Toyota Tundra. Manual — part 1223

TYPICAL MALFUNCTION THRESHOLDS

TYPICAL MALFUNCTION THRESHOLDS

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the Techstream. Freeze frame data records the engine condition when

malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was

moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data

from the time the malfunction occurred.

1. CHECK DTC

a. Clear DTC (See DTC CHECK/CLEAR ).

b. Turn the ignition switch OFF.

c. Disconnect the cable from the negative battery terminal and wait for 1 minute.

d. Connect the cable to the negative battery terminal.

e. Turn the ignition switch ON.

f. Check DTC.

OK: P0606 is not present.

NG : REPLACE ECM (See REMOVAL )

OK : CHECK FOR INTERMITTENT PROBLEMS (See CHECK FOR INTERMITTENT

PROBLEMS )

DTC P0607 CONTROL MODULE PERFORMANCE

DESCRIPTION

The ECM continuously monitors its internal processors (CPUs), A/F sensor transistors and heated oxygen

sensor (HO2S) transistors. This self-check ensures that the ECM is functioning properly. This is diagnosed by

internal "mirroring" of the main and sub CPUs to detect processor errors. If outputs from the processors deviate

from the standards, the ECM will illuminate the MIL and set a DTC immediately.

DTC TROUBLE DETECTION CONDITION CHART

CPU reset

Occurred

DTC No.

DTC Detection Condition

Trouble Area

P0607

When one of following conditions is met:

ECM CPUs malfunction

A/F sensor transistors malfunction

HO2S transistors malfunction

Exhaust gas leak

HO2S

ECM

2008 Toyota Tundra

2008 ENGINE PERFORMANCE Engine Control System (1GR-FE) - Tundra

MONITOR STRATEGY

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

TYPICAL MALFUNCTION THRESHOLDS

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the Techstream. Freeze frame data records the engine condition when

malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was

moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data

from the time the malfunction occurred.

1. CHECK FOR EXHAUST GAS LEAK

a. Allow the engine to idle.

b. Check for exhaust gas leak around the HO2S.

OK: No leak from the HO2S.

NG : REPAIR LEAK

NOTE:

An exhaust gas leak generates noise in the HO2S output. The ECM may

interpret this as an HO2S transistor malfunction and set P0607.

Related DTCs

None

Required sensors/Components

(Main)

ECM

Required sensors/Components

(Related)

APP sensor, TP sensor, Stop light switch, Cruise control, A/F

sensor, HO2S

Frequency of operation

Continuous

Duration

60 seconds

MIL operation

immediate

Sequence of operation

None

Engine

Running

Estimated A/F sensor temperature

450 to 800°C (842 to 1472°F)

Estimated HO2S temperature

450 to 800°C (842 to 1472°F)

A/F sensor transistors

Fail

HO2S transistors

Fail

2008 Toyota Tundra

2008 ENGINE PERFORMANCE Engine Control System (1GR-FE) - Tundra

OK : Go to next step.

2. CHECK HEATED OXYGEN SENSOR

Fig. 178: Identifying Fuel-Trim & Rear HO2S Voltage Pattern

a. Warm up the engine.

b. Allow the engine to idle.

c. Connect the Techstream to the DLC3.

d. Turn the Techstream ON.

e. Enter the following menus: Powertrain/Engine and ECT Active Test/Control the Injection Volume

for A/F Sensor.

f. Check the O2S B1S2 (O2S B2S2) values when the Control the Injection Volume for A/F Sensor is

-12.5% (Lean fuel-trim).

g. Check the O2S B1S2 (O2S B2S2) values when the Control the Injection Volume for A/F Sensor is

25% (Rich fuel-trim).

Standard

VOLTAGE REFERENCE

NG : REPLACE HEATED OXYGEN SENSOR (See REMOVAL )

OK : Go to next step.

A/F CONTROL (Control the Injection Volume for A/F Sensor) O2S B1S2 (O2S B2S2)

-12.5%

Less than 0.2 V

25%

More than 0.8 V

2008 Toyota Tundra

2008 ENGINE PERFORMANCE Engine Control System (1GR-FE) - Tundra

3. CHECK DTC

a. Clear DTC (See DTC CHECK/CLEAR ).

b. Turn the ignition switch OFF.

c. Disconnect the cable from the negative battery terminal and wait for 1 minute.

d. Connect the cable to the negative battery terminal.

e. Start the engine.

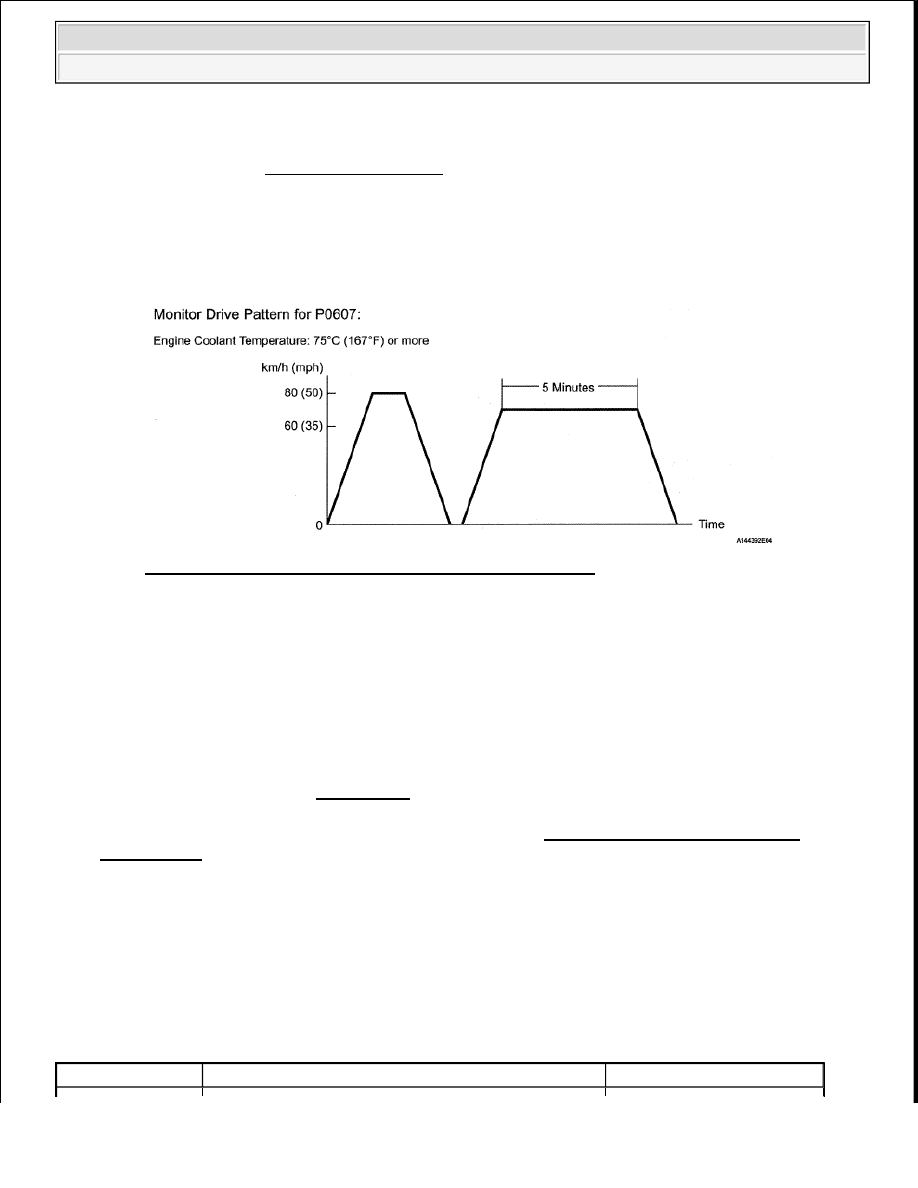

Fig. 179: Identifying Engine Coolant Temperature Pattern

f. Perform the drive pattern.

1. Warm up the engine.

2. Accelerate the vehicle until 50 mph (80 km/h) and stop the vehicle.

3. Drive the vehicle by 35 to 50 mph (60 to 80 km/h) for 5 minutes or more.

g. Check DTC.

OK: P0607 is not present.

NG : REPLACE ECM (See REMOVAL )

OK : CHECK FOR INTERMITTENT PROBLEMS (See CHECK FOR INTERMITTENT

PROBLEMS )

DTC P060A INTERNAL CONTROL MODULE MONITORING PROCESSOR PERFORMANCE

DESCRIPTION

The main CPU and sub CPU of the ECM perform data communication between each other. The main CPU

monitors the communications and WDC pulses from the sub CPU. When the signal malfunctions below are

detected, a DTC is output.

DTC TROUBLE DETECTION CONDITION CHART

DTC No.

DTC Detection Condition

Trouble Area

2008 Toyota Tundra

2008 ENGINE PERFORMANCE Engine Control System (1GR-FE) - Tundra

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст