Toyota Tundra. Manual — part 1208

Result

RESULT CHART

B : Go to step 6

C : REPLACE FRONT NO. 2 EXHAUST PIPE ASSEMBLY (See REMOVAL )

A : REPLACE EXHAUST PIPE ASSEMBLY

6. REPLACE FRONT EXHAUST PIPE ASSEMBLY

NEXT : REPLACE FRONT NO. 3 EXHAUST PIPE SUB-ASSEMBLY . (See EXHAUST PIPE

(FOR REGULAR CAB STANDARD DECK) ).

DTC P043E EVAPORATIVE EMISSION SYSTEM REFERENCE ORIFICE CLOG UP; DTC P043F

EVAPORATIVE EMISSION SYSTEM REFERENCE ORIFICE HIGH FLOW; DTC P2401

EVAPORATIVE EMISSION LEAK DETECTION PUMP STUCK OFF; DTC P2402 EVAPORATIVE

EMISSION LEAK DETECTION PUMP STUCK ON; DTC P2419 EVAPORATIVE EMISSION

SYSTEM SWITCHING VALVE CONTROL CIRCUIT LOW

DTC SUMMARY

DTC SUMMARY CHART

Result

Proceed To

P0420

A

P0430 (for Regular Cab Standard Deck)

B

P0430 (except Regular Cab Standard Deck) C

P0420 and P0430

A and B or C

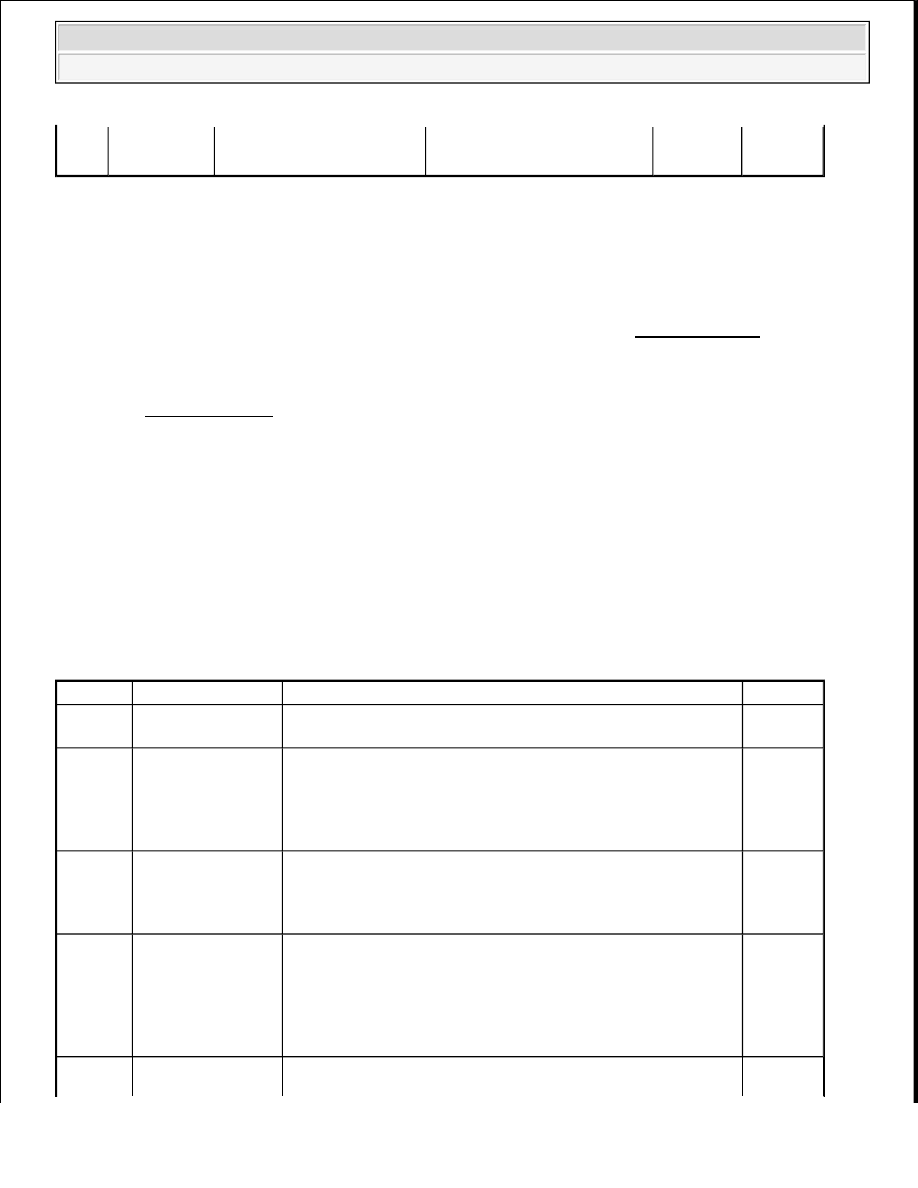

DTC

Monitoring

Item

Malfunction Detection

Condition

Trouble Area

Detection

Timing

Detection

Logic

P043E

Reference

orifice

clogged

P043E, P043F, P2401,

P2402 and P2419 present

when one of following

conditions met during key-

off EVAP monitor:

Reference orifice

clogged

Reference orifice

high-flow

Leak detection pump

OFF malfunction

Leak detection pump

ON malfunction

Canister pump module

(Reference orifice, leak

detection pump, vent

valve)

Connector/wire harness

(Canister pump module

- ECM)

EVAP system hose

(pipe from air inlet port

to canister pump

module, canister filter,

fuel tank vent hose)

ECM

While

ignition

switch OFF

2 trip

P043F

Reference

orifice high-

flow

P2401

Leak

detection

pump stuck

OFF

P2402

Leak

detection

pump stuck

ON

2008 Toyota Tundra

2008 ENGINE PERFORMANCE Engine Control System (1GR-FE) - Tundra

HINT:

The reference orifice is located inside the canister pump module.

DESCRIPTION

The description can be found in the EVAP (Evaporative Emission) System (See DESCRIPTION ).

INSPECTION PROCEDURE

Refer to the EVAP SYSTEM .

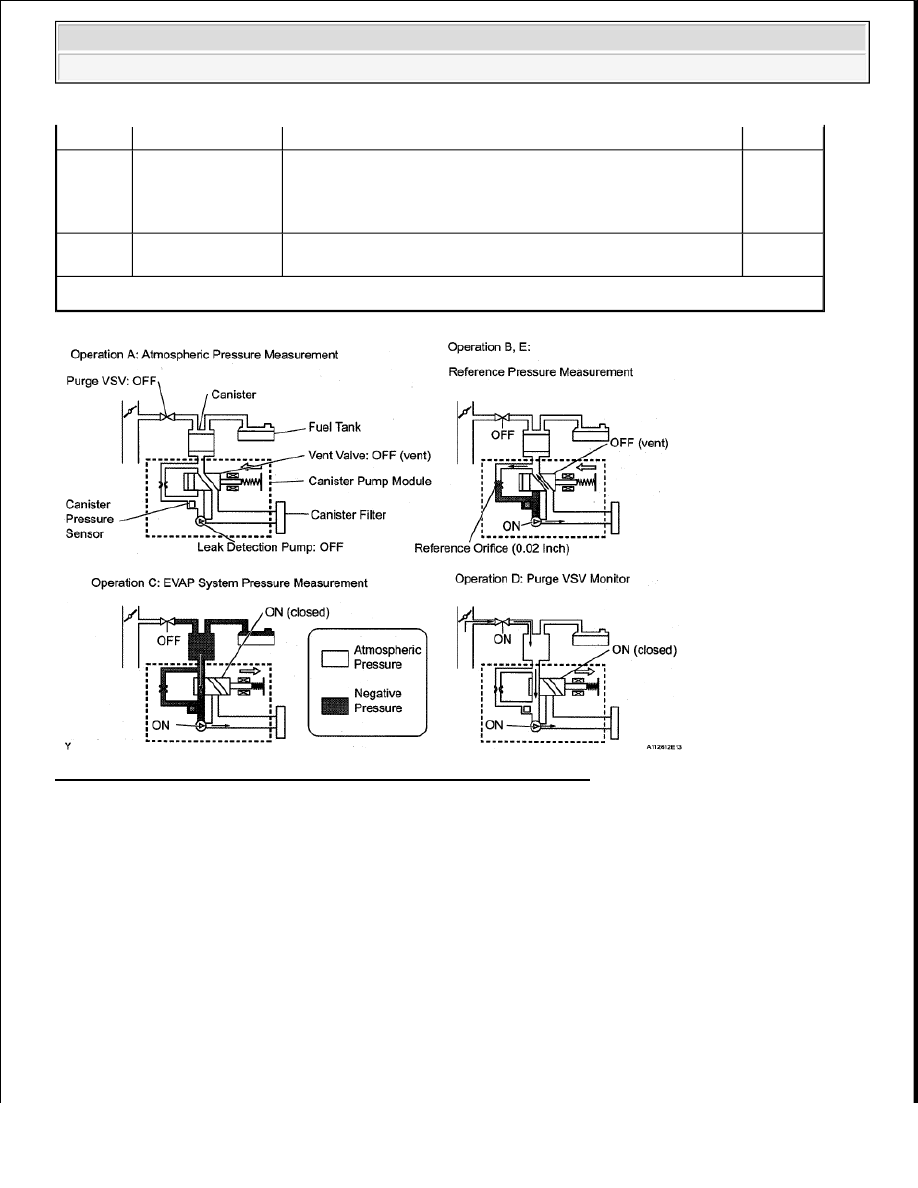

MONITOR DESCRIPTION

5 hours* after the ignition switch is turned OFF, the leak detection pump creates negative pressure (vacuum) in

the EVAP system. The ECM monitors for leaks and actuator malfunctions based on the EVAP pressure.

HINT:

*: If the engine coolant temperature is not below 35°C (95°F) 5 hours after the ignition switch is turned OFF,

the monitor check starts 2 hours later. If it is still not below 35°C (95°F) 7 hours after the ignition switch is

turned OFF, the monitor check starts 2.5 hours later.

MONITOR DESCRIPTION CHART

P2419

Vent valve

stuck closed

Vent valve ON (close)

malfunction

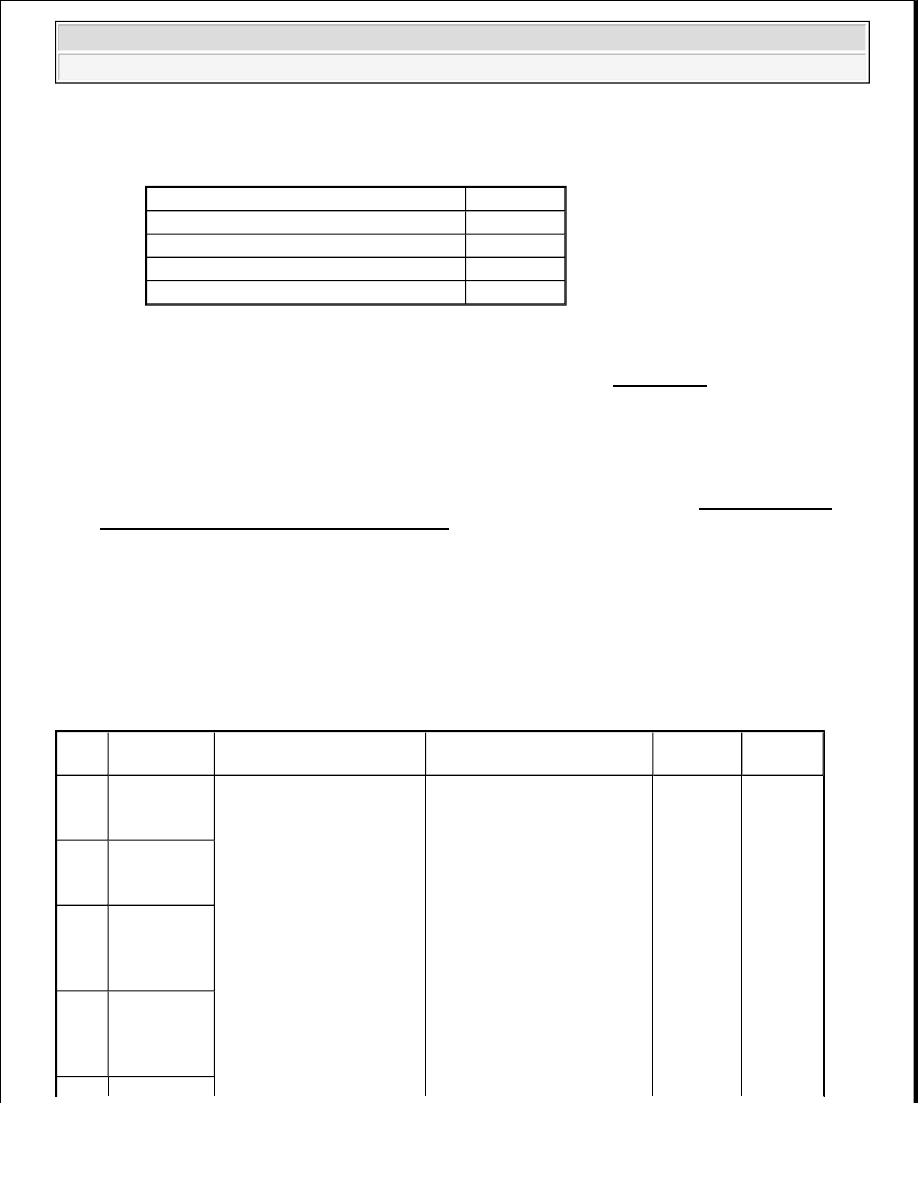

Sequence

Operation

Description

Duration

-

ECM activation

Activated by soak timer 5,7 or 9.5 hours after ignition switch

turned OFF.

-

A

Atmospheric

pressure

measurement

Vent valve turned OFF (vent) and EVAP system pressure

measured by ECM in order to register atmospheric pressure.

If pressure in EVAP system not between 70 kPa-a and 525

kPa-a (570 mmHg-a and 825 mmHg-a), ECM cancels EVAP

system monitor.

10

seconds

B

First reference

pressure

measurement

In order to determine reference pressure, leak detection pump

creates negative pressure (vacuum) through reference orifice

and then ECM checks if leak detection pump and vent valve

operate normally.

60

seconds

C

EVAP system

pressure

measurement

Vent valve turned ON (closed) to shut EVAP system.

Negative pressure (vacuum) created in EVAP system, and

EVAP system pressure then measured.

Write down measured value as it will be used in leak check.

If EVAP pressure does not stabilize within 15 minutes, ECM

cancels EVAP system monitor.

15

minutes

(1)

D

Purge VSV monitor Purge VSV opened and then EVAP system pressure measured

10

2008 Toyota Tundra

2008 ENGINE PERFORMANCE Engine Control System (1GR-FE) - Tundra

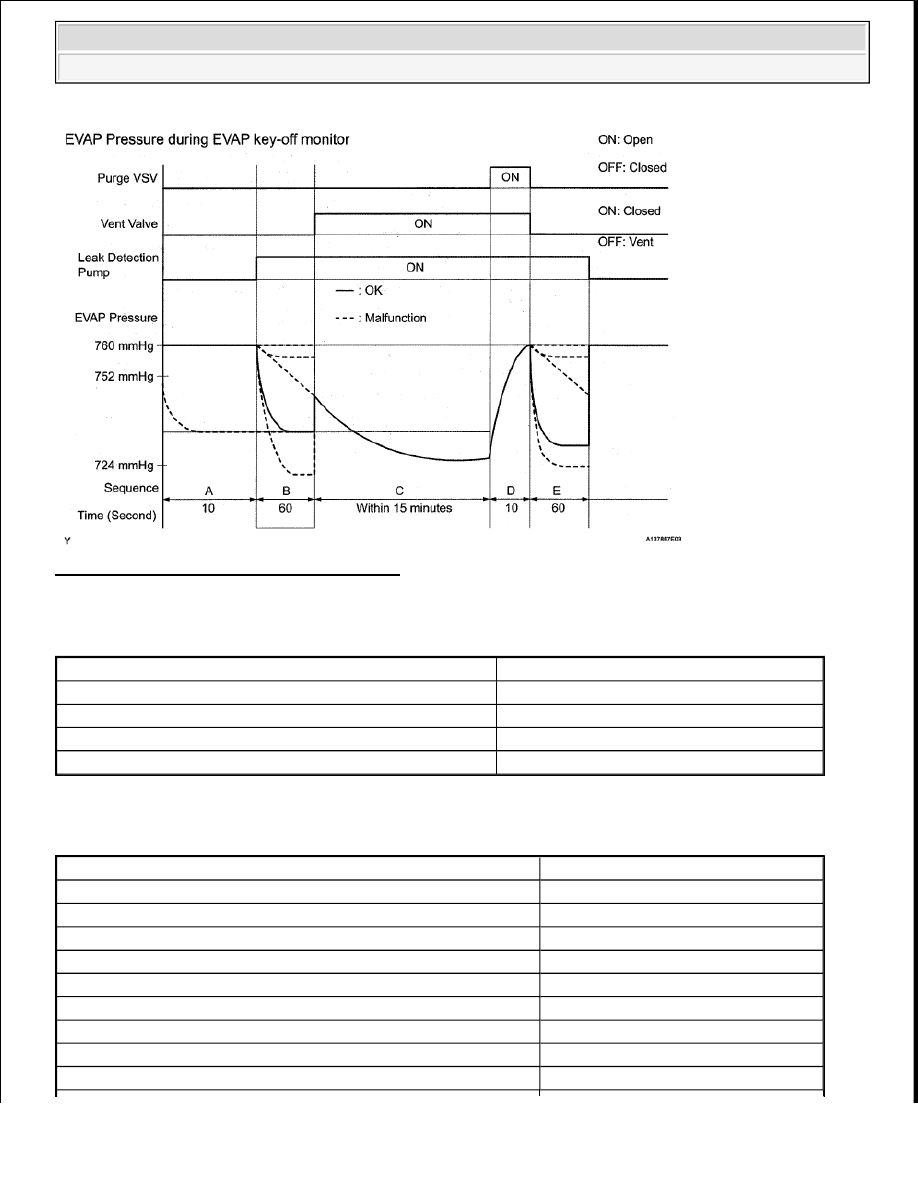

Fig. 149: Monitor Description - EVAP System Pressure Measurement

The leak detection pump creates negative pressure through the reference orifice. When the system is normal, the

EVAP pressure is between 724 to 752 mmHg* and saturated within a minute. If not, the ECM interprets this as

a malfunction. The ECM will illuminate the MIL and set DTC if this malfunction is detected in consecutive

drive cycles.

*: Typical value.

by ECM. Large increase indicates normality.

seconds

E

Second reference

pressure

measurement

After second reference pressure measurement, leak check

performed by comparing first and second reference pressure.

If stabilized system pressure higher than second reference

pressure, ECM determines that EVAP system leaking.

60

seconds

-

Final check

Atmospheric pressure measured and then monitoring result

recorded by ECM.

-

(1)

If only a small amount of fuel is in the fuel tank, it takes longer for the EVAP pressure to stabilize.

2008 Toyota Tundra

2008 ENGINE PERFORMANCE Engine Control System (1GR-FE) - Tundra

Fig. 150: EVAP Pressure Graph On Monitor

MONITOR STRATEGY

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL ENABLING CONDITIONS

Required Sensors/Components

Canister pump module

Frequency of Operation

Once per driving cycle

Duration

Within 2 minutes

MIL Operation

2 driving cycles

Sequence of Operation

None

Monitor runs whenever following DTCs not present

None

EVAP key-off monitor runs when all of following conditions met -

Atmospheric pressure

70 to 110 kPa-a (525 to 825 mmHg-a)

Battery voltage

10.5 V or more

Vehicle speed

Below 2.5 mph (4 km/h)

Ignition switch

OFF

Time after key off

5 or 7 or 9.5 hours

Canister pressure sensor malfunction (P0451, P0452 and P0453)

Not detected

Purge VSV

Not operated by scan tool

Vent valve

Not operated by scan tool

2008 Toyota Tundra

2008 ENGINE PERFORMANCE Engine Control System (1GR-FE) - Tundra

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст