Toyota Tundra. Manual — part 1645

When malfunctioning:

ACTIVE TEST REFERENCE VALUE (MALFUNCTIONING

B: REPLACE FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY (See

REMOVAL )

A: Go to Next Step

5. CHECK FUEL PRESSURE SWITCHING VALVE (POWER SOURCE)

a. Disconnect the fuel pressure switching valve connector.

Long FT #2

-2.4% -2.4%

AF Lambda B1 S1

0.99

0.96

AF Lambda B2 S1

1.00

0.96

Alcohol Density Estimate 73%

73%

Alcohol Density Learning Compl Compl

Change in Short FT while performing Active

Test

Less than 7%

7% or more

Active Test State

Low

High

Low

High

Fuel pressure when there is fuel leak from fuel pipes

Below 270

kPa

Below

370 kPa

Below

270 kPa

Below

370 kPa

Fuel pressure when fuel pressure in high pressure

side pressure regulator cannot remain stable

Below 270

kPa

Below

370 kPa

Below

270 kPa

Below

370 kPa

Fuel pressure when fuel pump ECU is

malfunctioning and drive voltage stuck at low

270 to 330

kPa

Below

370 kPa

-

-

Fuel pressure when fuel pump ECU is

malfunctioning and drive voltage stuck at high

370 kPa or

higher

370 to 430

kPa

-

-

Fuel pressure when fuel pressure switching valve

stuck

No change in pressure -

-

Fuel pressure when fuel pressure in low pressure

side pressure regulator cannot remain stable

-

-

Below

270 kPa

370 to 430

kPa

Fuel pressure when fuel pump discharge ability

decreases

-

Below

370 kPa

-

Below

370 kPa

2009 Toyota Tundra

2009 ENGINE PERFORMANCE Engine Control System (3UR-FBE) - Tundra

Saturday, June 19, 2010 7:34:49 PM

Page 673

© 2006 Mitchell Repair Information Company, LLC.

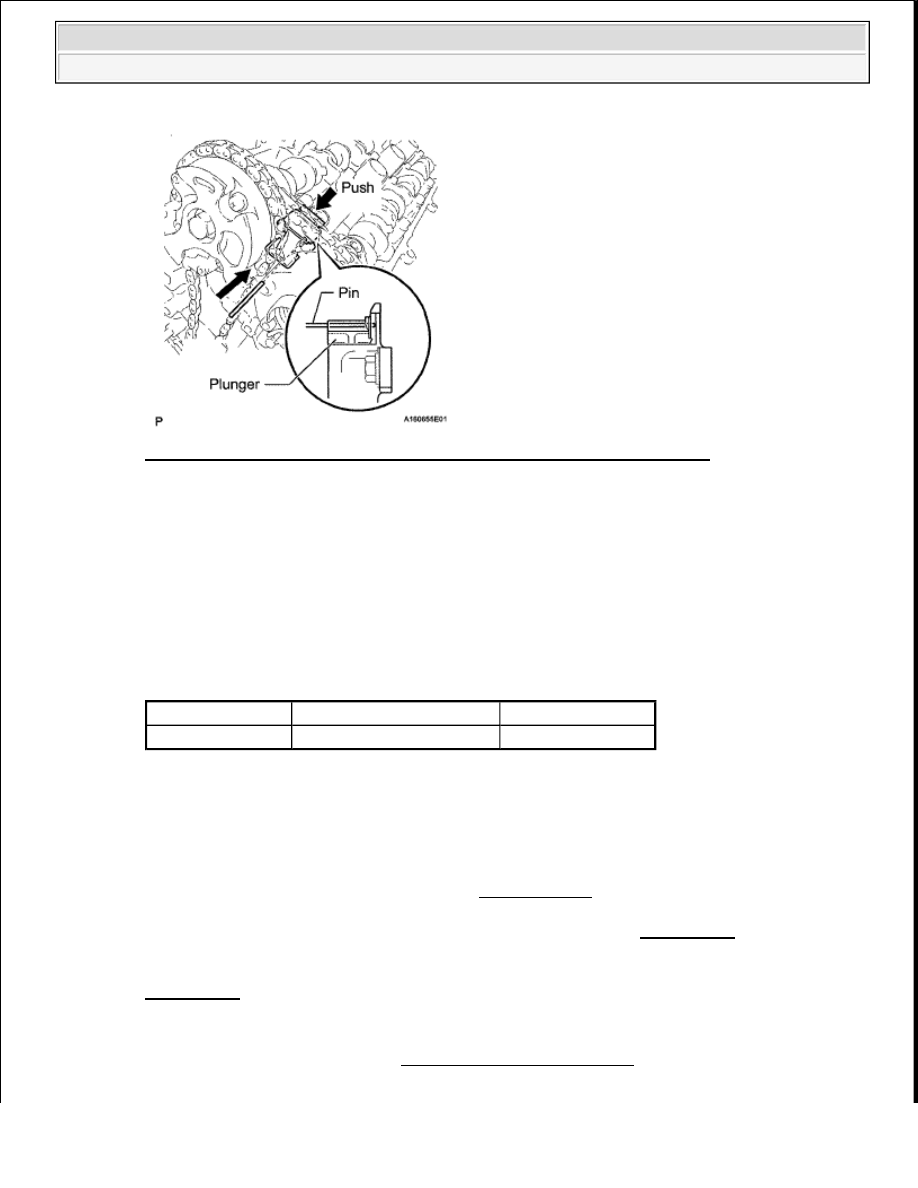

Fig. 321: Identifying Fuel Pressure Switching Valve Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Connect the Techstream to the DLC3.

c. Enter the following menus: Powertrain/Engine and ECT/Active Test/Activate the Fuel Pressure

Switching Valve.

d. Operate the fuel pressure switching valve.

e. Measure the voltage according to the value (s) in the table below.

Standard Voltage

VOLTAGE SPECIFIED CONDITION

NG: Go to step 7

OK: Go to Next Step

6. INSPECT FUEL PRESSURE SWITCHING VALVE

a. Inspect the fuel pressure switching valve (See INSPECTION ).

NG: REPLACE FUEL PRESSURE SWITCHING VALVE (See REMOVAL )

OK: REPLACE FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY (See

REMOVAL )

7. INSPECT RELAY (F/PMP VSV)

a. Inspect the F/PMP VSV relay (See ON-VEHICLE INSPECTION ).

Tester Connection

Condition

Specified Condition

1 - 2

High selected in Active Test

11 to 14 V

2009 Toyota Tundra

2009 ENGINE PERFORMANCE Engine Control System (3UR-FBE) - Tundra

Saturday, June 19, 2010 7:34:49 PM

Page 674

© 2006 Mitchell Repair Information Company, LLC.

NG: REPLACE RELAY (F/PMP VSV) (See ON-VEHICLE INSPECTION )

OK: Go to Next Step

8. CHECK RELAY (F/PMP VSV POWER SOURCE)

a. Remove the fuel pressure control valve relay (F/PMP VSV) from the engine room relay block.

Fig. 322: Identifying Fuel Pressure Control Valve Relay Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Measure the voltage according to the value (s) in the table below.

Standard Voltage

VOLTAGE SPECIFIED CONDITION

NG: GO TO ECM POWER SOURCE CIRCUIT

OK: Go to Next Step

9. CHECK HARNESS AND CONNECTOR (FUEL PRESSURE SWITCHING VALVE - F/PMP

RELAY, BODY GROUND)

a. Disconnect the fuel pressure switching valve connector.

b. Remove the fuel pressure control valve relay (F/PMP VSV) from the engine room relay block.

Tester Connection

Condition Specified Condition

F/PMP VSV relay (5) - Body ground Always

11 to 14 V

2009 Toyota Tundra

2009 ENGINE PERFORMANCE Engine Control System (3UR-FBE) - Tundra

Saturday, June 19, 2010 7:34:49 PM

Page 675

© 2006 Mitchell Repair Information Company, LLC.

Fig. 323: Identifying Fuel Pressure Switching Valve And Fuel Pressure Control Valve Relay

Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

c. Measure the resistance according to the value (s) in the table below.

Standard Resistance

RESISTANCE SPECIFIED CONDITIONS

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

OK: REPLACE FUEL SUCTION WITH PUMP AND GAUGE TUBE ASSEMBLY (See

REMOVAL )

CRANKING HOLDING FUNCTION CIRCUIT

DESCRIPTION

The cranking holding control system provides current to the starter when the ECM detects the ignition switch's

start signal (STSW). When the ECM performs a firing judgment, the system cuts current to the starter. When an

ECM receives the STSW signal, it turns on the ACC Cut relay, which prevents flickering of the combination

meter, clock, audio system, etc. Also, the ECM sends a signal to the ECM's STAR terminal. Then the STAR

output signal travels through the Park/Neutral Position (PNP) switch to the STARTER relay, causing the starter

to activate.

When the engine is cranking, the starter operation signal is sent to the ECM's STA terminal.

Fig. 324: Cranking Holding Function Circuit

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

WIRING DIAGRAM

Tester Connection

Condition Specified Condition

R9-1 - F/PMP VSV relay (3)

Always

Below 1 ohms

R9-2 - Body ground

Always

Below 1 ohms

R9-1 or F/PMP VSV relay (3) - Body ground Always

10 kohms or higher

2009 Toyota Tundra

2009 ENGINE PERFORMANCE Engine Control System (3UR-FBE) - Tundra

Saturday, June 19, 2010 7:34:49 PM

Page 676

© 2006 Mitchell Repair Information Company, LLC.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст