Daewoo Musso. Manual — part 274

5A-128 AUTOMATIC TRANSMISSION

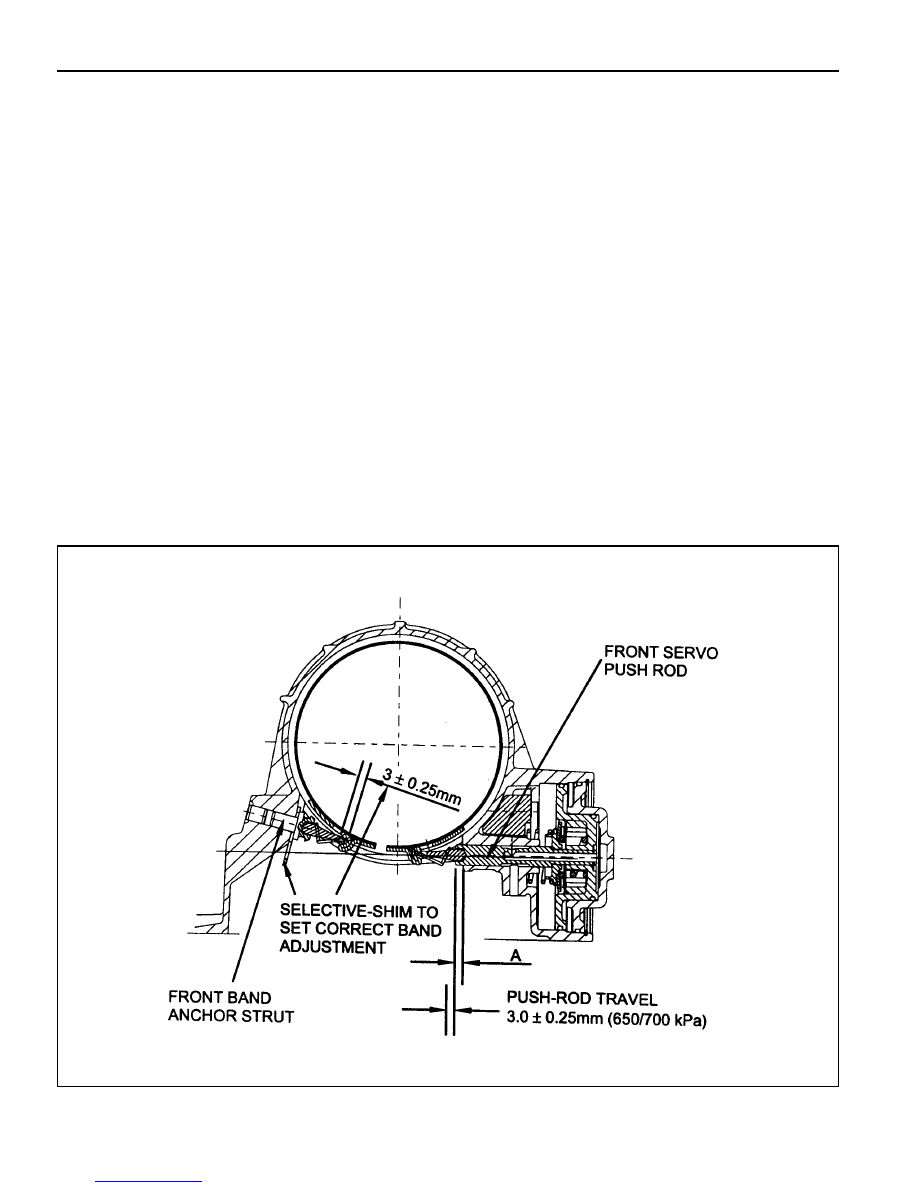

FRONT AND REAR BAND ADJUSTMENT

Front Band Setting Procedure

To set the front band, proceed as follows.

1. Measure the projection of the front servo push rod from the transmission case. Refer to figure 8.66, dimension A.

a. Apply air at 650/700 kPa to the front servo apply area (B1 outer). (Refer to figure 8.67.)

b. Measure the travel of the push rod and subtract 3 mm to find the shim size required.

c. Release the air.

Notice

A minimum of one shim is required at all times - minimum shim size is 1 mm. The thicknesses of available shims

are listed in table 8.2.

2. Fit the selected shim(s) to the shank of the anchor strut as follows:

a. Inspect the shim(s) for damage, wear or corrosion. Replace as necessary.

b. The shim(s) are to be installed between the case abutment face and the anchor strut flange. Refer to figure

8.66.

c. The shim(s) are to be fitted by hand and under no circumstances to be hammered or forced.

d. Shim(s) are to be pressed on by hand until an audible click is heard. The click indicates that the shim is clipped

home correctly.

3. Re-check that the push rod travel is 3 mm ± 0.25 mm.

Figure 8.66 - Front Band Settings

AUTOMATIC TRANSMISSION 5A-129

Figure 8.68 - Rear Band Settings

Rear Band Setting Procedure

To set the rear band, proceed as follows.

1. Measure distance ‘A’ from the rear servo piston to the inner face of the transmission case using vernier calipers.

Refer to figure 8.68.

a. Apply air at 650/700 kPa to the rear servo apply area (B2 outer). Refer to figure 8.67.

b. Measure the travel of the piston, subtract 3.75 mm and divide the remainder by 2.5 to find shim size.

c. Release the air.

Notice

A minimum of one shim is required at all times - minimum shim size is 1 mm. The thickness of available shims

are listed in table 8.2.

2. Fit the selected shim(s) to the shank of the anchor strut as follows.

a. Inspect the shim(s) for damage, wear or corrosion and replace as necessary. The shim(s) are to be installed

between the case abutment face and the anchor strut flange. Refer to figure 8.68.

c. The shim(s) are to be fitted by hand and under no circumstances to be hammered or forced.

d. The shim(5) are to be pressed on by hand until an audible click is heard. The click indicates that the shim is

clipped home correctly.

3. Re-check that the piston travel is 3.75 mm

±

0.625 mm.

5A-130 AUTOMATIC TRANSMISSION

Table 8.2 - Thickness of Available Shims

Thickness

0.95/1.05

1.15/1.25

1.44/1.56

1.73/1.87

Part Number

0574-037017

0574-037018

0574-037019

0574-037020

Thickness

1.93/2.07

2.12/2.28

2.42/2.58

2.61/2.79

Part Number

0574-037021

0574-037022

0574-037023

0574-037024

Figure 8.68 - Thickness of Available Shims

Model

Type

Gear Ratio

Oil

Weight (Dry)

SECTION 5B

MANUAL TRANSMISSION

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 5B-1

General Specifications . . . . . . . . . . . . . . . . . . 5B-1

Fastener Tightening Specifications . . . . . . . . . 5B-2

External View . . . . . . . . . . . . . . . . . . . . . . . . 5B-3

Gear Train . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-3

Power Flow . . . . . . . . . . . . . . . . . . . . . . . . . 5B-4

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-5

Will not Shift (Control Lever Moves) . . . . . . . . 5B-5

Hard Shift or Control Lever Will not Move Into

Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-5

Gears Crash When Shifting . . . . . . . . . . . . . . 5B-5

Transmission Jumps Out . . . . . . . . . . . . . . . . . 5B-6

Transmission Locked in One Gear . . . . . . . . . 5B-6

Transmission Noise . . . . . . . . . . . . . . . . . . . . . 5B-6

Transmission Leakage . . . . . . . . . . . . . . . . . . 5B-7

Diagnosis Table . . . . . . . . . . . . . . . . . . . . . . . 5B-8

Component Locator . . . . . . . . . . . . . . . . . . . 5B-9

Maintenance and Repair . . . . . . . . . . . . . . 5B-11

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 5B-11

Shift Control Cable . . . . . . . . . . . . . . . . . . . . 5B-11

Transmission . . . . . . . . . . . . . . . . . . . . . . . . 5B-14

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . . . 5B-17

Major Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-17

Main Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-27

Input Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-32

Counter Shaft . . . . . . . . . . . . . . . . . . . . . . . . 5B-34

Extension Housing . . . . . . . . . . . . . . . . . . . . 5B-35

Shift Cover . . . . . . . . . . . . . . . . . . . . . . . . . . 5B-36

Inspection of Components . . . . . . . . . . . . . . 5B-40

Pre-Installation Checks . . . . . . . . . . . . . . . . . 5B-45

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application

Description

T5WC

Floor Change

3.97 : 1

2.34 : 1

1.46 : 1

1.00 : 1

0.85 :1

3.71 : 1

ATF DEXRON II / III

3.4 L

Check : Every 15,000km, Replace : Every 50,000km

33kg

1st

2nd

3rd

4th

5th

Reverse

Specification

Capacity(litre)

Change Interval

Notice

Add LUBRIZOL (280cc) in oil after overhauling.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст