Defender (1993+). Manual — part 68

FRONT

AXLE AND

FINAL

DRIVE

INSPECTION

4.

Carefully examine the sun and planet gears

for wear on the teeth and the running surfaces

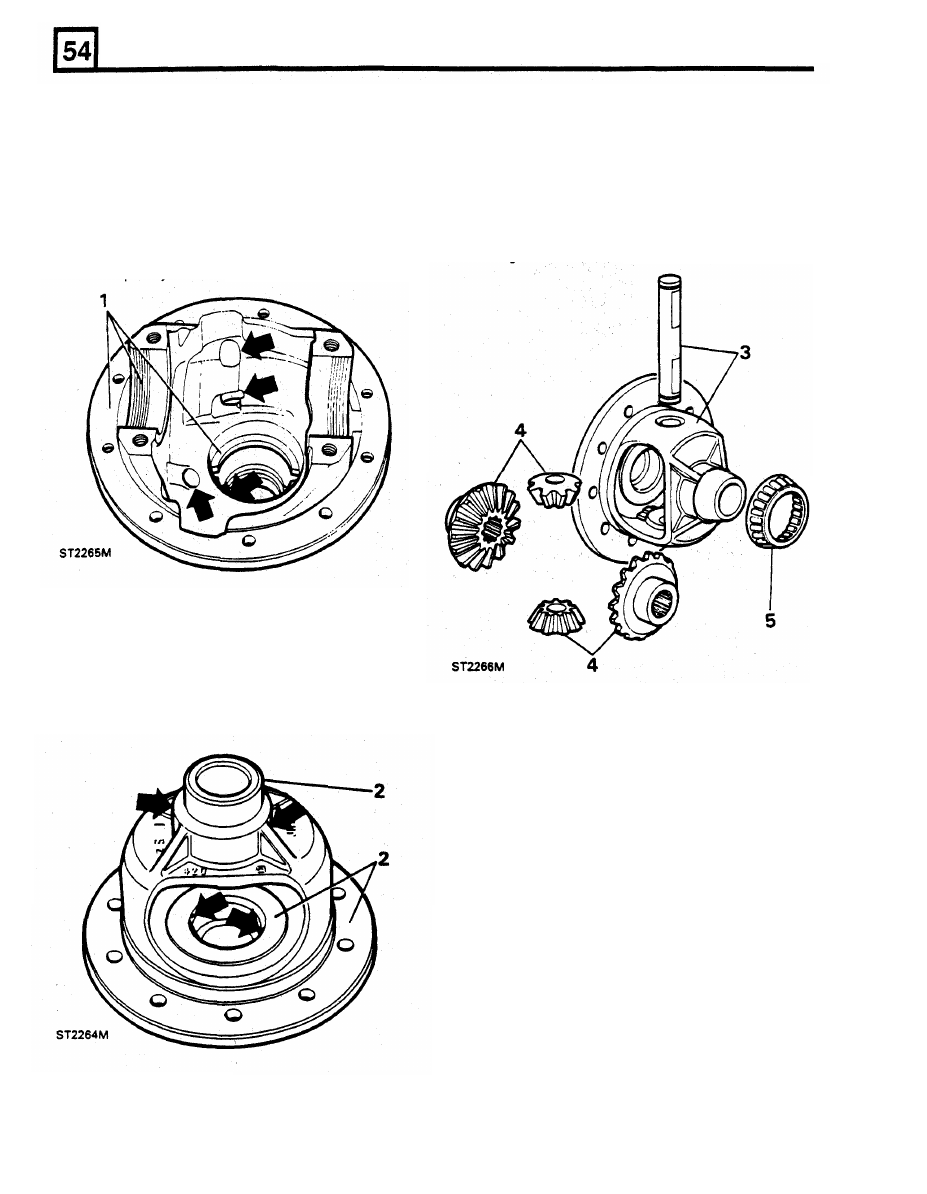

1.

Examine the pinion housing for damage.

in contact with the carrier. Check also for

Check the machined surfaces and remove any

signs of over heating.

burrs. Check the carrier bearing nut threads in

5.

Inspect all the bearings for wear, pitting, flats

the housing and caps and adjusting nuts for

on the rollers and overheating.

If

the bearings

damage and repair as necessary. Make sure

are serviceable they can be refitted but

if

new

that the cast-in lubrication passages (arrowed)

ones are available they must be renewed

including the passage

to the

tail bearing, are

together with the tracks.

completely clear of any obstruction.

2. Examine the machined surfaces of the

differential carrier for damage, pitting, scores

and wear and in particular the surfaces on

which the sun and planet gears run. Also,

ensure that the four

lubrication holes

(arrowed) are clear. Any obstruction here

could cause future bearing failure.

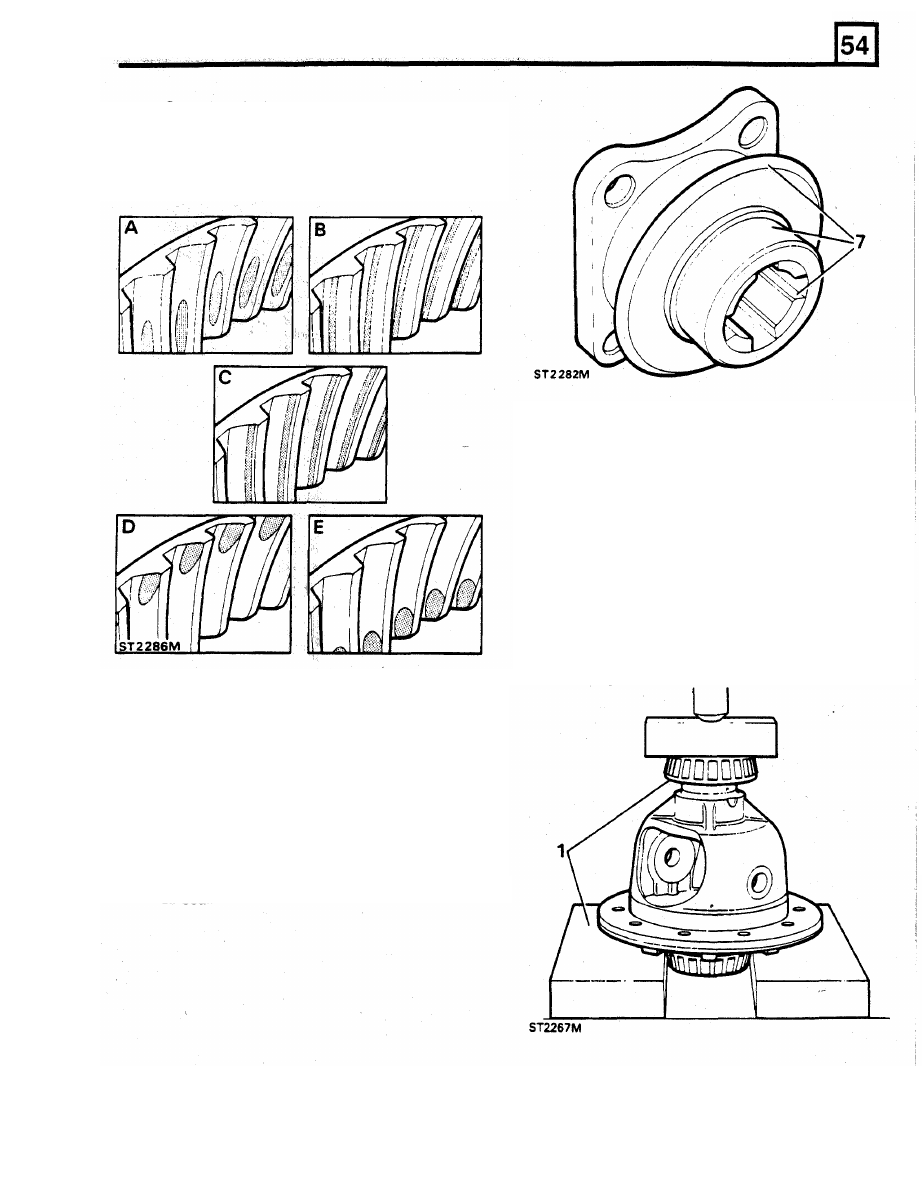

6.

Examine the crown wheel and pinion for

excessive and abnormal wear and signs of

over-heating. Compare the

tooth

contact on

the crown wheel driving side with the

examples illustrated below. These examples,

however, are for the rear axle crown wheel

where the pinion

is

driven clockwise. Tooth

contact for the front axle crown wheel, where

the pinion is driven anticlockwise, is the same

but on the opposite side

of

the

tooth. The first

example

" A " shows the marks that should be

made by a correctly meshed crown wheel and

pinion.

The

remaining examples

show

incorrect tooth contact.

3.

Check the cross shaft

for

scores and pitting.

Insert the shaft in the carrier to check for

excessive wear.

FRONT AXLE AND FINAL

DRIVE

A.

Correct contact.

B.

C.

D.

E.

Heel contact - Insufficient backlash.

Root contact - Pinion too far in mesh.

Peak contact - Pinion too far out of mesh.

Toe contact - Excessive backlash.

ASSEMBLE

Differential carrier and crown wheel

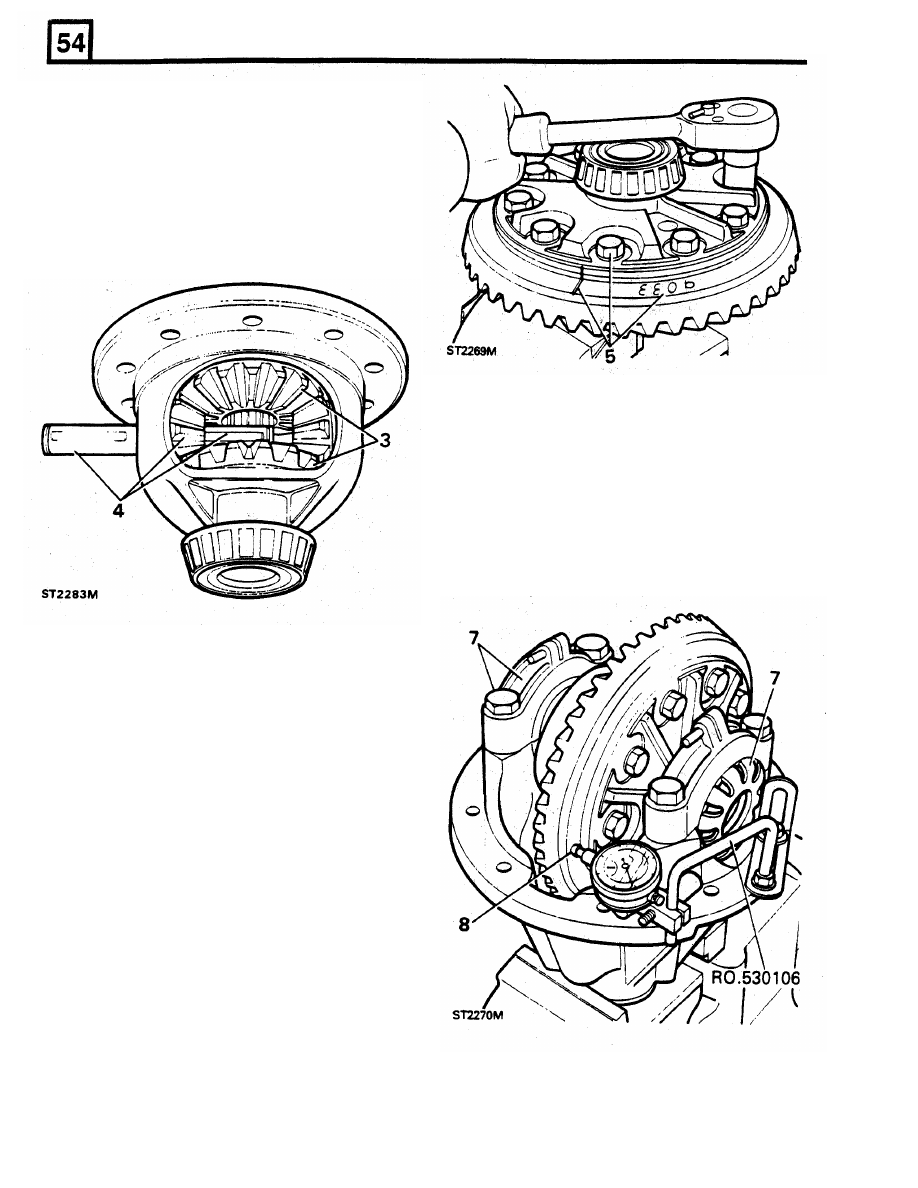

1.

Lubricate the carrier bearing journals with

clean oil and start the bearing squarely on to

one side of the carrier, largest diameter

towards the carrier.

It

does not matter which

bearing is fitted first. Mount the carrier

squarely under a suitable press, supporting

it

under the flange, as close as possible to the

journals. Slowly press the bearing fully home

against the carrier shoulder.

2. Repeat the above procedure

to

fit the second

bearing.

NOTE: The crown wheel and pinion are only

supplied as a matched set likewise the sun and

planet differential gears.

7.

Finally, check the condition

of the pinion and

driving flange splines and ensure that the

machined outer diameter

of the flange is free

from any damage that could destroy a new oil

seal. Check that the mud deflector is not

damaged or buckled

to

the extent that

it

cannot deflect mud and water away

from the

oil seal.

FRONT AXLE AND FINAL DRIVE

3.

Lubricate and

fit

the

two

sun gears followed

by the planet gears.

4.

Align the planet gears

with

the carrier holes

and

fit

the cross shaft. Secure the shaft with

new circlips. Check the gears for freedom of

rotation and that there are not tight spots.

Only nominal backlash should be present but

if

excessive, the gears or the carrier or both

should be changed since there is no provision

for adjustment.

6.

To check the crown wheel for run out, secure

the pinion housing in the vice in a vertical

position. Fit the tracks to the carrier bearings

and lower the assembly into the pinion

housing.

7.

Fit the bearing caps, lining up the marks and

just nip the bolts.

Do not fully tighten. Fit the

bearing adjuster nuts and tighten using

service tool

RO

530105

until there is no end

float between the bearings. Now, tighten the

bearing cap bolts evenly to the correct torque.

5. Check that the serial number etched on the

pinion end face is the same as that marked

on the crown wheel. Clean the crown wheel

and carrier mating faces and check that there

are

no

burrs or any other damage that could

cause excessive run-out

of the crown wheel. If

the

original crown wheel and pinion is being

refitted ensure that the marks made when

dismantling line up. Since the crown wheel is

a fairly tight fit on the carrier, the bolt holes

should be lined up first while locating the

crown wheel squarely on the carrier. Fit and

tighten the bolts evenly, a little at a time, until

the crown wheel has pulled down on

to the

carrier flange. Tighten the bolts temporarily

to

the correct torque.

FRONT

AXLE AND FINAL DRIVE

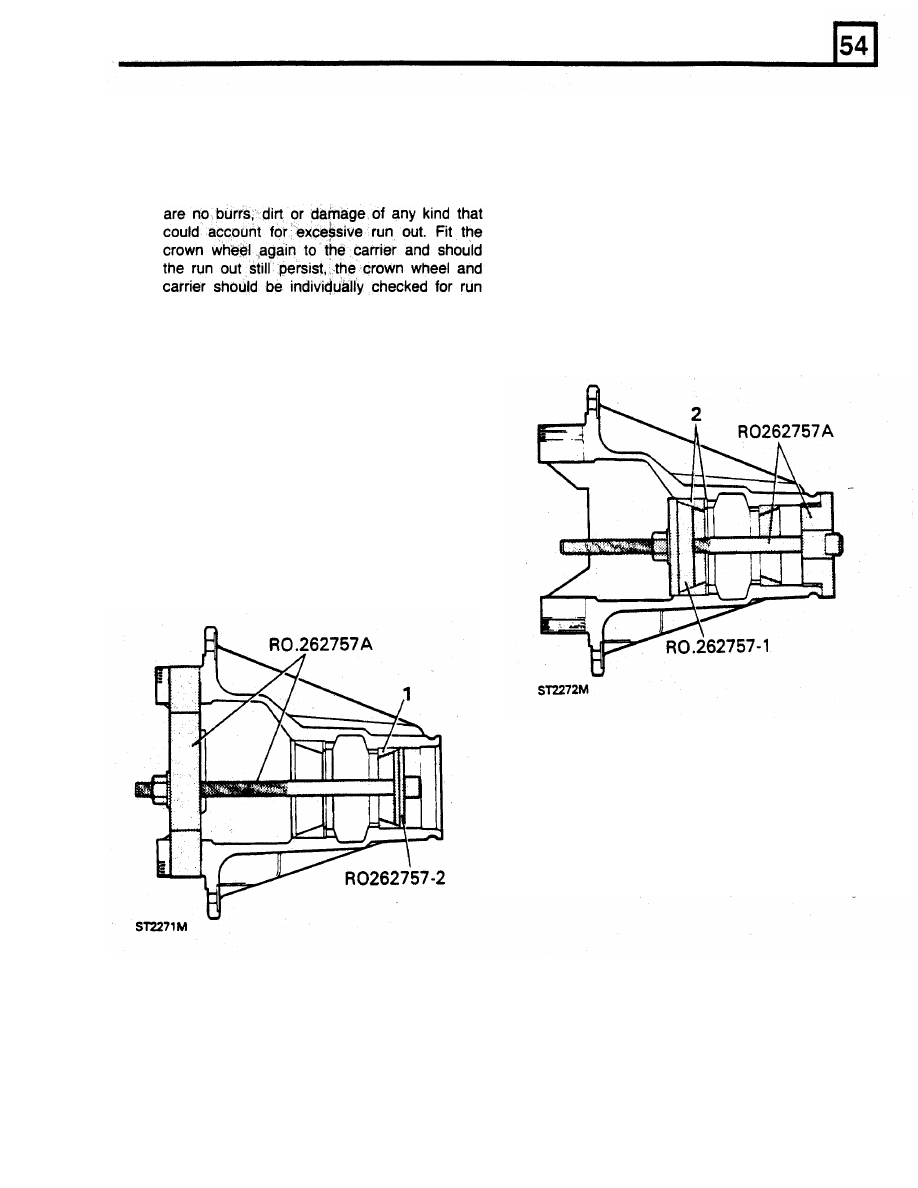

8.

Mount a dial test indicator on the flange of the

2. Fit the bearing head track and the original

pinion housing using bracket RO 530106 so

shim using main

tool RO 262757A and

that the stylus rests on the back of the crown

adaptor

RO 262757-1. Lubricate and start the

wheel. Turn the crown wheel and

if

the run

track squarely in the housing and assemble

out exceeds 0,10mm remove the crown wheel

the

tool

as shown below.

If

the shim was

from the carrier and check again that there

damaged during removal

fit

a new one

of the

same thickness.

If the

shim

was lost before

the size

was measured,

fit

a

replacement

shim at least 1,27mm

thick. Turn

the nut

slowly, using a

box spanner,

until the track is

fully home against

the housing

shoulder.

It

is

out on a lathe or similar equipment where the

vital to the successful

assembly

of the

parts can be accurately turned and measured.

differential and in particular the following

pinion height setting, that the track and shim

9.

When

satisfied

that

the run

out

is within the

specified limit,

remove

the crown wheel bolts,

one stud

at a

time,

coat

the

theads

with Loctite

Studlock

and refit the

bolts tightening evenly

1. To fit the pinion tail

bearing

track, lubricate

and start the track

squarely

in the pinion

housing. Assemble

the

special tool

RO

262757A and adaptor RO

262757-2

as

illustrated below. Slowly turn the nut clockwise

until

the

track

is fully

home against the

housing shoulder.

Pinion height setting

1.

Fit the pinion head bearing to the pinion with

press M.S. 47 and collets 18G 47-6 and 18G

47-6/2. Note that the smaller register on 18G

47-6/2 must be uppermost against the

bearing. Ensure that the larger diameter of the

bearing is towards the gear. Lubricate the

pinion and press it slowly on to the bearing.

to the correct torque.

Fitting pinion bearing tracks

is indeed pressed fully home.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст