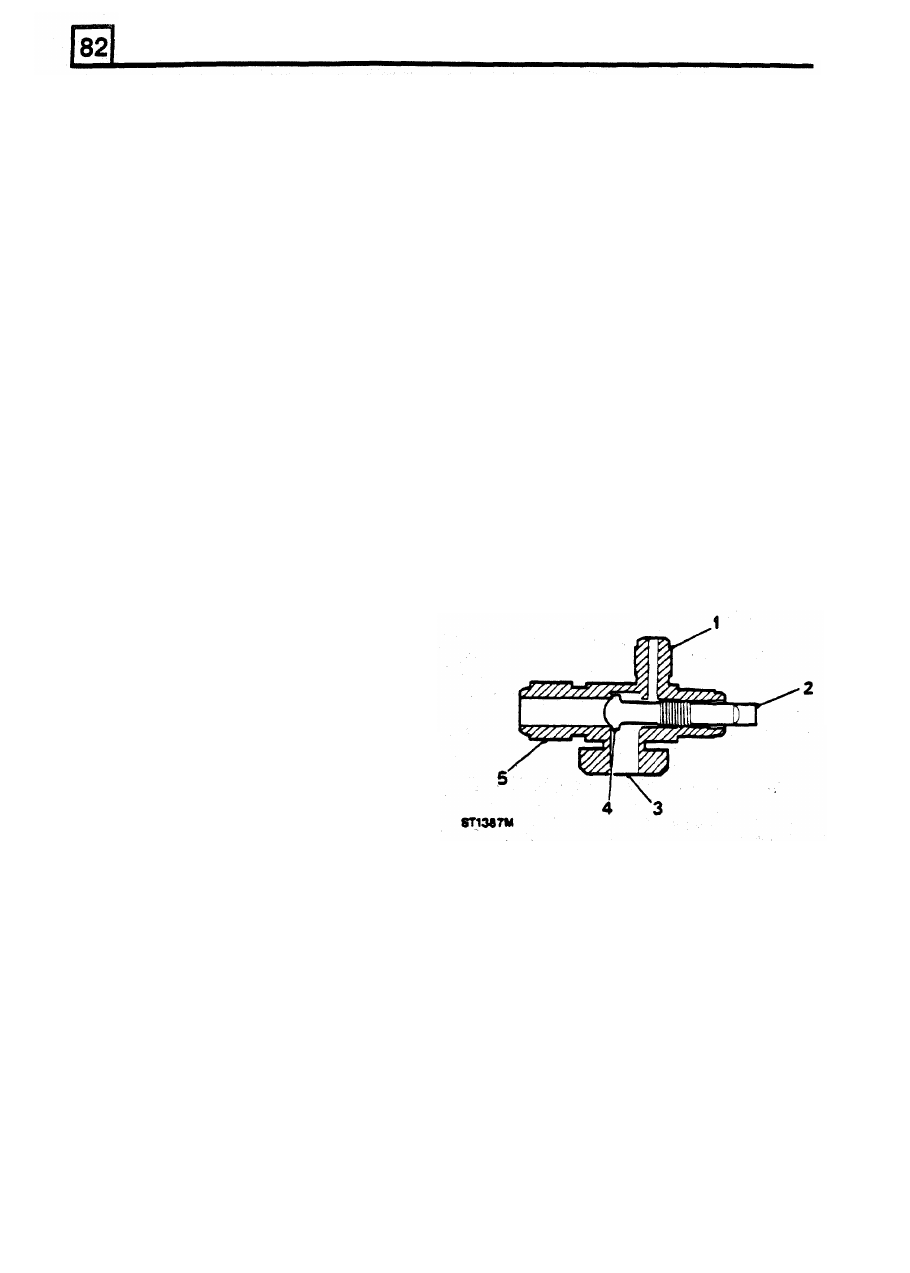

Condenser

1

servlce port

With

a

hose pipe or air line.

clean

the

face of

the

2. Valve stem

condenser

to

remove flies. leaves etc. Check the

3 . Compressor

port

pipe connections

for

signs

of

oil leakage.

4.

Valve

seat

Compressor

5.

Hose connector

Check hose connections

for

signs of oil leakage.

Check flexible

hoses

for swelling. Examine the

compressor belt

for

tightness and condition.

Checking the compressor oil level and topping-up is

only necessary after charging the system

or

in the

event

of

a malfunction

of

the system.

Receiver/Drier

Stem type service valve

Examine the sight glass

for

bubbles with the system

operating. Check connections

for

leakage.

2

RE-ISSUED: FEB

1993

AIR

CONDITIONING

NOTE:

A

special wrench should be used to

adjust the valve to prevent damage to the stem.

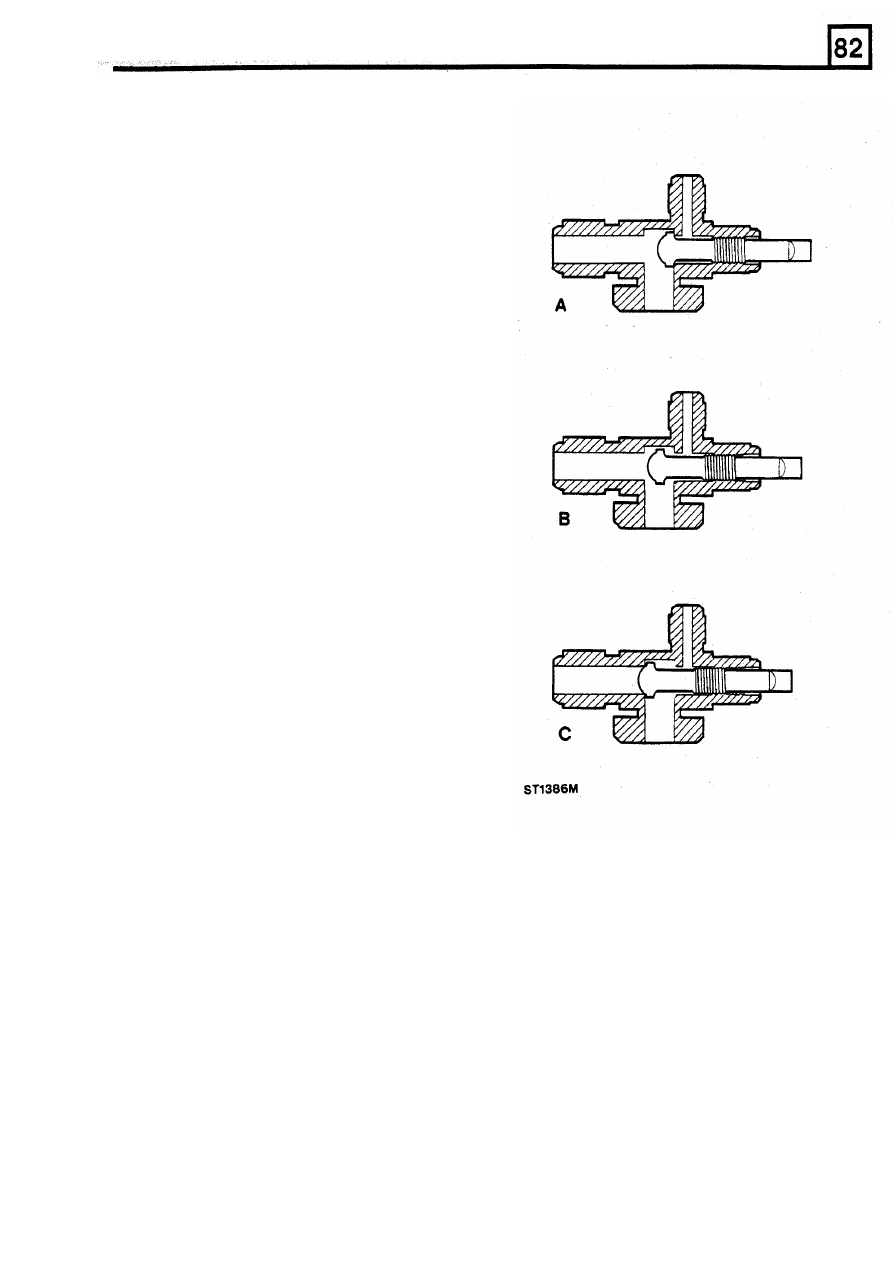

The stem type service valve has three positions, the

operation of which is explained as follows.

A. ON: FULLY ANTICLOCKWISE -

Normal

operating position, and the position which is

used for connecting and disconnecting the

manifold gauge set, is the on position. The

stem is turned fully anticlockwise. This seals

the service gauge port from receiving any

refrigerant flow.

B. MID (Test) POSITION -

After the service

gauge manifold has been installed (the valve

stem is in the on position), turn the valve stem

the required number of turns clockwise. This

will put the valve stem seat midway in the

service valve and allow full system operation

while permitting refrigerant pressure to reach

the gauges.

C. OFF: FULLY CLOCKWISE -

With the service

valve stem turned fully clockwise, the valve

will block passage of refrigerant flow through

the system. As illustrated, the refrigerant flow

to or from the compressor (depending on

whether it is high side or low side) is blocked.

WARNING: NEVER operate the air conditioning

system with the service valves in the

OFF

POSITION, it

will cause severe damage to the

compressor.

REISSUED:

FEB

1993

3

AIR

CONDITIONING

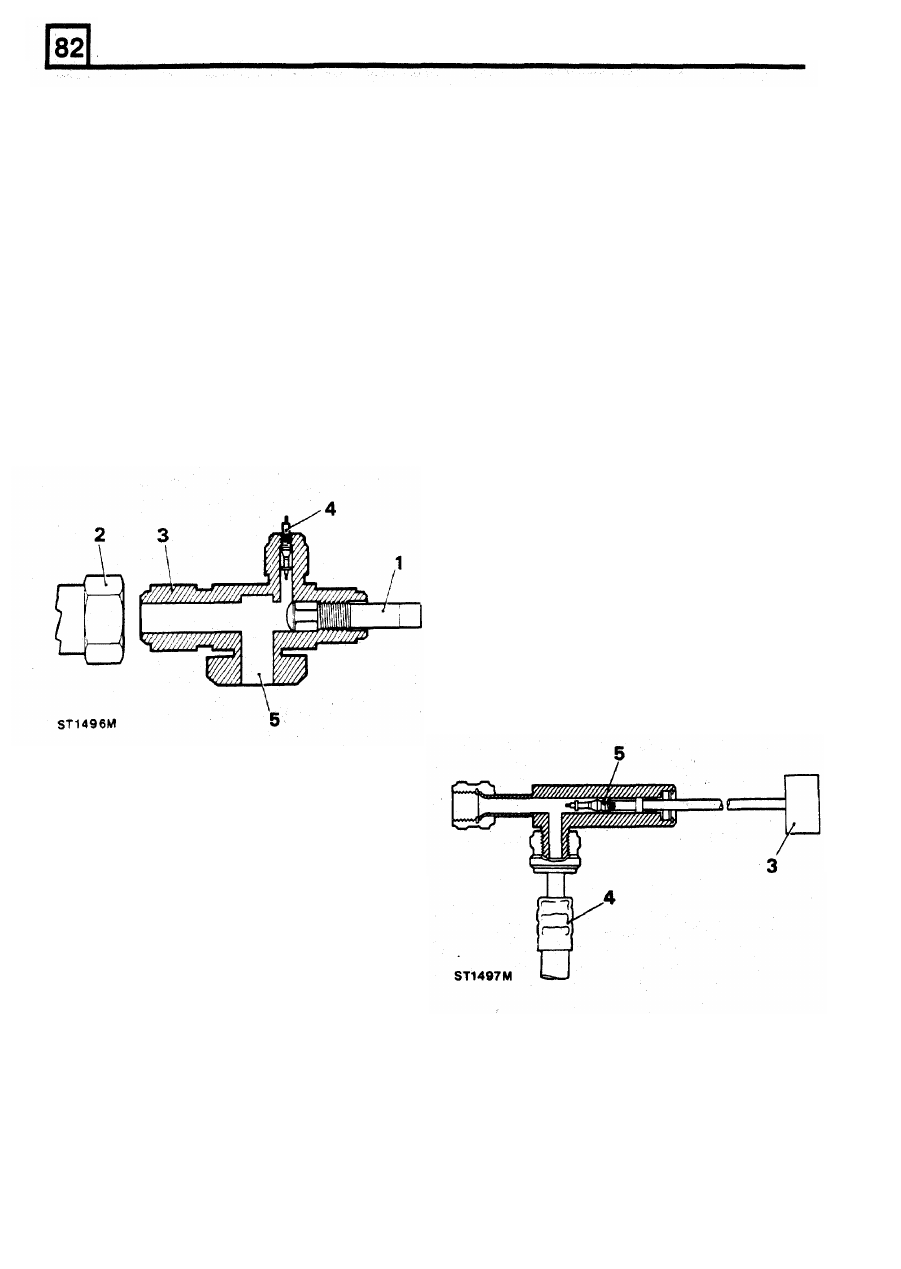

Schrader Type

B. OFF: FULLY CLOCKWISE -

With the service

valve stem turned fully clockwise, the valve

These are secured

to

the head of the compressor,

will block passage of refrigerant flow through

and the suction and discharge flexible end

the system. As illustrated, the refrigerant flow

connections are secured to them by unions.

to

or

from the compressor (depending on

The service valves are identified as suction or low

whether

it

is high side or low side) is blocked.

pressure, and discharge or high pressure. Whilst

they are identical in operation they are not

WARNING: NEVER operate the air conditioning

interchangeable, as the connections are of different

system with the service valves

in

the

OFF

sizes.

POSITION, it will cause severe damage

to

the

The valve with the larger connections fits the suction

side.

As the name suggests, these valves are for service

purposes,

providing

connections

to

external

pressure/vacuum gauges for test purposes. In

Where Schrader Valve depressors are not fitted to

combination with charging and testing equipment

the Testing equipment lines Valve core removers

they are used to charge the system with refrigerant.

Schrader service valve

compressor.

Valve Core Remover

can be used.

Valve Core Removal

The use of valve core removers will facilitate

servicing operations and should be used as follows:

1. Close all valves on the charging trolley.

2.

Remove the service valve cap and seals from

the valve core remover.

3.

Withdraw the plunger as far as possible and

connect the core remover to the service valve.

4.

Connect the hose to the core remover.

5. Depress the plunger until it contacts the valve

core. Unscrew the valve until it is free.

Withdraw the plunger to its full extent.

Service valve caps must be replaced when service

operations are completed. Failure to replace caps

could result in refrigerant

loss

and system failure.

1.

Valve stem

2. Hose connection

3. Service valve

4.

Schrader valve core

5 . Compressor port

NOTE: A special wrench

should be used to

adjust the valve to prevent damage to the stem.

The Schrader type service valve has

two

positions,

the operation of which is explained as follows

A. ON: FULLY ANTICLOCKWISE -

Normal

operating position, and the position which is

used for connecting and disconnecting the

manifold gauge set, is the on position. The

stem is turned fully anticlockwise. This seals

the service gauge port from receiving any

refrigerant flow.

4

REISSUED: FEB

1993

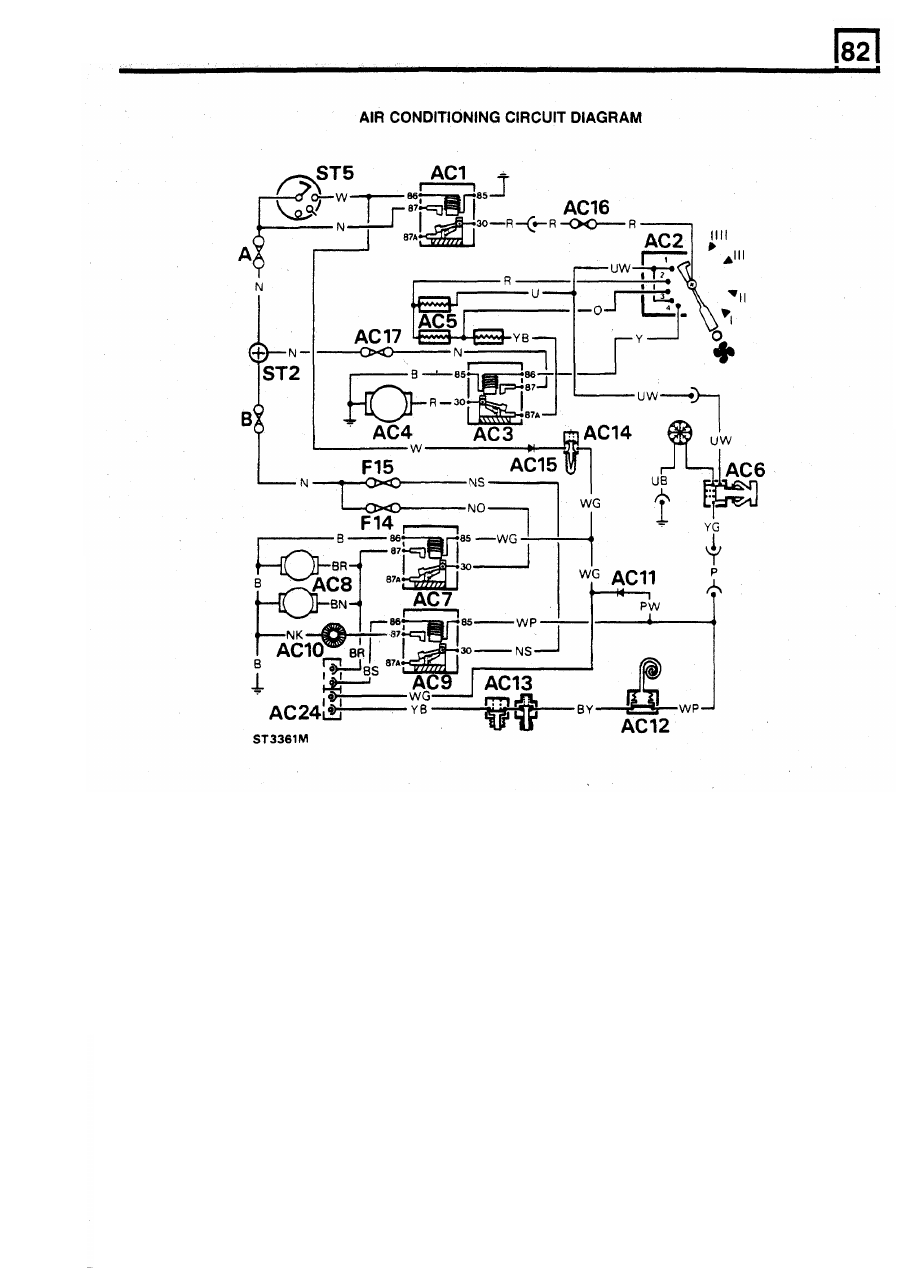

AIR CONDITIONING

Key

to

Circuit Diagram

AC1.

System relay module

AC13.

Refrigerant pressure switches

AC2.

Evaporator/heater fan switch

AC14.

Engine coolant temperature switch

AC3.

Evaporator/heater fan relay module

AC15.

Diode

AC4.

Evaporator/heater fan

AC16.

Fuse in holder

-

30 amp

AC5.

Evap/heater fan speed resistor

AC17.

Fuse in holder

-

30 amp

AC6.

A/C on/off switch

AC24.

Connectors to

MFI

ECM

AC7.

Condenser fan relay

ST2.

Terminal post starter solenoid

AC8.

Condenser fans

ST5.

Starter/ignition switch

AC9.

Compressor relay module

B.

60 amp fuse, main fuse box

AC10.

Compressor

F14

20

amp fuse, main fuse box

AC11.

Diode

F15

5

amp fuse, dash fuse box

AC12.

Thermostat

REISSUED: FEB

1993

5

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст