Toyota Sequoia (2005). Manual — part 111

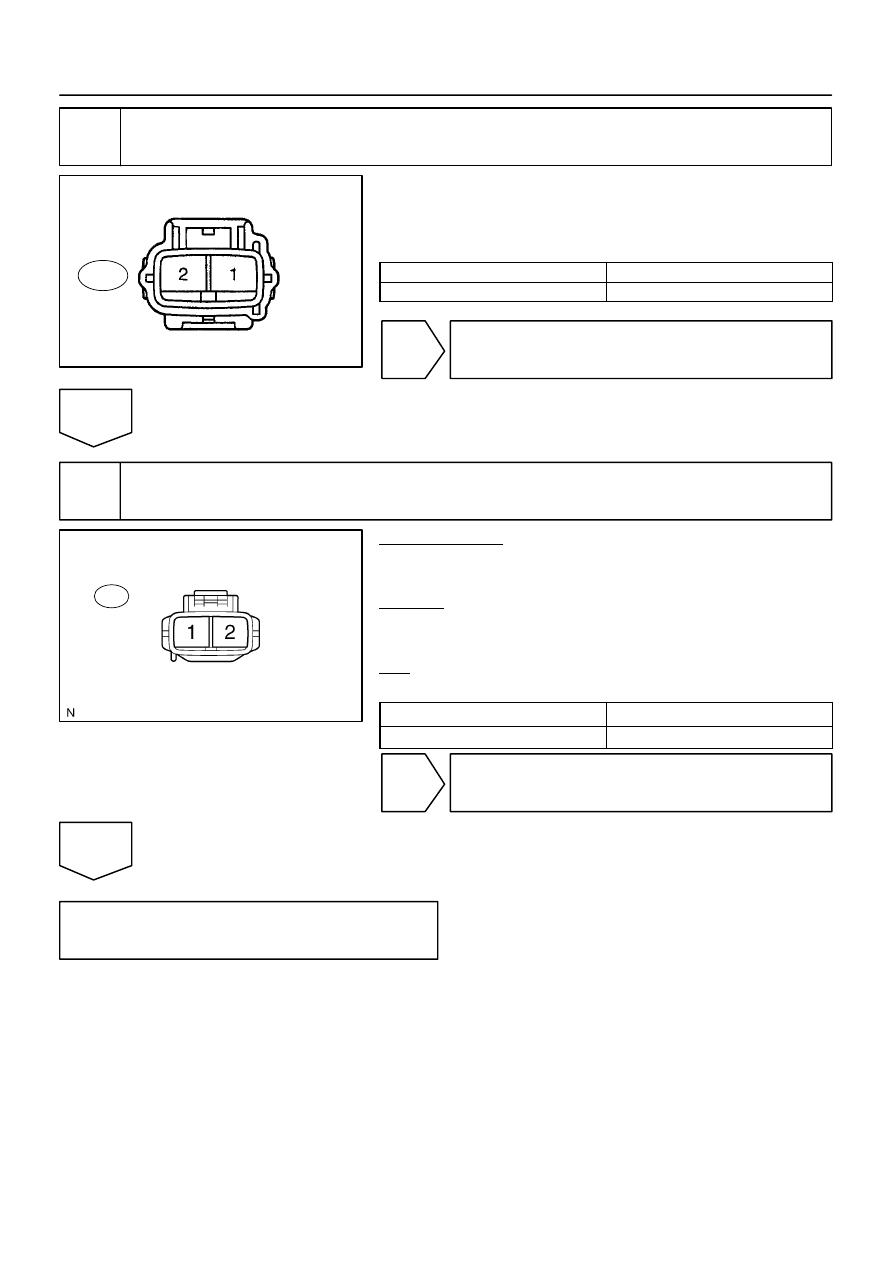

A23498

Component Side:

Air Pump Connector

Front View

A43

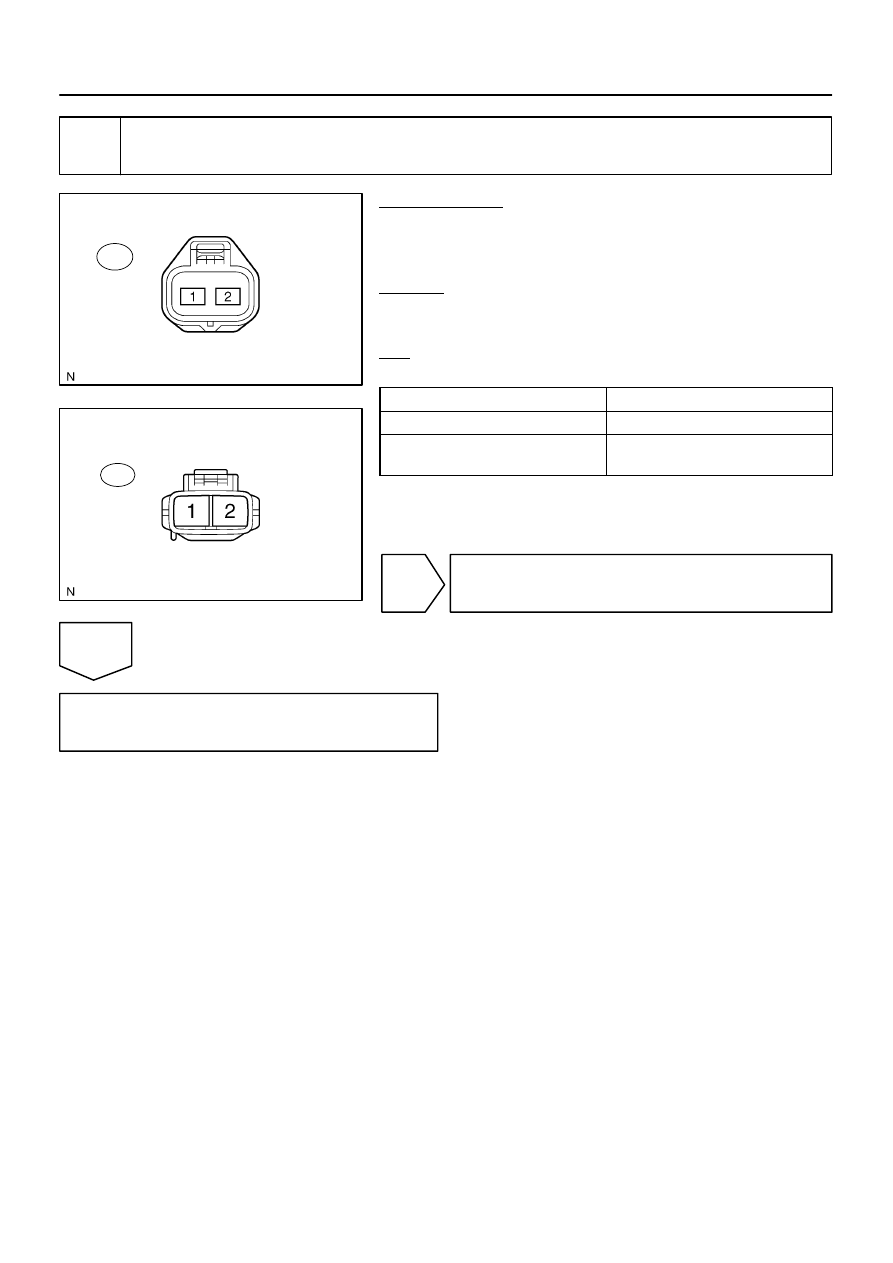

B17438

Wire Harness Side:

Air Pump Connector

A43

–

DIAGNOSTICS

ENGINE

DI–247

441

2

Check air pump resistance.

(a)

Remove the intake manifold (see page

).

(b)

Disconnect the air pump connector.

(c)

Measure the resistance of the air pump.

Standard:

Tester Connections

Specified Conditions

A43–1 – A43–2

0.4 to 1.0

Ω

NG

Replace air pump assembly.

OK

3

Check for open in harness and connector between air pump and body ground.

PREPARATION:

(a)

Remove the intake manifold (see page

).

(b)

Disconnect the A43 air pump connector.

CHECK:

Measure the resistance between the wire harness side connec-

tors and body ground.

OK:

Standard:

Tester Connection

Specified Condition

A43–1 – Body ground

Below 1

Ω

NG

Repair or replace harness or connector.

OK

Check for intermittent problems

(See page

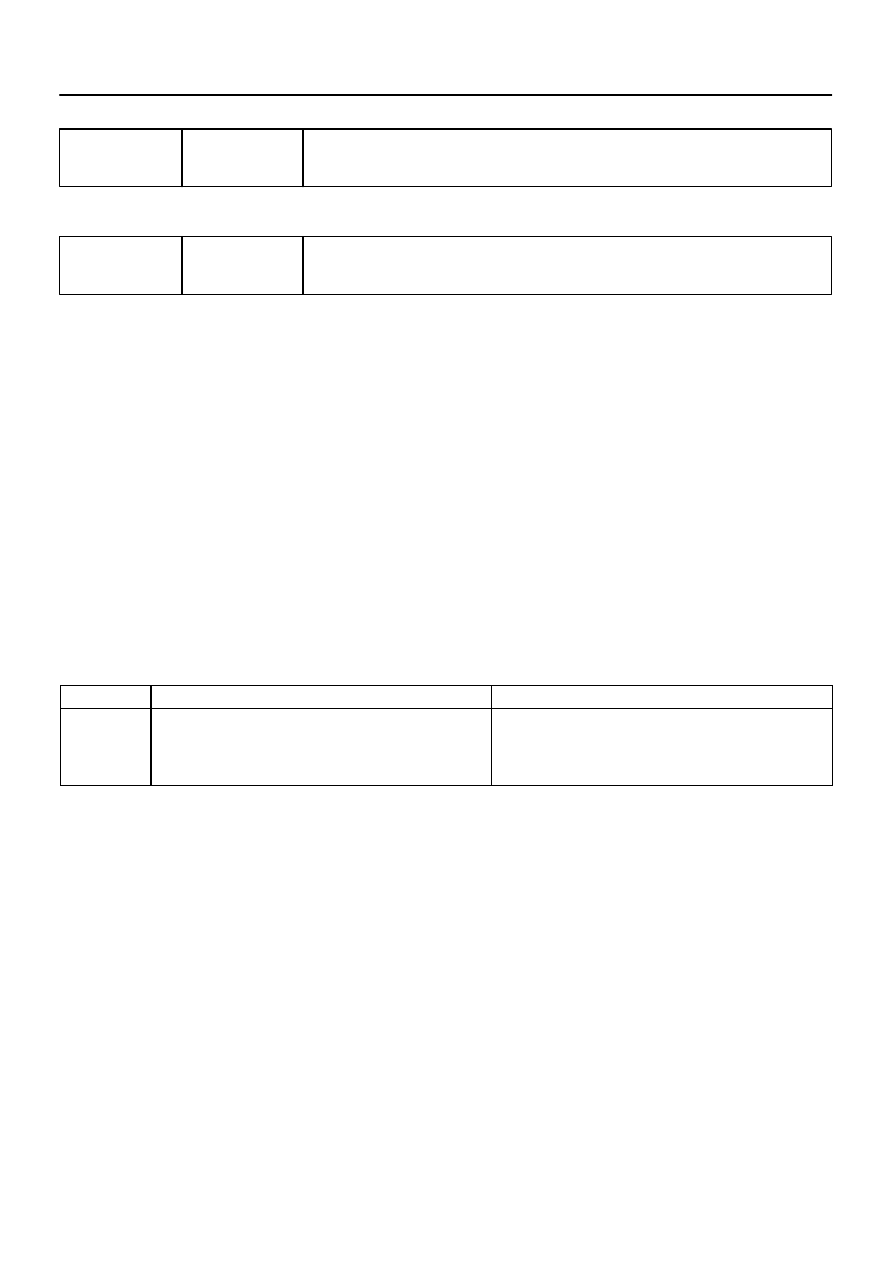

B17443

Wire Harness Side:

Air Injection Driver Connector

A40

B17438

Wire Harness Side:

Air Pump Connector

A43

DI–248

–

DIAGNOSTICS

ENGINE

442

4

Check for open and short in harness and connector between air injection driver

and air pump.

PREPARATION:

(a)

Remove the intake manifold (see page

).

(b)

Disconnect the A40 air injection driver connector.

(c)

Disconnect the A43 air pump connector.

CHECK:

Measure the resistance between the wire harness side connec-

tors.

OK:

Standard:

Tester Connection

Specified Condition

VP (A40–2) – A43–2

Below 1

Ω

VP (A40–2) or A43–2 –

Body ground

10 k

Ω

or higher

NG

Repair or replace harness or connector.

OK

Replace air injection driver.

–

DIAGNOSTICS

ENGINE

DI–249

443

DTC

P0420

Catalyst System Efficiency Below Threshold

(Bank 1)

DTC

P0430

Catalyst System Efficiency Below Threshold

(Bank 2)

MONITOR DESCRIPTION

The ECM uses the two sensors, mounted in front of and behind the Three–way Catalytic Converter (TWC),

to monitor its efficiency.

The first sensor, the Air–Fuel Ratio (A/F) sensor (sensor 1), sends pre–catalyst information to the ECM. The

second sensor, the Heated Oxygen (HO2) sensor (sensor 2), sends post–catalyst information to the ECM.

The ECM compares the information transmitted by these two sensors to determine the efficiency of the TWC

performance and its ability to store oxygen.

When the TWC is functioning properly, the variation in the oxygen concentration in the exhaust gas, after

it has passed through the TWC, is small. In this condition, the voltage output of sensor 2 slowly alternates

between the rich and lean signal voltages (shown in the illustration below). As the TWC performance efficien-

cy deteriorates, its oxygen storage capacity decreases, and the variation in the oxygen concentration in the

exhaust gas increases. As a result, the sensor voltage output fluctuates frequently.

While the catalyst monitor is running, the ECM measures the signal lengths of both sensors 1 and 2, and

calculates the ratio of the signal lengths to determine the extent of the TWC deterioration. If the deterioration

level exceeds the preset threshold, the ECM interprets this as the TWC malfunction. The ECM then illumi-

nates the MIL and sets the DTC.

DTC No.

DTC Detecting Condition

Trouble Area

P0420

P0430

OSC value smaller than standard value under active air–fuel

ratio control (2 trip detection logic)

Gas leakage on exhaust system

A/F sensor (Bank 1, 2 sensor 1)

Heated oxygen sensor (bank 1, 2 sensor 2)

Three–way catalytic converter

HINT:

Bank 1 refers to the bank that includes cylinder No.1.

Bank 2 refers to the bank that does not include cylinder No.1.

Sensor 1 refers to the sensor mounted in front of the Three–Way Catalytic Converter (TWC) and lo-

cated near the engine assembly.

Sensor 2 refers to the sensor mounted behind the TWC and located far from the engine assembly.

DID87–01

DI–250

–

DIAGNOSTICS

ENGINE

444

MONITOR STRATEGY

R l t d DTC

P0420

Bank 1 catalyst is deteriorated

Related DTCs

P0430

Bank 2 catalyst is deteriorated

Main sensors/components

Front and rear heated oxygen sensor

Required sensors/components

Related sensors/components

Mass air flow meter, Engine coolant temperature

sensor, Engine speed sensor, Intake air tempera-

ture sensor

Frequency of operation

Once per driving cycle

Duration

20 sec.

MIL operation

2 driving cycles

Sequence of operation

None

TYPICAL ENABLING CONDITIONS

It

Specification

Item

Minimum

Maximum

The monitor will run whenever these

DTCs are not present

See page

Battery voltage

11 V

–

Intake air temperature

–10

C (14

F)

–

Engine coolant temperature

75

°

C (167

°

F)

–

Atmospheric pressure coefficient

0.75

–

Idle

OFF

Engine RPM

–

3,200 rpm

A/F sensor

Activated

Fuel system status

Closed loop

Engine load

10 to 70 %

All of the following conditions are met

Condition 1, 2 and 3

1. MAF

6

to 75 g/sec

2. Front catalyst temperature (estimated)

620

to 830

C (1,148 to 1,526

F)

3. Rear catalyst temperature (estimated)

410 to 830

C (770 to 1,526

F)

Rear HO2S monitor

Completed

Shift position

4th

–

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria

Threshold

Oxygen storage capacity (OSC) of catalyst

Less than 0.16

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст