Kia Carnival (2007 year). Manual — part 92

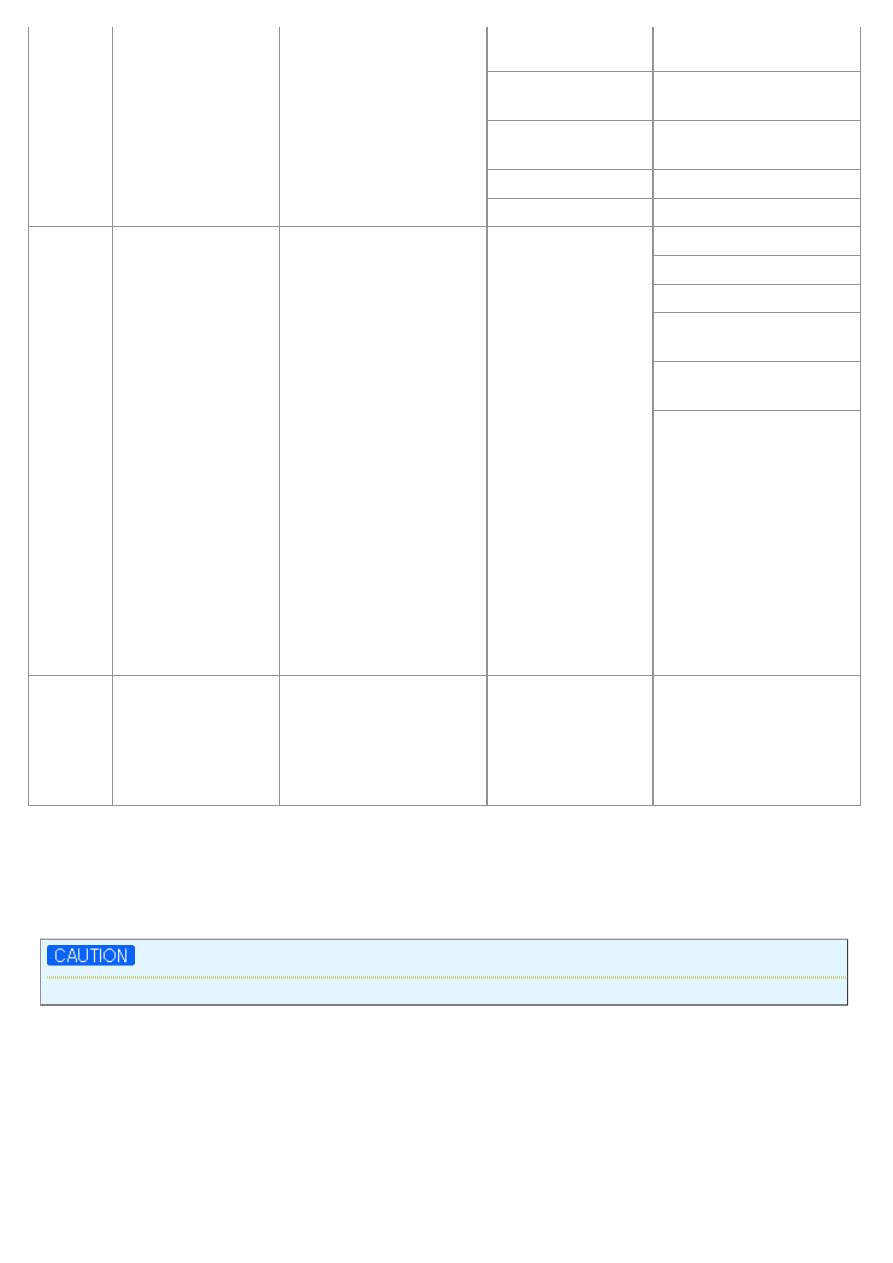

13

OIL TEMPERATURE

°C

40°C

Current Oil temperature

80°C

14

SHIFT POSITION

N,P,REV/1st G/…/5th

G

D

Current shift position

P, N

15

SELECT LEVEL

P,N/R/D/SPORTS

D

Current shift lever position

P, N

16

A/CON SWITCH

OFF/ON/-/NOT

SUPP

OFF

-

17

IDLE STATUS

OFF/ON/-/NOT

SUPP

ON

When idling, ON

18

BRAKE SWITCH

OFF/ON/-/NOT

SUPP

ON

When braking, ON

19

AUTO CRUISE

SWITCH

OFF/ON/-/NOT

SUPP

20

AUTO CRUISE

RELEASE

―

―

21

SPORT MODE

SELECT SW

OFF/ON/-/NOT

SUPP

ON

When selecting sport mode, ON

22

SPORT MODE UP SW

OFF/ON/-/NOT

SUPP

ON

When Selecting Sport mode up, ON

23

SPORT MODE DOWN

SW

OFF/ON/-/NOT

SUPP

ON

When selecting sport mode down,

ON

24

A/T CONTROL RELAY

VOLT

V

12.9V

0V

25

ENGINE TORQUE

%

20%

26

HIVEC MODE

A/B/C/D/E/F/G/H/I/J/K

F

A/B/C/D is control mode, F is

release mode

F

HIVEC -SAT(SIEMENS ADAPTIVE TRANSMISSION CONTROL) Mode (Shift Patten)

Shift patten

Description(Help)

SCAN DISPLAY

ECONOMY

Economy Driver shift patten for flat road

A

MEDIUM

Shift patten for medium road

B

SPORTS

Shift patten for sport road

C

LOAD 1

Shift patten for low land, slow grade and slope

D

LOAD 2

Shift patten for low land, steep grade and slope

E

LOAD 3

Shift patten for downhill road

F

LOAD 1 HI ALT

Shift patten for high land, steep grade and slope

G

LOAD 2 HI ALT

Shift patten for low land, steep grade and slope

H

HI TEMP

Shift patten for high temperture ATF

I

WARM UP

Shift patten for exhaust gas decrease

J

HOLD

Shift patten for when hold, switch on

K

Actuator inspection

NO

ITEM NAME

Actuator Driving

Condition

1

LR SOLENOID(SCSV A)

1. IG Key ON

2. Inhibitor SW normal

3. P range

2

UD SOLENOID(SCSV B)

3

2ND SOLENOID(SCSV C)

Solenoid valve driver for 5sec.

3. P range

4. Vehicle speed 0km/h

5. Engine stop

6. No failure

7. TPS < 1V

4

OD SOLENOID(SCSV D)

5

TORQUE CONVERTER SOLENOID VALVE

6

A/T CONTROL RELAY

OFF for 3 sec.

-

7

INTELLIGENT SHIFT PROHIBIT

Prohibit until IG off

-

8

CLEAR LEARNING VALUE

-

-

ROAD TEST

No.

Condition

Operation

Judgment value

Check item

1

Ignition switch : OFF

Ignition switch

(1) ON

Battery voltage (mV)

Control relay

2

a. Ignition switch :

ON

b. Engine : Stopped

c. Selector lever

position : P

Selector lever position

(1) P, (2) R, (3) N, (4) D

(1) P, (2) R, (3) N, (4)

D

Transaxle range switch

Accelerator pedal

(1) Released

(2) Half depressed

(3) Depressed

(1) 400~1,000 mV

(2)Gradually rises

from (1)

(3) 4,500~5,000 mV

Throttle position sensor

Brake pedal

(1) Depressed

(2) Released

(1) ON

(2) OFF

Brake switch

3

a. Ignition switch : ST

b. Engine : Stopped

Starting test with lever P or

N range

Starting should be

possible

Starting possible or

impossible

4

Warming up

Drive for 15 minutes or

more so that the automatic

fluid temperature becomes

70~90°C

Gradually rises to

70~90°C

Oil temperature sensor

5

a. Engine : Idling

b. Selector lever

position : N

A/C switch

(1) ON

(2) OFF

(1) ON

(2) OFF

Triple pressure switch

Accelerator pedal

(1) Released

(2) Half depressed

(1) ON

(2) OFF

Idle position switch

(1) 600~900 rpm

(2) Gradually rises

from (1)

(1) Data changes

Communication with

engine-ECU

Selector lever position

(1) N

→D

(2) N

→R

Should be no

abnormal shifting

shocks

Time lag should be

within 2 seconds

Malfunction when starting

Selector lever position

: N (Carry out on a

flat and straight road)

Selector lever position and

vehicle speed

a. Idling in 1st gear

(Vehicle stopped)

b. Driving at constant

speed of 20 km/h in 1st

gear

(2) 1st, (4) 3rd, (3)

2nd, (5) 4th

Shift condition

(2) 0%, (4) 100%, (3)

100%, (5) 100%

Low and reverse solenoid

valve

(2) 0%, (4) 0%, (3)

0%

Underdrive solenoid valve

6

c. Driving at constant

speed of 30 km/h in 2nd

gear

d. Driving at 50 km/h in 3rd

gear with accelerator

fully closed

e. Driving at constant

speed of 50 km/h in 4th

gear

(1) 100%, (2) 0%, (3)

100%

Second solenoid valve

(2) 100%, (3) 100%,

(4) 0%

Overdrive solenoid valve

(1) 0km/h

(4) 50km/h

Vehicle speed sensor

(4) 1,800 ~ 2,100rpm

Input shaft speed sensor

(4) 1,800 ~ 2,100rpm

Output shaft speed sensor

7

Selector lever position

: D (Carry out on a

flat and straight road)

a. Accelerate to 4th gear at

a throttle position sensor

output of 1.5V

(accelerator opening

angle of 30 %).

b. Gently decelerate to a

standstill.

c. Accelerate to 4th gear at

a throttle position sensor

output of 2.5 V

(accelerator opening

angle of 50%).

d. While driving at 60 km/h

in 4th gear, shift down

to 3rd gear.

e. While driving at 40 km/h

in 3rd gear, shift down

to 2nd gear.

f. While driving at 20 km/h

in 2nd gear, shift down

to 1st gear.

For (1), (2) and (3),

the reading should be

the same as the

specified output shaft

torque, and no

abnormal shocks

should occur.

For (4), (5) and (6),

downshifting should

occur immediately

after the shifting

operation is made.

Malfunction when shifting

Displaced shift points

Does not shift

Does not shift from 1 to 2 or

2 to 1

Does not shift from 2 to 3 or

3 to 2

Does not shift from 3 to 4 or

4 to 3

8

Selector lever position

: N (Carry out on a

flat and straight road)

Move selector lever to R

range drive at constant

speed of 10km/h

The ratio between

input and output shaft

speed sensor data

should be the same

as the gear ratio

when reversing.

Does not shift

TORQUE CONVERTER STALL TEST

This test measures the maximum engine speed when the selector lever is in the D or R position. The torque converter

stalls to test the operation of the torque converter, starter motor, one-way clutch operation, the holding performance of

the clutches, and brakes in the transaxle.

Do not let anybody stand in front of or behind the vehicle while this test is being carried out

1. Check the automatic transmission fluid level and temperature, and the engine coolant temperature.

a. Fluid level : At the HOT mark on the oil level gauge

b. Fluid temperature : 80~100°C (176~212°F)

c. Engine coolant temperature : 80~100°C(176~212°F)

2. Prevent all the wheels from moving during the test.

3. Pull the parking brake lever up, with the brake pedal fully depressed.

4. Start the engine.

5. Move the selector lever to the "D" position, fully depress the accelerator pedal and take a reading of the maximum

engine speed at this time.

Stall speed : 2,100~2,900rpm

a. The throttle should not be left fully open for any more than five seconds.

b. If carrying out the stall test two or more times, move the selector lever to the "N" position and run the

engine at 1,000 r/min to let the automatic transaxle fluid cool down before carrying out subsequent tests.

6. Move the selector lever to the "R" position and carry out the same test again.

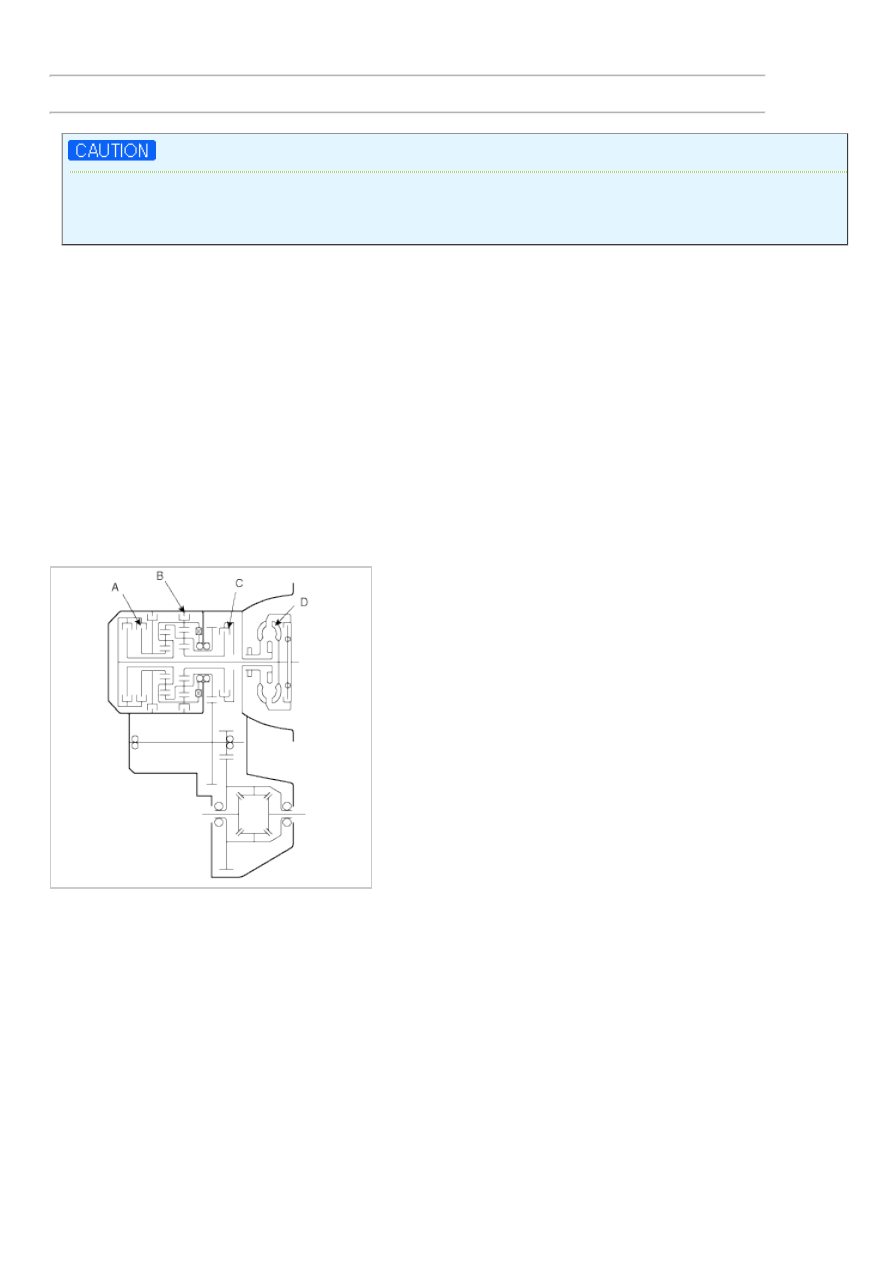

TORQUE CONVERTER STALL TEST CONCLUSION

1. Stall speed is too high in both "D" and "R" ranges

a. Low line pressure

b. Low & reverse brake(B) slippage

2. Stall speed is to high in "D" range only

a. Underdrive clutch(C) slippage

3. Stall speed is too high in "R" range only

a. Reverse clutch(A) slippage

4. Stall speed too low in both "D" and "R" ranges

a. Malfunction of torque converter(D)

b. Insufficient engine output

HYDRAULIC PRESSURE TEST

1. Warm up the engine until the automatic transaxle fluid temperature is 80-100°C.

2. Lift up the vehicle so that the wheels are free to turn.

3. Connect the special tool (oil pressure gauge) to each pressure discharge port.

4. Measure the hydraulic pressure at each port under the conditions given in the standard hydraulic pressure table,

and check that the measured values are within the standard value ranges.

5. If a value is outside the standard range, correct the problem while referring to the hydraulic pressure test diagnosis

table.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст