Nissan Qashqai J11. Manual — part 508

EC9-188

< DTC/CIRCUIT DIAGNOSIS >

[R9M]

P0016 CKP - CMP CORRELATION

P0016 CKP - CMP CORRELATION

DTC Logic

INFOID:0000000010309090

DTC DETECTION LOGIC

NOTE:

• If DTC P0016 is displayed with DTC P0335, P0560, P0657, or P0641, perform the trouble diagnosis for

DTC P0335, P0560, P0657, or P0641. Refer to

.

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 1 minute before conducting the next test.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Start engine and let it idle for at least 1 second.

2.

Check DTC.

Is DTC detected?

YES

>>

EC9-188, "Diagnosis Procedure"

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000010309091

1.

CHECK CKP SENSOR

Check CKP sensor. Refer to

EC9-189, "Component Inspection (Crankshaft Position Sensor)"

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Replace error-detected parts.

2.

CHECK CMP SENSOR

Check CMP sensor. Refer to

EC9-189, "Component Inspection (Camshaft Position Sensor)"

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Replace error-detected parts.

3.

CHECK SIGNAL PLATE OF CAMSHAFT REAR END

Visually check for chipping signal plate of camshaft rear end (bank 2 intake side).

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace camshaft. Refer to

EM-421, "Removal and Installation"

4.

CHECK SIGNAL PLATE WITH FLYWHEEL

Visually check for chipping signal plate with flywheel.

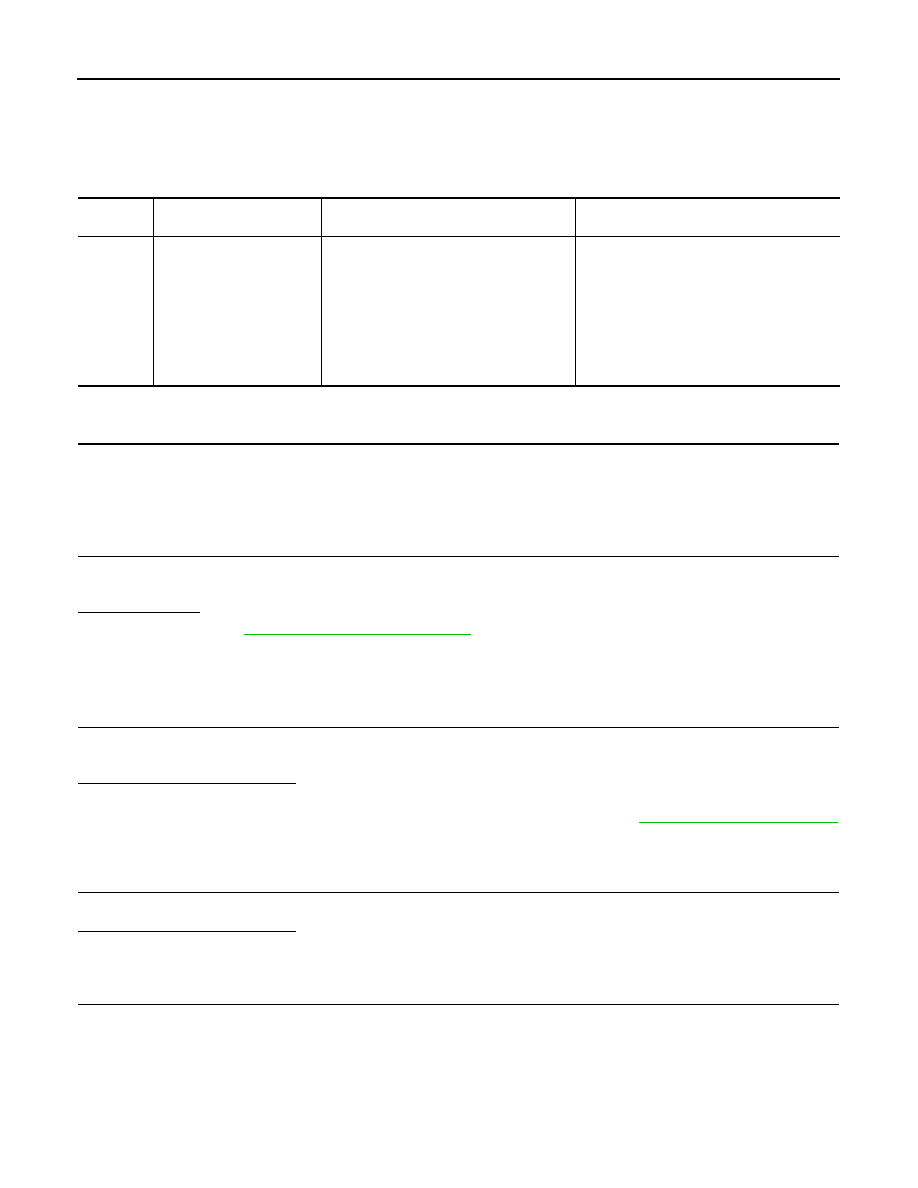

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0016

COHER BTWN CSFT SEN/

ENG SPD

(Crankshaft position - cam-

shaft position correlation bank

1 sensor A)

• 1.DEF: SIGNAL INCOHER-

ENCE

The correlation between crankshaft position

sensor signal and camshaft position sensor

signal is out of the normal range.

• Harness or connectors

(CKP sensor circuit is open or shorted.)

(CMP sensor circuit is open or shorted.)

• Crankshaft position sensor

• Camshaft position sensor

• Timing chain

• Signal plate

P0016 CKP - CMP CORRELATION

EC9-189

< DTC/CIRCUIT DIAGNOSIS >

[R9M]

C

D

E

F

G

H

I

J

K

L

M

A

EC9

N

P

O

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Replace signal plate with flywheel. Refer to

.

5.

CHECK TIMING CHAIN

Check timing chain. Refer to

EM-413, "Removal and Installation"

.

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-41, "Intermittent Incident"

.

NO

>> Replace timing chain. Refer to

EM-413, "Removal and Installation"

.

Component Inspection (Crankshaft Position Sensor)

INFOID:0000000010309092

1.

CHECK CRANKSHAFT POSITION SENSOR

1.

Turn ignition switch OFF.

2.

Disconnect crankshaft position (CKP) sensor harness connector.

3.

Check the resistance between CKP sensor terminals.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace CKP sensor. Refer to

EC9-12, "Component Parts Location"

Component Inspection (Camshaft Position Sensor)

INFOID:0000000010309093

1.

CHECK CAMSHAFT POSITION SENSOR

1.

Turn ignition switch OFF.

2.

Disconnect camshaft position (CMP) sensor harness connector.

3.

Check the resistance between CMP sensor terminals.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace CMP sensor. Refer to

.

CKP sensor

Resistance

+

−

Terminal

1

2

520 - 860

Ω

CMP sensor

Resistance

+

−

Terminal

1

2

More than 100 k

Ω

EC9-190

< DTC/CIRCUIT DIAGNOSIS >

[R9M]

P0045 TC BOOST CONTROL SOLENOID VALVE

P0045 TC BOOST CONTROL SOLENOID VALVE

DTC Logic

INFOID:0000000010309094

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 1 minute before conducting the next test.

>> GO TO 2.

2.

PERFORM DTC CONFIRMATION PROCEDURE

1.

Turn ignition switch ON and wait at least 1 second.

2.

Check DTC.

Is DTC detected?

YES

>> Proceed to

EC9-190, "Diagnosis Procedure"

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000010309095

1.

CHECK ECM HARNESS CONNECTOR CONNECTION

1.

Turn ignition switch OFF.

2.

Check ECM harness connector connection.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ECM harness connector connection. Refer to

(LEVER LOCKING TYPE).

2.

CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE HARNESS CONNECTOR CONNEC-

TION

Check turbocharger boost control solenoid valve harness connector connection.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace turbocharger boost control solenoid valve harness connector connection.

3.

CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE POWER SUPPLY

1.

Turn ignition switch OFF.

2.

Disconnect turbocharger boost control solenoid valve harness connector.

3.

Turn ignition switch ON.

4.

Check the voltage between turbocharger boost control solenoid valve harness connector and ground.

DTC No.

CONSULT screen terms

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P0045

TC SOLENOID VALVE CN-

TRL CIRC

(Turbocharger/supercharg-

er boost control “A” circuit/

open)

• 1.DEF: VOLTAGE TOO

LOW

• 2.DEF: VOLTAGE TOO

HIGH

• ECM detects turbocharger boost control

solenoid valve circuit is open.

• ECM detects turbocharger boost control

solenoid valve circuit is short to ground.

• ECM detects turbocharger boost control

solenoid valve circuit is short to power.

• Harness or connectors

(Turbocharger boost control solenoid valve

circuit is open or shorted.)

• Turbocharger boost control solenoid valve

P0045 TC BOOST CONTROL SOLENOID VALVE

EC9-191

< DTC/CIRCUIT DIAGNOSIS >

[R9M]

C

D

E

F

G

H

I

J

K

L

M

A

EC9

N

P

O

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Perform trouble diagnosis for power supply circuit.

4.

CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE GROUND CIRCUIT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between turbocharger boost control solenoid valve harness connector and ECM har-

ness connector.

4.

Also check harness for short to ground and to power.

Is the inspection result normal?

YES

>> Replace turbocharger boost control solenoid valve.

NO

>> Repair or replace error-detected parts.

+

−

Voltage

Turbocharger boost control solenoid

valve

Connector

Terminal

F134

2

Ground

Battery voltage

+

−

Continuity

Turbocharger boost control so-

lenoid valve

ECM

Connector

Terminal

Connector

Terminal

F134

1

F83

149

Existed

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст