Ford Bronco (2022 year). Manual in english — page 24

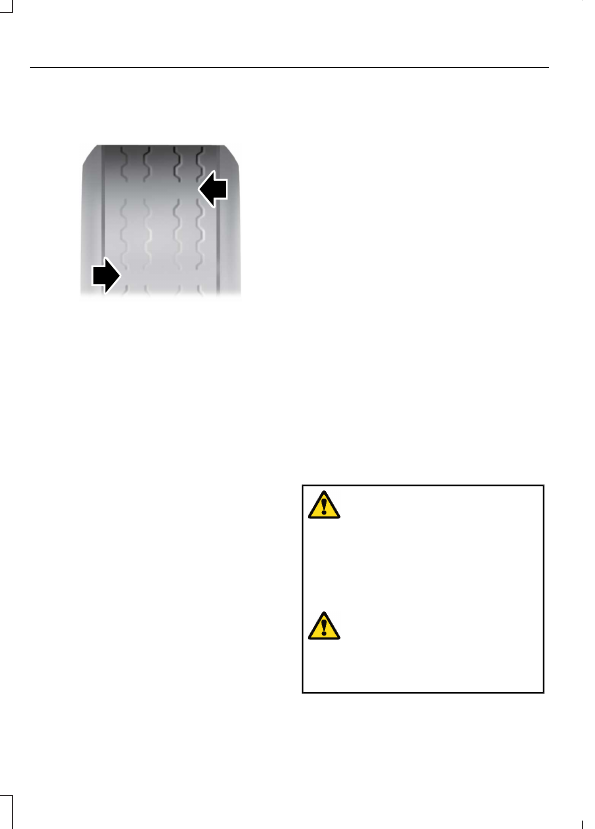

INSPECTING THE TIRE FOR

WEAR

E142546

When the tread is worn down to

one sixteenth of an inch (2 mm),

tires must be replaced to help

prevent your vehicle from skidding

and hydroplaning. Built-in

treadwear indicators, or wear bars,

which look like narrow strips of

smooth rubber across the tread

will appear on the tire when the

tread is worn down to one

sixteenth of an inch (2 mm).

When the tire tread wears down

to the same height as these wear

bars, the tire is worn out and must

be replaced.

The tires should also be balanced

periodically. An unbalanced tire

and wheel assembly may result in

irregular tire wear.

Periodically inspect the tire treads

for uneven or excessive wear and

remove objects such as stones,

nails or glass that may be wedged

in the tread grooves.

INSPECTING THE TIRE FOR

DAMAGE

Inspect the tire sidewalls for

cracking, cuts, bruises and other

signs of damage or excessive

wear. If internal damage to the tire

is suspected, have the tire

dismounted and inspected in case

it needs to be repaired or replaced.

For your safety, tires that are

damaged or show signs of

excessive wear should not be used

because they are more likely to

blow out or fail.

Periodically inspect the tire treads

and sidewalls for damage, such

as bulges in the tread or sidewalls,

cracks in the tread groove and

separation in the tread or sidewall.

If damage is observed or

suspected, have the tire inspected

by a tire professional.

Safety Practices

WARNING:

If your vehicle

is stuck in snow, mud or sand, do

not rapidly spin the tires;

spinning the tires can tear the

tire and cause an explosion. A

tire can explode in as little as

three to five seconds.

WARNING:

Do not spin the

wheels at over 34 mph

(55 km/h). The tires may fail and

injure a passenger or bystander.

388

Tire Care

Highway Hazards

No matter how carefully you drive,

there is always the possibility that

you could eventually have a flat

tire on the highway. Drive slowly

to the closest safe area out of

traffic. This could further damage

the flat tire, but your safety is

more important.

If you feel a sudden vibration or

ride disturbance while driving, or

you suspect your tire or vehicle

has been damaged, immediately

reduce your speed. Drive with

caution until you can safely pull

off the road. Stop and inspect the

tires for damage. If a tire is

under-inflated or damaged,

deflate it, remove the wheel and

replace it with your spare tire and

wheel. If you cannot detect a

cause, have the vehicle towed to

the nearest repair facility or tire

dealer to have the vehicle

inspected.

Tire and Wheel Alignment

A bad jolt from hitting a curb or

pothole can cause the front end

of your vehicle to become

misaligned or cause damage to

your tires. If your vehicle seems to

pull to one side when you are

driving, the wheels could be out of

alignment. Have an authorized

dealer check the wheel alignment

periodically.

Wheel misalignment in the front

or the rear can cause uneven and

rapid treadwear of your tires and

should be corrected by an

authorized dealer.

INSPECTING THE WHEEL

VALVE STEMS

Check the valve stems for holes,

cracks, or cuts that could permit

air leakage.

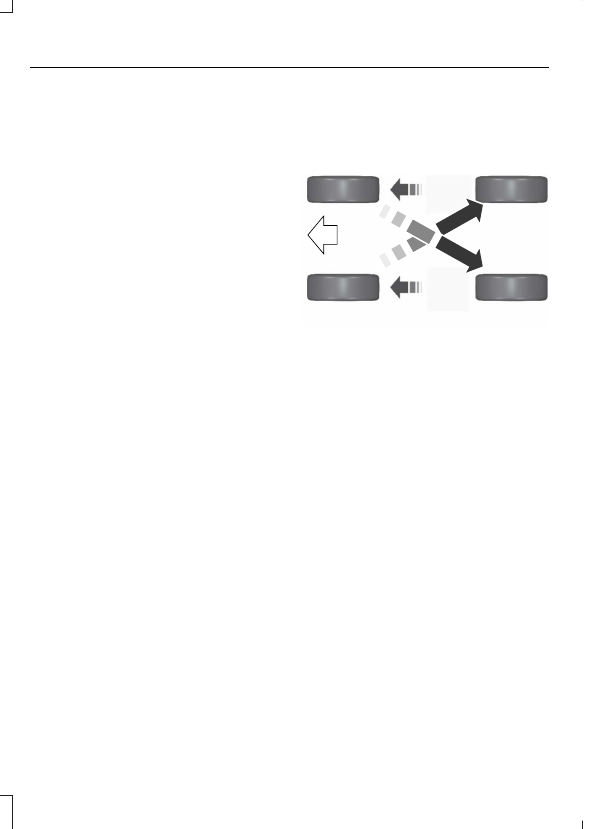

TIRE ROTATION

WARNING:

If the tire label

shows different tire pressures for

the front and rear tires and the

vehicle has a tire pressure

monitoring system, then you

need to update the settings for

the system sensors. Always

perform the system reset

procedure after tire rotation. If

you do not reset the system, it

may not provide a low tire

pressure warning when

necessary.

Note:

If your tires show uneven

wear ask an authorized dealer to

check for and correct any wheel

misalignment, tire imbalance or

mechanical problem involved

before tire rotation.

Note:

After having your tires

rotated, inflation pressure must be

checked and adjusted to the

vehicle requirements.

389

Tire Care

Rotating your tires at the

recommended interval, as

indicated in the scheduled

maintenance chapter, will help

your tires wear more evenly,

providing better tire performance

and longer tire life.

For the best tire life, a five tire

rotation is recommended that

includes the matching spare tire

mounted on the back of the

vehicle. This rotation requires a

forced re-learning of your tire

pressure monitor system sensors

by your vehicle, and should be

performed by an authorized dealer

or a service center to ensure the

tire pressure monitor system will

provide proper warning at all

times. When performing the tire

rotation yourself, a four tire

rotation is recommended, without

using the spare tire in the rotation,

so that no tire pressure monitor

system sensor re-learn is required.

If a five tire rotation is performed

without a tire pressure monitor

system sensor re-learn, the

system may not provide a low tire

pressure warning when necessary.

Keep in mind that a spare tire that

is not used in the tire rotation

should only be used temporarily

in the event of a flat tire, not as a

permanent replacement. The

spare tire should always be

replaced if it exceeds 6 years of

age, regardless of whether it is

part of the tire rotation.

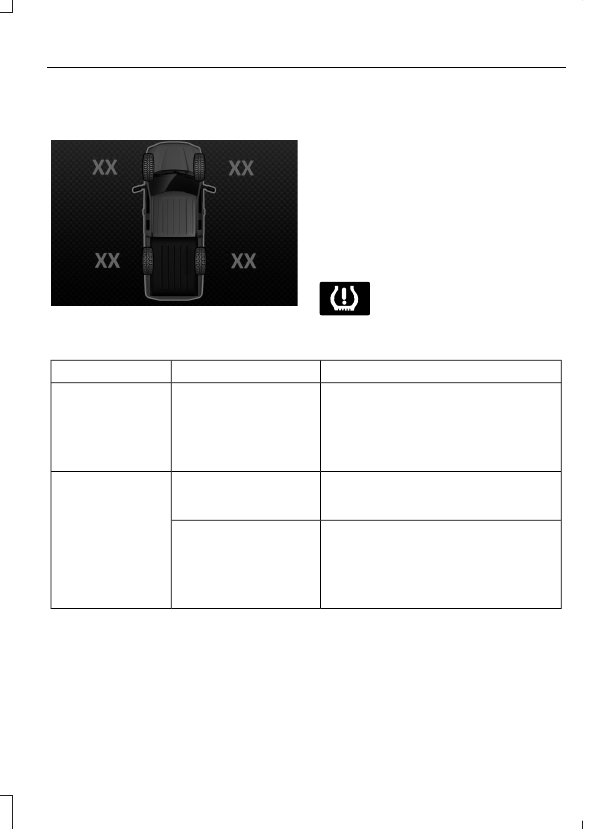

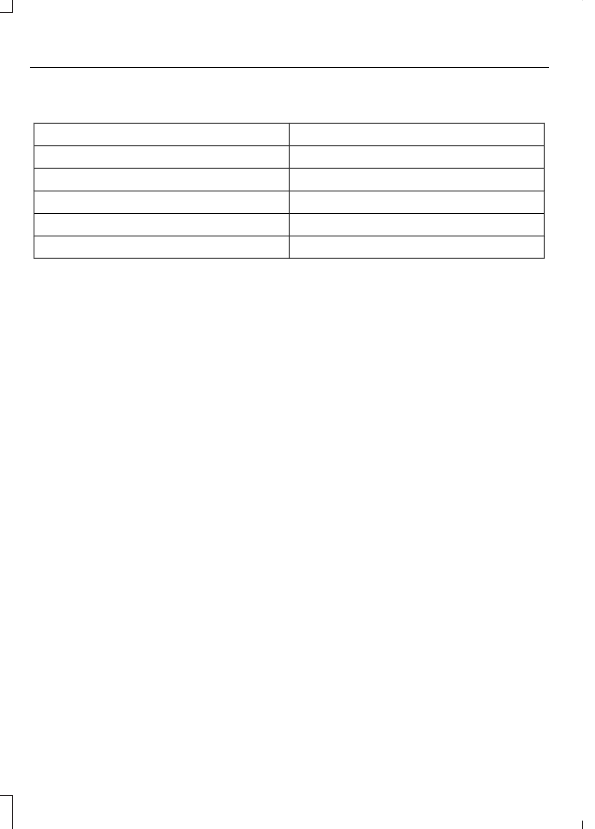

Rear-wheel drive vehicles and

four-wheel drive vehicles with four

tire rotation, front tires at left of

diagram.

E142548

Sometimes irregular tire wear can

be corrected by rotating the tires.

390

Tire Care

WHAT IS THE TIRE PRESSURE

MONITORING SYSTEM

The tire pressure monitoring

system measures the vehicle's

tire pressures. A warning lamp

illuminates if one or more tires are

significantly underinflated or if there is a

system malfunction.

TIRE PRESSURE MONITORING

SYSTEM OVERVIEW

WARNING:

If the tire pressure

monitor sensor becomes damaged it

may not function.

WARNING:

Under-inflation is the

most common cause of tire failures and

may result in severe tire cracking, tread

separation or blowout, with unexpected

loss of vehicle control and increased risk

of injury. Under-inflation increases

sidewall flexing and rolling resistance,

resulting in heat buildup and internal

damage to the tire. It also may result in

unnecessary tire stress, irregular wear,

loss of vehicle control and accidents. A

tire can lose up to half of its air pressure

and not appear to be flat!

WARNING:

To determine the

required pressure(s) for your vehicle, see

the Safety Compliance Certification

Label (on the door hinge pillar,

door-latch post or the door edge that

meets the door-latch post, next to the

driver seat) or the Tire Label on the

B-Pillar or the edge of the driver door.

Each tire, including the spare (if provided),

should be checked monthly when cold and

inflated to the inflation pressure

recommended by the vehicle manufacturer

on the vehicle placard or tire inflation

pressure label. (If your vehicle has tires of

a different size than the size indicated on

the vehicle placard or tire inflation pressure

label, you should determine the proper tire

inflation pressure for those tires).

As an added safety feature, your vehicle

has been equipped with a Tire Pressure

Monitoring System (TPMS) that

illuminates a low tire pressure telltale

when one or more of your tires is

significantly under-inflated. Accordingly,

when the low tire pressure telltale

illuminates, you should stop and check

your tires as soon as possible, and inflate

them to the proper pressure. Driving on a

significantly under-inflated tire causes the

tire to overheat and can lead to tire failure.

Under-inflation also reduces fuel efficiency

and tire tread life, and may affect the

vehicle’s handling and stopping ability.

Please note that the TPMS is not a

substitute for proper tire maintenance, and

it is the driver’s responsibility to maintain

correct tire pressure, even if under-inflation

has not reached the level to trigger

illumination of the TPMS low tire pressure

telltale.

Your vehicle has also been equipped with

a TPMS malfunction indicator to indicate

when the system is not operating properly.

The TPMS malfunction indicator is

combined with the low tire pressure

telltale. When the system detects a

malfunction, the telltale will flash for

approximately one minute and then remain

continuously illuminated. This sequence

will continue upon subsequent vehicle

start-ups as long as the malfunction exists.

391

Tire Pressure Monitoring System

When the malfunction indicator is

illuminated, the system may not be able

to detect or signal low tire pressure as

intended. TPMS malfunctions may occur

for a variety of reasons, including the

installation of replacement or alternate

tires or wheels on the vehicle that prevent

the TPMS from functioning properly.

Always check the TPMS malfunction

telltale after replacing one or more tires or

wheels on your vehicle to ensure that the

replacement or alternate tires and wheels

allow the TPMS to continue to function

properly.

WARNING:

Changes or

modifications not expressively approved

by the party responsible for compliance

could void the user's authority to operate

the equipment. The term "IC:" before the

radio certification number only signifies

that Industry Canada technical

specifications were met.

This device complies with Part 15 of the

FCC Rules and with License exempt RSS

Standards of Industry Canada. Operation

is subject to the following two conditions:

1.

This device may not cause harmful

interference, and

2. This device must accept any

interference received, including

interference that may cause undesired

operation.

TIRE PRESSURE MONITORING

SYSTEM PRECAUTIONS

WARNING:

The tire pressure

monitoring system is not a substitute for

manually checking tire pressures. You

should periodically check tire pressures

using a pressure gauge. Failure to

correctly maintain tire pressures could

increase the risk of tire failure, loss of

control, vehicle rollover and personal

injury.

WARNING:

Do not use the tire

pressure displayed in the information

display as a tire pressure gauge. Failure

to follow this instruction could result in

personal injury or death.

Note:

The use of tire sealants can damage

the tire pressure monitoring system.

TIRE PRESSURE MONITORING

SYSTEM LIMITATIONS

When the outside temperature drops

significantly, the tire pressure could

decrease and activate the low tire pressure

warning lamp.

The warning lamp could also illuminate

when you use a spare wheel, or tire sealant

from the inflator kit.

Note:

Regularly checking the vehicle tire

pressures can reduce the possibility for the

warning lamp to illuminate due to outside

air temperature changes.

Note:

After you inflate the tires to the

recommended pressure it could take up to

two minutes of driving over 20 mph

(32 km/h) for the warning indicator to turn

off.

392

Tire Pressure Monitoring System

VIEWING THE TIRE

PRESSURES

E224333

Using the information display

arrow keys navigate to the truck

info section where you can view

the tire pressures.

TIRE PRESSURE MONITORING

SYSTEM –

TROUBLESHOOTING

TIRE PRESSURE MONITORING

SYSTEM – WARNING LAMPS

The low tire pressure warning

lamp has combined functions,

as it warns you when your tires

need air, and when the system is no longer

capable of functioning as intended.

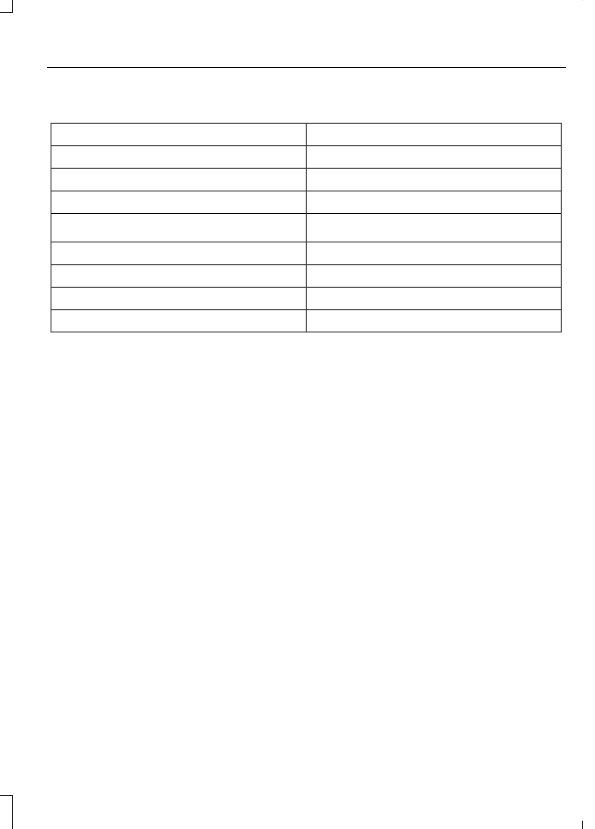

Action Required

Possible Cause

Warning Lamp

After inflating your tires to the manufac-

turer’s recommended pressure as shown

on the tire label, on the edge of driver

door or the B-pillar, drive your vehicle for

at least two minutes over 20 mph

(32 km/h) before the light turns off.

One or more tires are

significantly under

inflated

Solid warning lamp

Repair the damaged road wheel and tire

and refit it to your vehicle to restore

operation of the system.

Temporary spare wheel

in use

Solid warning lamp

or flashing warning

lamp

If the tires are inflated to the recom-

mended tire pressures and the temporary

spare wheel is not in use, the system

detected a fault that requires service.

Have your vehicle checked as soon as

possible.

Tire pressure monitoring

system malfunction

393

Tire Pressure Monitoring System

TIRE PRESSURE MONITORING SYSTEM – INFORMATION MESSAGES

Action

Message

After inflating your tires to the manufacturer’s recommended

pressure as shown on the tire label, on the edge of the driver

door or the B-pillar, drive your vehicle for at least two minutes

over 20 mph (32 km/h) before the light turns off.

Tire Pressure Low

The system has detected a fault that requires service. Have

your vehicle checked as soon as possible.

Tire Pressure Monitor

Fault

The system has detected a fault that requires service or a

spare tire is in use. Have your vehicle checked as soon as

possible.

Tire Pressure Sensor

Fault

394

Tire Pressure Monitoring System

CHANGING A FLAT TIRE

Note:

You should only use tire sealants in

roadside emergencies as they may cause

damage to the tire pressure monitoring

system sensor.

Note:

The tire pressure monitoring system

indicator light illuminates when the spare

tire is in use. To restore the full function of

the monitoring system, all road wheels

equipped with tire pressure monitoring

sensors must be mounted on the vehicle.

If you get a flat tire when driving, do not

apply the brake heavily. Instead, gradually

decrease your speed, hold the steering

wheel firmly, and slowly move to a safe

place on the side of the road.

Have your flat serviced by an authorized

dealer in order to prevent damage to the

tire pressure monitoring system sensors.

Replace the spare tire with a road tire as

soon as possible. During repairing or

replacing of the flat tire, have the

authorized dealer inspect the tire pressure

monitoring system sensor for damage.

Tire Change Procedure

WARNING:

Failure to follow these

guidelines could result in an increased

risk of loss of vehicle control, injury or

death.

WARNING:

Do not get under a

vehicle that is supported by a jack.

WARNING:

The jack supplied with

this vehicle is only intended for changing

a flat tire in an emergency. Do not

attempt to do any other work on your

vehicle when it is supported by the jack,

as your vehicle could slip off the jack.

Failure to follow this instruction could

result in personal injury or death.

WARNING:

To help prevent your

vehicle from moving when changing a

wheel, shift the transmission into park

(P), set the parking brake and use an

appropriate block or wheel chock to

secure the wheel diagonally opposite to

the wheel being changed. For example,

when changing the front left wheel,

place an appropriate block or wheel

chock on the right rear wheel.

WARNING:

Only use the jack

provided as original equipment with your

vehicle.

WARNING:

Only use the specified

jacking points. If you use any other

locations you could damage vehicle

components, such as brake lines.

WARNING:

Never place anything

between the vehicle jack and your

vehicle.

WARNING:

Never place anything

between the vehicle jack and the ground.

WARNING:

Do not attempt to

change a tire on the side of the vehicle

close to moving traffic. Pull far enough

off the road to not obstruct the flow of

traffic and avoid the danger of being hit

when operating the jack or changing the

wheel.

WARNING:

Do not attempt to

change a tire on the side of the vehicle

close to moving traffic. Pull far enough

off the road to not obstruct the flow of

traffic and avoid the danger of being hit

when operating the jack or changing the

wheel.

395

Changing a Road Wheel

WARNING:

Always fully apply the

parking brake. Failure to follow this

instruction could result in personal injury

or death.

WARNING:

The jack should be

used on level firm ground wherever

possible.

Note:

Make sure all passengers are out of

your vehicle.

Note:

Jack at the specified locations to

avoid damage to the vehicle.

Note:

No maintenance or additional

lubrication of your jack is required over the

service life of your vehicle.

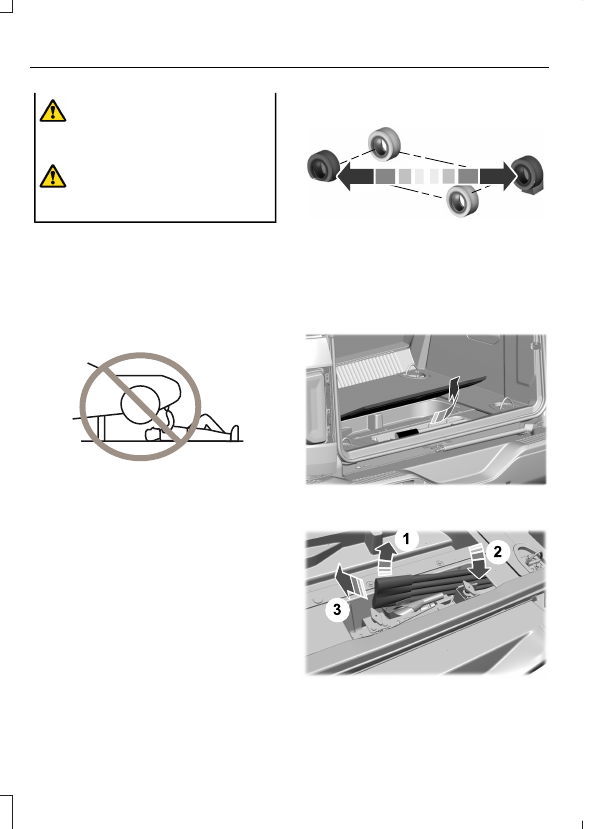

E166722

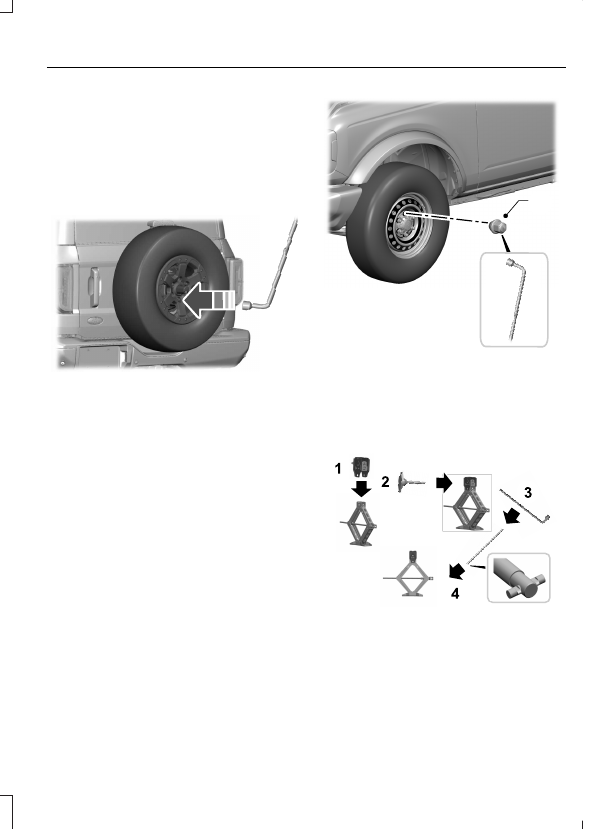

1.

Park the vehicle on a level, firm surface

and activate the hazard flashers.

2. Apply the parking brake, and place the

transmission in park (P) for an

automatic transmission or reverse (R)

for a manual transmission and turn the

engine off.

3. Block the wheel diagonally opposite of

the flat tire. For example, if the left

front is flat, block the right rear wheel.

E142551

4. Find the jack and tool kit in the rear

trunk of the vehicle. Turn the jack

retainer counterclockwise to remove

the jack and jack extension block.

E324358

5. Remove the tool bag.

E343390

396

Changing a Road Wheel

6. Remove the lug wrench from the tool

bag. Turn the spare tire fasteners

counterclockwise starting with the

lowest first, and remove the spare tire

from the rear of the vehicle.

Note:

Insert the wheel lock key into the

wheel lock nut before using the lug wrench

to loosen the lock nut.

E328591

Note:

Do not lay the wheel face down on

the ground, as there is a risk of scratching

or marring the wheel if laid down on an

uneven surface.

7.

Loosen each road wheel nut a half a

turn counterclockwise, do not remove

them until the flat tire is raised off the

ground.

E328732

1

2

8. When you are changing a flat front tire,

connect the extension block to the jack

loadrest using the wing bolt as shown.

Connect the jack handle to the jack,

and use the lug nut wrench to operate

the jack.

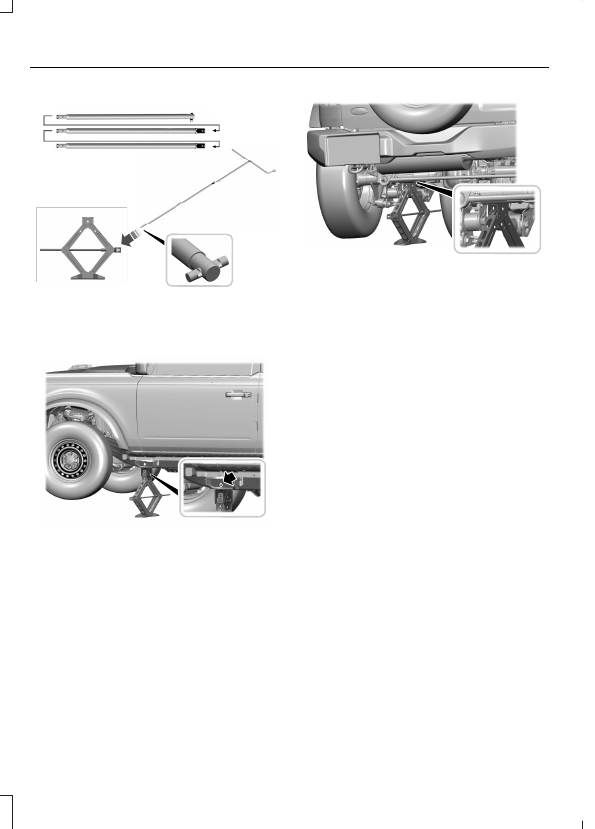

E330077

9. Do not use the extension block when

you are changing a flat tire on the rear

axle of the vehicle. Assemble the jack

handle using the extensions as shown

to operate the jack when placing under

the rear axle.

397

Changing a Road Wheel

E330076

10.

The front jacking point location is

indicated by an arrow-shaped mark

on the frame.

E343635

11.

Use the rear axle tube for the rear

jacking point.

E330074

Note:

Only use the jack on the specified

jacking points and as close to the affected

wheel as possible.

12.

Place the jack at the jacking point

closest to the flat tire you are

changing. Turn the lug wrench handle

clockwise until the flat tire is

completely off the ground.

13.

Remove the wheel nuts with the

wheel nut wrench.

14.

Replace the flat tire with the spare

wheel. Make sure the wheel is on with

the valve stem facing outward.

15.

Install the wheel nuts snug against

the hub. Do not fully tighten the

wheel nuts until the vehicle is lowered

back onto the ground.

16.

Turn the wrench handle

counterclockwise to lower the jack.

17.

Remove the jack and fully tighten the

lug nuts in the order shown below.

398

Changing a Road Wheel

E166719

18.

Stow the flat tire on the rear of the

vehicle and fully tighten the securing

nuts.

E324079

19.

Remove the wheel blocks.

20. Stow the jack and tools in the original

locations shown in the removal

section and tighten the retaining

screws by turning clockwise.

399

Changing a Road Wheel

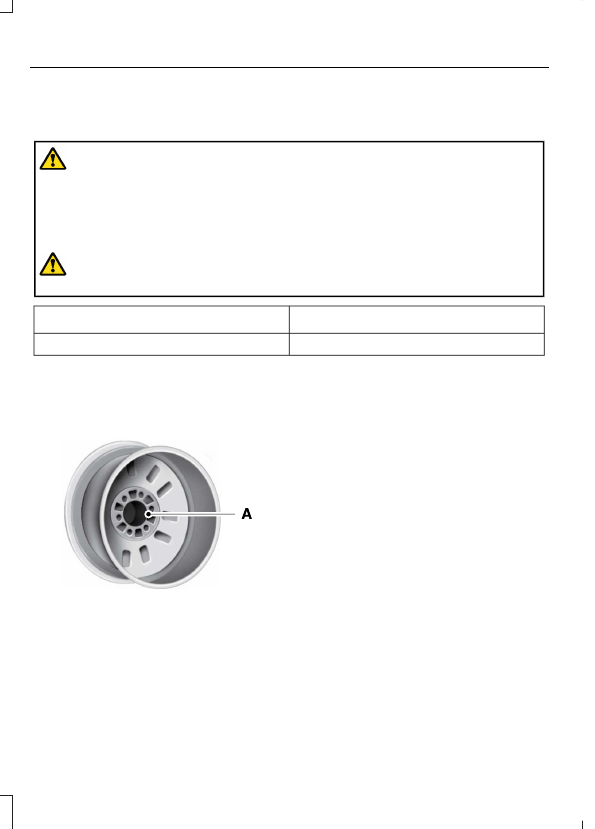

WHEEL NUTS

Wheel Nut Torque Specifications

WARNING:

When you install a wheel, always remove any corrosion, dirt or foreign

materials present on the mounting surfaces of the wheel or the surface of the wheel

hub, brake drum or brake disc that contacts the wheel. Make sure to secure any fasteners

that attach the rotor to the hub so they do not interfere with the mounting surfaces of

the wheel. Installing wheels without correct metal-to-metal contact at the wheel

mounting surfaces can cause the wheel nuts to loosen and the wheel to come off while

your vehicle is in motion, resulting in loss of vehicle control, personal injury or death.

WARNING:

If the tire pressure monitor sensor becomes damaged it may not

function.

lb.ft (Nm)

*

Bolt size

100 lb.ft (135 Nm)

M12 X 1.5

*

Torque specifications are for nut and bolt threads free of dirt and rust. Use only our

recommended replacement fasteners.

Retighten the lug nuts to the specified torque within 100 mi (160 km) after any wheel

disturbance (such as tire rotation, changing a flat tire, wheel removal).

E145950

Wheel pilot bore

A

Inspect the wheel pilot bore and

mounting surface prior to installation.

Remove any visible corrosion or loose

particles.

400

Changing a Road Wheel

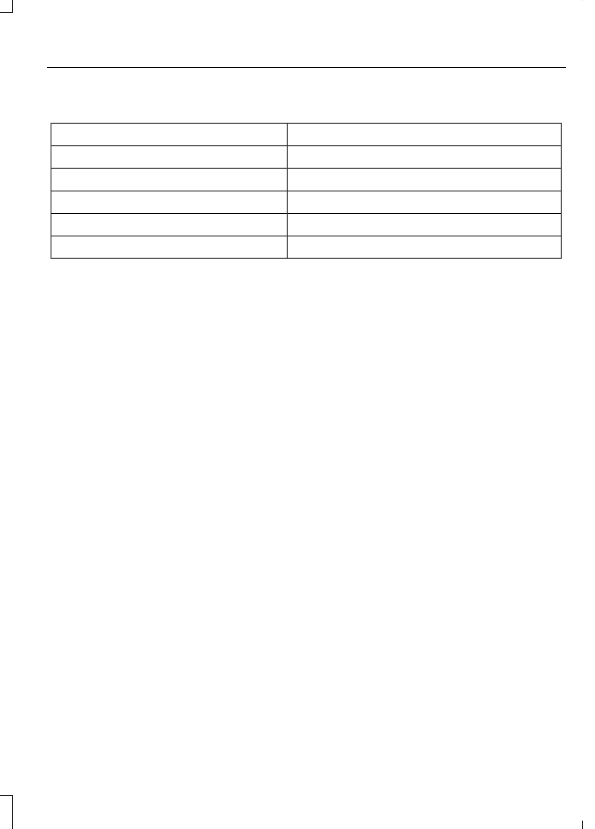

ENGINE SPECIFICATIONS - 2.3L ECOBOOST™

Specification

Engine

10.0:1

Compression ratio.

138 in³ (2,261 cm³)

Displacement.

1-3-4-2

Firing order.

Coil on plug

Ignition system.

0.028 in (0.7 mm) - 0.031 in (0.8 mm)

Spark plug gap.

401

Capacities and Specifications

ENGINE SPECIFICATIONS - 2.7L ECOBOOST™

Specification

Engine

10.0:1

Compression ratio.

165 in³ (2,700 cm³)

Displacement.

1-4-2-5-3-6

Firing order.

Coil on plug

Ignition system.

0.028 in (0.7 mm) - 0.031 in (0.8 mm)

Spark plug gap.

402

Capacities and Specifications

MOTORCRAFT PARTS - 2.3L ECOBOOST™

Motorcraft Part Number

Component

FA-2022

Air filter element.

BAGM-94RH7-800

Battery.

FP-93

Cabin air filter.

FL-910-S

Engine oil filter.

1

SP-594

Spark plug.

FT-215

Transmission fluid filter.

WW-1703

Windshield wiper blade-front.

WW-801

Windshield wiper blade-rear.

1

If a Motorcraft oil filter is not available, use an oil filter that meets industry performance

specification SAE/USCAR-36.

We recommend Motorcraft parts that are available at your authorized dealer or at

www.parts.ford.com. We engineer these parts for your vehicle to meet or exceed our

specifications. Use of other parts could impact vehicle performance, emissions and

durability. Your warranty could be void for any damage related to use of other parts.

403

Capacities and Specifications

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст